Cummins L10 Parts for Australia - Gasket Section

Loading...

Loading... -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

762 Hi-Temperature jointing compound for Detroit Diesel and Cummins turbos

762

225 gm tube - Temp range 550C to 760CPrice: $ 188.19 -

-

-

-

-

-

-

Gasket Spray -High Tack Sealant (Hold & Seals Cut Gaskets)

99MA

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 25.67 -

3H Gasket Maker

3H

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 16.38 -

-

-

-

-

Gasket Maker - Ultra Blue RTV Silicone Sensor Safe

77BR

For Detroit Diesel & Cummins enginesPrice: $ 11.03 -

Cummins L10 Engine Gasket Catalog

The Cummins L10 engine is widely used in industrial, construction, and marine applications thanks to its reliability and mid-range power. Like any heavy-duty diesel engine, maintaining proper sealing integrity is essential to performance and longevity. Gaskets prevent fluid leaks, maintain compression, and protect against contaminant intrusion in critical engine systems.

At Diesel Pro Power, we provide a full range of Cummins L10 gasket solutions—from complete upper and lower gasket sets to specialized seals for the oil cooler, rocker cover, and turbo oil lines. With over 40,000 satisfied customers worldwide, we’ve built a reputation for supplying only high-quality gasket components that keep Cummins engines running at peak efficiency.

Complete Gasket Sets for Cummins L10

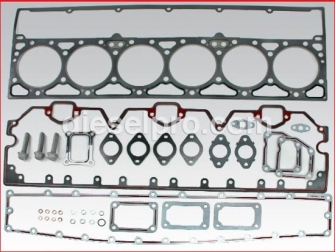

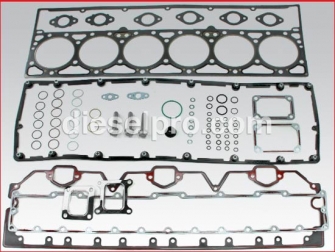

Upper Gasket Sets

Upper gasket sets are designed to reseal the top end of the Cummins L10 during maintenance or rebuilds. These kits typically include cylinder head gaskets, intake and exhaust manifold gaskets, valve cover gaskets, and all necessary seals for the upper engine.

-

Application: Ideal for cylinder head service, valve adjustments, or top-end rebuilds.

-

Coverage: Compatible with L10, M11, and ISM variants, ensuring flexibility for fleets running multiple engine models.

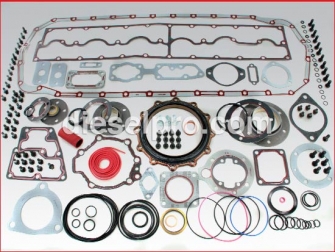

Lower Gasket Sets

Lower gasket sets restore the sealing integrity of the bottom end of the L10. These include the oil pan gasket, front and rear crankshaft seals, timing cover gaskets, and other seals that protect the crankcase and lubrication system.

-

Application: Essential during overhaul, bearing replacement, or oil pan removal.

-

Benefits: Prevents oil leaks that can compromise lubrication and shorten engine life.

Individual Gaskets & Seals for Cummins L10

While complete sets are ideal for major repairs, many service operations require individual gaskets. Below are the most common replacements for the Cummins L10.

Cylinder Head and Liner Seals

-

Liner Seal Rings: Ensure coolant and oil separation at the cylinder liner base, preventing cross-contamination.

-

Head Gaskets: Provide a high-pressure seal between the block and cylinder head, maintaining compression.

Oil Pan Gaskets

Two types of oil pan gaskets are used on the L10 depending on damper configuration:

-

Internal Damper Applications – Designed for engines where the vibration damper is mounted internally.

-

External Damper Applications – Built to handle the stresses of externally mounted dampers.

Rocker Cover Gaskets

-

Earlier Style: Suited to early production L10 engines.

-

Later Style: Redesigned for improved sealing on newer L10 and M11 variants.

-

Rocker Cover Housing Gasket: Provides additional sealing between the rocker cover housing and cylinder head.

Exhaust & Intake Gaskets

-

Exhaust Manifold Gaskets: Seal the connection between the cylinder head and exhaust manifold, preventing exhaust leaks that reduce performance and increase emissions.

-

Exhaust Outlet Connection Gasket: Ensures a secure seal where exhaust exits the manifold, important for turbocharged engines.

Turbocharger Gaskets

-

Turbo Oil Supply Gaskets: Maintain a leak-free connection in the turbo lubrication line.

-

Turbo Mounting Gaskets: Provide reliable sealing at the turbo flange for consistent boost pressure and exhaust flow.

Oil Cooler & Heat Exchanger Gaskets

-

Oil Cooler Gaskets: Installed between the cooler housing and block, preventing oil and coolant from mixing.

-

Heat Exchanger Gaskets: Found in marine L10 applications, these gaskets maintain coolant circulation and prevent seawater leaks.

Gear Cover & Timing Cover Seals

-

Gear Cover Plate Gasket: Ensures proper sealing of the gear train compartment.

-

Gear Cover Seal: Prevents oil leakage around the front cover assembly.

-

Front Cover Seal Rings & Rectangular Seals: Reinforce the durability of the timing gear cover under vibration and high-temperature operation.

Rear Cover Plate & Hand Hole Gaskets

-

Rear Cover Plate Gasket: Protects against oil leakage at the rear cover.

-

Hand Hole Gasket: Provides access for inspection or service without compromising oil tightness.

Thermostat & Cooling Gaskets

-

Thermostat Gaskets: Guarantee accurate temperature control by sealing the thermostat housing.

-

Thermostat Seals: Reinforce sealing integrity, preventing coolant leaks in high-pressure systems.

Sealants, Compounds, and Gasket Makers

In addition to precision-cut gaskets, Cummins L10 maintenance often requires chemical sealing solutions:

-

High-Temperature Jointing Compounds: Withstand extreme turbocharger and exhaust manifold heat.

-

Gasket Spray Sealants: Enhance sealing capability of cut gaskets.

-

Liquid Sealants: Provide flexible sealing for irregular mating surfaces.

-

RTV Silicone Gasket Makers: Available in high-temp and sensor-safe varieties for different applications.

-

Non-Hardening Pliable Sealants: Allow disassembly without damaging the gasket surface.

-

Threadlocker Compounds: Prevent vibration-induced loosening of bolts in high-stress areas like manifolds and gear covers.

-

Cold Weld Solutions: Emergency repair option for small cracks or leaks in metal surfaces.

Why Proper Gaskets Are Critical for Cummins L10 Engines

-

Preventing Leaks: Oil, fuel, and coolant leaks can quickly escalate into major engine failures.

-

Maintaining Compression: Cylinder head and liner gaskets are directly responsible for combustion efficiency.

-

Reducing Downtime: Correctly installed gaskets extend service intervals and prevent unscheduled repairs.

-

Protecting Adjacent Systems: Failures in gaskets like oil cooler seals can lead to catastrophic oil-coolant mixing.

Maintenance Tips for Cummins L10 Gaskets

-

Always Replace, Never Reuse – Once compressed, gaskets cannot reliably reseal.

-

Use Correct Torque Specs – Over-tightening can crush gaskets; under-tightening can allow leaks.

-

Inspect Sealing Surfaces – Clean and flat surfaces are essential for gasket performance.

-

Pair with OEM-Quality Sealants – Certain gaskets are designed to work with specific compounds.

-

Replace in Sets When Possible – Ensures uniform sealing and avoids mixing new and old gaskets.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588