Cummins NH855 Engine Parts for Australia - Cylinder Head Section

Loading...

Loading... Cylinder Heads & Related Components for Cummins NH855

The Cummins NH855 engine is a heavy-duty, high-performance powerplant widely trusted in industrial, marine, and generator applications. Maintaining peak operation of the NH855 requires robust and reliable cylinder head components. At Diesel Pro Power, we provide new NH855 cylinder heads complete with valves and springs, along with every supporting part needed for a full top-end rebuild or cylinder head replacement. Below is an in-depth guide to the NH855 cylinder head and all associated parts we carry—designed for professionals seeking quality, compatibility, and long-term durability.

Complete Cylinder Head Assembly for NH855

New Cylinder Head With Valves and Springs Installed

Our new cylinder head for Cummins NH855 engines comes fully assembled with valves and springs. This is the optimal solution for operators who want a fast and complete top-end refresh without dealing with individual valve installations or machining.

Key benefits:

-

100% new casting with no core return required

-

Includes intake and exhaust valves pre-installed

-

Valve springs and guides installed to OE specification

-

Eliminates guesswork in component pairing

Whether you're doing a proactive top-end rebuild or responding to signs of cylinder head failure—such as white smoke, poor compression, or coolant intrusion—a full replacement with a preloaded cylinder head is the most efficient approach.

Intake and Exhaust Valves for NH855

The NH855 intake valve is designed for high-temperature resistance and precise sealing. Manufactured from hardened materials to endure combustion chamber heat, these valves maintain correct airflow into the cylinder during the intake stroke. Ideal for full or partial top-end rebuilds, or individual valve replacements due to seat wear or breakage.

The exhaust valves on the NH855 are built for durability and heat dissipation under extreme load conditions. These valves are engineered with precision angles and surface treatments to resist pitting and elongation in turbocharged applications. Exhaust valves are often replaced during cylinder head servicing or when performing a full valve job.

Valve Springs for NH855

Each NH855 engine uses 24 valve springs—12 for intake and 12 for exhaust. These springs maintain the correct tension to close valves properly and prevent valve float at high RPMs. Our springs are precision-wound and tested to maintain correct compression forces over time, reducing the risk of misfire or compression loss.

Use valve springs in:

-

New cylinder head builds

-

Cylinder head reconditioning

-

Routine maintenance after prolonged service cycles

Valve Seals and Guides

Valve seals are critical in preventing oil from entering the combustion chamber via the valve stem. They help control oil consumption and reduce carbon buildup. High-temp rubber materials ensure long service life and consistent performance under heavy-duty operating conditions.

Valve guides ensure the valve stem travels in a straight and aligned path. Excessive play in the guides can lead to combustion inefficiencies and increased oil consumption. Our precision valve guides are machined to meet Cummins specifications and are suitable for both intake and exhaust sides.

Injector Tubes and Seals

Each NH855 cylinder head uses individual injector tubes. These tubes seat the injector and provide a leak-free channel for fuel delivery to the combustion chamber. Over time, they can become carbon-fouled or suffer wear that compromises fuel atomization. Replacing worn tubes during a top-end refresh is best practice.

These seals prevent combustion gas and fuel leakage at the injector tube base. It's highly recommended to replace injector tube O-rings during any injector servicing or cylinder head removal.

Cylinder Head Bolts for NH855

Cylinder head bolts for the NH855 engine must be replaced whenever the cylinder head is removed. These bolts undergo extreme torque and heat cycles and are designed for one-time use to ensure correct head clamping force. NH855 heads require 36 bolts per engine.

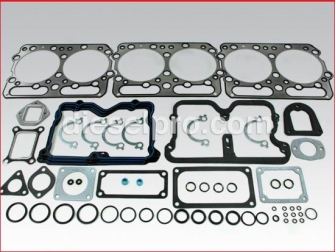

Upper Gasket Set for Cylinder Head Installation

A complete upper gasket set includes all the necessary gaskets for reassembling the top-end of the engine following head removal or replacement. These sets typically include:

-

Head gaskets

-

Valve cover gaskets

-

Injector seals

-

Thermostat housing gaskets

-

Rocker box gaskets

We offer NH855 upper gasket sets compatible with Big Cam and earlier engine configurations. Choosing the right gasket set ensures a leak-free and long-lasting rebuild.

Valve Inserts for NH855

Valve seat inserts—also known as valve inserts—provide a hardened surface for intake and exhaust valves to seal against. When rebuilding a cylinder head or performing a valve job, worn or cracked valve seats must be replaced. Our hardened steel inserts match Cummins specifications and ensure proper sealing and durability.

Rocker Components and Valve Cover Accessories

Our replacement rocker covers for the NH855 are manufactured from heavy-duty stamped steel and are compatible with OE mounting points. They're available in both new-style and traditional cork-seal configurations.

Valve cover gaskets come in two main options:

-

New Style Gasket: Uses modern composite materials for longer life and better sealing.

-

Old Style Cork Gasket: Traditional option preferred for restoration work or to match original components.

Both styles are stocked and ready for replacement during valve train maintenance.

Valve Train Hardware

Push Rods for NH855 Valve Rockers

NH855 engines use different push rods depending on whether the configuration is Small Cam or Big Cam. Push rods are critical for transferring motion from the camshaft to the rocker arms.

-

Valve Rocker Push Rods: Typically, 12 per engine in Big Cam versions.

-

Injector Rocker Push Rods: Varies by cam type—6 per engine for injector control.

Always match your push rods to engine variant (Big Cam or Small Cam) to ensure correct length and geometry.

These nuts are used for adjusting the rocker arm screws and maintaining proper valve lash. Replacement is often overlooked but essential for accurate and stable valve timing.

Temperature Switches and Engine Monitoring

For NH855 engines equipped with legacy mechanical temperature switches, we offer high-quality replacements. These close at 205°F and are compatible with ½" NPT thread ports. Ideal for marine and generator applications where dependable cooling system monitoring is critical.

When Should You Replace Your NH855 Cylinder Head?

Typical signs include:

-

Cracked cylinder head (external or between valves)

-

Coolant loss with no external leaks

-

Excessive white smoke from the exhaust

-

Poor compression or frequent misfires

-

Oil in coolant or vice versa

If you’re rebuilding your NH855 after significant hours of use or following a cooling system failure, it’s highly recommended to install a new head rather than recondition a damaged one. This avoids downtime, performance issues, and costly repeat labor.

Supporting a Top-End Rebuild: Why Every Part Matters

Performing a top-end rebuild on a Cummins NH855 involves more than just replacing the head. Below are the components that complete the job—and why they matter.

-

Valves and Valve Springs: Ensure precise opening and closing of intake and exhaust ports, directly impacting combustion and emissions.

-

Valve Guides and Seals: Provide alignment and sealing, crucial for oil control and valve durability.

-

Head Gasket & Gasket Set: Must withstand extreme cylinder pressure and thermal expansion. Always use a full set to prevent future leaks.

-

Injector Tubes & Seals: Protect fuel delivery paths, prevent misfires and loss of power.

-

Cylinder Head Bolts: Ensure proper torque and cylinder sealing. Reusing old bolts is not recommended.

Trust Diesel Pro Power For Your NH855 Top-End Needs

With over 40,000 satisfied customers worldwide, Diesel Pro Power is the trusted supplier for Cummins engine components. Our inventory includes:

-

New NH855 cylinder heads pre-assembled with valves and springs

-

Premium-quality OEM-style components

-

Fast worldwide shipping and expert technical support

Whether you're maintaining a genset, marine propulsion engine, or industrial power unit, we ensure you get the right parts, every time.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588