MG 507 Twin Disc Marine Transmission Parts for Australia - Overhaul Plate Kit Section

Loading...

Loading... MG507 Twin Disc Marine Transmission Parts — Overhaul Plate Kit Section

This catalog section groups the core clutch, sealing, and related service items most shops stage together when working on Twin Disc MG507 series gears (MG507, MG507-1, and MG507-A). Use it to identify what each component is, what it includes, the symptoms that point to replacement, and practical selection notes so you can order once and complete the repair in a single maintenance window. Sourcing from Diesel Pro Power adds MG507-specific curation, clear specifications, quality components matched for correct stack height and marine-grade compatibility, fast fulfillment to reduce downtime, and the confidence of 40,000+ satisfied customers who trust our consistent fit and long service life.

Overhaul Plate Kit for MG507, MG507-1 & MG507-A

What it is

A complete clutch “plate pack” tailored to the MG507 family. The kit restores the friction interface that transmits engine torque through the gear, bringing back crisp, predictable engagement.

What it includes

A matched set of friction plates and steel separator plates built to the thickness, metallurgy, and surface finish appropriate for MG507 applications. The stack is engineered to achieve the correct total height once installed and pre-lubed, protecting apply pressure and heat management.

Typical symptoms that point to replacement

-

Slip under load: Engine RPM rises without proportional thrust, especially during docking or hard acceleration.

-

Harsh or chattering engagement: Shudder when shifting into gear, often from glazed or heat-checked plates.

-

Overheated oil or burnt odor: Evidence of prolonged micro-slip and thermal stress in the clutch pack.

-

Dark debris in the screen or filter: Fine metallic or friction material indicating active plate wear.

Why it matters

In the MG507, correct coefficient of friction and stack height are essential for torque capacity and temperature control. Running on thinned, warped, or contaminated plates accelerates wear on the drum and hub, risks apply piston damage, and can lead to schedule-killing downtime.

Selection notes

-

Model confirmation: Verify the gearbox tag reads MG507, MG507-1, or MG507-A before ordering. The plate count and thickness are tuned to these models.

-

Duty cycle: Heavy docking, towing, charter, and patrol craft typically benefit from a full plate refresh on a shorter interval than light-duty pleasure applications.

-

Oil plan: If plates show heat spotting, plan for a complete drain, flush, and new filtration to protect the fresh pack.

Installation pointers (at a glance)

-

Measure and record total stack height after soaking the frictions in approved oil.

-

Inspect hub and drum splines for step wear; replace mating hardware that’s out of tolerance.

-

Use a controlled break-in with gentle load cycles to seat the new friction surfaces.

Ring Drive for MG506, MG507 & MG507-1 (SAE #2 Housing)

What it is

The ring drive couples the engine flywheel to the marine gear input, transmitting torque while aligning the rotating group. This unit is specified for installations using an SAE #2 housing and is compatible with MG506, MG507, and MG507-1 where that housing size applies.

What it addresses

-

Rattle or lash noises at idle: Excessive backlash or worn teeth telegraph noise through the driveline.

-

Visible tooth wear or chipping: Accelerated wear can follow repeated shock loads or misalignment.

-

Vibration during engagement: Out-of-true or damaged components can introduce harmonics that shorten clutch life.

Selection notes

-

Confirm SAE housing size and mounting pattern before ordering.

-

Inspect pilot engagement and companion components (fasteners, spacers, alignment dowels) and replace as a set if wear patterns suggest systemic issues.

-

After installation, perform an alignment check; coupling and mount condition influence ring drive life as much as the part itself.

Gasket & Seal Kit for MG507 and MG507-A

What it is

A comprehensive reseal package for MG507-series cases and covers. It’s designed to stop leaks, stabilize operating pressure, and prevent aeration that can mimic clutch problems.

What it includes

Application-correct case gaskets, shaft lip seals, O-rings, and sealing washers for the typical split lines and service interfaces on MG507 and MG507-A units.

Typical symptoms that point to replacement

-

Oil weeping at seams or output: Film on the case or a recurring bilge sheen indicates hardened or compressed seals.

-

Pressure instability or delayed engagement: Tired O-rings can pull air, reducing apply pressure and causing lag into gear.

-

Post-service seepage: Reusing flattened gaskets after a clutch job often leads to weeping once the gear heats and cools.

Why it matters

Correct oil level and pressure are fundamental to clutch life. Resealing during a plate replacement prevents future disassembly, keeps the bilge clean, and supports stable hydraulic performance.

Installation pointers (at a glance)

-

Clean and inspect sealing surfaces; remove old gasket residue without gouging.

-

Lightly pre-lube lip seals and confirm orientation before installation.

-

Follow cross-pattern torque sequences and specs to avoid case distortion and leaks.

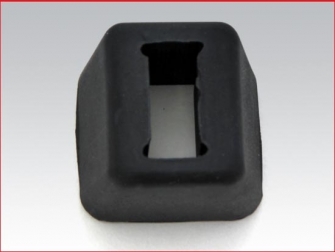

Rubber Block for MG507 Mounting/Isolation

What it is

A high-durometer rubber isolation block used at gear mounting points to control torsional input and damp vibration. Healthy blocks help the gear maintain alignment and reduce noise.

What it fixes

-

New vibration or “buzz” at specific RPM: Flattened or cracked blocks transmit engine harmonics into the hull.

-

Alignment drift: Repeated coupling corrections or unusual wear patterns often trace back to collapsed isolation.

-

Clunk on shift: Excess movement as load transfers forward/aft signals deteriorated mounts.

Selection and service notes

-

Replace in sets to keep the gear level and prevent housing twist.

-

After replacement, re-check alignment warm and under typical onboard loading if feasible.

-

Consider environment: oil exposure and heat cycles shorten rubber life; plan inspection intervals accordingly.

Oil Filter for MG507

What it is

A gear oil filter element sized for MG507 applications. Clean filtration is critical to clutch longevity, especially after a plate change when residual break-in debris is most likely.

When to replace

-

After any clutch service or reseal.

-

When oil analysis shows elevated particulates or when the screen captures noticeable fines.

-

At or before the manufacturer’s recommended service interval for your operating profile.

Best practices

-

Pair filter replacement with a full oil change when installing a new plate pack.

-

Cut the old filter open and inspect; findings help predict future service needs.

-

Keep records of hours, oil type, and service intervals to fine-tune maintenance for your vessel.

Smart Service Bundles for MG507

-

Clutch Refresh: Overhaul Plate Kit + Oil Filter + Oil/Screen Service

Restores torque capacity and engagement quality while protecting the new plates with clean lubrication. -

Leak Stop & Pressure Stabilization: Gasket & Seal Kit + Oil Filter

Eliminates nuisance leaks, supports proper apply pressure, and reduces the chance of aeration-related symptoms. -

Noise & Alignment Tidy-Up: Rubber Blocks + Alignment Check

Quiets the drivetrain, reduces bearing stress, and provides a stable foundation for long clutch life.

Why Buy These MG507 Parts from Diesel Pro Power

-

MG507-specific curation: Parts on this page are selected for the MG507 family to cut out guesswork.

-

Clear, catalog-style specs: Straightforward descriptions help you stage exactly what you need, the first time.

-

Quality you can trust: Frictions, steels, and sealing materials are chosen for correct stack height, durability, and marine compatibility.

-

Fast fulfillment: Streamlined logistics minimize downtime for commercial operators and private owners alike.

-

Proven track record: Trusted by 40,000+ satisfied customers who rely on consistent fit and long service life.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588