Parts for Detroit Diesel 671 Turbo for Australia - Marine Water Pump Section

Loading...

Loading... -

Marine Water Pump for Detroit Diesel 53 & 71 Series Marine Engines

5145578

Bidirectional Pump (It Turns Right or Left)

Port Type: 1” Flange. Includes Drive Gear and Mounting Adapter

Price: $ 802.29 -

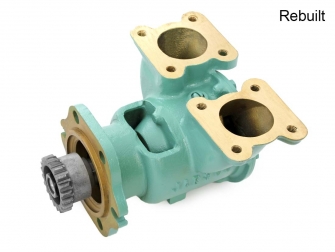

Marine Water Pump for Detroit Diesel 53, 71 and 92 Series Marine Engines, Rebuilt

23507971R

Sold with refundable core deposit. See details

Bidirectional Pump (It Turns Right or Left)

Port Type: 1 1/2” Flange. Includes Adapter & Drive Gear.

Impeller Height: 2 1/2”

Price: $ 892.00 -

Marine Water Pump for Detroit Diesel 53, 71 and 92 Series Marine Engines

23507971

Bidirectional Pump (It Turns Right or Left)

Port Type: 1 1/2” Flange. Includes Adapter & Drive Gear.

Impeller Height: 2 1/2”

Price: $ 1,068.69 -

Impeller for Caterpillar, Detroit Diesel, and Volvo Penta Marine Water Pumps

8924838

Impeller with 12 Blades and 12 Spline Drive.

Diameter: 3 3/4” - Height: 2 1/2”

Price: $ 96.73 -

-

-

-

Detroit Diesel Marine Water Pump repair kit 6V53, 6V71, 6-71, 6V92

5197224P

For 2 1/2" impeller height

Price: $ 630.32 -

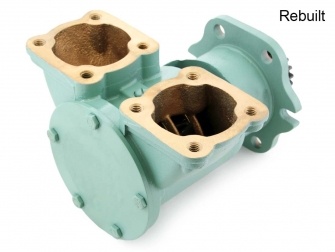

Marine Water Pump for Detroit Diesel 71 and 92 Series Marine Engines - Rebuilt

23507972R

Sold with refundable core deposit. See details

Bidirectional Pump (It Turns Right or Left)

Port Type: 2” Flange. Includes Adapter & Drive Gear.

Impeller Height: 3 1/2” - Splined Shaft.

Price: $ 939.00 -

Marine Water Pump for Detroit Diesel 71 and 92 Series Marine Engines

23507972

Bidirectional Pump (It Turns Right or Left)

Port Type: 2” Flange. Includes Adapter & Drive Gear.

Impeller Height: 3 1/2” - Splined Shaft.

Price: $ 1,124.90 -

Detroit Diesel Marine Water Pump repair kit for 6-71, 8V71, 8V53, 12V71, 6V92, 8V92

5197222

For 3 1/2" height impeller - spline pump shaft

Price: $ 706.12 -

Impeller for Detroit Diesel, Scania and Volvo Penta Marine Water Pumps

8924839

Impeller with 12 Blades and 12 Spline Drive.

Diameter: 3 3/4” - Height: 3 1/2”

Price: $ 145.72 -

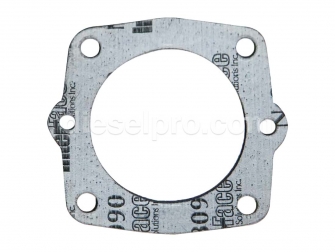

Detroit Diesel Gasket, Marine Water Pump

5115395

Each pump uses 2 of this gasket. Water inlet and outletPrice: $ 4.38 -

-

Impeller for Detroit Diesel and Volvo Penta Marine Water Pumps

5193602

Impeller with 10 Blades and 12 Spline Drive.

Diameter: 2 1/2” - Height: 2”

Price: $ 49.82 -

Seal for Detroit Diesel Marine Water Pump

5199150

used with raw water pump with 1" water inlet, outlet port that has a 2" impeller

Price: $ 106.55 -

-

-

-

-

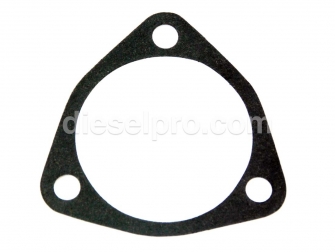

Detroit Diesel Marine Water Pump gasket

5112143

Each pump uses 2 of this gasket. Water inlet and outletPrice: $ 4.59 -

-

-

-

-

Detroit Diesel Heat Exchanger Gasket Kit for Marine Engines for Series 53, 71 and 92

5192637

.Price: $ 97.18 -

-

-

-

-

Zinc for Marine Engine - for Heat Exchangers

E4C

Brass plug NPT 3/4", zinc length 3 3/8"Price: $ 33.43 -

Zinc for Marine Engine - for Marine Water Pumps

E3C

Brass plug NPT 3/4", zinc length 2"Price: $ 32.05 -

Zinc for Marine Engine - for Marine Water Pumps

E2C

For Detroit heat exchanger For Cummins heat exchanger and aftercooler For Brass plug NPT 1/2", zinc length 2"Price: $ 27.53 -

Zinc for Marine Engine - for Fuel Coolers & Oil Coolers

E1C

Brass plug NPT 3/8", zinc length 2"Price: $ 24.54 -

Zinc for Marine Engine - for Fuel Coolers & Oil Coolers

E00

Brass plug NPT 1/8", zinc length 2"Price: $ 18.72 -

Detroit Diesel Cam for Marine Water Pump or Marine Water Pump

5193554

For 2 1/2" dia raw water pump

Price: $ 168.90 -

-

Detroit Diesel Shaft for raw or Marine Water Pump - spline

5196169

For 3 1/2" dia raw water pump (Brass)

Price: $ 221.84 -

-

Detroit Diesel Cover for Marine Water Pump with 2 1/2 and 3 1/2 inch dia impeller

5193555

For 2 1/2" and 3 1/2 impeller

Price: $ 94.00 -

-

-

-

-

-

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

-

-

-

-

-

-

-

-

-

-

-

Clamp for a coolant and fuel Hose

10H

Effective Diameter Range:

Minimum 9/16", Maximum 1-1/16"

Price: $ 3.04 -

Clamp for a coolant Hose

4920417

Effective Diameter Range:

Minimum 13/16", Maximum 1-3/4"

Price: $ 15.78 -

Clamp for a coolant Hose

3412320

Effective Diameter Range:

Minimum 11/16", Maximum 1-1/4"

Price: $ 14.76 -

Clamp for a coolant Hose

3922846

Effective Diameter Range:

Minimum 1-5/16", Maximum 2-1/4"

Price: $ 15.72 -

Clamp for a coolant Hose

3922847

Effective Diameter Range:

Minimum 1-9/16", Maximum 2-1/2"

Price: $ 15.90 -

Clamp for a coolant Hose

3922849

Effective Diameter Range:

Minimum 2-5/16", Maximum 3"

Price: $ 16.35 -

-

Controls Cables & More...

-

Marine Control

-

Industrial Cable

-

Marine Cables 1/16 thread

-

Marine Cables 1/4 thread

-

Marine Steering

-

Rubber Bearing

-

Searchlight

-

Marine Bulb

-

Navigation Light

-

Parts for Detroit Diesel 6-71 Turbo – Marine Water Pump Section

The Detroit Diesel 6-71 Turbo marine engine is one of the most legendary powerplants ever built for maritime applications, known for its rugged reliability, mechanical simplicity, and long-lasting performance. Like all marine engines, it depends on a properly functioning raw water pump system to keep operating temperatures under control. A seawater pump—often called a marine water pump or raw water pump—draws in cool seawater to absorb heat from the engine’s closed-loop coolant system via the heat exchanger. Without this vital component, engine temperatures would rise rapidly, causing performance loss, overheating, or even engine failure.

At Diesel Pro Power, we provide a complete selection of raw water pumps and cooling system components for the Detroit Diesel 6-71 Turbo engine—each part designed to meet OEM specifications for performance and durability in demanding marine environments. Whether you need a complete marine water pump, impeller, seal, or gasket kit, you’ll find it all in one place, ready to ship worldwide.

Marine Water Pumps for Detroit Diesel 6-71 Turbo Engines

The heart of the cooling system is the raw water pump—responsible for circulating seawater through the heat exchanger, oil cooler, and other auxiliary cooling components. Diesel Pro Power offers both new and rebuilt options for 6-71 Turbo applications.

New Marine Water Pump for Detroit Diesel 6-71 Turbo

This bidirectional pump (capable of turning either right or left) is ideal for various marine installations where shaft rotation may differ.

-

Port Type: 1” flange for easy connection

-

Includes: Drive gear and mounting adapter for a direct fit

-

Construction: Marine-grade bronze for corrosion resistance in seawater applications

-

Performance: Engineered for consistent seawater flow to protect critical engine components from heat stress

Each new pump is tested before shipping to ensure correct flow and pressure, providing long-term peace of mind for operators of Detroit Diesel 53, 71, and 92 Series engines.

Rebuilt Marine Water Pump for Detroit Diesel 6-71 Turbo

A rebuilt unit provides OEM-level performance at a lower cost. Diesel Pro Power’s rebuilt pumps undergo full disassembly, inspection, and testing. Every wear component—bearings, seals, shafts, and impellers—is replaced or reconditioned.

-

Port Type: 1½” flange

-

Includes: Adapter and drive gear

-

Impeller Height: 2½”

-

Bidirectional Functionality: Designed to turn right or left for flexible marine installation

Each pump is backed by a refundable core deposit, allowing customers to return their old unit for recycling and credit.

Marine Water Pump – New OEM Replacement for 6-71 Turbo

For customers seeking new equipment rather than rebuilt options, Diesel Pro Power supplies brand-new OEM-quality pumps designed for maximum longevity.

-

Impeller Height: 2½”

-

Materials: Brass housing, stainless-steel shaft, and high-grade seals to resist saltwater corrosion

-

Compatibility: Direct-fit replacement for Detroit Diesel 53, 71, and 92 Series marine engines

This new water pump is ideal for operators looking for zero downtime and factory-grade dependability.

Impellers for Detroit Diesel 6-71 Turbo Raw Water Pumps

The impeller is the core moving component inside every marine water pump. It’s a flexible rubber rotor with blades that push seawater through the system. Replacing the impeller regularly prevents overheating and ensures consistent cooling flow.

Impeller for 2½” Pumps

-

Blade Count: 12 blades

-

Drive: 12 spline

-

Diameter: 3¾”

-

Height: 2½”

Compatible with multiple marine pump brands, this impeller provides a balanced blend of flow efficiency and longevity.

Impeller for 3½” Pumps

Designed for larger raw water pumps used in higher-horsepower 6-71 Turbo configurations:

-

Blade Count: 12 blades

-

Drive Type: 12 spline

-

Diameter: 3¾”

-

Height: 3½”

This heavy-duty impeller delivers greater seawater throughput to manage elevated heat loads typical of turbocharged engines.

Marine Water Pump Repair Kits

Rather than replacing the entire pump, many operators opt for repair kits that allow them to rebuild their existing unit. Diesel Pro Power offers complete kits for both the 2½” and 3½” impeller configurations used on the 6-71 Turbo engine.

Repair Kit for 2½” Impeller Pumps

-

Designed for 6V53, 6V71, 6-71, and 6V92 marine engines

-

Includes bearings, mechanical seal, gaskets, wear plate, and shaft components

-

Restores the pump to original operating efficiency

Repair Kit for 3½” Impeller Pumps

-

Compatible with 6-71, 8V71, 8V53, 12V71, 6V92, and 8V92

-

For 3½” impeller pumps with splined shafts

-

Provides all key wear components to ensure proper sealing and mechanical alignment

Seals, Shafts, and Wear Plates

Each marine pump relies on precision-machined internal parts to maintain pressure and prevent leakage.

A high-grade mechanical water seal protects against saltwater intrusion into the bearing housing. Essential for preventing premature failure and rust inside the pump body.

This seal retains lubrication and prevents oil from escaping the bearing chamber, ensuring smooth operation at all engine speeds.

Manufactured in brass and precision-ground to tight tolerances, this splined pump shaft transmits torque from the drive gear to the impeller. Available for both 2½” and 3½” impeller models.

The wear plate forms a smooth surface behind the impeller, minimizing friction and maximizing flow efficiency. Diesel Pro Power supplies replacements for both impeller sizes.

Each raw water pump includes a cover plate that seals the housing and maintains suction pressure. Replacement screws and gaskets are also available for complete reassembly.

Cooling System Components

A marine cooling system is only as strong as its weakest part. Diesel Pro Power provides comprehensive supporting components to keep the entire cooling system of the Detroit Diesel 6-71 Turbo functioning at its best.

Thermostat and Gaskets

-

Detroit Diesel Thermostat: Opens at 173°F to regulate coolant flow

-

Thermostat Housing Gasket: Provides a perfect seal to prevent leaks under high pressure

-

Mounting and Adapter Gaskets: Maintain tight seals between the pump and engine block

Heat Exchanger & Tank Assemblies

-

Marine Heat Exchange Tank: Direct-fit replacement for 371, 471, and 671 engines

-

Heat Exchanger Core: Precision-designed to transfer heat efficiently from engine coolant to raw seawater

-

Gland and Seal Kits: Maintain watertight joints in the exchanger assembly

-

Radiator Gaskets: Prevent coolant leakage between cooling system flanges

Anodes and Corrosion Protection

Saltwater environments are notoriously harsh. To prevent galvanic corrosion, Diesel Pro Power offers a range of zinc anodes specifically designed for Detroit Diesel marine engines.

Zinc Anodes for Heat Exchangers

-

NPT ¾” brass plug with zinc insert, 3⅜” long

-

Protects the entire cooling circuit from electrolysis damage

Zinc Anodes for Marine Water Pumps

-

NPT ¾” plug, 2” zinc length

-

Protects bronze and brass components within the raw water pump housing

Zinc Anodes for Fuel & Oil Coolers

-

Available in ½”, ⅜”, and ⅛” plug sizes

-

Ideal for small passages in coolers and compact heat exchangers

Replacing zinc anodes regularly prevents metal degradation inside pumps, coolers, and exchangers, significantly extending service life.

Hoses, Clamps, and Accessories

The flow of coolant through the system depends on flexible, durable hoses and properly fitted clamps.

Silicone Coolant Hoses

Available in multiple inner diameters—from 1” to 4”—these reinforced silicone hoses resist heat, salt, and oil contamination. Each length is sold in 1-foot increments for custom fitment.

Hose Clamps

Each cooling line should be secured with marine-grade stainless-steel clamps to prevent leaks under vibration and pressure. Diesel Pro Power offers several size ranges, including:

-

9/16" to 1-1/16"

-

13/16" to 1-¾"

-

1-5/16" to 2-¼"

-

2-5/16" to 3"

A 21-tooth accessory drive coupling ensures smooth engagement between the engine’s camshaft gear and the raw water pump. Built for long-term reliability in harsh marine operating conditions.

Marine Paint and Finishing Touches

To protect your 6-71 Turbo from rust and corrosion, Diesel Pro Power supplies Detroit Green Engine Paint, the authentic OEM color. This durable enamel coating resists heat and oil, preserving the engine’s professional finish.

Why Buy Raw Water Pumps for Your Detroit Diesel 6-71 Turbo from Diesel Pro Power

When it comes to maintaining a classic marine powerhouse like the Detroit Diesel 6-71 Turbo, the quality of replacement parts directly determines engine longevity and performance. Diesel Pro Power has become the global standard for professional-grade Detroit Diesel parts, with over 40,000 satisfied customers across commercial shipping, military, and private fleets.

The Diesel Pro Power Difference

1. All-in-One Availability

Every component—from complete raw water pumps to zincs, impellers, and thermostat gaskets—is available under one roof. You no longer have to source parts from multiple suppliers.

2. Ready-to-Ship Inventory

All marine water pump parts are in stock and ready for immediate worldwide shipment, with full tracking and fast delivery options.

3. Expert Fitment Assistance

Our Detroit Diesel–trained support team can help you identify the correct impeller height, drive gear type, and pump configuration for your 6-71 Turbo installation.

4. Proven Marine Quality

Each pump and component meets or exceeds OEM standards for saltwater durability, precision fitment, and flow performance.

5. Worldwide Trust

For decades, Diesel Pro Power has supplied marine engineers, shipyards, and vessel operators worldwide with dependable Detroit Diesel components. From small fishing vessels to large commercial fleets, customers trust Diesel Pro to keep their engines running cool and efficient.

Maintaining Your 6-71 Turbo Cooling System

To ensure maximum engine life:

-

Replace impellers every 12 months or at the first sign of cracking.

-

Inspect zinc anodes every 3–6 months and replace as needed.

-

Verify seal integrity during each service interval to prevent seawater contamination.

-

Keep the heat exchanger clean of scale and salt deposits for efficient cooling.

By maintaining your marine water pump system with genuine Detroit Diesel–spec parts from Diesel Pro Power, you safeguard your investment and ensure consistent, reliable operation on every voyage.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588