Parts for Detroit Diesel 471 Non-Turbo - (2 Valve Head Type) for Australia - Exhaust Section

Loading...

Loading... Parts for Detroit Diesel 4-71 Non-Turbo – (2 Valve Head Type) – Exhaust Section

The Detroit Diesel 4-71 Non-Turbo engine is one of the most iconic powerplants from the legendary 71 Series, a line renowned for its rugged reliability and long service life. Designed for industrial, stationary, and marine applications, the 4-71’s simple two-valve configuration and mechanically driven blower system make it a workhorse in every sense. Its exhaust system plays a vital role in maintaining performance, managing heat, and ensuring proper backpressure for efficient combustion.

Below, Diesel Pro Power offers a complete catalog of Detroit Diesel 4-71 Non-Turbo exhaust components, including marine manifolds, flanges, gaskets, insulation, mufflers, and accessories—all designed to OEM specifications. Whether you’re maintaining a generator, marine propulsion engine, or industrial setup, you’ll find every part you need to keep your 4-71 engine running cool, clean, and quiet.

Detroit Diesel 4-71 Exhaust System Overview

The exhaust system on the Detroit Diesel 4-71 serves three essential purposes:

-

Efficient Heat Transfer: The exhaust manifold collects hot gases from each cylinder and channels them out of the engine. In marine versions, water-cooled manifolds prevent excessive heat buildup in confined engine rooms.

-

Backpressure Management: Proper backpressure enhances scavenging, ensuring cleaner combustion and optimal power output.

-

Noise and Emission Control: Mufflers and flexible exhaust pipes reduce vibration, noise, and exhaust resonance while allowing safe routing of gases away from the engine compartment.

Because the 4-71 engine is often used in demanding environments, its exhaust components must withstand constant exposure to high temperatures, moisture, and corrosive conditions. Diesel Pro Power’s marine manifolds, gaskets, and related fittings are engineered specifically for durability in these settings.

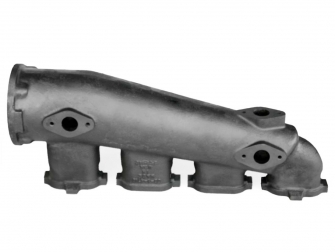

Marine Exhaust Manifold

The Detroit Diesel Marine Manifold for Series 71 and 92 engines fits models such as the 4-71, 8V71, and 16V92. Constructed from high-grade cast iron and internally water-cooled, this manifold is designed to transfer exhaust gases while maintaining manageable surface temperatures.

-

Application: 4-71 Non-Turbo Marine Engines

-

Design: Water-cooled for efficient heat management

-

Durability: Corrosion-resistant internal water jackets

-

Installation: Compatible with 1-inch threaded marine fittings

-

Maintenance Tip: Regularly inspect for salt or mineral buildup in the water jacket to ensure consistent cooling performance.

This manifold is an essential component for marine operators who need dependable exhaust cooling in harsh marine environments. Whether you’re running twin 4-71s in a workboat or a single setup in an auxiliary power generator, this part provides both reliability and performance.

Head-to-Manifold Gaskets

The Detroit Diesel Head-to-Manifold Gasket ensures a proper seal between the cylinder head and the exhaust manifold. Available for both 4-71 and larger Series 71 and 92 engines, this gasket prevents exhaust leaks that can lead to reduced performance and excessive heat.

-

Material: High-temperature composite resistant to warping and cracking

-

Fitment: 4-71, 6-71, 8V71, and 16V92 engines

-

Function: Seals the junction between the exhaust manifold and cylinder head

-

Replacement Tip: Always replace these gaskets during manifold removal or maintenance to prevent leaks.

A secure seal is crucial for maintaining backpressure and preventing heat damage to nearby engine components.

Marine Manifold Flange and Gasket

The Marine Exhaust Manifold Flange and its corresponding Gasket provide a secure transition between the manifold and the rest of the exhaust system.

-

Flange Size: 4-inch NPT thread

-

Gasket Dimensions: 6.25" outside diameter, 4.25" inside diameter

-

Usage: Connects manifold to risers or water outlet elbows

-

Installation Tip: Use high-temp anti-seize compound on threads to prevent galling or corrosion during removal.

In marine engines, proper sealing at the flange is critical to prevent exhaust leaks that could allow hot gases or water intrusion near the manifold connection.

Manifold Insulation Tape

To reduce radiant heat from the manifold and protect nearby components, insulation tape is used to wrap the manifold and exhaust elbows.

Available options include:

This fiberglass-based insulation resists high temperatures and is particularly useful in tight marine engine compartments where airflow is limited. Proper insulation minimizes engine room heat, protects hoses and wiring, and improves comfort and safety.

Fasteners and Mounting Hardware

Each component of the exhaust system must be securely mounted using durable hardware designed to withstand vibration and thermal expansion.

-

Manifold Studs: 7/16"–14/20 x 2.10" studs anchor the manifold to the cylinder head.

-

Crabs (Manifold Clamps): Hold the manifold sections firmly in alignment and distribute pressure evenly.

-

Washers and Nuts: Hardened steel construction resists thermal cycling and corrosion.

Always replace worn or corroded hardware during manifold service. Even a single stripped or heat-weakened fastener can compromise the entire exhaust seal.

Water Outlet Plates and Gaskets

The Marine Manifold Water Outlet Plate and corresponding gasket are key to directing cooling water through the manifold and out of the exhaust stream.

-

Function: Controls the flow of coolant within the water-cooled manifold

-

Threaded Plate Option: Available with ¾-inch NPT threads for attaching cooling hoses or elbows

-

Gasket Compatibility: Designed for Series 71 and 92 engines

Replacing these plates and gaskets during overhaul ensures optimal cooling efficiency and prevents leaks in the manifold’s internal water circuit.

Marine Elbows and Fittings

For routing exhaust gases and cooling water, Diesel Pro offers a full range of marine exhaust elbows:

-

90° Elbows (1" and ¾" thread) – Ideal for tight installations where space limits straight-line piping.

-

45° Elbows (¾" thread) – Provide smoother bends for reduced backpressure.

These fittings are machined from corrosion-resistant metal, ensuring long service life even in saltwater environments. Proper installation of elbows ensures efficient exhaust flow and optimal water discharge from the manifold outlet.

Industrial Exhaust Flanges and Gaskets

For land-based or stationary 4-71 engines, Diesel Pro Power carries industrial exhaust flanges in both 3" and 4" diameters.

-

3" Flange: Suitable for smaller applications and generators

-

4" Flange: Common in higher-output or multi-engine systems

-

Matching Gaskets: Designed for precise sealing with reinforced fiber material

These components allow connection to custom exhaust piping and mufflers while maintaining proper alignment and heat resistance.

Industrial Mufflers

Detroit Diesel industrial mufflers are engineered to control exhaust noise and vibration for stationary engines. Available in 3-inch and 4-inch National Pipe Thread (NPT) configurations, these mufflers provide quiet operation without sacrificing flow efficiency.

-

3" Muffler: Compact design ideal for generators or auxiliary equipment

-

4" Muffler: Larger capacity for main drive applications

-

Construction: Steel casing with internal baffles for long life

-

Maintenance: Inspect periodically for rust or carbon buildup

A properly installed muffler not only improves noise control but also contributes to a cleaner and safer operating environment.

Muffler Caps

Protecting the exhaust system from moisture ingress is essential, especially when the engine is not in operation. Diesel Pro Power’s muffler caps prevent water, debris, and insects from entering the exhaust.

Available in several sizes:

Made from durable, corrosion-resistant metals, these caps automatically lift when the engine starts and close when it shuts down.

Flexible Metal Exhaust Hoses

Flexible exhaust hoses absorb vibration, thermal expansion, and engine movement. The 4" diameter x 18" length flexible metal hose offered by Diesel Pro Power is designed specifically for Detroit Diesel Series 71 engines.

-

Application: Marine and industrial exhaust systems

-

Construction: Reinforced metal weave with threaded ends

-

Benefit: Prevents cracks and stress on rigid manifold connections

Properly installed flexible hoses extend the life of your exhaust system and improve safety in high-vibration applications.

Temperature Switch

The Temperature Switch is a crucial safety device used across Detroit Diesel, Cummins, and Caterpillar engines. It closes at 205°F, providing an alert or shutting down the engine if overheating occurs.

-

Thread Size: ½” NPT

-

Function: Prevents overheating-related damage

-

Use Case: Works in conjunction with gauges and alarm panels

This component helps maintain safe operating temperatures, protecting your investment in the long run.

Gauges and Monitoring Accessories

Diesel Pro Power also carries a selection of mechanical and electrical gauges—both 12V and 24V—allowing operators to monitor exhaust temperature, pressure, and coolant flow in real time. Proper monitoring is essential for early detection of exhaust restrictions or cooling system failures.

Why Buy Detroit Diesel 4-71 Exhaust Parts from Diesel Pro Power

With over 40,000 satisfied customers worldwide, Diesel Pro Power has built a reputation for reliability, precision, and exceptional service. When you purchase your Detroit Diesel 4-71 Non-Turbo exhaust components here, you get:

-

Guaranteed Fit: Every part is engineered or remanufactured to OEM specifications.

-

Fast Worldwide Shipping: From Miami, Florida to ports and facilities around the world.

-

Marine & Industrial Expertise: Our catalog is organized by engine model, ensuring quick identification of compatible components.

-

Comprehensive Inventory: From manifolds to mufflers, every part you need is available in one place.

-

Dedicated Support: Experienced technicians ready to assist with installation questions and compatibility.

For decades, Diesel Pro Power has supplied commercial fleets, marine operators, and industrial facilities with parts that deliver consistent performance and long-term reliability.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588