Parts for Detroit Diesel 8V71 Non-Turbo for Australia - Exhaust Section

Loading...

Loading... Detroit Diesel 8V71 Non-Turbo – Exhaust System Parts Catalog

The Detroit Diesel 8V71 Non-Turbo engine is one of the most reliable and long-lived members of the legendary Detroit Diesel Series 71 family. Known for its two-stroke design, mechanical simplicity, and rugged dependability, the 8V71 engine has been used for decades in marine vessels, buses, trucks, and stationary equipment worldwide. Its distinctive exhaust note and durability make it a favorite among professional operators who need consistent performance in demanding environments.

This catalog focuses exclusively on the exhaust system components for the Detroit Diesel 8V71 Non-Turbo engine. Each part listed below has been carefully selected and verified by Diesel Pro Power to ensure optimal compatibility, corrosion resistance, and long-term reliability for both marine and industrial applications.

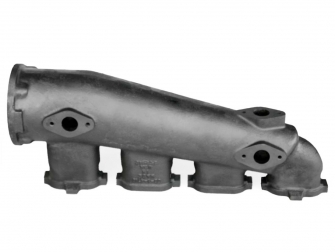

Marine Exhaust Manifold for Detroit Diesel 8V71

The marine exhaust manifold serves as the foundation of the exhaust system. It collects exhaust gases from each cylinder and routes them toward the exhaust outlet while maintaining proper heat management and back pressure.

Diesel Pro Power’s Detroit Diesel marine manifold for 4-71, 8V71, 16V71, 8V92, and 16V92 engines is precision-cast for durability and thermal stability. Each manifold is manufactured using marine-grade materials to resist corrosion from seawater exposure, especially in wet exhaust configurations where cooling water mixes with the exhaust stream.

The smooth internal design minimizes exhaust turbulence, improving flow and reducing the likelihood of soot buildup. For marine users, this also means a cleaner engine room and improved exhaust water discharge consistency at the stern.

Head to Manifold Gasket

Between the cylinder head and the exhaust manifold lies the head-to-manifold gasket, an essential component that seals combustion gases and prevents exhaust leaks.

Diesel Pro Power provides OEM-quality gaskets for the 8V71 engine, also compatible with other Series 71 and 92 engines, including 6-71, 12V71, and 16V71 configurations. Each gasket is manufactured with multi-layer composite materials designed to handle high temperatures and vibration.

A failing gasket in this area can cause performance issues, increased exhaust noise, or even overheating due to escaping gases near sensitive engine components. By using Diesel Pro Power’s precisely machined gaskets, operators ensure a perfect fit and long-lasting seal integrity.

Marine Exhaust Manifold Flange and Gasket

The marine exhaust manifold flange is where the manifold connects to the rest of the exhaust line. It must withstand both mechanical stress and high thermal cycles while maintaining watertight integrity.

Diesel Pro Power supplies heavy-duty flanges with 4" NPT threads, machined to factory specifications for a secure fit. Paired with the marine manifold flange gasket, which features precise inner and outer diameters (4.25" and 6.25" respectively), the result is a robust seal that prevents water intrusion and exhaust gas leaks.

These components are vital in marine environments where condensation, saltwater, and temperature fluctuations can quickly corrode lesser materials. Diesel Pro Power ensures that each flange and gasket is built to last under constant exposure to heat and vibration.

Exhaust Manifold Insulation Tape

To protect surrounding components and improve safety, insulation is key. Diesel Pro Power’s manifold insulation tape comes in both 3-inch and 4-inch widths, each 100 feet long and 1/8-inch thick.

This high-temperature insulating material helps maintain cooler engine room temperatures, reduces the risk of burns during maintenance, and minimizes heat loss for more efficient exhaust gas flow. It also prevents damage to wiring, hoses, and nearby hardware that might otherwise degrade under prolonged heat exposure.

For operators performing full exhaust overhauls, replacing the insulation tape during manifold or riser installation is highly recommended.

Manifold Studs, Nuts, Washers, and Crabs

The hardware used to secure the exhaust manifold plays an equally important role in system integrity. Diesel Pro Power offers studs, nuts, washers, and manifold crabs—all engineered for marine-grade corrosion resistance and precise fitment.

-

Manifold Studs: 7/16" - 14/20 x 2.10" size, providing strong and secure fastening that can withstand vibration and temperature shifts.

-

Manifold Nuts: Heat-treated steel ensures tight sealing without loosening under expansion.

-

Manifold Washers: Designed to distribute clamping force evenly and prevent thread damage.

-

Manifold Crabs: Used for manifold alignment and secure mounting, ensuring even torque distribution along the joint.

Every fastener is precision-machined to maintain alignment, prevent leaks, and simplify reinstallation during maintenance.

Marine Manifold Water Outlet Plates and Gaskets

The marine manifold water outlet plate and corresponding gasket are responsible for routing cooling water through the exhaust system. Diesel Pro Power’s plates and gaskets are direct-fit replacements for Detroit Diesel 8V71 applications.

These parts are built from corrosion-resistant metals and gasket materials designed to maintain watertight seals under varying thermal loads. The water outlet gasket, designed for Series 71 and 92 engines, ensures leak-free operation between the plate and manifold.

Proper water circulation in the exhaust system helps prevent thermal damage to the manifold and extends component life. Replacing the outlet gasket during manifold servicing is essential to ensure continued efficiency and safety.

Threaded Plates and Elbows for Marine Manifolds

Marine manifolds often integrate threaded plates and elbows to facilitate water connections, risers, and discharge lines.

-

Threaded Plate (3/4” thread): Used for custom cooling configurations and secure fittings.

-

90° Elbows (3/4” and 1”): Allow directional adjustment of cooling water lines or exhaust flow.

-

45° Elbow (3/4”): Commonly used in tight engine spaces to maintain proper alignment without kinking hoses.

These fittings are made from heavy-duty marine-grade metals to resist corrosion and maintain pressure sealing under marine conditions.

Marine Manifold Flange Spacer Gasket

The flange spacer gasket provides the necessary clearance and sealing between flange joints, particularly when integrating flexible hoses or risers. With an outside diameter of 6.25" and an inside diameter of 3.50", Diesel Pro Power’s flange spacer gasket ensures a secure and vibration-resistant connection.

These gaskets are essential for vibration isolation, helping to reduce noise and extend the life of the manifold assembly and attached piping.

Muffler Caps for Exhaust Protection

When the engine is not in use, muffler caps protect exhaust outlets from rain, seawater, and debris. Diesel Pro Power offers a full range of cap sizes:

-

3” Cap – Common for auxiliary engines or smaller generators.

-

3.5” Cap – For standard industrial configurations.

-

4.5” Cap – Ideal for mid-size marine engines.

-

5” Cap – Best suited for full-size 8V71 non-turbo marine or stationary engines.

Each cap is constructed from stainless or galvanized steel for corrosion resistance and smooth hinge operation. Regular use of these caps helps prevent internal rust, protecting the exhaust manifold and turbo housings from moisture damage.

Flexible Metal Exhaust Hoses

Flexible exhaust hoses are critical for absorbing vibration and accommodating engine movement while maintaining a gas-tight seal. Diesel Pro Power provides reinforced metal hoses in various diameters:

-

4” x 18” Hose – Compact, ideal for tight engine spaces.

-

6” x 18” Hose – Suitable for mid-range exhaust systems.

-

8” x 18” Hose – Handles high-volume exhaust discharge in large marine applications.

Each hose features a flexible corrugated design that minimizes stress on manifold joints and muffler connections. Made from marine-grade stainless steel, these hoses resist heat, corrosion, and fatigue from engine vibration.

Temperature Switch

Maintaining safe operating temperatures is vital in exhaust systems. Diesel Pro Power’s temperature switch closes at 205°F, providing a reliable means to monitor and control engine cooling.

The 1/2” NPT thread design ensures compatibility with Detroit Diesel, Cummins, and Caterpillar applications. This sensor can be integrated into the exhaust manifold or water outlet area to trigger alarms or shutdowns if overheating occurs.

Why Buy Detroit Diesel 8V71 Non Turbo Exhaust Parts from Diesel Pro Power

Proven Quality and OEM Compatibility

Diesel Pro Power has supplied over 40,000 satisfied customers worldwide, earning its reputation as the most trusted online source for Detroit Diesel replacement parts. Each component is hand-inspected and verified to meet or exceed OEM standards, ensuring seamless installation and long-lasting performance.

Specialized Marine Expertise

The 8V71 engine is a staple in marine propulsion and auxiliary systems. Diesel Pro Power understands the unique requirements of saltwater applications, offering corrosion-resistant materials, precision engineering, and product availability that supports both commercial and recreational operators globally.

Fast Global Shipping and Easy Ordering

From a single gasket to a complete manifold set, Diesel Pro Power ships quickly—domestically and internationally—with real-time order tracking. Their intuitive online catalog simplifies part selection by engine model, helping you find exactly what you need without cross-referencing outdated manuals.

Comprehensive Support and Technical Guidance

With decades of Detroit Diesel expertise, Diesel Pro Power provides unmatched technical support. Whether you’re maintaining an 8V71 in a classic yacht, generator, or industrial unit, you can rely on their team for advice on installation, compatibility, and troubleshooting.

Durability That Lasts

Each exhaust component—from studs to insulation tape—is engineered to withstand the high heat, vibration, and corrosive environments typical of diesel engines. Investing in genuine Diesel Pro Power parts ensures your 8V71 Non-Turbo engine continues to perform as intended for years to come.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588