Cummins NH855 Engine Parts for Australia - Exhaust Section

Loading...

Loading... Cummins NH855 Exhaust System Parts Catalog

The exhaust system is one of the most critical assemblies on the Cummins NH855 engine. Designed to handle extreme heat, reduce emissions, and optimize flow, the exhaust components ensure that combustion gases are efficiently expelled while protecting the rest of the engine. On large displacement engines like the Cummins NH855 and its close relative, the NT855, a properly maintained exhaust system is essential not only for performance but also for long-term durability and compliance with industrial and marine standards.

Below, you’ll find a complete breakdown of exhaust system components for the Cummins NH855, including manifolds, gaskets, insulation, flanges, mufflers, and related accessories.

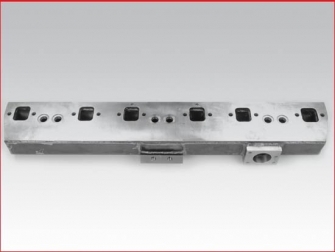

Exhaust Manifolds for Cummins NH855

Heavy-Duty Water-Cooled Exhaust Manifolds

The Cummins NH855 uses a robust, water-cooled exhaust manifold. This design is engineered to withstand the extremely high temperatures generated during combustion while maintaining structural integrity over thousands of hours of operation. The water-cooled construction reduces the likelihood of warping, cracking, or premature wear—a common concern in high-output diesel engines.

Key features:

-

Optimized gas flow to support efficient turbocharging.

-

Water-cooled design prevents thermal overload and prolongs service life.

-

Compatible with both NH855 and NT855 configurations.

-

Cast from high-strength materials to resist corrosion and thermal fatigue.

Exhaust Manifold Gaskets

High-Performance Gasket Sets

Each Cummins NH855 engine requires six exhaust manifold gaskets to ensure a proper seal between the manifold and the cylinder head. These gaskets are designed to handle the pressure and heat cycles of continuous duty operation without leaking or degrading prematurely.

Key features:

-

Heat-resistant sealing surface prevents gas leaks.

-

Engineered for NH855, NT855, and select N14 applications.

-

Ensures consistent manifold alignment and stability.

Without a proper gasket seal, exhaust leaks can lead to reduced power, higher fuel consumption, and potential damage to valves and cylinders.

Exhaust Insulation & Heat Protection

Manifold Insulation Tape

Insulation tape is an important accessory for NH855 exhaust systems, particularly in marine and industrial environments where reducing heat transfer is critical. Wrapping the exhaust manifold and connecting pipes with insulation tape helps:

-

Lower engine room temperatures.

-

Protect nearby wiring and hoses from heat damage.

-

Improve energy efficiency by retaining exhaust heat for optimized turbo performance.

Available in widths of 3 inches and 4 inches, these tapes are supplied in 100-foot rolls at 1/8-inch thickness, providing ample coverage for a full exhaust system installation.

Exhaust Flanges & Gaskets

Industrial Exhaust Flanges

To secure the manifold outlet and connect it to the rest of the exhaust piping, the NH855 exhaust system uses precision-machined 4-inch inside diameter flanges. These heavy-duty flanges provide a solid, vibration-resistant connection capable of withstanding thermal cycling.

Flange Gaskets

A 4-inch flange gasket is required to create a leak-proof seal between the flange and adjoining components. These gaskets are manufactured from high-temperature resistant materials to ensure long-lasting durability.

Industrial Mufflers for Cummins NH855

Heavy-Duty Muffler Assemblies

On many industrial and marine NH855 applications, exhaust noise reduction is handled by a 4-inch diameter muffler. These mufflers are designed to absorb sound while maintaining optimal back pressure for the turbocharger.

Key features:

-

4-inch National Pipe Thread (NPT) connections on both inlet and outlet.

-

Rugged steel construction designed for extended service life.

-

Built to handle high flow rates without restricting performance.

A properly sized muffler not only reduces decibel output but also contributes to operator safety and comfort, especially in enclosed spaces such as marine engine rooms or industrial power stations.

Exhaust System End Caps

Muffler End Caps for Industrial Engines

To protect the exhaust system from debris, rain, and backflow, muffler caps are often installed on Cummins NH855 engines. These caps are available in multiple outside diameters to fit a wide range of exhaust outlet sizes, including:

These caps are especially important in marine environments where moisture ingress can cause corrosion and shorten the life of exhaust components. By sealing the system when not in use, muffler caps provide simple but critical protection.

Gauges for Exhaust System Monitoring

While not part of the exhaust flow path itself, mechanical and electrical gauges play a role in monitoring engine performance and exhaust health. Abnormal back pressure, temperature spikes, or changes in fuel efficiency can all be detected early through proper instrumentation.

Available gauges include:

-

Standard mechanical gauges for direct monitoring.

-

Mechanical gauges with alarm functions for operator safety.

-

Electrical gauges in both 12V and 24V configurations for marine and industrial systems.

Importance of Proper Exhaust Maintenance on the NH855

The Cummins NH855 is a workhorse engine, often running in demanding continuous-duty applications. A well-maintained exhaust system ensures:

-

Optimal turbocharger performance.

-

Prevention of exhaust leaks and harmful gas exposure.

-

Compliance with industrial and marine noise regulations.

-

Extended engine life through balanced operating temperatures.

Neglecting the exhaust system can lead to warped manifolds, cracked gaskets, and increased operating costs over time. Preventive maintenance with genuine Cummins-compatible components is the best way to keep an NH855 running reliably.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588