Twin Disc MG 509 Marine Transmission Parts for Australia - Overhaul Plate Kit Section

Loading...

Loading... Twin Disc MG509 Marine Transmission Parts – Overhaul Plate Kit Section

Overview of MG509 Clutch Overhaul Components

The Twin Disc MG509 is a workhorse marine reduction gear that appears across a wide range of commercial and recreational vessels. When service intervals come due—or when a gear starts to show signs of clutch slippage, delayed engagement, overheating, or metallic debris in the oil—the clutch pack and sealing elements are typically the first areas to inspect. That’s where a purpose-built Overhaul Plate Kit for Twin Disc MG509 and the correctly matched Gasket & Seal Kit become mission-critical.

This section explains, in clear and practical terms, what’s included in MG509 overhaul plate kits, how to match the correct shallow-case or deep-case gasket & seal kit to your ratio, how to recognize compatibility by serial/rating data, and what best practices technicians rely on to restore reliable operation. You’ll also find guidance for confirming whether your transmission uses the shallow case ratios (approximately 1.45:1 through 3.38:1) or the deeper case ratios (approximately 3.83:1 through 4.95:1) so you select the correct sealing set the first time. Finally, we include a quick note on the MG509 rubber block used across adjacent MG50x families as a vibration and torsional management component in control linkages or mounts.

Throughout this page, the focus remains tightly on the MG509. While some subcomponents may also appear on related Twin Disc marine gears, your selection here is curated around the MG509 platform so you can source the right plates, gaskets, and seals in one pass.

The MG509 Overhaul Plate Kit: What It Does and Why It Matters

A marine gear’s ability to transfer torque smoothly depends on the condition of its friction and steel plates, their surface finish, and the precise stack height inside each clutch pack. Over time, friction material glazing, thermal hot spots, contamination, and normal wear reduce the coefficient of friction and upset clearances, leading to:

-

Slipping under load (engine RPM climbs but shaft speed lags)

-

Harsh or delayed engagement when shifting from neutral

-

Rattling, chatter, or surge during low-speed maneuvers

-

Elevated oil temperature and discoloration or odor in the gear oil

-

Metallic fines found on the magnetic plug or in filter media

A complete Overhaul Plate Kit for Twin Disc MG509 addresses these issues by refreshing the friction interface with a matched set of components engineered to restore design-intent apply characteristics and heat management. The right kit eliminates guesswork around plate counts, friction material composition, and plate thicknesses that are compatible with MG509 stack tolerances.

What’s Typically Included

While exact contents can vary with clutch design trim and ratio family, a comprehensive MG509 plate kit is organized to cover both forward and reverse clutch assemblies. The typical inclusions are:

-

Friction plates – Manufactured to the correct spline and outside diameter, with a friction material selected for marine duty (oil-cooled, wet-clutch operation).

-

Steel plates (separator plates) – Precision-ground plates that provide the mating surfaces, selected for flatness, hardness, and finish to manage heat and prevent warpage.

-

Apply/cushion plates where applicable – Certain MG509 configurations utilize specialized plates for progressive apply characteristics.

-

Snap rings / retainers as needed – To secure the clutch stack to the designed height and maintain end-play limits.

-

Thrust shims or spacers where required – System-dependent, included when stack height targets call for calibrated spacing elements.

All components are selected to work together as a system—mixing random plate sources or thicknesses can create an overly tight or loose pack, both of which compromise clutch life and shift quality.

Friction Material Considerations

Marine gears like the MG509 operate in a fluid bath that must both lubricate and carry away heat. Friction materials used here are designed to:

-

Maintain stable friction coefficients across a wide temperature window

-

Resist glazing during repeated low-speed docking maneuvers

-

Tolerate momentary overloads without shearing or smearing

-

Provide predictable break-in behavior so shift feel normalizes quickly after service

When you replace friction plates as a full set, you also restore uniformity across the pack—critical for synchronized apply. Partial replacement invites uneven loading and hotspots.

Steel Plate Quality and Finish

Steel separators in a wet clutch are more than simple spacers. Their metallurgy and surface finish determine how heat is absorbed and released with each engagement. MG509 steel plates in a quality kit will be:

-

Flat within tight tolerances to ensure full contact area

-

Heat treated for hardness that resists grooving and distortion

-

Finished with controlled roughness to stabilize oil film thickness and friction material bedding

A matched set of steels prevents one “high” plate from concentrating load and creating premature hot spots.

Matching Your MG509 Ratio and Case Style to the Correct Seal Kit

The MG509 family spans multiple reduction ratios. Those ratios are split into two broad case groups that use different gasket and seal configurations. Selecting the correct sealing kit ensures proper coverage for all interfaces opened during clutch service and prevents reassembly leaks.

Shallow Case: Ratios Approximately 1.45:1 to 3.38:1

For MG509 units in the lower to mid reduction range, the shallow case sealing architecture is used. The Gasket & Seal Kit for MG509 – Shallow Case (≈1.45–3.38) is curated for that housing depth and the shaft/bearing arrangements associated with these ratios. Expect coverage for:

-

Input and output shaft oil seals sized for shallow-case layouts

-

O-rings for clutch piston(s) and hydraulic circuits designed to these ratios

-

Paper/fiber and metal-faced gaskets for housing splits, covers, inspection ports, and pump flanges

-

Selective sealing elements (formed seals, quad-rings) tailored to the shallow case pathing

-

Miscellaneous seals for control valve bodies and external adapter plates found on these models

If your nameplate or service records indicate a ratio like 1.45:1, 1.54:1, 2.00:1, 2.47:1, 3.00:1, or up to 3.38:1, this is typically the correct sealing kit family.

Deep Case: Ratios Approximately 3.83:1 to 4.95:1

Higher reduction MG509 units use a deeper case and may incorporate different geartrain spacing, bearing positions, and shaft seal sizes. The Gasket & Seal Kit for MG509 – Deep Case (≈3.83–4.95) mirrors those differences. Coverage parallels the shallow kit but with sealing diameters, gasket outlines, and counts tuned to the deep-case architecture. If your ratio is 3.83:1, 4.00:1, 4.50:1, up through ~4.95:1, this is the correct path.

Tip: Always validate your case style by ratio and by the transmission identification plate. When in doubt, reference both ratio and serial to eliminate any ambiguity.

How to Confirm MG509 Identity, Ratio, and Case Style

Correct parts start with correct identification. Before ordering an overhaul plate kit or gasket & seal kit, capture the following from the gear’s data plate and inspection:

1) Gear Model

Confirm it states MG509. Adjacent models (MG506, MG507, MG5111, etc.) can look similar in a tight engine room, but small differences in spline counts, plate diameters, or seal sizes make interchange errors costly.

2) Reduction Ratio

Look for the ratio stamped on the nameplate (e.g., 2.00:1, 3.00:1, 4.50:1). The ratio range will point you to shallow or deep case sealing families. If the plate is missing, you may infer the ratio by counting ring and pinion teeth or referencing vessel build documentation. When those aren’t practical, a qualified marine transmission tech can determine ratio by turning input and measuring output revolutions with the shaft uncoupled.

3) Serial Number and Build Code

Twin Disc serials and bill-of-material codes can indicate internal trims, clutch options, or production changes. If you have the serial/build code handy, note it. It can help align exact plate thickness and count, especially across revision updates.

4) Visual Clues

Experienced technicians can often recognize shallow vs deep case by overall housing depth and cover profiles. However, visual judgment can be tricky in crowded compartments. Combine visual cues with the ratio and serial to be certain.

Why Replace Plates and Seals Together

Anytime you break the case plane to re-stack clutches, you should plan to renew seals and gaskets as well. Here’s why the Overhaul Plate Kit and the Gasket & Seal Kit are complementary:

-

Fresh Plates = New Heat Cycles. As friction recovers, the pack can generate higher, more uniform torque. Aged seals hardened by past heat exposure may not tolerate renewed pressure and temperature swings.

-

Eliminate Weeping and Drips. Housing gaskets that were heat-set for years often crack or cold-flow when disturbed. Renewing them is the best insurance against oil weeps after reassembly.

-

Restore Hydraulic Integrity. Clutch piston O-rings and apply circuit seals lose elasticity over time. Replacing them ensures crisp engagement and full clamp load at spec pressures.

-

Avoid Repeat Haul-Outs. A tiny seal saved today can become the leak that forces an unplanned yard visit later. Bundling plates and seals is the most cost-effective approach over the service interval.

Selecting the Right MG509 Overhaul Plate Kit (Forward and Reverse)

Although MG509 clutch architecture is consistent in concept, minor differences in plate counts and thickness can exist between production runs and ratio families. Quality kits are curated to those differences so you don’t need to chase individual counts. To ensure the kit you select is right for your gearbox:

-

Gather the basics: MG509 model, ratio, and serial/build code.

-

Note any prior modifications: Non-OEM plates, spacer deletions, or clutch pack “tuning” done by previous rebuilders can create anomalies.

-

Decide on friction strategy: Standard-duty marine friction is appropriate for most vessels. For high-duty cycles (tow, charter, frequent docking), a heavy-duty friction option may be preferred if available for your trim.

-

Plan the full refresh: Pair the plate kit with the shallow-case or deep-case gasket & seal kit determined by your ratio family.

Installation Planning & Best Practices (Non-Procedural)

While this page avoids step-by-step instructions, a few planning notes help ensure your overhaul produces reliable, repeatable results:

Benchmark Before Disassembly

-

Verify complaint: Slip under load, harsh shift, overheat, abnormal debris.

-

Record pressures and temperatures: Baseline data helps confirm success after reassembly.

-

Oil inspection: Note odor, discoloration, water intrusion, or metallic fines.

Keep Components Organized

-

Forward vs reverse clutch components should be kept separate as you teardown.

-

Note existing stack order and counts before discarding worn plates; photos are invaluable for reference.

-

Measure steels for flatness if re-evaluating any reusable items (many shops replace as a set to avoid mixing).

Use the Correct Fluids

-

Follow the MG509-approved oil spec for friction compatibility and thermal stability. The wrong oil can glaze new plates quickly.

-

Prime oil circuits and clutches during reassembly to reduce dry-start friction.

Verify Controls and Linkage

-

Misadjusted shift cables or electronic controls can mimic clutch faults. Confirm linkage throws and detents match spec after the gearbox is back in place.

Understanding Shallow vs Deep Case Implications

The case depth on MG509 isn’t merely cosmetic. It reflects internal geometry that changes sealing surfaces, shaft positions, and sometimes plate stack allowances. Choosing the right sealing kit for your case depth ensures:

-

All openings you disturb are resealed with the correct outlines and thicknesses

-

Shaft seals match diameters and lip designs for the specific bearing carriers in your housing

-

Apply piston O-rings fit grooves intended for that generation/case style

If your ratio hovers near the boundary between ranges, confirm using serial/build data rather than eyeballing the housing alone.

Troubleshooting Clutch Symptoms Before You Commit to Parts

Clutch slippage is common to several root causes. Before assuming plates alone will solve the issue, consider these quick checks:

-

Hydraulic pressure at the clutch apply port: If low, look for pump wear, relief valve issues, leaks, or clogged strainers.

-

Oil condition: Water or fuel contamination reduces friction dramatically.

-

Overheat history: Repeated thermal overloads can temper steels and damage seals.

-

Control logic: If electronically commanded, ensure the control module isn’t feathering apply pressure abnormally.

-

Input coupling and mounts: Excess torsional vibration can accelerate clutch wear; inspect couplings and the rubber block components in control linkages or mounts where applicable.

These checks help confirm that installing a new overhaul plate kit and gasket & seal set will address the true cause and deliver the expected improvement.

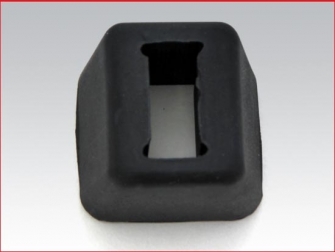

The Role of the MG509 Rubber Block

Listed alongside the MG509 service kits, the rubber block is a small but meaningful element in the broader MG50x ecosystem. Its job is to:

-

Dampen vibration and take up small misalignments in mechanical linkages

-

Reduce chatter transmitted to controls under load transitions

-

Protect brackets and light hardware from cyclic fatigue

While simple, replacing a fatigued rubber block during clutch service is inexpensive insurance against nuisance vibrations and premature wear of control hardware. If you notice cracking, hardening, or permanent set in the rubber, add it to your refresh list.

After the Overhaul: What “Good” Looks Like

Once your MG509 is re-stacked with a fresh plate kit and resealed with the correct gasket & seal kit for your ratio family, you should expect:

-

Clean, decisive engagement from neutral into forward or reverse without flare or bang

-

Stable oil temperatures consistent with your vessel’s duty cycle

-

Predictable low-speed maneuvering without chatter during docking

-

Minimal observable debris on the magnetic plug or in the filter at early oil checks

-

Consistent pressure readings at test ports under spec RPM and load

Plan an early post-service oil & filter inspection after initial sea trials to confirm a healthy break-in. Slight discoloration can be normal as plates bed; significant metallic content or rapid darkening warrants a second look.

Frequently Asked Selection Questions (MG509 Focus)

Do all MG509 units use the same plate counts?

Not necessarily. Plate counts and thickness can vary by ratio and production revision. A curated MG509 overhaul plate kit is built around those variations so you achieve the correct stack height without hunting individual pieces.

I’m at the crossover between 3.38:1 and 3.83:1. Which sealing kit do I choose?

Use your exact stamped ratio and confirm housing style by serial/build code. Ratios up to about 3.38:1 typically align with shallow case, while 3.83:1 and higher align with deep case. When in doubt, validate by serial.

Can I replace only friction plates and reuse steels?

Technically possible, but not recommended unless you can verify steel flatness, hardness, and finish are still within tolerance. Mixed old/new stacks increase the chance of uneven loading and premature glaze.

Is there a “heavy-duty” friction option for high-cycle vessels?

For operations involving frequent docking, towing, or high-load maneuvering, consult for heavy-duty friction availability matched to MG509. If offered for your trim, it can provide longer life under harsh cycles when combined with correct oil and cooling.

Will a gasket & seal kit stop minor sweating at old cover joints?

Yes—assuming the mating surfaces are in good condition. New gaskets, correctly torqued fasteners, and proper surface prep typically eliminate weeps that develop as old gaskets take a set.

Quality, Fitment, and Support You Can Trust

Choosing MG509 overhaul components from a dedicated marine diesel supplier means your kit is purpose-curated—no generic, “almost fits” hardware. Expect:

-

Precisely matched friction and steel plates for MG509 spline/diameter standards

-

Sealing coverage specific to shallow or deep case variants across the full ratio span

-

Consistent QC so pack height and apply characteristics remain within design intent

-

Clear, MG509-specific fitment guidance to avoid return-inducing mismatches

With Diesel Pro Power, you also benefit from a proven track record—40,000+ satisfied customers worldwide who rely on fast fulfillment and application expertise tailored to marine platforms.

Practical Tips for a Smoother MG509 Service Cycle

Plan Your Downtime Window

Scope the service beyond the clutch packs: consider cooler flushing, oil change supplies, control linkage inspection, and new rubber block(s). Consolidating tasks minimizes time off-hire.

Stage the Workspace

Protect coupling surfaces, label hydraulic lines, and cap open circuits to keep debris out. Cleanliness pays dividends in clutch longevity.

Measure What You Can

Even without performing a comprehensive teardown analysis, simple checks—endplay, apply pressure at ports, and gear lash by feel—help flag anomalies before reassembly.

Consider Companion Parts

Depending on inspection findings, common companion items during an MG509 clutch refresh can include:

-

Input coupling hardware (bolts/washers) if corrosion is present

-

Shift control bushings if linkage play is noted

-

Oil cooler gaskets or hoses if age-hardened or weeping

-

Mount isolators if delaminated or oil-soaked

Indicators You Chose the Correct Kit

After you receive your overhaul plate kit and gasket & seal kit, quick visual checks reinforce that you selected correctly:

-

Spline profiles and diameters of friction plates match your clutch hubs

-

Steel plate OD/ID corresponds to your drum geometry without rub risk

-

Seal lip diameters align with measured shafts and carriers for your case style

-

Gasket outlines mirror housing splits and cover profiles on your MG509

If anything seems off, pause and verify ratio and case style again before proceeding.

Environmental & Longevity Considerations

Marine gears operate in environments that are hard on materials: salt air, heat soak, vibration, and variable loads. To extend the life of your MG509 after a clutch refresh:

-

Maintain fluid quality by following change intervals and monitoring for contamination

-

Inspect cooler performance—restricted flow elevates oil temps and accelerates plate degradation

-

Keep alignment within spec—misalignment between engine, gear, and shafting adds heat and shock loads

-

Audit ventilation—engine room heat increases oil temp and attacks elastomers; improving airflow can materially extend seal life

Summary: Your MG509 Refresh, Done Right

An MG509 clutch overhaul is one of the most impactful maintenance actions you can perform on your propulsion system. Selecting a complete Overhaul Plate Kit matched to MG509 and bundling it with the correct Gasket & Seal Kit for your shallow-case (≈1.45–3.38) or deep-case (≈3.83–4.95) ratio ensures the friction interface and hydraulic integrity are both restored. Add a new rubber block where applicable to tame vibration at the margins, and you’ll put your vessel back to work with crisp engagement, steady temperatures, and reliable thrust—day after day.

When you’re ready, have your MG509 model, ratio, and serial/build information at hand. That’s all you need to confidently select the right kits and avoid rework. If questions arise, application-savvy support is here to help confirm the best match for your specific gearbox configuration.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588