Parts for Detroit Diesel 671 Turbo for Australia - Gasket Section

Loading...

Loading... -

-

-

-

Detroit Diesel Crankshaft seal for 8V53, 3-71, 4-71, 6-71, 6v71, 8v71, 12v71 engines

5115454

Front - Standard - Universal rotation

Price: $ 22.56 -

Detroit Diesel Rear Crankshaft seal

5114335

Rear for 271, 371, 471, 671,6V71, 8V71, 12V71, 8V53 and Front for 16V71, 12V92, 16V92. - Standard - Single Lip

Price: $ 33.18 -

Detroit Diesel Rear Crankshaft seal.

5197860

Rear - Oversize - Single Lip for 271, 371, 471, 671, 6V71, 8V71, 8V53 and Front for 16V71,12V92, 16V92 Engines

Price: $ 45.45 -

Detroit Diesel Crankshaft seal for 3-71, 4-71, 6-71, 6v71, 8v71, 12v71 engines

5127821

Rear - Standard - Double lip

Price: $ 41.05 -

Detroit Diesel Rear seal for 3-71, 4-71, 6-71, 6v71, 8v71, 12v71 engines

5196927

Real - Oversize - Double Lip.

Price: $ 119.36 -

Detroit Diesel Sleeve seal

5197159

Oversize - Rear for 71 series and Front for 16V71, 12V92 and 16V92 engines.

Price: $ 55.43 -

-

-

Detroit Diesel Rocker cover kit for 6-71, 12V71

5149512

For use with aluminum rocker covers. New stylePrice: $ 115.28 -

-

-

-

Detroit Diesel Rocker cover gasket for 6-71 and 12V71

5143407

For tin cover, old style - black rubber

Price: $ 22.64 -

-

-

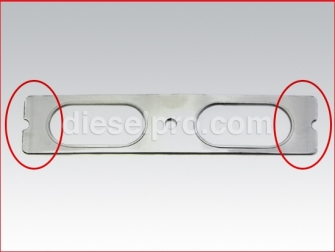

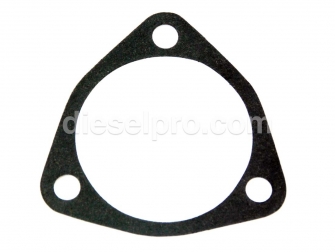

Allison Flywheel Gasket for Marine Transmission M and MH - SAE 2 (Most Common)

29503155

Use when engine housing size is the same as transmission

Price: $ 102.60 -

-

-

Detroit Diesel Blower Installation Gasket Kit for 671 By Pass Turbo

23514286

By Pass Turbo BlowerPrice: $ 139.37 -

-

-

-

-

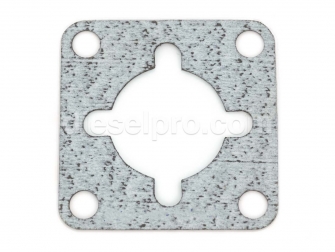

Detroit Diesel Governor Gasket

5150890

Gasket between the governor housing and the governor drive

Price: $ 3.52 -

-

-

Detroit Diesel Head to Manifold Gasket for 6-71 and 12V71

5120223

Click on + Pictures below to see how many are needed per engine

Price: $ 10.78 -

Detroit Diesel Head to Manifold Gasket for 471, 671, 8V71, 12V71, 16V71, 8V92, 16V92

5120224

Click on + Pictures below to see how many are needed per engine

Price: $ 13.74 -

Detroit Diesel Gasket for marine manifold flange

23504701

Outside diameter 6.25", inside diameter 4.25"

Price: $ 31.22 -

Detroit Diesel Turbo riser gasket

8923492

Inner width 2”, Inner Length 3.75”, Outer width 3.75”, Outer Length 5.5”Price: $ 9.08 -

762 Hi-Temperature jointing compound for Detroit Diesel and Cummins turbos

762

225 gm tube - Temp range 550C to 760CPrice: $ 188.19 -

-

-

Detroit Diesel Intercooler Gasket for 671,12V71,12V92

5149433

Use 2 of this gasket per intercoolerPrice: $ 37.46 -

Detroit Diesel Intercooler Gasket for 671, 12V71, 12V92

5147423

Use 2 of this gaskets per intercoolerPrice: $ 14.13 -

Detroit Diesel Intercooler Gasket for Engine 671, 12V71, 12V92

23511698

4 gaskets per Intercooler

Price: $ 74.39 -

-

-

Detroit Diesel Gasket for Hydraulic Governor

23509675

Gasket between Governor and DrivePrice: $ 5.50 -

-

-

-

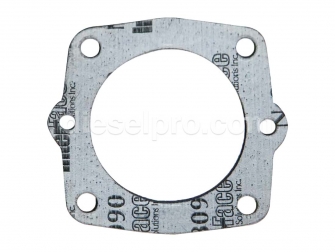

Detroit Diesel Gasket, Marine Water Pump

5115395

Each pump uses 2 of this gasket. Water inlet and outletPrice: $ 4.38 -

-

-

-

-

-

-

-

Detroit Diesel Marine Water Pump gasket

5112143

Each pump uses 2 of this gasket. Water inlet and outletPrice: $ 4.59 -

-

Detroit Diesel Heat Exchanger Gasket Kit for Marine Engines for Series 53, 71 and 92

5192637

.Price: $ 97.18 -

-

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

Gasket Spray -High Tack Sealant (Hold & Seals Cut Gaskets)

99MA

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 20.55 -

3H Gasket Maker

3H

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 17.46 -

-

-

-

-

Gasket Maker - Ultra Blue RTV Silicone Sensor Safe

77BR

For Detroit Diesel & Cummins enginesPrice: $ 11.03 -

-

Gaskets & Sealing Components for Detroit Diesel 6-71 Turbo

The Detroit Diesel 6-71 Turbo is a two-stroke, inline-six workhorse whose name comes from its displacement: ~71 cubic inches per cylinder across six cylinders. Turbocharged variants deliver higher airflow and cylinder pressure than naturally aspirated models, which means sealing surfaces, gaskets, and shaft seals are under greater thermal and mechanical stress. A leak-free 6-71 Turbo depends on a complete, application-correct set of gaskets and seals—from the crank nose to the flywheel housing, from the rocker covers to the oil pan, and across every air, oil, and coolant interface in between.

This catalog section focuses specifically on gasket and sealing solutions for the 6-71 Turbo. While several components may also fit other Detroit Diesel families, everything below is framed around the needs, failure modes, and install practices of the 6-71 Turbo to help you select the right parts and install them right the first time.

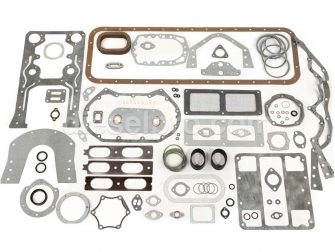

For Detroit Diesel 6-71 Turbo: Complete Overhaul & Top-End Gasket Coverage

Overhaul Gasket Kit (Full Engine Coverage)

A full engine overhaul on a 6-71 Turbo is the moment to replace all static and dynamic gaskets you disturb during tear-down. The overhaul gasket kit for the 6-71 consolidates the critical soft goods you’ll need during a rebuild: cylinder head and upper engine gaskets, oil pan gasket, timing and front cover gaskets, intake and exhaust manifold gaskets, coolant and oil sealing rings, plus select seals and hardware-side grommets and O-rings. Using a matched kit instead of piecemeal sourcing ensures the materials are engineered to work together across pressure and temperature ranges typical of turbocharged two-stroke operation.

When to choose:

-

You’re performing a full in-frame or out-of-frame rebuild.

-

You want a matched set to eliminate guesswork about compatibility.

-

You’ve seen evidence of cross-system leaks (oil into coolant, boost into crankcase, etc.) and will be opening multiple assemblies.

Cylinder Head Gasket Kit (Top-End Service)

Top-end refreshes—valve work, injector service, or head removal for inspection—require a dedicated cylinder head gasket kit. On a turbo 6-71, the cylinder head interface must hold boost pressure and withstand repeated thermal cycling. A correctly spec’d head gasket kit will include the head gasket(s), fire ring/combustion sealing elements as designed, and the complementary seals for coolant passages and oil returns in the head assembly.

Pro tips for head gasket success on a 6-71 Turbo:

-

Surface prep matters. Deck and head surfaces should be flat, clean, and free of corrosion or old sealant residue. Use plastic scrapers and solvent; avoid gouging.

-

Dry fit, then seal. Match every water, oil, and pushrod opening before committing to sealant or torque.

-

Follow the sequence. Use the OEM bolt torque pattern and staged tightening. Torque specs vary by fastener and revision; follow your service manual.

For Detroit Diesel 6-71 Turbo: Crankshaft Seals, Sleeves & Front/Rear Covers

Front Crankshaft Seal (Universal Rotation)

Turbocharged operation increases crankcase pressure pulses, so a healthy front crankshaft seal is essential to prevent oil misting at the pulley and accessory drive. The front seal offered here is designed for universal rotation, accommodating both clockwise and counter-clockwise rotation installations seen in marine and industrial layouts.

Install quick-check: Verify the seal’s lip faces the oil side, lubricate the lip lightly at installation, and press squarely into a clean, burr-free bore. Inspect the crank hub for grooves; if present, add a wear sleeve.

Rear Crankshaft Seals (Single-Lip & Double-Lip; Standard & Oversize)

At the flywheel end, the rear main seal contains sump oil despite the torsional vibrations and temperature cycling present in high-load turbo use. You can select standard or oversize outside diameters to match housing condition, and single-lip or double-lip designs based on leak history and environment.

-

Single-lip (standard/oversize): A good choice for tight, undamaged housings.

-

Double-lip (standard/oversize): Adds an auxiliary dust lip—ideal for harsher environments or housings with minor wear.

Choose oversize only when the bore requires it; pairing an oversize seal with the companion sleeve restores proper crush and fit.

Rear Seal Wear Sleeve (Oversize Housing Rescue)

When the housing or crank journal shows wear tracks, a precision sleeve lets the new seal ride on an unworn surface. For the 6-71’s rear position, the oversize sleeve solution is your go-to when you want longevity from a new seal in a previously grooved or polished running surface.

Front Lower Cover & Balance Weight Cover Gaskets

Minor cover gaskets can cause major messes if neglected. The front lower cover gasket and the balance weight cover gasket keep oil where it belongs around accessory drives and counterweights. Replace them anytime the covers are off to service front-end components, belts, or timing interfaces.

For Detroit Diesel 6-71 Turbo: Rocker Cover, Valve Train & Upper Engine Sealing

Rocker Cover Gaskets (Old-Style Tin Covers & New-Style Aluminum)

The 6-71 family uses either tin (stamped) or aluminum rocker covers. Using the correct gasket profile and compound prevents oil weeping at the top of the engine—especially on turbo units where under-cover heat is higher.

-

Old-style (black rubber): Designed for tin rocker covers; pliable enough to fill minor flange irregularities.

-

New-style (gray rubber) & rocker cover kit: Purpose-made for aluminum covers with the right compressibility and edge retention. Kits may include fastener grommets or seals to prevent wicking along studs.

Tip: Do not overtighten cover fasteners; a slight crush on the gasket is all that’s required.

Governor Interface Gaskets (Head-to-Governor, Governor Housing, Cap & Spring Cover)

Speed control integrity depends on oil-tight, air-tight governor interfaces. Replace the head-to-governor gasket after governor removal, and refresh the small but critical gaskets at the governor housing, cap, and spring cover. These prevent oil seepage and contamination of governor internals—key for stable idle and smooth turbo spool behavior under changing loads.

For Detroit Diesel 6-71 Turbo: Intake Air, Blower & Boost-Side Sealing

Blower Installation Gasket Kit (By-Pass Turbo)

Turbocharged 6-71s still rely on the Roots-type blower to scavenge the two-stroke cylinders. A dedicated blower installation kit for by-pass turbo setups ensures the blower-to-block, blower screen, and striker plate gaskets seal perfectly under boost and at idle. Using the proper gasket stack height and materials prevents boost loss into the crankcase and keeps the blower’s inlet and outlet passages sealed against back-flow.

-

Blower screen gasket: Sits under the protective screen; replace whenever the screen is disturbed.

-

Blower & striker plate gasket: Correct thickness preserves rotor clearance and air path geometry.

-

Blower-to-block gasket: A primary seal between the scavenge air path and crankcase—critical on turbo engines.

Head-to-Manifold Gaskets (Exhaust Interface on 6-71)

The exhaust manifold interface must survive thermal shock, turbo back-pressure, and flange movement. Fit the correct head-to-manifold gasket pattern for your 6-71 configuration and replace as a set—warped manifolds will punish new gaskets, so check flatness and studs.

For Detroit Diesel 6-71 Turbo: Turbocharger, Exhaust & Intercooler Gaskets

Turbo riser gaskets seal the turbo outlet to the riser or elbow. Correct inner/outer dimensions ensure a full sealing land without overhang into the gas path. On marine 6-71 Turbo installations, this gasket sees salt-laden moisture and heat; replace at any sign of carbon tracking, edge fray, or clamp loosening.

Turbo Oil Supply & Return Gaskets

Oil supply and drain gaskets must withstand hot oil and turbo housing temperatures. A weeping oil feed gasket can oil-soak the compressor end; a leaking return gasket can dribble onto the hot manifold. Replace both whenever the turbo is removed. Clean mating faces and use proper torque—thin flanges warp easily.

High-Temperature Jointing Compound (Turbo Interfaces)

A high-temp jointing compound rated for extreme heat is useful on select turbo joints where the OEM allows a dressing. It’s not a substitute for the right gasket, but it can help fill micro-imperfections on flanges and prevent fretting under vibration. Use sparingly; excess compound can extrude into the flow path.

Intercooler & Charge-Air Gaskets (End Plates & Core Interfaces)

Where fitted, intercooler end plate and core gaskets must keep boost air separate from coolant and atmosphere. For the 6-71 Turbo, you’ll typically use multiple gaskets per intercooler assembly (often two end plate gaskets plus additional core/interface gaskets). Always replace them as a complete set to avoid staged failures after reassembly.

Leak diagnosis tip:

-

Oily residue at an intercooler seam usually indicates a charge-air leak (oil mist from the compressor deposits at the lowest-pressure point).

-

Milky coolant or unexplained coolant loss combined with oily sheen may indicate a core breach—pressure test before condemning the unit.

For Detroit Diesel 6-71 Turbo: Cooling System Gaskets

The water rail manifold distributes coolant across the head. Even a slight seep here can mist the top end, inviting corrosion around injector harnesses and head fasteners. Replace the water manifold gasket anytime the rail is disturbed, and inspect for pitting on the rail’s sealing land.

The thermostat housing is a frequent source of nuisance leaks. Replacing the housing gasket is quick insurance against coolant loss and steam pockets that can stress the head gasket on a hard-worked turbo engine.

Engine (Fresh) Water Pump Cover Gasket

The jacket-water (fresh water) pump cover gasket stops seepage at the pump cover interface. On marine units, air entrainment can occur if this interface leaks, reducing pump efficiency and raising operating temperatures. Replace the gasket during pump service; ensure the cover is flat and fasteners seat smoothly.

Raw (Sea) Water Pump Gaskets & Mounting/Plate Gaskets

Raw water pumps typically use two inlet/outlet gaskets per pump, plus a mounting gasket and occasional plate gasket depending on model. These gaskets prevent air leaks on the suction side (which can cause pump cavitation) and stop saltwater drips that corrode accessory brackets and belt drives. Replace as a set and rinse with fresh water after initial run-in to remove any salt residues from installation.

The heat exchanger gasket kit refreshes the sealing interfaces around the end bells, covers, and select internal partitions. On a turbocharged 6-71, maintaining stable coolant temperature under boost is non-negotiable, so don’t reuse flattened or brittle exchanger gaskets. Pressure-test after reassembly.

For Detroit Diesel 6-71 Turbo: Lubrication System Gaskets

The oil cooler has multiple gasketed interfaces—cooler-to-block and often cover plates. Replace both primary oil cooler gaskets whenever you break the circuit. Any seep here can masquerade as “rear main leaks” due to airflow flinging oil aft. Clean the surfaces, use the correct gasket orientation, and torque evenly.

The oil pan is the sump for your turbo 6-71’s lifeblood. A new oil pan gasket, fitted to clean, straight flanges with proper fastener torque, prevents slow wicking along the pan rail. Inspect for pan flange waves; gently straighten before installation. Pair the new pan gasket with fresh drain plug sealing to complete the job.

The adapter interface is a small, flat gasket that can cause big headaches if it seeps down the block. Replace during filter head service or whenever you see oil halos forming beneath the adapter.

For Detroit Diesel 6-71 Turbo: Flywheel Housing, Marine Interfaces & Starters

Flywheel Housing Gaskets & Covers

The flywheel housing gasket seals the bell housing to the block, while the large flywheel housing cover (inspection or access cover) gets its own dedicated gasket. On marine 6-71 Turbos, salt-air and bilge humidity accelerate gasket aging—replace at the first sign of damp oil film to keep the bilge clean and to prevent clutch or coupling contamination.

Flywheel-to-Raw Water Pump & Adapter Gaskets

Certain marine raw water pumps mount to the flywheel housing; they use dedicated adapter and interface gaskets. Maintaining these seals prevents both oil and seawater cross-contamination near the coupling and keeps the suction side airtight for reliable priming.

A fresh starter gasket keeps grime and moisture out of the starter mounting interface and prevents oil film from migrating along the joint. Replace when the starter is off for service.

Allison Marine Gear Interface (SAE #2 Flywheel Housing to Transmission)

Many 6-71 Turbo marine packages couple to Allison M and MH marine gears. The flywheel housing-to-gear gasket (SAE #2 in common setups) ensures a clean, oil-tight interface. Replace it during gear removal/installation to avoid oil fogging or drip lines that can end up under the gear case.

For Detroit Diesel 6-71 Turbo: Sealants, Dressings & Assembly Aids

High-Tack Gasket Spray

Use a high-tack spray to hold cut gaskets in place on vertical surfaces or where assembly alignment is tricky. Apply a thin, even coat; let it tack before assembly. It’s especially handy on oil pan rails and timing covers.

Liquid Gasket Maker & RTV (Sensor-Safe, Ultra-Blue, High-Temp)

Select the correct RTV type for the location:

-

Sensor-safe RTV: For areas near sensors to avoid corrosion or false readings.

-

Ultra-blue RTV: General-purpose, oil-resistant joints where a formed-in-place gasket is specified.

-

High-temp RTV: For hotter zones around turbo interfaces where OEMs permit RTV as an adjunct.

Use RTV only where specified—never as a replacement for a required solid gasket.

Non-Hardening Pliable Sealant

A classic choice for threaded plugs, minor cover corners, or paper gasket edges that see frequent service. It remains flexible and is easy to clean off at the next service interval.

Threadlocker (High-Strength Red)

A high-strength threadlocker secures studs and fasteners that should not vibrate loose in high-heat, high-load environments—common near turbo hardware, exhaust manifolds, and accessory brackets. Use sparingly and only where called for; not on fasteners that require periodic removal unless specified.

Cold Weld Epoxy

A two-part metal-filled epoxy helps with emergency cosmetic fills and small non-structural surface imperfections on non-pressurized covers. Do not rely on epoxy to repair cracks in pressure vessels, heads, or structural brackets.

For Detroit Diesel 6-71 Turbo: Selecting the Right Gasket Material & Design

Material matters on a turbo 6-71. You’ll encounter composite fiber, beaded steel, rubber-coated, molded elastomer, and soft metal crush styles across the engine:

-

Composite fiber gaskets handle oil and coolant well at modest flange loads—common for covers and pans.

-

Beaded steel/MLS-type edges appear in high-load joints like head or manifold interfaces; they maintain seal under thermal growth.

-

Rubber-coated or molded elastomer profiles shine on rocker covers and water pump covers thanks to reusability and consistent compression.

-

Soft metal crush washers or rings are used where thermal conductivity and micro-sealing are needed.

Match the material to the joint: hotter/harder joints (turbo/exhaust) need more robust, often metallic solutions; cooler/softer joints (covers) can use elastomeric or fiber designs.

For Detroit Diesel 6-71 Turbo: Installation Best Practices (Leak-Free From Day One)

Preparation & Inspection

-

Cleanliness is king. Degrease mating faces; remove old gasket material without scratching.

-

Check flatness. Use a straightedge on manifolds, covers, and rails. Heat can bow exhaust manifolds and warp stamped covers.

-

Chase threads. Clean stud and bolt threads; replace any that are stretched or corroded.

Dry-Fit & Orientation

-

Test fit gaskets to verify hole alignment and orientation. Some gaskets are directional—look for printed “up/front” indicators or asymmetrical port shapes.

Sealant Discipline

-

Use only where specified. Over-applying RTV or liquid sealants can cause extrusion into oil passages or turbo oil drains.

-

Thin films, not blobs. A whisper-thin coat is enough on paper gaskets if dressing is recommended.

Torque Pattern & Re-Torque

-

Follow sequences. Head, manifold, and cover patterns minimize warp.

-

Heat cycles & re-checks. After an initial run-in, re-check accessible fasteners (where the OEM allows) to catch relaxation.

Break-In & Fluids

-

Monitor leaks live. Use a clean rag and a bright light after the first heat soak and again after load testing.

-

Use the right coolant & oil. Proper chemistry reduces attack on gasket materials and prevents deposit formation.

For Detroit Diesel 6-71 Turbo: Troubleshooting Common Leak Paths

Oil at the front pulley area

-

Likely front crank seal or front cover gasket seep. Check for groove on the hub; install a new seal and sleeve if needed.

Oil at bell housing drain slot

-

Suspect rear main seal or oil pan rear arch. Verify oil cooler interfaces above aren’t the actual source (oil can travel).

Oil film on rocker cover edges

-

Cover bolts overtightened (warped flange) or wrong gasket style for your cover generation. Replace with the correct gasket and torque properly.

Sooty streaks at turbo riser

-

Turbo riser gasket losing seal, clamp torque loss, or warped flange. Replace gasket and verify mating surface flatness.

Coolant on head’s outboard face

-

Water manifold (rail) gasket weeping. Remove rail, clean, and replace gasket. Inspect for pitting.

Boost loss / oily mist at intercooler

-

Charge-air gasket leak at end plates or core interfaces. Pressure-test, replace all intercooler gaskets as a set.

Saltwater drips beneath raw water pump

-

Inlet/outlet gasket or plate gasket failure; also check mounting gasket. Replace both and verify hose clamp alignment.

For Detroit Diesel 6-71 Turbo: Maintenance Intervals & Replacement Triggers

-

Every major service (valve/injector set): Inspect rocker cover gaskets, head-to-manifold joints, and water rail.

-

At turbo replacement/removal: Always renew turbo oil supply and return gaskets, plus the turbo riser gasket.

-

Cooling system service: Replace thermostat housing and water pump cover gaskets; evaluate heat exchanger gaskets if end bells are removed.

-

After overheat event: Inspect head gasket integrity, intercooler seams (if equipped), and water rail gasket.

-

At overhaul: Use the complete overhaul gasket kit; do not reuse any old gasket in critical joints.

For Detroit Diesel 6-71 Turbo: Ordering Checklist (Do It Once, Do It Right)

-

Overhaul gasket kit or cylinder head gasket kit (depending on scope)

-

Front and rear crankshaft seals (choose standard vs. oversize; single vs. double lip based on condition)

-

Rear seal sleeve if bore/journal shows wear

-

Rocker cover gasket type matched to your cover style (old tin vs. new aluminum)

-

Blower installation gasket kit (by-pass turbo), blower screen gasket, and blower-to-block gasket

-

Head-to-manifold gaskets (complete set)

-

Turbo riser, turbo oil supply, and turbo oil return gaskets

-

Intercooler gaskets (end plates and core interfaces as required)

-

Water rail manifold, thermostat housing, and engine water pump cover gaskets

-

Raw water pump inlet/outlet, mounting, and plate gaskets; heat exchanger gasket kit if opened

-

Oil cooler gaskets (both interfaces), oil pan gasket, oil filter adapter gasket

-

Flywheel housing gasket, large housing cover gasket, starter gasket

-

Flywheel-to-raw water pump adapter gasket and, where used, the marine gear interface gasket

-

High-tack gasket spray, correct RTV (sensor-safe/ultra-blue/high-temp), non-hardening sealant, threadlocker, and cleaning supplies

Why Buy 6-71 Turbo Gaskets from Diesel Pro Power

Choosing the right gasket is as important as choosing the right piston or injector—especially on a turbocharged two-stroke like the Detroit Diesel 6-71. Diesel Pro Power curates gasket kits and individual seals that match the realities of marine and industrial service: heat, vibration, boost pressure, and the occasional salty environment. Here’s what you can expect when you source your 6-71 Turbo gaskets here:

Engine-Specific Fit & Material Confidence

Every gasket and seal in this catalog is selected with the 6-71 Turbo’s operating envelope in mind. That means materials that stand up to high exhaust temperatures at the manifold, oil-resistant elastomers for rocker and cover interfaces, and properly dimensioned turbo oil line gaskets that won’t creep under heat soak.

Rebuild-Ready Completeness

Whether you’re doing a top-end refresh or a full overhaul, our kits are assembled to minimize downtime and parts chasing. You’ll have the correct number of gaskets where multiples are needed (such as intercooler end plates or raw water pump ports) and the small but critical items (governor cap and spring cover gaskets) that often get forgotten.

Marine-Savvy Sealing Solutions

Many 6-71 Turbo engines live in boats. Our selection includes the marine-specific pieces—raw water pump gaskets, heat exchanger gasket kits, and flywheel-to-gear interface gaskets—along with corrosion-aware sealants and dressings suitable for bilge environments.

In-Stock Reliability & Fast Fulfillment

Downtime is expensive. Items in this section are stocked with rapid shipping options so you can reseal, reassemble, and return to service with minimal delay.

Practical Support & Documentation Mindset

We organize gasket coverage around real-world service steps and assemblies—head, blower, turbo, cooling, lubrication—so you can plan a job and confirm you’ve covered every leak path before re-firing a fresh 6-71 Turbo.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588