Cummins QSL Parts for Australia - Fuel Pump Section

Loading...

Loading... -

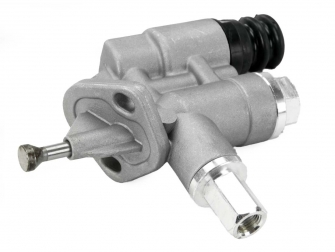

Cummins Fuel Transfer Pump

3936319

Pump Style Mechanical Piston, Used with non-rotary pumpsPrice: $ 101.38 -

-

-

Cummins Fuel Filter

3890017

3.7" diameter, 5.46" height, thread: + 13/16- 18" - 14 UNF-28Price: $ 32.59 -

-

-

Cummins Fuel Filter & Water Separator

3329289

3.66" diameter, 9.92" height, thread size: 1-14 UNPrice: $ 39.19 -

-

-

-

1000 Racor Replacement fuel and water separator filter unit

1000

Filter element 2020 includedPrice: $ 449.65 -

-

-

-

-

-

-

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

Cummins QSL Fuel System Components Catalog

The Cummins QSL engine is one of the most reliable mid-range diesel platforms ever produced, widely respected in industrial, marine, and power generation applications. A key reason for its long-lasting performance is the efficiency and durability of its fuel system. Proper fuel delivery ensures consistent combustion, reduced emissions, and extended engine life.

At Diesel Pro Power, we provide a complete catalog of fuel pumps, fuel filters, gaskets, couplings, water separators, pressure switches, and related components designed specifically for the Cummins QSL. With more than 40,000 satisfied customers worldwide, we are the trusted source for keeping your QSL engine running at peak performance.

Fuel Pumps for Cummins QSL

The fuel pump is the heart of the QSL’s fuel delivery system. It ensures that diesel is transferred from the tank to the injection system at the proper pressure and volume.

Mechanical Fuel Transfer Pump

The Cummins QSL relies on a mechanical piston-style transfer pump for many configurations. This pump is durable, efficient, and specifically engineered to deliver reliable operation in high-demand environments such as marine propulsion, construction equipment, and stationary power units.

Key Features:

-

Mechanical piston design for durability

-

Consistent pressure output

-

Designed for non-rotary fuel systems

-

Built to withstand long hours of operation under load

This pump is vital for maintaining steady fuel flow, preventing cavitation, and ensuring smooth engine performance even under heavy fuel demand.

Fuel Transfer Pump Gasket

Each QSL transfer pump requires secure sealing to prevent fuel leakage. The gasket is a small but critical component that ensures tight sealing between pump surfaces.

Details:

-

High-quality sealing material

-

Prevents leaks that could cause air intrusion into the system

-

Essential for reliable pump operation and safety

Fuel Pump Couplings for Cummins QSL

The pump coupling connects the transfer pump to the rest of the system, allowing for smooth energy transfer and stable pump function.

Benefits of a Reliable Coupling:

-

Ensures vibration-free operation

-

Reduces wear on pump components

-

Provides a secure connection that withstands high-pressure cycles

A worn coupling can cause misalignment, leading to premature pump wear or failure. Replacing it as part of preventive maintenance ensures long-term reliability.

Fuel Filters for Cummins QSL

Clean fuel is essential for the Cummins QSL engine. Contaminants such as dirt, water, and rust particles can cause injector damage, power loss, or even catastrophic engine failure. The filters in our catalog are engineered to meet Cummins specifications, providing superior protection.

Spin-On Fuel Filters

The spin-on filter is the most commonly used style on QSL engines. Its compact design and robust build ensure easy replacement and effective filtration.

Features:

-

Available in multiple sizes to fit QSL applications

-

Designed to capture fine particulates before they reach injectors

-

Built with high-capacity media for extended service intervals

Secondary Fuel Filters

For engines operating in harsher environments, secondary fuel filters offer an additional layer of protection. They work in tandem with the primary filter to ensure only clean fuel reaches the combustion chamber.

Fuel Filters with Water Separation

Water contamination is one of the leading causes of injector and pump failure. Filters with built-in water separation technology protect the QSL engine by removing moisture before it can cause damage.

Advantages:

-

Integrated water separation chamber

-

Protects against corrosion and injector erosion

-

Extends the life of fuel system components

Fuel Filter & Water Separator Units

For vessels, industrial machines, and stationary engines, a combined fuel filter and water separator is often the preferred solution. These systems provide maximum protection against both particulate contamination and water intrusion.

Standard Separator Units

-

Designed for continuous operation

-

Durable construction suitable for high-flow demands

-

Clear housing options available for easy inspection

Filter Elements in Multiple Micron Ratings

To adapt to different operational needs, elements are available in 2 micron (ultra-fine filtration) and 30 micron (coarser filtration for high-volume flow).

Micron Rating Guide:

-

2 Micron: Protects precision injectors from the smallest contaminants

-

30 Micron: Ideal as a primary filter to handle large debris and extend service life of secondary filters

By combining coarse and fine filtration, operators can build a layered defense against fuel system contamination.

Fuel Pressure Switches for Cummins QSL

Pressure switches monitor the fuel and oil systems, sending electrical signals to alert operators of abnormal conditions. These switches are a safeguard for preventing damage due to low fuel pressure.

Available Settings:

Each pressure setting is designed for different monitoring applications, ensuring you always have accurate feedback from your QSL engine.

Benefits:

-

Protects against fuel starvation

-

Helps maintain correct injector operation

-

Supports advanced monitoring systems in modern installations

Fuel Filter Tools & Accessories

Routine maintenance on the Cummins QSL is simplified with specialized tools. One of the most important is the fuel filter removal wrench, designed to safely and efficiently loosen filters without damaging housings.

Key Advantages:

-

Adjustable design fits multiple filter sizes

-

Prevents overtightening or stripping during installation/removal

-

Essential for quick service in tight engine compartments

Gauges for Monitoring Fuel System Performance

Accurate monitoring is essential for maintaining optimal engine operation. Diesel Pro Power offers both mechanical and electrical gauges designed to integrate seamlessly with the QSL’s fuel and oil systems.

Options Include:

-

Mechanical gauges with built-in alarms

-

Electrical gauges for both 12-volt and 24-volt systems

-

Reliable readouts for pressure and flow consistency

Properly calibrated gauges provide early warnings, allowing operators to address issues before they become costly failures.

Why Choose Diesel Pro Power for Cummins QSL Fuel System Parts?

With decades of experience serving marine and industrial engine operators, Diesel Pro Power offers:

-

Fast worldwide shipping – Parts delivered quickly, wherever you operate

-

40,000+ satisfied customers – Proven trust in our quality and service

-

Expert support – Knowledgeable staff ready to help identify the right part

-

High-quality components – Designed to match or exceed OEM standards

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588