Cummins QSB 7.0 Parts for Australia - Fuel Pump Section

Loading...

Loading... Cummins QSB 7.0 Fuel Pump & Fuel System Components Catalog

The Cummins QSB 7.0 is one of the most versatile and dependable electronically controlled diesel engines in the Cummins marine and industrial range. Whether it’s powering a commercial fishing vessel, a passenger ferry, a harbor tug, or a stationary industrial generator, the QSB 7.0’s fuel system is the lifeblood of its performance. A single weak link — a worn gasket, a clogged filter, or a faulty transfer pump — can bring operations to a halt.

At Diesel Pro Power, Inc., we supply premium aftermarket Cummins fuel system parts that meet or exceed OEM specifications. Every item in our catalog is engineered for long service life, precise fitment, and reliable operation under the harshest marine and industrial conditions. With global shipping and over 40,000 satisfied customers, we make it easy to get the parts you need, wherever you are in the world.

Fuel Transfer Pumps for Cummins QSB 7.0

A fuel transfer pump draws fuel from your storage tank and delivers it to the high-pressure injection pump at a steady, reliable rate. Without it, the QSB 7.0’s electronically controlled injectors cannot deliver consistent power.

We offer two primary pump configurations to suit different QSB 7.0 setups and retrofit requirements.

Mechanical Lever-Style Fuel Transfer Pump

-

Compatibility: QSB 7.0, as well as legacy Cummins 4BT and 6BT engines.

-

Design Features: Simple lever-actuated mechanism with minimal moving parts to reduce maintenance needs.

-

Marine & Industrial Advantages:

-

Resists performance drop-off under continuous load.

-

Operates without dependence on electronic controls — ideal for backup systems or harsh conditions.

-

Maintenance Tip: Check lever pivot points and seals regularly for signs of wear or seepage.

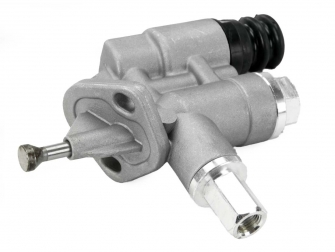

Mechanical Piston-Style Fuel Transfer Pump

-

Compatibility: Used with non-rotary injection pumps on QSB 7.0 applications.

-

Design Features: Piston-driven design provides steady output pressure even during rapid throttle changes.

-

Why Choose This Pump:

-

Better suited for operations with variable load demands (harbor pilots, tow vessels, crane barges).

-

Reduced risk of vapor lock in high-temperature environments.

-

Maintenance Tip: Periodically inspect for fuel staining around body seals — early detection prevents full pump failure.

Fuel System Gaskets & Seals

Even the best pump cannot perform if the sealing surfaces in the fuel system are compromised. Gaskets and seals maintain pressure integrity and prevent fuel leaks — a critical factor for both performance and environmental compliance in marine operations.

Fuel Transfer Pump Gasket

-

Function: Creates a seal between the pump and mounting flange.

-

Details: Two gaskets are typically used per pump.

-

Importance in Marine Use: Prevents fuel seepage into bilges, which could lead to safety hazards.

Fuel Injection Pump Gasket

-

Application: Works with QSB 7.0 and earlier B and C series engines.

-

Function: Prevents leaks between the injection pump and engine block.

-

Service Note: Always replace gaskets when removing or reinstalling an injection pump.

Fuel Shutoff Control

12-Volt Fuel Shutoff Solenoid

-

Role in Engine Safety: Quickly stops fuel flow to shut down the engine during emergencies or maintenance.

-

Marine Application: Often integrated into safety circuits to prevent engine restart after oil pressure loss.

-

Troubleshooting Tip: If the engine cranks but doesn’t start, test the solenoid for actuation before checking injectors.

Fuel Filtration & Water Separation

Marine diesel engines face a unique challenge: fuel contamination from water ingress. Even small amounts of water can corrode injectors and damage pumps. The QSB 7.0’s filtration system should be maintained meticulously to protect the fuel injection system.

Cummins Fuel Filters

-

Primary Role: Captures fine particles before they can damage injectors.

-

Construction: High-strength casing with vibration-resistant sealing.

-

Replacement Interval: Follow Cummins maintenance schedules; in marine use, inspect more frequently due to possible tank condensation.

Cummins Fuel Filter with Integrated Water Separator

-

Dual Function: Filters fuel and removes entrained water.

-

Marine Benefit: Extends injector life and prevents water-related combustion problems.

-

Service Tip: Drain the water bowl regularly in humid or high-moisture operating areas.

Racor®-Style Marine Fuel & Water Separation Systems

For marine QSB 7.0 engines, Racor-style separators are standard equipment because of their high moisture-removal efficiency.

Complete Racor Fuel/Water Separator Assemblies

-

Models Available: 500, 900, and 1000 series.

-

Use Case: Choose flow rate according to engine horsepower and operating hours.

-

Included: Each assembly comes with a filter element.

Racor Filter Elements

-

2010 Series:

-

Brown top – 2 micron for ultra-fine final filtration.

-

Red top – 30 micron for primary filtration in dual-stage systems.

-

2040 Series:

-

2020 Series:

-

High-capacity elements for large-flow separators.

-

Brown top (2 micron) and red top (30 micron) available.

Fuel System Service Tools

Fuel Filter Removal Wrench

-

Fitment Range: 3-7/16" to 3-3/4" filter canisters.

-

Purpose: Allows secure grip for filter removal without damaging the housing.

-

Marine Use Tip: Keep one onboard for emergency filter swaps during voyages.

Fuel Cooler Protection

Marine Zinc Anodes for Fuel & Oil Coolers

-

Material: Brass plug with replaceable zinc core.

-

Function: Sacrificial anode protects cooler cores from galvanic corrosion in saltwater.

-

Service Interval: Replace regularly; check during every scheduled fuel system inspection.

Fuel & Oil Pressure Monitoring

Monitoring fuel and oil pressure is critical for early detection of system faults.

Pressure Switches

-

Available Settings: 5, 10, 20, and 27 PSI.

-

Function: Activates alarms or triggers shutdowns if pressure falls below safe thresholds.

-

Marine Safety Role: Helps prevent catastrophic engine damage during offshore operation.

Gauges

-

Types: Mechanical, 12V electrical, and 24V electrical.

-

Optional Alarms: Built-in alarms can alert operators before damage occurs.

-

Installation Tip: Place gauges where they can be monitored from both the helm and the engine room.

Maintenance & Troubleshooting Scenarios for the QSB 7.0 Fuel System

To help operators, here’s how common QSB 7.0 fuel system issues manifest and how these parts can resolve them:

-

Hard Starting or No Start

-

Likely Causes: Weak or failed fuel transfer pump, stuck fuel shutoff solenoid, clogged primary filter.

-

Solution: Replace the pump with the correct lever or piston style; verify solenoid operation; change filters.

Loss of Power Under Load

-

Likely Causes: Water contamination, partially clogged filter, or failing pressure switch triggering safety cutout.

-

Solution: Drain or replace separators; install new filter elements; check fuel pressure against specs.

Fuel Odor in Engine Room

-

Likely Causes: Leaking gaskets or pump body seals.

-

Solution: Replace pump gaskets; torque fittings to manufacturer recommendations.

Erratic Fuel Pressure Readings

-

Likely Causes: Faulty gauge or pressure switch.

-

Solution: Replace gauge or switch with correct PSI rating.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588