When it comes to serious marine and industrial operations — from ocean-going commercial vessels powered by Detroit Diesel engines, to Cummins-driven dredges, Caterpillar offshore generators, and John Deere pumping stations in mining operations — 24-volt electrical systems are the industry standard. Why? Because they provide the electrical muscle needed for large diesel starters, long wire runs, and multi-system integration, all while keeping amperage manageable and voltage drops minimal. Your gauges must match this standard. A properly configured 24-volt electrical gauge system isn’t just about convenience; it’s about ensuring real-time, accurate monitoring of oil pressure, coolant temperature, battery health, fuel levels, and engine RPM. Without this, you risk missed alarms, catastrophic failures, and costly downtime. Marine and Industrial Demands Are Unique On a tugboat pushing container ships, your Detroit Diesel needs gauges that function flawlessly despite constant vibration, salt exposure, and round-the-clock operation. A Cummins-powered gravel pump needs instant feedback on oil pressure and coolant temperatures to avoid multi-day shutdowns in a remote pit. Caterpillar power packs on offshore platforms can’t afford voltage drop errors on long cable runs. John Deere industrial engines managing water supplies across rugged sites rely on stable 24-volt readings to keep operations precise. That’s why Diesel Pro Power specializes in 24V electrical gauges engineered and selected specifically for heavy-duty marine and industrial applications. The 24V System Advantage Unlike 12-volt systems common in smaller craft and vehicles, 24-volt systems reduce amperage by half for the same power demand. This means: Thinner wires can safely carry power across long runs (critical on large vessels or big installations). Starters can crank massive diesel engines without the need for excessively large cables. Voltage drop is minimized over distance, protecting sensitive monitoring equipment. Senders + Gauges: The Vital Connection Each 24-volt electrical gauge pairs with a sender (or sensor) mounted directly on your engine. As pressure, temperature, or fuel levels change, the sender alters electrical resistance or generates voltage pulses. These signals travel back through marine- or industrial-grade wiring to your dashboard or control room gauges. Designed for Distance and Durability With no delicate capillary tubes or hot oil lines running from the engine room to the wheelhouse or remote panel, these systems are perfect for sprawling ship layouts and rugged industrial sites. When your operations run on Detroit Diesel, Cummins, Caterpillar, or John Deere engines in marine or industrial environments, you can’t gamble on generic gauges. Diesel Pro Power is the global leader in dedicated heavy-duty diesel monitoring — trusted by more than 40,000 customers worldwide for a reason. What Sets Us Apart? Complete, calibrated systems: Our 24-volt electrical gauges are matched precisely to the senders and wiring needs of your engine type. Massive inventory: From 24V oil pressure and water temperature gauges to tachometers, voltmeters, hourmeters, and fuel level indicators, we stock it all. Built for harsh environments: Vibration, salt, oil, heat, or mud — our gauges are proven to stand up where standard automotive parts fail. Always in stock, always ready: We ship within 24 hours so your downtime stays minimal. Secure, seamless transactions: Order confidently from our SSL-encrypted site. Expert support: Need help tracing a sender or verifying gauge ranges for your Detroit, Cummins, CAT, or Deere? We’re ready by phone or email. Why Oil Pressure Must Be Monitored Oil is what keeps your bearings, pistons, turbochargers, and camshafts from turning into scrap. In large marine and industrial diesels — especially under continuous loads — pressure drops can destroy thousands in engine components in mere minutes. How 24V Oil Pressure Gauges Work A rugged sender screws directly into your engine’s oil circuit. As pressure changes, the sender’s resistance shifts, sending a precise electrical signal over heavy-duty wires. Your 24-volt gauge converts that into a dial or digital readout, showing exact system pressure on your control panel. Applications Across Major Diesel Brands Detroit Diesel tugs, trawlers, and dredges that need constant assurance bearings are lubricated under strain. Cummins-powered barge pumps or crushers that run for days on end. Caterpillar generators on offshore rigs operating with huge oil galleries. John Deere industrial water movers ensuring oil stays pressurized during endless irrigation or mining cycles. The Danger of Heat Large diesel engines generate intense heat under load. If coolant stops flowing or fails to transfer heat properly, metal expands, heads warp, pistons seize, and your operation stops cold. How Electrical Temperature Gauges Work in 24V Systems A temperature sender threaded into your engine’s water jacket reads coolant temp. As it rises, the sender’s resistance changes, driving your 24-volt gauge needle upward. You get a clear, live view of exactly how hot your engine is running. Marine and Industrial Relevance Detroit Diesel engines on commercial vessels handle high sustained loads that demand precise temp control. Cummins drives on industrial pumps need temperature checks to prevent long-term damage in continuous use. Caterpillar 3406, 3412, and 3512 engines in marine propulsion depend on accurate temperature gauges to avoid catastrophic failures at sea. John Deere sets running for hours on end in harsh sun rely on these gauges to keep operations safe. Why RPM Control Matters RPM governs everything from piston velocity to turbo speed to fuel delivery rates. Over-revving can destroy an engine by pushing valves into pistons or overspeeding turbo bearings. How 24V Electrical RPM Gauges Function RPM senders on the engine or alternator create pulse signals that your 24-volt tachometer translates into dial readings. This allows operators to keep engines inside manufacturer-specified limits. Protecting Your Equipment On a Detroit Diesel commercial trawler, tachometers ensure you stay below max RPMs hauling nets. Cummins power packs on river dredges use RPM gauges to maintain optimal pump speeds. Caterpillar marine propulsion systems watch RPMs to avoid gearbox overloading. John Deere irrigation setups track engine speed precisely to match water delivery requirements. Your Electrical Backbone Marine and industrial systems are packed with pumps, winches, radar, lights, sensors, and automation gear. Monitoring system voltage and amperage is critical. How They Work Voltmeter: Ties into your 24V battery system to show charge and alternator output levels. Ammeter: Measures flow into and out of batteries, indicating whether you’re drawing more than you’re charging. Engine Brand Examples Detroit Diesel ships rely on 24V systems to crank large engines and power navigation. Cummins engines on remote pumps use voltmeters to monitor alternator health. Caterpillar gensets keep tabs on starting batteries for reliable auto-start. John Deere installations ensure steady voltage to controllers and automated valves. Always Know When to Refuel Large operations mean large tanks — and running out of diesel mid-job can mean lost days. How They Operate A resistive sender inside your tank changes output as fuel height shifts. This signal travels back to your 24-volt gauge, which shows operators exactly how much diesel remains. Why It Matters for Your Engines Detroit Diesel-powered sand dredges stay productive with clear fuel reads. Cummins long-run industrial dewatering operations can plan timely refuels. Caterpillar offshore equipment can’t afford sudden shutdowns from empty tanks. John Deere pumping stations avoid air locks and costly bleed downs. Log Every Hour for Exact Servicing Marine and industrial diesel maintenance schedules revolve around engine hours — not miles. Oil changes, filter swaps, injector checks, and valve lash intervals all hinge on accurate logs. How Electrical Hourmeters Function Wired to ignition or run circuits, these hourmeters tick up only when engines operate, giving you a crystal-clear picture of run time for Detroit Diesel, Cummins, Caterpillar, and John Deere systems. The Most Overlooked (But Crucial) Piece Your 24-volt gauge is only as reliable as its senders and wires. Marine and industrial environments introduce corrosion, vibration, oil, salt spray, mud, and extreme temperatures — all of which can degrade poor wiring. Why Diesel Pro Power Is Different We supply marine- and industrial-grade wiring harnesses, robust connectors, and sender setups that are engineered to survive. Each gauge is precisely matched to the sender’s electrical range, ensuring accurate readings for your exact diesel brand. Avoids misreadings that could falsely show safe oil pressure or miss rising temperatures until it’s too late. Typical Issues Gauge pinned high or low: Usually a sender problem or a corroded ground. No reading: Often a break in the circuit or blown inline fuse. Jumping needle: Can be loose connections or high-resistance corrosion in terminals. Quick Diagnostic Tips Use a multimeter to check voltage at the gauge. Test sender resistance to ensure it matches spec curves. Inspect and clean all connectors, especially in salty or humid marine installs. When your operations rely on Detroit Diesel main engines, Cummins barge pumps, Caterpillar dredgers, or John Deere industrial sets, your gauges are your early warning system. Downtime isn’t just costly — it can be catastrophic. The Diesel Pro Power Difference Orders ship within 24 hours, so your vessel or site stays operational. Warranty-backed gauges built specifically for heavy-duty marine and industrial demands. Secure shopping and seamless logistics worldwide. Technical support from diesel specialists who understand Detroit, Cummins, CAT, and Deere inside and out. Diesel Pro Power carries the industry’s most complete inventory of 24-volt electrical gauges and connection systems for Detroit Diesel, Cummins, Caterpillar, and John Deere engines — all focused on rugged marine and industrial environments. Explore our extensive online catalog or call +1-888-433-4735 (USA) or +1-305-545-5588 (International) to speak with a dedicated diesel expert. See why more than 40,000 marine and industrial customers worldwide trust Diesel Pro Power to keep their operations running safely, efficiently, and profitably.

24V Electrical Gauges for Australia

-

Select Parts Category

Loading...

Loading... 24-Volt Electrical Gauges for Detroit Diesel, Cummins, Caterpillar & John Deere Marine and Industrial Engines

Why 24-Volt Electrical Gauges Are Critical for Heavy-Duty Marine and Industrial Diesel Systems

How 24-Volt Electrical Gauges Work with Diesel Engines

The Diesel Pro Power Advantage: Why Buy 24V Gauges From Us

24-Volt Oil Pressure Gauges for Diesel Engines

24-Volt Water Temperature Gauges to Protect Against Overheating

24-Volt Diesel Engine Tachometers (RPM Gauges)

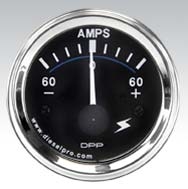

24-Volt Voltmeters and Ammeters for Electrical Health

24-Volt Fuel Level Gauges to Avoid Mid-Operation Shutdowns

24-Volt Hourmeters for Maintenance Schedules

Proper Wiring & Sender Connections for 24-Volt Systems

Common Problems with 24-Volt Electrical Gauges and Troubleshooting Tips

Why Marine & Industrial Operators Trust Diesel Pro Power for 24V Gauges

Find the Right 24-Volt Electrical Gauges for Your Diesel Engines Today

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588