Parts for Detroit Diesel 12V71 Turbo for Australia - Engine Water Pump Section

Loading...

Loading... -

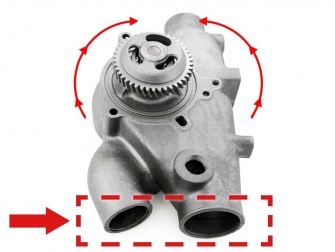

Detroit Diesel Water Pump for 12V71 - Truck and Industrial

23506714

BI-DIRECTIONAL rotation for truck and industrial applications. Sold with refundable core deposit. See details

Price: $ 1,730.26 -

Detroit Diesel Water Pump for 8V92 Turbo and 12V71 Non-Turbo and Turbo - marine - Rebuilt

23506763

BI-DIRECTIONAL rotation - for marine application. Sold with refundable core deposit. See details

Price: $ 2,194.70 -

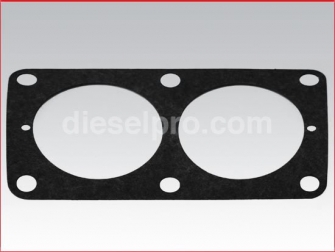

Detroit Diesel Engine Water Pump repair kit for 12V71, 16V71, 8V92T

23506367

Fresh water pump repair kit for Bi-directional pumps shown on this page

Price: $ 254.84 -

Detroit Diesel Engine Water Pump repair kit for 12V71, 16V71 & 8V92T

23506368

Hi Capacity water pumpPrice: $ 421.17 -

-

-

Detroit Diesel Water Manifold to Oil Cooler Housing Seal

5159457

2 1/2" outside diameter, with inner lipPrice: $ 5.48 -

Detroit Diesel Seal, Water Manifold to Oil Cooler Housing

5156770

2 3/4" outside diameter, with inner lipPrice: $ 5.46 -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $ 97.19 -

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

-

-

-

-

-

-

-

-

-

-

-

-

Clamp for a coolant and fuel Hose

10H

Effective Diameter Range:

Minimum 9/16", Maximum 1-1/16"

Price: $ 3.04 -

Clamp for a cooland and fuel Hose

5104592

Effective Diameter Range:

Minimum 1", Maximum 1.5"

Price: $ 4.52 -

Clamp for a coolant Hose

3412320

Effective Diameter Range:

Minimum 11/16", Maximum 1-1/4"

Price: $ 14.76 -

Clamp for a coolant Hose

4920417

Effective Diameter Range:

Minimum 13/16", Maximum 1-3/4"

Price: $ 15.78 -

Clamp for a coolant Hose

3922846

Effective Diameter Range:

Minimum 1-5/16", Maximum 2-1/4"

Price: $ 15.72 -

Clamp for a coolant Hose

3922847

Effective Diameter Range:

Minimum 1-9/16", Maximum 2-1/2"

Price: $ 15.90 -

Clamp for a coolant Hose

3922849

Effective Diameter Range:

Minimum 2-5/16", Maximum 3"

Price: $ 16.35 -

Clamp for a coolant Hose

5188036

Effective Diameter Range:

Minimum 2-7/8", Maximum 3.5"

Price: $ 5.16 -

-

Detroit Diesel 12V71 Turbo – Fresh Water Pump & Cooling System Components Catalog

The Detroit Diesel 12V71 Turbo engine is one of the most legendary two-stroke powerplants in the V71 family. Known for its durability, adaptability, and power delivery, the 12V71 Turbo found its way into trucks, buses, industrial machines, power generation units, and heavy-duty marine applications. Whether operating under the hood of a long-haul rig, powering a dredge, or propelling a vessel across open waters, the engine’s cooling system is central to its longevity and reliability.

At the core of that system is the fresh water pump, which circulates coolant through the cylinder block, oil cooler, and heat exchanger. Supporting components such as seals, gaskets, thermostats, hoses, clamps, and temperature sensors ensure consistent performance and protect the engine from overheating. This catalog brings together everything you need for the 12V71 Turbo’s cooling system in one organized resource, trusted by over 40,000 customers worldwide.

The Role of the Fresh Water Pump in the Detroit Diesel 12V71 Turbo

The two-stroke Detroit Diesel 12V71 Turbo produces substantial heat under load. Unlike smaller engines, it requires a high-capacity coolant flow to maintain optimal operating temperature. The fresh water pump is bi-directional, allowing it to function across multiple applications (marine, truck, and industrial) with minimal modification.

Its main functions include:

-

Coolant circulation – Moving coolant from the block through heat exchangers and back.

-

Heat management – Ensuring cylinder heads, liners, and turbo components remain at safe operating temperatures.

-

System integration – Working in harmony with the raw water pump (in marine configurations) or radiator (in land-based setups).

-

Lubricant protection – Supporting the oil cooler circuit to maintain optimal viscosity.

Without a reliable pump, the 12V71 Turbo risks overheating, which can lead to cracked cylinder heads, warped liners, or catastrophic turbocharger failure.

Fresh Water Pump Options for the 12V71 Turbo

Truck and Industrial Fresh Water Pump

For on-highway trucks, off-highway machinery, and stationary power units, the truck and industrial pump provides heavy-duty cooling performance. Its bi-directional rotation ensures compatibility with a wide range of setups, making it an ideal replacement for legacy fleets still running the 12V71 Turbo in demanding duty cycles.

-

Designed for long service life in constant-duty conditions.

-

Equipped with durable bearings and seals to withstand high vibration environments.

-

Supports direct circulation through block and radiator systems.

Marine Fresh Water Pump

In marine applications, the 12V71 Turbo water pump is paired with a raw water pump to handle closed-loop cooling. The marine pump is specifically engineered for continuous load operation where engines run at high RPMs for extended periods.

-

Bi-directional rotation for flexible installation.

-

Engineered for saltwater-adjacent environments with corrosion-resistant construction.

-

Integrates seamlessly with marine heat exchangers, keel coolers, and auxiliary cooling circuits.

Water Pump Repair Kits for the 12V71 Turbo

Instead of replacing the entire pump, many operators prefer to rebuild their existing units using a fresh water pump repair kit. Diesel Pro Power supplies complete kits for both standard and high-capacity versions used on the 12V71 Turbo.

Standard Repair Kits

-

Includes bearings, seals, impeller, and gaskets.

-

Cost-effective solution for extending pump service life.

-

Recommended for engines operating in moderate duty cycles.

High-Capacity Repair Kits

-

Built for heavy-duty and turbocharged applications.

-

Provides enhanced flow to handle elevated heat loads.

-

Ideal for marine propulsion, industrial compressors, and power generation sets.

By rebuilding instead of replacing, operators save costs while ensuring OEM-level performance.

Seals and Rings for 12V71 Turbo Pumps

The reliability of the water pump depends heavily on properly fitted seals. Even the smallest leak can compromise coolant pressure, leading to overheating or corrosion.

-

Seal Rings – Designed for the pump body, keeping coolant contained.

-

Water Seals – Prevent leaks between rotating components.

-

Housing Seals – For joints between water manifold, pump, and oil cooler housing.

Each seal is manufactured to meet or exceed Detroit Diesel’s original specifications, ensuring leak-free performance in high-pressure environments.

Thermostats and Temperature Regulation

A properly functioning thermostat is vital to engine efficiency. The 12V71 Turbo can be fitted with thermostats of different temperature ratings depending on application:

-

160°F Thermostat – For cold-weather operation or light-duty applications.

-

170°F Thermostat – Standard operating range for most marine and industrial units.

-

180°F Thermostat – For truck and highway use where higher coolant temperatures improve efficiency.

Thermostat-Related Components

-

Thermostat Seals – Prevent leaks around the housing.

-

Thermostat Gaskets – Ensure a tight seal between housing and block.

-

Housing Gaskets – Designed for precise fit on the 12V71 Turbo.

Together, these ensure accurate regulation of engine temperatures, preventing both overcooling and overheating.

Heat Exchanger and Radiator Components

The 12V71 Turbo relies on different heat rejection systems depending on application:

-

Marine Engines – Use a heat exchanger with raw seawater cooling. Gaskets and seals specific to the exchanger prevent saltwater intrusion into the coolant system.

-

Industrial and Truck Engines – Use radiators with pressurized caps, necks, and hoses to manage flow. Radiator caps are available in multiple pressure ratings to suit different setups.

Hoses, Clamps, and Flexible Connections

Silicone coolant hoses are vital for carrying coolant through the block, pump, radiator, and auxiliary systems. For the 12V71 Turbo, hoses are available in multiple diameters, ranging from small connections (¾”) to large diameter lines (4”).

Silicone Hose Benefits

-

Superior heat resistance compared to rubber.

-

Longer service life in marine and industrial environments.

-

Resistance to cracking and swelling under pressure.

Hose Clamps

High-torque clamps secure hoses under vibration and pressure. Available in multiple size ranges, they provide consistent sealing without damaging the hose material.

Cooling System Accessories

Supporting parts round out the cooling system for the Detroit Diesel 12V71 Turbo:

-

Drain Cock Fittings – Allow quick coolant drainage for maintenance.

-

Temperature Switches – Monitor coolant temperature, activating alarms or shutdown systems at high thresholds.

-

Radiator Cleaner – Keeps passages clear from scale and deposits.

-

Detroit Green Paint – Protects external cooling components from corrosion while maintaining authentic appearance.

Gauges and Monitoring

For proper maintenance, operators must track engine temperature in real-time. Diesel Pro Power offers both mechanical and electric gauges for 12V71 Turbo cooling systems:

-

Mechanical Gauges – Simple, reliable, and durable.

-

Electrical Gauges – Available in 12V and 24V configurations for marine and truck applications.

-

Alarm Gauges – Provide immediate alerts when coolant temperatures exceed safe limits.

Why Buy Detroit Diesel 12V71 Turbo Cooling System Parts from Diesel Pro Power?

Selecting the right supplier is as important as selecting the right part. Diesel Pro Power has built a reputation as the world’s most trusted source for Detroit Diesel cooling system components.

-

Global Reputation – Trusted by more than 40,000 satisfied customers in over 180 countries.

-

Premium Aftermarket Quality – Every pump, gasket, seal, thermostat, and accessory meets or exceeds Detroit Diesel performance standards.

-

Comprehensive Catalog – Organized by engine model and system for fast and accurate part identification.

-

Fast Worldwide Shipping – Minimize downtime with dependable delivery to ports, marinas, truck depots, and industrial sites.

-

Expert Technical Support – Specialists provide guidance on pump selection, repair kit compatibility, thermostat ratings, and cooling system troubleshooting.

Maintenance Best Practices for the 12V71 Turbo Cooling System

Keeping the Detroit Diesel 12V71 Turbo in top condition requires proactive cooling system care.

-

Replace seals and gaskets during every major service.

-

Flush coolant at recommended intervals to prevent scale and rust.

-

Inspect hoses regularly for cracks, soft spots, or bulges.

-

Verify thermostat function during seasonal changes.

-

Rebuild or replace water pumps at the first sign of bearing noise or leakage.

Proper maintenance not only extends the life of the pump but also protects the entire engine from costly overheating damage.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588