Parts for Detroit Diesel 671 Non-Turbo - (2 Valve Head Type) for Australia - Fuel Pump & Injector Section

Loading...

Loading... -

-

-

-

-

Detroit Diesel Fuel Pump Repair Kit

5195078

Standard. Universal for repair right or left hand fuel pump.Price: $ 98.50 -

-

-

-

-

-

-

-

-

Detroit Diesel Injector N55 - rebuilt - Premium Heavy Duty

PRO55

Sold with refundable core deposit. See detailsPrice: $ 298.39 -

Detroit Diesel Injector N60 - rebuilt - Premium Heavy Duty

PRO60

Sold with refundable core deposit.Price: $ 298.39 -

Detroit Diesel Injector N65 - rebuilt - Premium Heavy Duty

PRO65

Sold with refundable core deposit.Price: $ 298.39 -

Detroit Diesel Injector N70 - rebuilt - Premium Heavy Duty

PRO70

Sold with refundable core deposit.Price: $ 303.36 -

Detroit Diesel Injector N75 - rebuilt - Premium Heavy Duty

PRO75

Sold with refundable core deposit.Price: $ 298.39 -

Detroit Diesel Injector N80 - rebuilt - Premium Heavy Duty

PRO80

Sold with refundable core deposit.Price: $ 298.39 -

-

-

-

-

Detroit Diesel Fuel Line (Short) for Series 71 and 92

5111526

Short. Each engine uses short and long fuel lines

Price: $ 11.37 -

Detroit Diesel Fuel Line (Long) for Series 71 and 92

5111527

Long. Each engine uses short and long fuel lines

Price: $ 11.97 -

Socket To Install & Remove Injector Fuel Lines For Detroit Diesel 53, 71, 92

J8932B

.Price: $ 154.53 -

-

Detroit Diesel Primary fuel filter base

5148023

For spin on filter type - 1 inch thread

Price: $ 136.66 -

-

-

Detroit Diesel Secondary fuel filter base

5148171

For spin on filter type - 3/4 thread

Price: $ 121.10 -

-

Detroit Diesel Elbow

8924161

45 degree Inverted flare elbow - with no restriction - 1/4 X 3/8

Price: $ 22.48 -

Detroit Diesel Suction Elbow for Engine

8924155

Fuel pump 90 degree Inverted flare elbow - with no restriction - 3/8 x 1/2

Price: $ 20.28 -

Detroit Diesel Elbow for primary and secondary filter base

8925030

Filter base 90 degree inverted flare elbow - with no restriction - 3/8

Price: $ 13.20 -

-

Detroit Diesel Fuel cooler

5136348

2" water inlet and outlet, 3/8' fuel inlet and outlet

Price: $ 742.00 -

1000 Racor Replacement fuel and water separator filter unit

1000

Filter element 2020 includedPrice: $ 449.65 -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Detroit Diesel Bearing for mechanical governor

9431896

Upper bearing for operating shaftPrice: $ 16.10 -

Detroit Diesel Bearing for mechanical governor

9436682

Lower bearing for operating shaftPrice: $ 18.97 -

Detroit Diesel Bearing for mechanical governor

9437108

Bearing for governor weights riserPrice: $ 37.74 -

Detroit Diesel Bearing for mechanical governor

9424121

Bearing for governor weights shaftPrice: $ 12.22 -

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

-

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

Detroit Diesel Fuel Gauge Sender for Diesel Engines

194SENDER

Adjusts up to 19" DepthPrice: $ 67.76 -

-

-

-

Detroit Diesel 6-71 Non-Turbo (2-Valve Head) – Fuel Pump & Injector Catalog Overview

The Detroit Diesel 6-71 non-turbo (2-valve head) engine relies on a simple, rugged, and highly tunable fuel system that has powered workboats, standby generators, construction equipment, buses, and on-highway trucks for decades. This section brings every critical fuel and injection component into one place—left-hand and right-hand fuel pumps (new and rebuilt), complete injector options (HV-series and N-series calibrations), timing tools, filter bases and elements, fuel lines and hardware, couplings and forks, governor service parts, elbows and bypass valves, Racor-style fuel/water separation, and the often-overlooked fuel cooler. You’ll find application guidance, selection tips, maintenance best practices, installation notes, and troubleshooting advice—written specifically for the naturally aspirated 6-71 with the two-valve cylinder head.

At Diesel Pro Power, everything you see is curated for fitment on the 6-71 non-turbo platform, backed by expert support, fast shipping worldwide, and a reputation built with more than 40,000 satisfied customers across commercial, military, and private fleets. Whether you’re refreshing a single injector or refitting your entire low-pressure supply and filtration layout, this page is designed to help you choose quickly and confidently.

How the 6-71 Non-Turbo Fuel System Works (At a Glance)

The classic 6-71 mechanical system has three tiers:

-

Low-Pressure Supply & Filtration

Fuel is drawn from the tank through a primary filter/water separator, then into the engine-mounted fuel pump. From the pump, fuel moves through a secondary (fine) filter on its way to the cylinder head gallery and injectors. Excess fuel circulates back to the tank, carrying away heat and air. -

High-Pressure Injection

Each cylinder has a mechanically actuated unit injector. The injector’s internal plunger and barrel generate injection pressure. Injector timing is set mechanically using a feeler-style timing gauge to a precise height that corresponds to the injector model. -

Control & Return

A mechanical governor regulates rack position to control fuel quantity. Bypass valves and properly sized elbows manage pressure and return flow. A compact fuel cooler may be used in continuous-duty marine or generator applications to stabilize fuel temperature and protect viscosity.

Because the 6-71 platform uses individual unit injectors driven by the cam, timing accuracy, injector calibration, and clean, air-free fuel have an outsized impact on power, smoke, and durability.

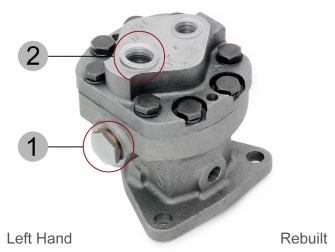

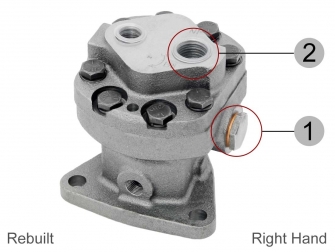

Fuel Pumps for 6-71 Non-Turbo: Left-Hand vs Right-Hand

Determining Hand (Rotation & Mounting)

Detroit labelled inline fuel pumps as left-hand or right-hand based on drive orientation and internal rotation. On a 6-71, the easiest way to confirm hand is to reference your existing pump’s tag and observe the drive as mounted on the blower side:

-

Left-Hand Pump – Typically used on one set of installations; rotation and inlet/outlet porting suit specific plumbing runs.

-

Right-Hand Pump – Mirror configuration for applications that route lines differently or use alternative accessory layouts.

When replacing, match the hand to your current unit to avoid re-routing lines or altering brackets.

New vs Rebuilt

-

New Fuel Pumps deliver factory-fresh housings, gears, and relief hardware. They’re ideal for fleets standardizing preventive maintenance or engines running high annual hours.

-

Rebuilt Fuel Pumps are fully remanufactured with wear components replaced and calibrated to spec. They’re cost-effective and backed by a core deposit program. If your housing and drive are sound, a rebuilt unit returns the pump to like-new performance with excellent value.

Pump Repair Kits & Seals

If your pump moves fuel but seeps at the shaft or cover, or pressure drifts under load, a pump repair kit with gaskets, seals, and critical wear items can restore performance. Pair the kit with a fresh shaft seal and a new pump gasket to prevent air leaks on reassembly. Air entrainment is a major cause of surging and hard starts; replacing sealing components during any pump service is strongly recommended.

Couplings & Forks

The mechanical coupling between the pump and drive must be tight, aligned, and free of cracks. A worn coupling or a bent coupling fork introduces lash and erratic pressure. If you replace the pump, inspect and replace coupling components together—small, inexpensive parts that protect the life of your new or rebuilt pump.

Fuel System Plumbing: Elbows, Bypass Valves & Pressure Control

Elbows (Supply, Discharge, Suction)

Inverted flare elbows without internal restriction are used to route fuel to and from the pump, filters, and the cylinder head gallery. Ensure the thread sizes match your lines and filter bases. Avoid mismatched or restricted elbows that can starve the pump at high RPM or create excessive return pressure.

Fuel Bypass Valve (Pressure Regulation)

The bypass (or relief) valve regulates system pressure and return flow. Weak or sticky valves cause unstable idle, hot-soak hard starts, or injector chatter. Replacing a tired bypass valve is a quick win for engines showing intermittent rail issues after filter changes.

Filtration & Water Separation for the 6-71

Primary (Coarse) Filtration

The primary filter is your first defense against water and particulate. Many operators upgrade to a spin-on primary base for faster service, clean element changes, and better sealing. Others prefer a cartridge-style primary for heritage appearance and robust bowl design. Both approaches are fully supported here—choose the style that matches your maintenance workflow.

Pro tip: If you operate in humid or marine environments, a dedicated fuel/water separator head with a clear bowl and drain makes pre-trip checks simple. Our complete separator assemblies include an element and are sized to maintain proper suction at high load.

Secondary (Fine) Filtration

After the pump, a secondary (fine) filter protects injectors from micro-contamination. As with the primary, you can choose spin-on or cartridge formats. Always replace the secondary element after any injector or pump work and prime the element with clean diesel to minimize cranking.

Racor-Style Fuel/Water Separation

For vessels or high-moisture applications, a Racor-pattern 1000-size unit provides excellent air separation and water knock-out before fuel ever reaches the engine. Match the element micron rating to your system (2-micron elements capture fines but require vigilant element changes; 10-micron offers more flow margin). Keep spare elements onboard and replace at the first sign of restriction or water accumulation.

O-Rings, Washers & Sealing Hardware

Don’t reuse flattened sealing washers on injector jumpers or filter connectors. Two washers are typically used per injector jumper union; replace them whenever lines are disturbed. The cost is minimal compared to the labor of chasing down a micro-leak.

Fuel Lines, Jumpers & Routing on the 6-71

The 6-71 uses short and long jumper lines to connect injectors in series and supply/return manifolds. Always replace lines in matched pairs (short and long) to preserve proper routing and clamp points. Stainless or plated flares should be clean and burr-free; any nick can lead to weeping under vibration. After installation, run the engine at governed speed and inspect each union with a bright light—what looks dry at idle can show a halo at load.

The Unit Injector Family: HV-Series & N-Series Choices

HV6 & HV7 Rebuilt Injectors

The HV-series injectors are legacy workhorses for naturally aspirated 6-71 applications. A properly rebuilt HV6 or HV7 delivers crisp idle, smooth midrange, and reliable fueling in industrial or marine service. Rebuilt injectors are supplied ready to set; simply verify timing and rack synchronization.

N-Series Calibrations for NA Engines (N55, N60, N65, N70, N75, N80)

The N-series identifies injector flow/shot size. On a non-turbo 6-71, choosing the correct N-rating is essential:

-

N55–N60: Excellent for standby generators, industrial pumps, yard tractors, and vessels prioritizing longevity, low smoke, and fuel economy.

-

N65: A very common choice for general-duty marine and on-highway work where a balance of torque and economy is desired.

-

N70–N75: Suited to heavier continuous loads or applications needing stronger mid-range without a turbocharger. Monitor exhaust temperature and ensure cooling/propeller load are appropriate.

-

N80 (and above): Generally aggressive for a non-turbo 6-71. Consider only with careful load analysis, adequate cooling, and experienced tuning; many operators reserve larger N-sizes for aftercooled or lightly boosted builds, but they can be used in special NA scenarios with caution.

Tip: If you are replacing injectors due to smoke, fuel dilution, or runaway EGTs, don’t “up-size” to fix a symptom. Start by restoring proper injector timing and governor control, then select the N-rating that fits the duty cycle.

Premium Heavy-Duty Rebuilds

Our rebuilt N-series options are calibrated to spec, pop-tested, and supplied with fresh wear components for dependable service. A refundable core program keeps costs down and ensures sustainable remanufacturing.

Injector Components: Tips, Plungers, Valves & Springs

If your injector bodies are sound, you can service the wear components:

-

Injector Tips (Nozzles): Available for popular N-ratings (e.g., N55/N60/N65 and N70/N75, and higher ratings such as N80/N90 where applicable). A fresh nozzle restores atomization and reduces smoke on cold starts.

-

Plungers: Matched to the injector rating for precise quantity control. Replace any plunger showing scuffing, corrosion, or out-of-round wear.

-

Valve, Spring & Seat Sets: Small parts that have a big impact on idle quality and return flow. Replace whenever you observe inconsistent injector leak-down or “hunting” idle after a warm soak.

-

Injector Brackets & Control-Tube Springs: Secure, consistent rack movement depends on tight brackets and correct spring tension. Replace bent brackets and fatigued springs; these are inexpensive reliability upgrades.

Timing Tools & Setup for the 6-71 Two-Valve Head

Accurate injector timing is the heart of 6-71 performance. The two-valve head engines use feeler-style timing gaugeswith specific heights that correspond to the injector family:

-

1.484 Gauge – Commonly used for HV6 and certain N-series combinations (including many N65 and N80 use-cases).

-

1.460 Gauge – Often specified for HV7 and a range of N-series (N45, N50, N55, N60, N70, N90 in various service manuals and CPLs).

-

1.508 Gauge – Used in specific service contexts and model years where Detroit published this setting. It’s a must-have if your manual calls it out.

Best Practice: Always verify the correct timing height for your exact injector and cam follower configuration. If in doubt, ask our Detroit-trained team with your engine serial data and injector designation.

High-Level Timing Procedure (For Reference Only)

-

Prep: Engine at operating temperature (if possible), clean valve cover area, disable fuel as required for safe cranking/turning.

-

Positioning: Bar the engine to the appropriate cylinder and cam follower position per the Detroit sequence.

-

Set Height: Insert the correct timing gauge between the injector follower and the injector body per manual instructions; adjust the injector rack to lightly drag the gauge.

-

Lock & Verify: Tighten locknuts to spec, re-check drag, and move to the next cylinder following the Detroit firing order.

-

Rack Synchronization: With all injectors set, verify that the rack moves smoothly and evenly under governor actuation with no binding.

-

Final Checks: Prime the system, start, and observe idle quality, smoke, and governor response. Re-inspect for leaks.

Safety Note: This is a simplified overview for experienced mechanics. Always follow the official Detroit procedure and torque values.

Governor & Control Hardware

A smooth-idling 6-71 depends on a healthy mechanical governor. Small roller and needle bearings on the governor operating shaft and weight carrier can develop flat spots that cause hunting. If you’re chasing a stubborn idle after setting timing, inspect and refresh:

-

Upper and lower operating shaft bearings

-

Weights carrier bearing

-

Weights-shaft bearing

-

Booster spring shoulder bolt (if worn or stretched)

Pair governor refresh with new gaskets for the mechanical or hydraulic cover as applicable. Minor seepage at the governor cover is common with age; a fresh gasket eliminates air ingestion and oil mist.

Fuel Cooling for Continuous-Duty Engines

Marine propulsion and standby generator sets frequently recirculate warm fuel. A compact fuel cooler stabilizes fuel temperature, maintains viscosity, reduces vapor formation, and extends injector life. If you notice rising return-fuel temperatures, periodic vapor lock, or power sag after long hot runs, a fuel cooler is an inexpensive insurance policy. Plumb it with clean water supply and ensure hose clamps are marine-grade stainless.

Primary & Secondary Filter Bases: Spin-On vs Cartridge

Spin-On Conversions

Spin-on bases for primary (coarse) and secondary (fine) stages simplify service: pre-fill the element, spin to seal, and you’re done. Choose bases with the correct thread sizes for your plumbing and verify clearance under the rocker cover or nearby accessories.

Cartridge Systems

Cartridge filters remain popular with vintage restorations and certain commercial fleets. They offer robust bowls and visual inspection opportunities. When servicing, clean the bowl, replace the cartridge and lid gasket, and torque the cover evenly to avoid air leaks.

Element Micron Choice

-

Primary: 10–30 micron depending on separator usage and fuel quality.

-

Secondary: 2–10 micron to protect injectors; the finer the element, the more critical on-time changes become.

Tools & Service Aids Worth Having Onboard

-

Injector Line Socket/Wrench sized for Detroit 53/71/92 fuel lines—prevents rounding the hex and speeds leak checks.

-

Timing Gauges (1.460, 1.484, 1.508) in a labelled pouch, so the correct tool is always at hand.

-

Filter Strap or Cup Wrench to service spin-on elements cleanly.

-

Bright Inspection Light & Mirror for post-service leak checks along the head rail and behind elbows.

Selecting the Right Injector for Your 6-71 NA Application

Marine Workboat / Trawler (Continuous Duty)

A naturally aspirated 6-71 that spends hours at steady load benefits from conservative fueling. N60 or N65 maintains clean exhaust, manageable EGTs, and excellent longevity. Pair with a fuel cooler and 2-micron secondary filtration.

Harbor Tug / Pushboat / Heavy Dock Work

Frequent bursts of throttle with moderate cruise favor N65–N70. Watch prop loading and cooling capacity. If you see sustained haze at cruise, consider stepping back one size after confirming timing.

Standby Generator / Pump / Industrial

Steady RPM under predictable load is where N55–N60 shines. Cold-start smoke is low, and fuel economy is excellent. Keep filters fresh and schedule a timing check annually.

Vintage Coach / On-Highway

Balanced mid-range torque with reasonable smoke points to N60–N65. If you climb long grades regularly, ensure your radiator and shrouding are in top shape before moving to N70.

Reminder: Calibrations are guidelines. The exact best choice depends on cam timing, altitude, ambient temps, and load. If you’re uncertain, our team can help you choose the safest, cleanest option for your duty cycle.

Installation Notes & Torque Reminders (General Guidance)

-

Cleanliness is critical. Cap open lines, wipe flare seats, and use lint-free rags.

-

Prime filters with clean diesel to reduce cranking time and protect the pump.

-

Replace washers and O-rings every time a union is cracked open.

-

Support lines with the correct clips to prevent vibration fatigue.

-

After first run-in, re-check every union and the pump cover for seeps.

-

Synchronize racks after injector replacement; a single tight rack segment can cause rough idle.

(Always follow Detroit Diesel service literature for torque values and step-by-step procedures appropriate to your engine’s build.)

Troubleshooting Guide: 6-71 NA Fuel System

Hard Starting (Cold or Hot)

-

Air leaks at filter base or pump cover → replace gaskets and seals.

-

Weak bypass valve → replace to restore rail pressure.

-

Incorrect injector timing → verify with the correct gauge.

Surging or Hunting at Idle

-

Governor bearings worn → refresh upper/lower shaft and weight carrier bearings.

-

Mixed injector settings or sticky rack → re-synchronize and lubricate per manual.

Low Power / Haze at Cruise

-

Clogged secondary filter → replace and cut open to inspect contamination.

-

Over-fueling (too large N-rating) for prop or terrain → step down one size after timing check.

-

Suction restriction at primary filter or elbow → confirm no restricted fittings and that the element is fresh.

Fuel in Crankcase (Oil Level Rising)

-

Injector plunger/barrel wear → replace plungers or injectors.

-

Compromised jumper line washers → renew both per injector.

High EGT / Smoke on Accel

-

Late timing → re-set with correct gauge height.

-

Dirty injector tips → replace with the correct rating and re-time.

Maintenance Intervals (Practical Rhythm)

-

Every 250 hours or 6 months: Inspect for leaks, check separator bowl, drain water, verify return flow.

-

Every 500 hours or annually: Replace primary and secondary filters; inspect pump coupling and fork; check bypass valve function.

-

Every 1000 hours or 2 years: Verify injector timing and rack synchronization; evaluate governor bearings; borescope injector tips if smoke or misfire present.

-

Anytime fuel is suspect: Replace both filters and purge system; consider a temporary polishing filter setup for the tank.

Why Buy Your 6-71 Fuel & Injector Parts Here

-

Everything in one place – Pumps (left-hand and right-hand), injectors (HV and N-series), timing gauges, brackets, washers, filters, separators, coolers, lines, elbows, and valves—curated for the 6-71 non-turbo, two-valve head.

-

In-stock, ready to ship worldwide – Fast fulfillment with real-time order tracking keeps downtime to a minimum.

-

Detroit-trained support – Get precise fitment guidance on pump hand identification, injector selection (N55 through N80), and the correct timing tool for your build.

-

Proven quality – New and rebuilt components meet or exceed OEM specifications, with rebuilt units calibrated and pop-tested.

-

Trusted reputation – More than 40,000 satisfied customers rely on Diesel Pro Power for consistent results, fair policies, and dependable technical help.

Core Deposit Guidance (For Rebuilt Pumps & Injectors)

Rebuilt pumps and injectors are sold with a refundable core deposit. After installation, return your old unit in rebuildable condition using the provided instructions. Once inspected, the core deposit is refunded promptly. This program lowers your total cost, promotes sustainability, and ensures that high-quality Detroit components remain available for the long term.

Quick Selection Checklist

-

Pump: Match left-hand or right-hand to your current unit; add a seal, gasket, and coupling fork if wear is visible.

-

Injectors: Choose HV6/HV7 or N-series rating (N55–N80) for your duty cycle; replace as a set for balanced fueling.

-

Timing Tools: Keep 1.460 and 1.484 gauges on hand; add 1.508 if your service literature calls for it.

-

Filtration: Pick spin-on or cartridge for both primary and secondary; consider a Racor-style separator and spare elements.

-

Lines & Washers: Order short and long jumpers as required and new sealing washers—two per jumper union.

-

Control & Cooling: Refresh the bypass valve, consider a fuel cooler for continuous duty, and service governor bearings if idle hunts.

Frequently Asked Questions (6-71 Non-Turbo Fuel & Injection)

Q: How do I know if my pump is left-hand or right-hand?

A: Check the tag and observe the drive orientation as mounted. If you still aren’t sure, send us a photo—our team will confirm the correct hand and any elbow thread sizes you need.

https://youtu.be/r3ne2CvfsMg?si=DOCU_aa9hem8qK5m

Q: What injector size should I use on a stock NA 6-71 in a trawler?

A: Most continuous-duty marine users are happiest with N60 or N65. They run clean, keep EGTs under control, and deliver reliable torque. If the boat is lightly loaded, N60 is often ideal.

Q: I switched to spin-on filters and now I have a slight surge. Why?

A: The base may be drawing air at the gasket or an elbow may be restricting flow. Re-seat the element, verify the O-ring is lightly oiled, and make sure the elbows are true no-restriction fittings sized for your lines.

Q: My engine starts, idles well, but smokes on throttle. Where do I start?

A: Verify injector timing with the correct gauge, confirm clean secondary filtration, and ensure the bypass valve holds pressure. If timing is correct and filters are fresh, consider stepping down one injector size.

Q: Do I need to replace injector lines when I change injectors?

A: If lines are clean, straight, and the flares are perfect, you can reuse them with new sealing washers. Replace any line that shows flattening, corrosion, or evidence of a past overtightening.

Q: When should I add a fuel cooler?

A: Continuous-duty marine or gen-set applications benefit most, especially in warm climates. If you see vapor bubbles in the return, or power sags after extended hot runs, a cooler is recommended.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588