Parts for Detroit Diesel 12V71 Turbo for Australia - Marine Water Pump Section

Loading...

Loading... -

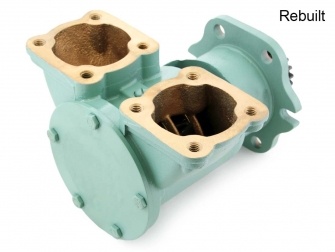

Marine Water Pump for Detroit Diesel 71 and 92 Series Marine Engines - Rebuilt

23507972R

Sold with refundable core deposit. See details

Bidirectional Pump (It Turns Right or Left)

Port Type: 2” Flange. Includes Adapter & Drive Gear.

Impeller Height: 3 1/2” - Splined Shaft.

Price: $ 939.00 -

Marine Water Pump for Detroit Diesel 71 and 92 Series Marine Engines

23507972

Bidirectional Pump (It Turns Right or Left)

Port Type: 2” Flange. Includes Adapter & Drive Gear.

Impeller Height: 3 1/2” - Splined Shaft.

Price: $ 1,293.63 -

Detroit Diesel Marine Water Pump repair kit for 6-71, 8V71, 8V53, 12V71, 6V92, 8V92

5197222

For 3 1/2" height impeller - spline pump shaft

Price: $ 777.39 -

Detroit Diesel raw Marine Water Pump, 12V71 TI, 16V71 T, 8V92 TA,12V92 TA, 16V92 - Rebuilt

23507475R

3 1/2 " Impeller. 6 screw cover, double flat impeller drive. Sold with refundable core deposit. See details

Price: $ 2,037.37 -

Marine Water Pump for Detroit Diesel 71 and 92 Series Marine Engines

23507475

Bidirectional Pump (It Turns Right or Left)

Port Type: 2” Flange. Includes Drive Gear.

Shifted Ports

Price: $ 3,602.20 -

Detroit Diesel Marine Water pump Repair Kit for Series 71 & 92

8927566

For pumps with 3 1/2 " diameter impeller. 6 screw cover, double flat impeller drivePrice: $ 1,778.64 -

Marine Water Pump for Detroit Diesel 71, 92 and 149 Series Marine Engines

8927296

Bidirectional Pump (It Turns Right or Left)

Port Type: 2” Flange. 4 1/2” Impeller height.

Non-Splined Shaft.

Price: $ 5,344.98 -

Impeller for Detroit Diesel, Scania and Volvo Penta Marine Water Pumps

8924839

Impeller with 12 Blades and 12 Spline Drive.

Diameter: 3 3/4” - Height: 3 1/2”

Price: $ 167.56 -

Detroit Diesel Marine Water Pump repair kit with shaft for 12V71TI, 12V92TA, 8V149, 12V149 and 16V149

23502097

For pump with 4 screw cover, 4 1/2" impellerPrice: $ 2,186.93 -

-

-

-

Impeller Puller for Marine Water Pumps

50070

Fit range: 2 9/16" to 4 5/8" diameter impeller puller for marine water pumps.

Price: $ 345.12 -

Impeller for Caterpillar and Detroit Diesel Marine Water Pumps

8927570

Impeller with 12 Blades and Double Flat Drive.

Diameter: 3 3/4” - Height: 3 1/2”

Price: $ 192.84 -

-

-

-

-

-

Detroit Diesel Marine Water Pump gasket

5112143

Each pump uses 2 of this gasket. Water inlet and outletPrice: $ 4.59 -

-

-

-

-

-

-

-

-

Detroit Diesel Gasket for Marine Heat Exchanger for 12V71, 16V71, 12V92, 16V92, 8V92

5117406

.

Price: $ 20.34 -

-

-

-

-

Zinc for Marine Engine - for Heat Exchangers

E4C

Brass plug NPT 3/4", zinc length 3 3/8"Price: $ 33.43 -

Zinc for Marine Engine - for Marine Water Pumps

E3C

Brass plug NPT 3/4", zinc length 2"Price: $ 32.05 -

Zinc for Marine Engine - for Marine Water Pumps

E2C

For Detroit heat exchanger For Cummins heat exchanger and aftercooler For Brass plug NPT 1/2", zinc length 2"Price: $ 27.53 -

Zinc for Marine Engine - for Fuel Coolers & Oil Coolers

E1C

Brass plug NPT 3/8", zinc length 2"Price: $ 24.54 -

Zinc for Marine Engine - for Fuel Coolers & Oil Coolers

E00

Brass plug NPT 1/8", zinc length 2"Price: $ 18.72 -

-

Detroit Diesel Shaft for raw or Marine Water Pump - spline

5196169

For 3 1/2" dia raw water pump (Brass)

Price: $ 221.84 -

-

Detroit Diesel Cover for Marine Water Pump with 2 1/2 and 3 1/2 inch dia impeller

5193555

For 2 1/2" and 3 1/2 impeller

Price: $ 94.00 -

-

-

-

-

-

-

-

-

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

-

-

-

-

-

-

-

-

-

-

-

Clamp for a coolant and fuel Hose

10H

Effective Diameter Range:

Minimum 9/16", Maximum 1-1/16"

Price: $ 3.04 -

Clamp for a coolant Hose

4920417

Effective Diameter Range:

Minimum 13/16", Maximum 1-3/4"

Price: $ 15.78 -

Clamp for a coolant Hose

3412320

Effective Diameter Range:

Minimum 11/16", Maximum 1-1/4"

Price: $ 14.76 -

Clamp for a coolant Hose

3922846

Effective Diameter Range:

Minimum 1-5/16", Maximum 2-1/4"

Price: $ 16.50 -

Clamp for a coolant Hose

3922847

Effective Diameter Range:

Minimum 1-9/16", Maximum 2-1/2"

Price: $ 16.68 -

Clamp for a coolant Hose

3922849

Effective Diameter Range:

Minimum 2-5/16", Maximum 3"

Price: $ 17.19 -

-

Controls Cables & More...

-

Marine Control

-

Industrial Cable

-

Marine Cables 1/16 thread

-

Marine Cables 1/4 thread

-

Marine Steering

-

Rubber Bearing

-

Searchlight

-

Marine Bulb

-

Navigation Light

-

Marine Raw Water Pumps & Cooling Components for Detroit Diesel 12V71 (Turbo)

Keep your Detroit Diesel 12V71 running cool, clean, and reliable with a complete selection of raw (sea) water pumps and matching cooling-system hardware designed for turbocharged marine applications. This section focuses on the 12V71 Turbo platform while acknowledging that many components are used across the wider 71 and 92 Series families. You’ll find fully rebuilt and new seawater pumps, service kits, impellers, cams and shafts, wear plates, gaskets and seals, heat exchanger tanks and cores, zinc anodes, premium silicone hose, clamps, strainers and more—curated for real-world marine duty.

How the 12V71 Marine Raw Water Circuit Works (and Why It Matters)

The 12V71 cooling system uses a two-loop design:

-

Closed (fresh-water) loop: Circulates treated coolant through the engine block and heads.

-

Raw (sea) water loop: Pulls seawater through a marine water pump, sends it across the heat exchanger and aftercooler/fuel-oil coolers as required, then discharges overboard.

The raw water pump is the heart of this second loop. It is a positive-displacement, cam-and-impeller pump that:

-

Self-primes quickly when installed correctly and wetted.

-

Delivers predictable flow across the rpm range.

-

Survives continuous saltwater exposure when maintained with correct anodes and seals.

A healthy pump prevents high coolant temps, protects turbochargers and aftercoolers from heat-soak, and reduces the risk of head gasket failure or piston scuffing in sustained-load conditions.

Quick Selector: 12V71 Marine Water Pump Options

Rebuilt Bidirectional Pump (2" Flange, Adapter & Drive Gear, 3-1/2" Impeller, Splined Shaft)

-

Best for: Direct replacements on many 12V71 turbo marine setups using a splined impeller drive and 3-1/2"impeller height.

-

Why it’s popular: Bidirectional rotation (right or left) eases installation. Comes with adapter and drive gear to streamline changeouts.

-

When to choose: If your cover uses six screws, your impeller height is 3-1/2", and your shaft is splined, this is typically the right call.

New Bidirectional Pump (2" Flange, Adapter & Drive Gear, 3-1/2" Impeller, Splined Shaft)

-

Best for: Owners who prefer a new assembly with the same fit profile as above.

-

Why it’s popular: Zero prior service hours, immediate drop-in, predictable longevity.

-

Best for: 12V71 TI/T/TA installations requiring a double-flat impeller drive (not splined) and six-screw cover.

-

Why it’s popular: Corrects mismatched drive styles that cause premature impeller wear.

Pump with Shifted Ports (2" Flange, Drive Gear Included)

-

Best for: Repowers or hulls where hose routing is tight and standard in-line ports cause interference.

-

Why it’s popular: Shifted ports improve hose clearance and service access without creative plumbing.

High-Capacity Pump (2" Flange, 4-1/2" Impeller Height, Non-Splined Shaft)

-

Best for: Heavy, continuous-duty 12V71 installations sharing hardware with 92/149 Series layouts, or where the heat load and auxiliary coolers demand greater seawater throughput.

-

Why it’s popular: Larger impeller height (4-1/2") increases raw water flow to match bigger heat exchanger cores and aftercoolers.

Service Kits & Critical Internals for 12V71 Raw Water Pumps

Complete Repair Kits (3-1/2" Impeller, Splined Shaft)

-

What’s inside: Typically includes the mechanical seal, cam, wear plate, key/splines interface parts, bearings, O-rings/gaskets, and fasteners aligned to the pump family.

-

Use case: Bring a tired pump back to spec without swapping the full assembly. Ideal for mid-season service or pre-voyage refreshes.

Repair Kits for 6-Screw, Double-Flat Drive Pumps (3-1/2" Impeller)

-

What’s inside: Seals, bearings, double-flat compatible components, cover gaskets, and hardware suited to the six-screw cover design.

-

Use case: Ensures you’re not mixing splined components into a double-flat pump—one of the most common causes of early failure.

Heavy-Duty Repair Kit with Shaft (4-Screw Cover, 4-1/2" Impeller)

-

What’s inside: The full complement of seals, bearings, cam, wear plate—and a new shaft—for high-capacity pumps used with larger heat exchanger packages.

-

Use case: When shaft wear, grooving, or corrosion is evident—or if the boat runs high-salinity routes with long intervals between haul-outs.

Impellers: Sizing, Drive Type & Material Tips

3-1/2" Height, Splined Drive Impellers

-

Fit: Pumps with splined shafts and 3-1/2" impeller height (common on many 12V71 turbo pumps).

-

Design: 12-blade neoprene/NBR for balanced priming and flow at typical 12V71 rpm bands.

-

Care: Replace at least every 12 months or 200–300 running hours, whichever comes first, and always carry a spare aboard.

3-1/2" Height, Double-Flat Drive Impellers

-

Fit: Pumps using the double-flat impeller drive and six-screw cover.

-

Note: Do not force a splined impeller onto a double-flat shaft (or vice versa); it will slip, shred the hub, and can damage the cam.

-

Fit: Larger, high-capacity pumps used in some 12V71 turbo builds (especially with big aftercoolers or multiple auxiliary coolers).

-

Flow: Increased height translates to more seawater throughput, ideal for hot climates, slow-speed trawling with high auxiliary loads, or vessels with marginal airflow to engine rooms.

Cams, Shafts, Wear Plates & Covers

-

Function: The cam compresses each impeller vane as it passes, creating suction on one side and discharge on the other.

-

Signs of wear: Grooves, pitting, and polished flats. A worn cam lowers net flow even with a new impeller.

Pump Shafts (Splined for 3-1/2")

-

Function: Transfers torque from the drive gear to the impeller hub.

-

Service note: Replace if you see corrosion pits near the seal land or any wobble. A scored shaft eats seals and causes persistent leakage.

-

Function: Protects the housing, keeps end-clearance tight, and stabilizes output.

-

Tip: Replace plates with any new impeller if plate scoring is visible; this preserves vane tips and improves priming.

Covers & Cover Screws (2-1/2" and 3-1/2" Families)

-

Function: Maintain end clearance and seal the pump chamber.

-

Best practice: Use fresh gaskets; torque evenly in a crisscross pattern; apply a touch of waterproof grease on screw threads to prevent galling.

Gaskets, Seals & Bearing Sets (Don’t Skip the Small Stuff)

-

Mounting gaskets between the pump and the engine ensure correct spacing and prevent weeping under vibration.

-

Plate and cover gaskets must match your cover style (four-screw vs six-screw). Mismatched gaskets can pinch, tear, and air-leak.

-

Inlet/outlet port gaskets are used in pairs on many pumps—replace both at the same time.

-

Mechanical seals keep raw water in and contaminants out; install with clean hands and never dry-run the pump. Wet the seal faces with clean water or a manufacturer-approved lube at assembly.

-

Bearing sets and oil seals protect against shaft wobble and brine intrusion—both are common culprits behind unexplained impeller failures.

Thermostats & Sealing (160° and 170° Options)

While thermostats regulate fresh-water side temperature—not raw water flow—they affect overall cooling behavior:

-

160°F units often suit warm seawater regions or heavy, continuous load where additional thermal margin is helpful.

-

170°F units may be preferred in cooler waters to speed warm-up and maintain ideal combustion temps.

Always replace the thermostat seal when you change thermostats to avoid seepage and air ingestion.

Heat Exchanger Tanks, Cores & Gasket Kits (12V71 Focus)

The heat exchanger is where the raw-water loop sheds heat from the fresh-water loop. We stock:

-

Tanks sized for 12V71 and related V-series engines.

-

Rebuilt cores to restore heat transfer efficiency when fins foul or tube bundles scale up.

-

Gasket kits for end-cap service, tank-to-core joints, and outlet connections.

-

Individual outlet gaskets to solve minor leaks without a full kit.

-

Glands and seals for tank service on 12V71 platforms.

Maintenance tip: If you’re swapping from a smaller pump to a high-capacity raw water pump, verify your heat exchanger and aftercooler bundles are clean and flow-tested. A bigger pump won’t fix a plugged core.

Sacrificial Zinc Anodes: Your First Line of Defense

Raw water pump bodies, heat exchangers, fuel coolers, and oil coolers are vulnerable to galvanic corrosion. Protect them with the correct thread sizes and zinc lengths:

-

Heat exchanger zincs: Commonly use larger NPT plugs and longer zincs for the main tank.

-

Raw water pump zincs: Typically shorter elements to fit the housing.

-

Fuel/oil cooler zincs: Often even smaller plugs; check thread and length before ordering.

Replace zincs every 60–90 days in warm, salty waters—or sooner if you notice rapid consumption.

Hoses, Clamps & Intake Strainers (Keep Flow Unrestricted)

Premium Silicone Coolant Hose (Various IDs by the Foot)

Resistant to heat, pressure, and oil mist—great for tight bends and hot engine rooms. Match inside diameter precisely to necks and fittings to reduce turbulence and chafe.

Stainless Hose Clamps (Wide Effective Ranges)

Choose the clamp that covers your hose OD with room to spare—but never bottomed out. Over-tightening can ovalize thin-wall necks and create future leaks.

Raw-Water Intake Strainers

A clean, right-sized strainer prevents eelgrass, shells, and plastic from starving the pump. Size the strainer to at least the flow rate your pump requires and service the basket frequently in weed-heavy harbors.

Installation & Commissioning Checklist (12V71 Turbo)

-

Confirm rotation (bidirectional pumps can be clocked either way; verify hose orientation and discharge).

-

Match the drive (splined vs double-flat) and cover style (four vs six screws).

-

Verify impeller height (3-1/2" or 4-1/2") to maintain the design flow your heat exchanger/aftercooler needs.

-

Pre-lube the impeller with an impeller-safe lubricant; do not use petroleum grease on neoprene.

-

Inspect the cam: Replace any cam with grooves or polished flats.

-

Set end-clearance: New wear plate and proper cover torque ensure strong suction.

-

Use new gaskets everywhere you broke a seal; wipe mating faces clean.

-

Prime the system: Fill the pump cavity and hoses with clean water before the first start.

-

Check for leaks at idle and at a fast-idle; re-torque cover screws evenly if needed.

-

Verify discharge: A strong, steady stream overboard at idle and rising with rpm indicates healthy flow.

Troubleshooting: Symptoms, Causes & Fixes

-

Engine temp creeps at cruise

Likely causes: Worn cam or impeller, air leak at inlet gasket, partially clogged strainer, collapsing suction hose.

Fix: Renew impeller and cam, replace gaskets, upgrade to wire-reinforced suction hose, clean strainer. -

Overheats only at wide-open throttle

Likely causes: Impeller vanes set (“tired”), glazed wear plate, belt slip on auxiliary drives, heat exchanger fouling.

Fix: New impeller, new wear plate, retension belts, clean core. -

Pump drips saltwater

Likely causes: Shaft seal worn, shaft land grooved, housing pitted near seal.

Fix: New mechanical seal and oil seal; if the shaft is worn, replace the shaft; consider a sleeve if the housing is otherwise serviceable. -

Cavitation noise / sputtering discharge

Likely causes: Air ingestion on suction side, wrong gasket alignment, or strainer lid gasket leaking.

Fix: Re-seat and replace suction gaskets, silicone-grease strainer lid O-ring, check hose clamps. -

Recurring impeller failures

Likely causes: Dry starts, mis-matched drive type (splined vs double-flat), excessive end-clearance, debris in the housing.

Fix: Prime before start, verify correct impeller for the shaft, install fresh wear plate, flush the system.

Pro Tips From the Dock

-

Carry spares: Keep at least two impellers (plus cover gaskets and screws) on board.

-

Tag your pump: Mark rotation, impeller height, and drive style on the housing with paint pen—saves time for the next haul-out.

-

Schedule zinc checks: Log zinc replacement dates; inspect more frequently in marinas with mixed-metal fleets.

-

Baseline temps: Record coolant temp at idle, 75% load, and WOT after a successful sea trial. It’s your early-warning system.

What to Order: 12V71 Turbo Marine Water Pump & Cooling Catalog

The items below are curated for the 12V71 Turbo marine platform. Many components are cross-compatible with other 71 and 92 Series engines, but the descriptions emphasize 12V71 fit and function. We do not list part numbers or prices here; click into any item for current availability and details.

Complete Pump Assemblies

-

Rebuilt, bidirectional pump with 2" flange, adapter, and drive gear; 3-1/2" impeller, splined shaft—optimized for common 12V71 turbo layouts.

-

New, bidirectional pump with 2" flange, adapter, and drive gear; 3-1/2" impeller, splined shaft—zero-hour alternative to the above.

-

Rebuilt pump for TI/T/TA setups using six-screw cover and double-flat impeller drive; 3-1/2" impeller.

-

Bidirectional pump with shifted ports (2" flange, drive gear included) to ease tight hose runs.

-

High-capacity pump with 4-1/2" impeller height and non-splined shaft for heavy-duty heat loads typical of big aftercoolers.

Pump Repair & Service Kits

-

Repair kit for 3-1/2" splined-shaft pumps (seals, gaskets, bearings, wear components).

-

Repair kit for six-screw, double-flat pumps (3-1/2" impeller).

-

Heavy-duty repair kit with shaft for 4-1/2" impeller pumps and four-screw covers.

Impellers

-

Impeller, 3-1/2" height, splined drive; 12-blade.

-

Impeller, 3-1/2" height, double-flat drive; 12-blade.

-

Impeller, 4-1/2" diameter class for larger-capacity pumps used with expanded exchanger packages.

Internal Components

-

Pump cams for 3-1/2" and 4-1/2" families.

-

Splined pump shaft for 3-1/2" impeller pumps.

-

Wear plates sized for 2-1/2" and 3-1/2" pump families.

-

Covers for 2-1/2" and 3-1/2" impeller pumps;

-

Cover screws (always replace if heads are corroded).

Gaskets & Seals

-

Mounting gasket (pump-to-engine).

-

Cover plate gasket and plate gaskets matched to cover style.

-

Inlet/outlet port gaskets (often two per pump).

-

Mechanical water seal, bearing oil seal, and shaft seal for marine raw water pumps.

Thermostats & Related

-

Thermostats in 160°F and 170°F options.

-

Thermostat seals for a leak-free install.

Heat Exchanger Components

-

Heat exchanger tanks sized for 12V71 and related V-series.

-

Rebuilt heat exchanger cores to restore heat-rejection capacity.

-

Gasket kits for 12V71 tanks and core end caps.

-

Outlet gaskets, glands, and tank seals as standalone service parts.

Zincs (Sacrificial Anodes)

-

Heat exchanger zincs with larger plugs and longer elements.

-

Raw water pump zincs sized for pump housings.

-

Fuel and oil cooler zincs in smaller thread sizes.

Hoses & Clamps

-

Silicone coolant hose by the foot in common diameters (1" through 4").

-

Stainless clamps in multiple effective ranges for a secure, corrosion-resistant hold.

Intake Water Strainers

-

Heavy-duty strainer sized for 2-1/2" pipe with serviceable baskets—ideal for 12V71 raw water flow rates.

Accessories

-

Detroit Green engine enamel for clean post-service touch-ups.

-

Radiator caps and necks (when your installation includes auxiliary tanks or expansion bottles).

Fitment Guide: Make the Right Choice First Time

-

Identify your drive style

-

Splined: Choose matching splined impeller and shaft components.

-

Double-flat: Use the six-screw cover service kit and double-flat impellers.

-

Measure your impeller height

-

3-1/2": Standard for many 12V71 Turbo builds.

-

4-1/2": Higher-capacity systems, bigger exchangers.

-

Count your cover screws

-

Four vs six determines your kit and gasket set.

-

Check port orientation

-

Tight engine rooms benefit from shifted-port pump bodies.

-

Confirm flange size

-

Most 12V71 turbo pumps here use a 2" flange—verify hose and strainer dimensions to match.

-

Consider duty cycle & waters

-

Hot climates or long trawls with auxiliary loads may justify the 4-1/2" impeller pump and upgraded strainer capacity.

Maintenance Intervals & Best Practices

-

Every outing: Glance at the overboard discharge; note any change in volume or pulsation.

-

Monthly: Open the strainer, clean the basket, inspect the lid O-ring.

-

Quarterly: Pull the pump cover, inspect impeller vanes for set, cracks, and missing tips; check wear plate gloss.

-

Every 6–12 months: Replace the impeller, plate gasket, and cover gasket (more frequently for high-hour commercial boats).

-

Each season: Replace zincs; inspect hoses for soft spots and clamp corrosion. Pressure-wash or acid-clean heat exchanger cores as indicated by temperature trends.

Why Order Your 12V71 Marine Water Pump Parts From Diesel Pro Power

-

Everything in one place – From complete seawater pumps to the smallest gasket and zinc, plus cams, shafts, wear plates, seals, hoses, clamps, and strainers—curated specifically for Detroit Diesel two-stroke marine applications.

-

In-stock and ready to ship worldwide – Fast dispatch with real-time tracking, clear ETAs, and export-friendly documentation to keep commercial and recreational vessels on schedule.

-

Detroit Diesel–trained support – Get precise fitment guidance on splined vs. double-flat drives, four- vs. six-screw covers, 3-1/2" vs. 4-1/2" impeller selections, and port orientation—before you buy.

-

Quality you can trust – Components built and tested for marine endurance, with strict QC on rebuilt pumps (seal faces, shaft lands, end-clearance) and new units alike.

-

Proven reputation – Trusted by 40,000+ satisfied customers across commercial, military, and recreational fleets—backed by consistent 5-star service feedback.

-

Same-day handling on most orders – Order early and we’ll move it the same business day; urgent dockside and ship-to-ship logistics available on request.

-

Core-friendly program (where applicable) – Straightforward, refundable core returns with clear instructions and fast processing to minimize downtime and paperwork.

-

Secure, marine-aware packaging – Pumps and delicate internals are protected against impact, moisture, and corrosion so parts arrive ready to install.

-

Hassle-free warranty & easy returns – Clear coverage and responsive support if something isn’t right—so you spend time boating, not negotiating.

FAQs: 12V71 Turbo Raw Water Pumps

Q: Can I run the engine briefly if the raw water pump hasn’t primed yet?

A: Do not dry-run. Even brief operation without water can burn the mechanical seal and deform impeller vanes. Pre-fill the pump and suction hose with clean water before the first start.

Q: My 12V71 overheats only at wide-open throttle—do I need a bigger pump?

A: Possibly, but diagnose first. Check impeller condition, end-clearance, strainer restrictions, suction hose collapse, and heat exchanger cleanliness. If everything is clean and temps still creep, a 4-1/2" impeller pump (with matching hardware) can help.

Q: How often should impellers be replaced?

A: Many operators plan for annual replacement or every 200–300 hours, sooner for hot, silty, or weedy waters.

Q: Can I swap a splined impeller into a double-flat pump (or vice versa)?

A: No. Mixing drive types leads to slippage and rapid failure. Match the impeller hub to your shaft style.

Q: Do I need zincs if I already have a galvanic isolator?

A: Yes. Zincs protect internal raw-water passages and components; monitor and replace regularly.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588