Parts for Detroit Diesel 16V71 Turbo for Australia - Gasket Section

Loading...

Loading... Parts for Detroit Diesel 16V71 Turbo – Gasket Section

The Detroit Diesel 16V71 Turbo is a legend—sixteen cylinders arranged in a compact 90-degree V, two-stroke architecture, a positive-displacement blower under every turbocharged configuration, and the kind of industrial durability that keeps fleets and vessels running for decades. Keeping that capability sealed, pressurized, and leak-free is the job of a surprisingly diverse family of gaskets, seals, and installation compounds. This page consolidates what matters most for the 16V71 Turbo gasket system—what each gasket does, where it lives, how to recognize wear or failure, and how to plan a confident repair or a complete reseal during an overhaul.

Below you’ll find plain-language guidance organized by system (block, crankshaft, heads, air and exhaust, fuel and oil, water and cooling, marine/transmission interfaces, and service sealants). Each section maps to the parts commonly ordered for this engine, with the focus squarely on 16V71 Turbo applications. Where a gasket is physically interchangeable across other Detroit Diesel families, we note it only when it clarifies orientation or use, and always bring the attention back to the 16V71 Turbo.

Block, Front/Rear Plates & Inspection Covers (16V71 Turbo)

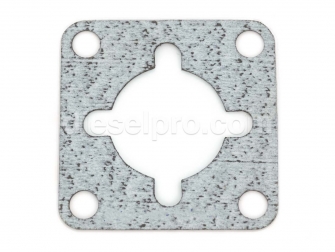

Block plug gasket (core/freeze openings)

This circular gasket seals the block plug that closes a coolant passage. On a 16V71 Turbo, even minor seepage at these plugs can leave tell-tale stains down the block skirt. Replace any plug gasket that shows swelling, hardening, or crusted coolant tracks. Clean the bore and plug thoroughly, lightly oil the new gasket if specified, then press-fit the plug evenly to avoid cocking the seal.

Front end plate gasket

Sandwiched between the block and front end plate, this gasket prevent leaks from the timing gear cavity and accessory drive area. On turbo engines that see higher crankcase pulsing and accessory loads, we recommend replacement anytime the front structure is disturbed (water pump service, accessory bracket changes, or front crank seal work). Surface prep is everything here: remove old material completely without gouging, chase bolt holes, and dry-fit the plate to verify perfect alignment before sealant or gasket placement.

Rear end plate & flywheel housing gaskets

At the back of the engine, the rear plate gasket sits between the block and end plate and works in tandem with the flywheel housing gasket behind it. Together they control oil mist and splash from the crankcase while keeping dust and salt-laden air out of the clutch or marine gear area. If you see oil hazing inside the bellhousing, don’t assume the rear main seal is at fault—these flat gaskets can be the real culprit. Replace as a set after inspection to eliminate stacked tolerances that lead to weeping.

Inspection block/cover gaskets

The 16V71’s castings include small cover plates for inspection and service access. Their thin gaskets are inexpensive “hero parts” that stop drips from wicking down the block. Any time a cover is removed, plan on a new gasket—these are not meant to be reused after compression and heat cycling.

Crankshaft Seals & Sleeves (16V71 Turbo)

Front and rear crankshaft seals (standard and oversize; single or double-lip; rotation-specific)

Turbocharged 16V71 engines can run higher crankcase pressure under sustained load, so primary sealing at the crank is critical. You’ll encounter:

-

Front main seal variants used on the 16V71 Turbo (with standard or oversize outside diameters depending on housing wear).

-

Rear main seal options that differ by lip count and rotation. “Universal rotation” versions are designed to manage right- or left-hand rotation common in marine twin installations. Rotation-specific seals employ helical lip features that pump oil inward—choose correctly for your rotation to avoid pushing oil out.

When journals or housings show wear, add the correct sleeve (sometimes called a wear ring). On the 16V71 Turbo, sleeves are available sized for the front or rear positions and matched to oversize seal options. A sleeve restores the sealing surface so the lip rides on a clean, consistent diameter. Lightly polish and solvent-clean the journal, align the sleeve square to the shaft, then press or drift evenly to avoid distortion. Always verify seal lip direction before installation.

When to choose oversize:

-

The seal bore is out-of-round or polished from previous service.

-

A sleeve has been installed, requiring a slightly larger seal OD.

-

Past weeping persists despite a new standard seal and correct installation.

Tell-tale symptoms:

-

Oil mist on the front accessories or inside the bellhousing.

-

A drip line that appears after long idle periods (lip hardening).

-

Fine oil sling patterns—often visible as a fan on nearby surfaces.

Cylinder Heads, Rocker Covers & Upper Engine Gaskets (16V71 Turbo)

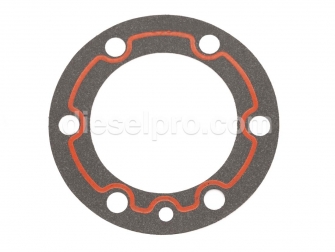

Head gasket kits

A 16V71 Turbo uses four head gasket kits (one per cylinder head bank section on this V-configuration). These kits combine the head-to-block fire ring interfaces and ancillary upper gaskets typically replaced during head service. Any time you disturb head torque, address gaskets and torque pattern together. On a two-stroke Detroit, combustion pressure spikes are high; clean deck surfaces and exact torque sequences prevent micro-leaks that masquerade as coolant loss or faint compression haze on start-up.

Rocker cover gasket sets (aluminum cover, new style)

Aluminum rocker covers call for the updated gasket profile and, where supplied, a matched hardware/seal kit. The 16V71 Turbo benefits from this “new style” because it tolerates repeated valve adjustments and avoids cold-shrink weeps. Inspect cover flatness on glass; even slight distortion at bolt holes can make a good gasket look bad. Hand-start all fasteners and snug progressively to avoid pinching.

Water manifold (water rail) gasket

Along the upper engine, the water rail distributes coolant. Its long, narrow gasket can weep from uneven torque or from corrosion trails under the rail. Clean the surfaces thoroughly, check bolt threads, and tighten in a center-out sequence to spread clamping load.

Turbocharger, Blower Interface & Exhaust Gaskets (16V71 Turbo)

Turbo riser and oil line gaskets

The 16V71 Turbo’s riser gasket seals the turbo outlet to the riser or elbow. Heat, vibration, and salt air can crisp this gasket over time. Replace at any evidence of soot lines or salt scale. Pair the riser service with fresh turbo oil supply and return gaskets—stiff or flattened oil film gaskets can let oil creep that burns on hot housings and mimics an internal turbo issue.

High-temperature jointing compound for turbo interfaces

Where the factory design allows, a thin, even layer of high-temperature compound applied to clean, dry flanges can help the gasket conform and stay sealed through repeated thermal cycles. Use sparingly: over-application can bead into passages.

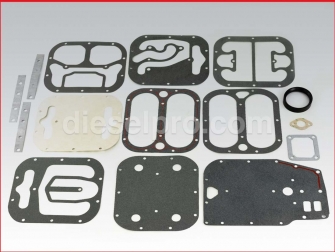

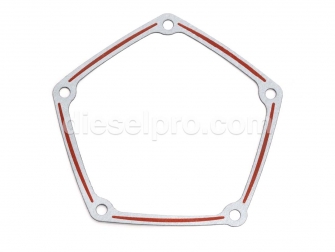

Blower installation gasket kit for turbo engines

Even on turbo variants, the Roots blower remains essential to charge scavenge air for the two-stroke cycle. The blower installation kit supplies the gaskets for the blower-to-block and related interfaces. Any time the blower is removed (for seal service or rotor clearance checks), plan on fresh gaskets. Air leaks here reduce scavenge efficiency and lead to smoky starts and higher EGTs.

Head-to-exhaust manifold gaskets & marine manifold flange gaskets

Each cylinder’s exhaust port uses a head-to-manifold seal. Replace them when the manifold comes off for turbo, riser, or water-jacket service. Soot tracks at the port are your early warning. For marine setups, the manifold flange and spacer gaskets keep saltwater jackets and exhaust gas paths separated. Always check flange flatness and spacer condition; corrosion creep on water-jacketed castings is common in marine service.

Oil System: Pans, Pumps & Inlets (16V71 Turbo)

Oil pan gaskets (main and lower pan segments)

The 16V71’s oil pan uses multiple segments. The main oil pan gasket seals the upper pan to the block, and front and rear lower pan gaskets complete the assembly (two of each lower style per engine). When resealing, don’t mix up the lower segments—mark their positions during teardown. Straighten any bolt-hole dimples using a flanging tool and backing block, then test-fit dry to confirm the gasket isn’t being dragged out of position as bolts are torqued.

Oil pump inlet and pickup tube gaskets

These small, flat gaskets are vital. A leak at the pickup flange invites aeration, dropping oil pressure and foaming the lubricant at high RPM—bad news for a turbocharged, high-output 16V71. Replace these any time the sump is open, and confirm the pickup tube sits fully seated without side-loading its gasket surface.

Oil filter adaptor gasket

Oil filter base leaks can masquerade as pan weeps. If you see oil tracks that start higher than the pan rail, inspect the adaptor gasket. Replace and clean both surfaces thoroughly before reassembly.

Oil cooler installation gasket set (for dual coolers)

Many 16V71 Turbo installations run dual coolers. The installation kit includes the interfaces needed to seal those units. Pay attention to gasket orientation: mixing a feed/return gasket can restrict flow, raising oil temperature at load. After reassembly, verify oil temperature under sustained power—gasket misplacement shows up fast in hot oil.

Fuel, Governor & Front-of-Engine Interfaces (16V71 Turbo)

Fuel pump/water pump shared gasket

The multi-purpose pump gasket seals a compact mating surface—clean off old material fully and inspect for corrosion tracks, especially on marine engines. A good practice is to snug fasteners, run briefly, cool, then retorque to spec.

Hydraulic governor gaskets (governor-to-drive and governor cover)

The 16V71 Turbo depends on stable governor behavior for smooth load transitions. Minor gasket seepage at the governor can attract dirt and salt spray, eventually interfering with linkages. Replace the governor-to-drive gasket whenever the governor comes off, and the governor cover gasket if you open it for spring or calibration work. After reassembly, confirm smooth actuation from idle to rated speed.

Starter mounting gasket

Often overlooked, this thin gasket keeps oil mist from escaping at the starter adapter and helps prevent external contamination from reaching the ring gear area. Replace whenever the starter is off for service.

Fresh Water & Raw Water Cooling Gaskets (16V71 Turbo)

Fresh water pump and cover gaskets

These gaskets seal the coolant pump body and its service cover. A drip at the weep hole is a bearing or seal issue, but leaks at the cover perimeter indicate gasket failure or uneven torque. Replace the gasket and inspect the cover for warpage.

Fresh water cover gasket (auxiliary cover on the block)

This gasket sits under a small cover on the coolant side of the block. Any evidence of dried coolant tracks or rust blooms around the fasteners calls for replacement and fastener thread sealing as required.

Raw water pump mounting and plate gaskets (marine)

On marine 16V71 Turbo engines, the raw water (salt water) pump mounting gasket and plate gasket keep seawater where it belongs. These gaskets must be perfect—saltwater leaks destroy belts, wiring, and paint quickly. Always flush, dry, and coat hardware lightly to slow future corrosion. When the pump is off, inspect the mounting face for pitting; minor imperfections can be dressed, but deep pitting may require a repair sleeve or component replacement.

Manifold flange spacer gasket (marine exhaust/water-jacket interface)

This specialized gasket sits between the manifold and its spacer, managing both hot exhaust flow and cooling jacket separation. Replace at any sign of steaming at the tailpipe or salt crust at the joint—these are red flags for jacket-to-gas crossover.

Turbo & Exhaust Fastener Compounds and Gasket Makers

High-temp RTV and ultra-blue RTV (sensor-safe)

Use sensor-safe RTVs for cover joints that specify form-in-place sealants (FIPG) and for localized dressing at corners where flat gaskets change direction. Do not coat entire flat gaskets unless the service literature indicates; too much RTV can squeeze into oil or coolant passages.

Non-hardening pliable sealant

Ideal for threaded plugs and low-pressure joints that may need periodic service. It remains flexible, doesn’t tear gaskets on removal, and helps with micro-porosity on older castings.

High-tack gasket spray

Perfect for large-area paper gaskets like oil pans and end plates. It “tacks” the gasket in place so long flanges can be assembled without the gasket walking out of position.

Threadlocker (red, high strength)

Use sparingly and only on fasteners that a) specify it, or b) are highly vibration-prone and not intended for frequent service (certain turbo hardware, bracket studs). Keep it off gasket surfaces.

Engine paint (Detroit green)

After a reseal, a proper engine enamel protects the metal and makes future leak detection easier: fresh leaks stand out against clean paint.

Marine Flywheel Housing to Transmission Interfaces (Allison M/MH Pairings)

Flywheel housing gaskets (SAE #1 and SAE #2)

Many 16V71 Turbo marine installations mate to Allison M and MH marine gears. The SAE #2 gasket is common, while some setups require SAE #1. These flat gaskets are critical: besides sealing oil mist, they help align the interface and prevent corrosion creep in the bellhousing. Always confirm your housing size and transmission SAE pattern before ordering. When reinstalling:

-

Inspect the housing runout and dowel condition.

-

Dry-fit the gear to ensure the gasket won’t be pinched.

-

Torque evenly in a star pattern, then recheck after the first warm cycle.

Flywheel housing large cover

This large inspection/service cover on the bellhousing uses its own gasket. It’s often removed for ring gear inspection or to access coupling bolts. Replace the gasket on every opening—reusing here is a common source of persistent mist leaks.

Overhaul vs. Targeted Reseal: Choosing Kits for the 16V71 Turbo

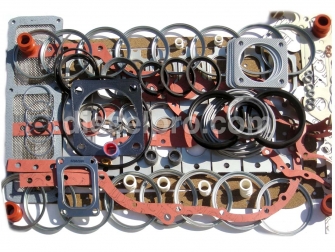

Complete overhaul gasket kit (engine-wide reseal)

When the engine is out for a major refresh—liners, bearings, heads—a comprehensive overhaul gasket kit is the most efficient path. It consolidates block, head, manifold, water, oil, and accessory gaskets typically replaced during a rebuild, saving time and ensuring compatibility across interfaces.

Cylinder head gasket kits (per head section)

For top-end work (valves, injectors, head torque checks), order the correct quantity for a 16V71 Turbo—you’ll need four kits. Add rocker cover kits (new-style aluminum cover) as needed. If you’re addressing chronic coolant seepage or compression leaks, plan to check deck flatness and liner protrusion while you’re in there; gaskets can’t compensate for out-of-spec geometry.

System-specific kits (blower install, oil cooler install)

These kits bundle the small gaskets you’d otherwise chase individually. They’re especially useful when you don’t plan a full overhaul but need a tight, reliable seal on a subsystem.

Diagnosing Gasket & Seal Issues on a 16V71 Turbo

Coolant around the block skirt or starter

Likely sources: block plug gasket, water rail (manifold) gasket weep, fresh water cover gasket, or water pump cover. Dye-test coolant if needed; green/white scale tracks often point directly to the offender.

Oil haze in the bellhousing

Do not assume rear main seal first. Inspect flywheel housing gasket, rear end plate gasket, and the large cover gasket. If those are dry and you still have mist, evaluate the rear main and verify correct rotation seal and sleeve condition.

Soot lines at the exhaust ports

Replace head-to-manifold gaskets and inspect manifold flatness. For marine manifolds, also check the spacer gasket and water-jacket integrity; crossover can produce steam and odd soot patterns.

Persistent drips at the sump rail after pan service

Look for bolt-hole dimpling in the pan flanges, misaligned lower pan segments, or over-compressed gasket edges at corners. High-tack spray helps prevent “walk-out” during assembly.

Oil on turbocharger housings

Check turbo oil supply and return gaskets. A tiny seep at the return can carbonize and resemble an internal turbo issue. Clean, reseal, and recheck before condemning the turbo center section.

Installation Best Practices for Long-Term Sealing

-

Surface preparation comes first. Scrape without gouging, finish with non-metallic pads, and wipe with lint-free towels. Any ridge, old sealant ribbon, or corrosion bloom will become a leak path.

-

Dry-fit everything. Especially long rail gaskets (oil pan, water manifold) and any gasket that wraps corners. Confirm holes line up and the gasket doesn’t bunch.

-

Follow torque sequences and re-torque where specified. On large covers and rails, work from the center out in stages. For parts that see large thermal swings (turbo/exhaust), re-check torque after initial heat cycles if service literature allows.

-

Use the right compound in the right place. Sensor-safe RTV where specified; non-hardening sealant on pipe threads and service plugs; high-temp compound on turbo/hot joints that call for it.

-

Mind rotation and lip direction on seals. Rear main seals are commonly rotation-specific; the lip helix must “pump” oil inward.

-

Sleeves save the day. If a journal shows a polished groove or the bore is worn, a matched sleeve plus the correct oversize seal restores sealing without machining.

-

Quantity planning for a 16V71 Turbo. Four head gasket kits for head service, pairs of lower pan gaskets (front and rear), and multiple head-to-manifold gaskets per bank—plan inventory before teardown to prevent delays.

Quick Reference: Where Each Gasket Lives on a 16V71 Turbo

-

Block & Plates: block plug gasket; front end plate gasket; rear end plate gasket; flywheel housing gasket; large flywheel housing cover gasket; small inspection cover gaskets.

-

Crankshaft Seals: front main seal; rear main seal (rotation-specific options); sleeves for worn journals/bores; oversize seals matched to sleeves.

-

Upper Engine: head gasket kits (four for a complete 16V71); rocker cover gaskets/kits (aluminum cover, new style); water rail (manifold) gasket.

-

Air & Exhaust: head-to-manifold gaskets; marine exhaust manifold flange and spacer gaskets; blower installation gasket kit; turbo riser gasket; turbo oil supply/return gaskets.

-

Oil System: main oil pan gasket; front and rear lower pan gaskets; oil pump inlet and pickup tube gaskets; oil filter adaptor gasket; dual oil cooler installation gaskets.

-

Cooling: fresh water pump cover gasket; fresh water cover gasket on the block; raw water pump mounting and plate gaskets (marine).

-

Controls & Electrical: governor-to-drive gasket; governor cover gasket; starter mounting gasket.

-

Transmission Interface (Marine): SAE #1/#2 flywheel housing to gear gasket (Allison M/MH pairings).

Troubleshooting Checklist Before You Button Up

-

Clean, inspect, and photograph mating surfaces—photos help if you need to revisit a leak path later.

-

Test-fit gaskets without sealant to ensure all holes align; trim nothing unless the part documentation instructs.

-

Confirm rotation before installing any rear main seal.

-

Lightly oil rubber lips on crank seals unless instructions specify dry install.

-

Sequence torque on all long flanges and re-check after the first warm cycle where allowed.

-

Pressure test cooling circuits (fresh and raw water sides) when practical to catch weeps in the shop, not at sea.

-

Prime the oil system after sump work; watch for leaks with a strong light during the first run.

-

Repaint disturbed areas to protect against corrosion and make future leak detection easier.

Notes for Marine 16V71 Turbo Installations

-

Salt environment = aggressive corrosion. Any gasket joint that sees salt spray benefits from clean paint, correct hardware coatings, and periodic washdowns.

-

Raw water pump attention. Mounting and plate gaskets on the seawater pump are small but critical—replace at every service interval and check for face pitting.

-

Allison M/MH gear interfaces. Verify the SAE housing size and dowel fit. A perfectly sealed bellhousing keeps corrosive air and oil mist in check and reduces clutch contamination.

Adhesives & Sealants: What to Use, Where, and Why

-

Sensor-safe RTV (blue/ultra-blue): cover corners, specific FIPG joints, and junctions where flat gaskets change planes; avoids O2/sensor contamination.

-

High-temp RTV: hot zones that explicitly call for RTV (not a substitute for missing gaskets).

-

Non-hardening sealant: threaded plugs, set screws, small covers likely to be removed again.

-

High-tack spray: large paper gaskets—holds position during assembly and resists “walking.”

-

Threadlocker (red): vibration-prone fasteners not routinely serviced (observe manufacturer guidance).

-

High-temperature jointing compound (turbo/exhaust): helps gaskets conform on hot flanges that see expansion cycles.

Planning Your 16V71 Turbo Reseal

-

Top-end refresh? Order four head gasket kits, rocker cover kits, water rail gasket, head-to-manifold gaskets, and blower installation gaskets if you’re removing the blower.

-

Bottom-end service? Main oil pan gasket, front and rear lower pan gaskets (two of each), oil pump inlet and pickup tube gaskets, and the oil filter adaptor gasket.

-

Crank sealing issues? Choose the correct front or rear main seal (rotation-right/left or universal as appropriate) and add sleeves if the journal or bore shows wear.

-

Marine interface work? Verify SAE size and select the correct flywheel housing gasket for your Allison M or MH gear, plus the large cover gasket.

-

Turbo/exhaust leak resolution? Turbo riser gasket, turbo oil line gaskets, head-to-manifold gaskets, and the appropriate marine flange/spacer gaskets.

Why Buy 16V71 Turbo Gaskets from Diesel Pro Power

When you’re resealing a 16V71 Turbo, you’re not just chasing drips—you’re protecting compression, scavenge efficiency, oil pressure, and cooling stability. Diesel Pro Power backs that mission with:

-

Application-correct coverage for the 16V71 Turbo. From head kits (four required on this engine) to the small, easy-to-miss gaskets on oil pickups, raw water pumps, and governor covers—we stock the pieces that keep this platform tight and reliable.

-

New-style solutions where they matter. Updated rocker cover gasket kits for aluminum covers, rotation-specific seal options, oversize and sleeve combinations for worn bores, and marine-grade gasket materials for water-jacketed exhaust components.

-

Consistent quality you can trust. Our gaskets, seals, and installation compounds are sourced to meet or exceed OEM performance so you get reliable clamping and long service life—critical on high-heat turbo joints and large sealing surfaces.

-

Marine know-how with Allison pairings. If your 16V71 Turbo is mated to an Allison M or MH gear, we carry the correct SAE interface gaskets and large bellhousing cover gaskets to keep the driveline clean and corrosion-free.

-

Fast, accurate fulfillment. We understand downtime costs money. Our inventory, documentation, and knowledgeable support help you select the exact gasket or kit you need the first time.

-

Proven customer satisfaction. Diesel Pro Power serves 40,000+ satisfied customers, from independent mechanics to commercial fleets and vessel operators who depend on timely parts and dependable sealing solutions.

Whether you’re planning a full overhaul or tackling a targeted reseal, you’ll find the correct 16V71 Turbo gaskets, seals, sleeves, and compounds here—organized by system, ready to ship, and backed by a team that understands how every joint on this engine contributes to performance.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588