Twin Disc MG 514C Marine Transmission Parts for Australia - Overhaul Plate Kit Section

Loading...

Loading... Twin Disc MG-514C Marine Transmission Parts — Overhaul Plate Kit Section

Welcome to the Twin Disc MG-514C Overhaul Plate Kit and related service components catalog—your focused hub for the exact clutch packs, gaskets and seals, ring drive (SAE #1), rubber mount isolators, and oil filter strainer the MG-514C requires. Each item below is presented in a clear, technician-friendly format—what the part is, what it includes, what it fixes, and why Diesel Pro Power is the right source—so you can move from symptom to solution without guesswork. Whether you’re correcting slip, stopping persistent oil weep, eliminating chatter, stabilizing alignment, or restoring hydraulic flow, this page gives you MG-514C-specific parts and practical install pointers that shorten downtime and deliver crisp, repeatable engagement on the first sea trial.

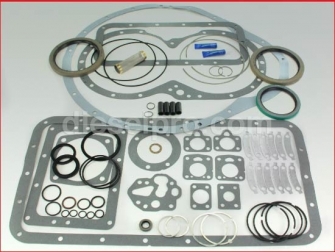

Overhaul Plate Kit for Twin Disc MG-514C

What this part is

A complete clutch pack refresh engineered for the Twin Disc MG-514C. The kit restores smooth, predictable engagement and consistent torque transfer by renewing the friction interface and stack geometry inside the MG-514C clutch assemblies.

What it includes

-

Friction plates engineered to the MG-514C’s operating pressures and thermal loads.

-

Steel separator plates precision-ground for flatness and parallelism to prevent hot spots.

-

Selective shims or setup guidance for achieving the correct clutch pack height.

-

Assembly aids (where applicable) to stage, align, and index the stack during install.

What it fixes

-

Slipping under load when engaging ahead/astern.

-

Slow, harsh, or double-bump engagement due to worn friction surfaces or warped steels.

-

Burnt-odor fluid, dark debris in oil, or glazing traces in the clutch carrier.

-

Unpredictable boat handling during docking caused by inconsistent bite.

MG-514C fitment notes

-

Specified for the MG-514C clutch design, control pressures, and case geometry.

-

Plate count and stack height guidance are aligned to MG-514C service data.

-

Compatible with lubricant types commonly specified for MG-514C marine use.

Service indicators you need this kit

-

RPM flare without corresponding vessel movement as you shift into gear.

-

Heat rise in the gear after repeated maneuvering despite normal oil level.

-

Shudder on pickup or a “grab-release-grab” sensation at low throttle.

-

Metallic or fibrous residue in the strainer after short operating intervals.

Installation highlights

-

Measure as-found pack height prior to teardown; record clearances and counts.

-

Dry-stage the stack to verify order and quantity; then pre-lube all plates.

-

Check directional cues on plates (if present); ensure steels are free of warp.

-

Torque clutch carrier hardware in a star pattern to spec; verify runout.

-

Warm, no-load run-in, then progressive loading with post-run oil and leak checks.

Related MG-514C components to consider during clutch service

-

Gasket & Seal Kit (reseal disturbed covers and bores).

-

Oil Filter Strainer (prevent re-circulation of legacy debris).

-

Ring Drive inspection (address coupling wear that can mimic clutch chatter).

-

Rubber Blocks (mount isolators) to stabilize alignment under torque.

Gasket & Seal Kit for Twin Disc MG-514C

What this part is

A complete reseal solution for the MG-514C. It replaces aged gaskets, O-rings, and shaft seals across cases, covers, and ports to stop weeping and stabilize hydraulic control pressures.

What it includes

-

Form-fit gaskets for inspection and service covers.

-

Lip seals and O-rings for input/output shafts and control interfaces.

-

Port washers (copper/aluminum, where applicable) for service plugs and banjos.

What it fixes

-

Chronic oil film that reappears around covers and perimeters.

-

Aeration/foaming from air ingress at worn seals.

-

Control pressure loss due to internal leakage paths.

-

Messy bilges and contamination risk that can shorten clutch life.

MG-514C fitment notes

-

Profiles, diameters, and thicknesses match MG-514C geometry and tolerances.

-

Materials are selected for marine lubricants and thermal cycling typical of MG-514C duty.

-

Reseal is recommended whenever the case is opened for clutch or coupling work.

Service indicators you need this kit

-

Repeat top-offs with no obvious drip—suggesting misting or seepage.

-

Dampness near input/output areas or selector cover.

-

Oil smear reappears soon after wipe-down or short trials.

Installation highlights

-

Remove old gasket residue without gouging aluminum faces.

-

Lightly oil seal lips; use guide sleeves to protect against spline nicks.

-

Seat and torque port fittings on clean, burr-free faces; confirm crush washer conformity.

-

Pressure or run test after reseal; reinspect perimeters and rotating shafts.

Related MG-514C components to consider

-

Overhaul Plate Kit (fresh clutches + fresh seals = best results).

-

Oil Filter Strainer (capture debris dislodged during service).

-

Approved lubricant per MG-514C guidance after a full reseal.

Ring Drive (SAE #1) for Twin Disc MG-514C

What this part is

A heavy-duty SAE #1 input coupling that mates your engine flywheel to the MG-514C input, preserving alignment and smoothing torsional loads across the driveline.

What it includes

-

SAE #1 pattern ring/coupling with precision-machined register and pilot.

-

Mounting hardware appropriate for common marine flywheel patterns (verify yours).

-

Concentricity and balance controls to minimize vibration.

What it fixes

-

Clutch chatter or squeal caused by coupling runout or fretting.

-

Premature input seal wear from minor misalignment at the bellhousing.

-

Ringing/knock at specific RPM, indicative of torsional resonance issues.

-

Erratic engagement feel despite fresh clutches and correct oil.

MG-514C fitment notes

-

Sized and registered for SAE #1 bellhousing configurations found on MG-514C installs.

-

Interfaces with the MG-514C input shaft and pilot; verify pilot bore and bolt circle against your engine build sheet.

Service indicators you need this part

-

Visible fretting or shiny dust near the coupling joint.

-

Persistent chatter after clutch renewal and alignment checks.

-

Repeat input seal failures that track with vibration symptoms.

Installation highlights

-

Dial-indicate bellhousing and coupling; correct runout before final torque.

-

Use new fasteners and follow a cross-torque pattern; apply thread locker if specified.

-

Recheck alignment after the first warm run as mounts settle.

Related MG-514C components to consider

-

Rubber Blocks (mount isolators) for alignment stability.

-

Gasket & Seal Kit if the gear was opened during coupling work.

-

Overhaul Plate Kit if coupling issues have caused plate glazing.

Rubber Block (Mount Isolator) for Twin Disc MG-514C Installations

What this part is

A vibration-damping isolator used to support and stabilize the MG-514C and adjacent drivetrain components, reducing shock transfer and helping long-term alignment hold.

What it includes

-

High-durometer marine-grade elastomer designed for compression and shear loads.

-

Bonded or captured interfaces (design varies) for secure mounting and repeatable preload.

What it fixes

-

Persistent cabin or deck vibration at cruise or specific RPM bands.

-

Alignment drift that returns after seemingly perfect shaft alignment.

-

Premature wear on couplings, seals, and bearings from hard mounting.

-

Structure-borne noise that travels through stringers or hull.

MG-514C fitment notes

-

Selected by load, footprint, and geometry appropriate for MG-514C installations.

-

Supports thrust and torque reactions typical of MG-514C service envelopes.

Service indicators you need this part

-

Compression set, cracks, or delamination visible on existing mounts.

-

Hard knock or bump when shifting from neutral into gear.

-

Vibration that worsens under load but eases off-throttle.

Installation highlights

-

Replace in matched sets to keep support heights equal.

-

Re-align engine and gear afterward; verify face and bore readings at the coupling.

-

Re-torque after initial operating hours as elastomer settles.

Related MG-514C components to consider

-

Ring Drive (alignment-sensitive).

-

Gasket & Seal Kit if seal lips have been stressed by misalignment.

-

Oil Filter Strainer inspection after any alignment-related teardown.

Oil Filter Strainer for Twin Disc MG-514C

What this part is

A serviceable strainer assembly sized to MG-514C flow requirements that captures particulate before it reaches hydraulic circuits and clutch packs.

What it includes

-

Strainer body and mesh area calibrated to MG-514C flow and pressure targets.

-

Sealing elements to prevent bypass or suction leaks at the housing.

-

Service cap or access feature for periodic cleaning (design varies).

What it fixes

-

Low pressure events from restricted flow through a clogged or damaged screen.

-

Re-circulation of debris that accelerates wear on fresh clutches.

-

Intermittent engagement anomalies due to aeration or pressure dips.

MG-514C fitment notes

-

Footprint and dimensions support direct service on MG-514C housings.

-

Always refresh or thoroughly clean the strainer after clutch or reseal work.

Service indicators you need this part

-

Dark, gritty oil even after a recent change.

-

Sluggish shift response without external leaks or control faults.

-

Recurring alarms tied to flow or pressure during longer passages.

Installation highlights

-

Clean the cavity meticulously; do not push debris into feed passages.

-

Inspect mesh integrity; replace if dented, torn, or deformed.

-

Prime with clean oil; confirm leak-free operation and pressure stability.

-

Adopt an early first service interval post-overhaul to trap residual debris.

Related MG-514C components to consider

-

Overhaul Plate Kit (new clutches deserve clean filtration).

-

Gasket & Seal Kit (if housing seals were disturbed).

-

Approved oil meeting MG-514C recommendations.

MG-514C Troubleshooting by Symptom (Quick Catalog Guide)

Slipping on engagement — Start with Overhaul Plate Kit, then inspect Oil Filter Strainer, confirm control pressure and oil spec.

Repeat oil film or misting — Install Gasket & Seal Kit, verify case vents and surface finish.

Chatter or torsional vibration — Inspect Ring Drive, confirm bellhousing runout, review Rubber Blocks and alignment.

Low or erratic pressure — Service Oil Filter Strainer, verify pickup and screen, then reseal with Gasket & Seal Kit if needed.

Alignment won’t hold — Replace Rubber Blocks, realign, then re-evaluate coupling face/bore readings.

MG-514C Service Workflow (Best-Practice Sequence)

Baseline: Record oil level/condition, control pressure, case temperature, engagement feel, and noise/vibration notes.

Teardown plan: If clutch service is planned, pre-order the Overhaul Plate Kit, Gasket & Seal Kit, and Oil Filter Strainer to complete the job in one window.

Execution:

-

Reseal disturbed covers/bores with the Gasket & Seal Kit.

-

Install the Overhaul Plate Kit following stack order and pack height specs.

-

Clean/replace the Oil Filter Strainer; refill with approved oil.

-

Inspect Ring Drive and Rubber Blocks; correct any alignment contributors.

Commissioning: Warm idle, neutral checks, light engagements both directions, then controlled harbor trial with post-run inspections.

Documentation: Save clearances, torques, and pressure readings for future reference.

MG-514C Selection & Ordering Checklist

Identify the gear: Confirm MG-514C on the data plate (model and ratio).

Match symptoms to parts:

-

Slipping/heat → Overhaul Plate Kit + strainer service.

-

Weeping/aeration → Gasket & Seal Kit.

-

Chatter/vibration → Ring Drive + Rubber Blocks + alignment check.

-

Pressure alarms/debris → Oil Filter Strainer replacement/cleaning.

Plan the window: Order all interdependent items together to minimize downtime.

Aftercare: Early oil and strainer service after the first hours of operation.

Additional resources (you can link your articles here)

-

MG-514C Clutch Inspection Photo Guide

-

MG-514C Reseal Walkthrough

-

MG-514C Pressure & Flow Diagnostics

-

Marine Driveline Alignment Basics (MG-514C Focus)

-

Choosing Oil for the MG-514C

Why Buy These Parts from Diesel Pro Power

Purpose-Built Coverage for the MG-514C

Focused fit for your exact gear

Every component above is curated and described exclusively for the Twin Disc MG-514C. You’ll find specifications, installation pointers, and symptom-to-solution guidance written for the MG-514C’s case geometry, clutch design, and service routines—so you can select confidently without sifting through unrelated models.

Consistency and compatibility

By pairing the Overhaul Plate Kit, Gasket & Seal Kit, Oil Filter Strainer, Ring Drive, and Rubber Blocks from one knowledgeable source, you reduce mismatch risk and ensure that sealing materials, plate thickness, filtration area, and coupling geometry complement the MG-514C as a system.

Proven Reliability and Marine-Ready Inventory

Parts you can put to work

Diesel Pro Power supplies marine-grade components ready for the MG-514C duty cycle—built to handle heat, load reversals, docking maneuvers, and long passages. Our selection emphasizes flat, parallel steels; clutch materials matched to MG-514C control pressures; seal elastomers that tolerate marine oils and temperature swings; and strainers with the flow area the MG-514C requires.

Quality you can measure

We emphasize fit, finish, and repeatability. Plate flatness, seal lip conformity, and coupling concentricity aren’t marketing terms—they’re the difference between a crisp engagement and a weekend lost to troubleshooting.

Expert Guidance that Speaks “MG-514C”

Catalog clarity, technician-level detail

Our product pages and support content are structured for the MG-514C specifically, so your crew can move from symptom to shortlist to purchase in minutes. Need help interpreting clutch pack height, coupling runout, or seal orientation? We map those critical points directly to the MG-514C so you’re not guessing.

Real-world install pointers

From dry-staging clutch stacks to dial-indicating the bellhousing, our notes are written for hands that turn wrenches. That means fewer surprises during teardown and a cleaner startup sequence when the vessel returns to service.

Rapid Fulfillment, Straightforward Support

Streamlined ordering

We keep the MG-514C essentials organized so you can order the overhaul kit, reseal set, strainer, coupling, and mounts together—shortening the maintenance window and limiting repeat haul-outs.

No-nonsense follow-through

If something isn’t right, our support focuses on resolution, not runaround. We’ll walk through your symptoms, verify selections, and make it right.

Trusted by a Large Customer Base

Confidence backed by scale

Diesel Pro Power has served 40,000+ satisfied customers, including commercial fleets, shipyards, and operators who rely on clear, accurate MG-514C guidance and dependable parts.

Bottom Line for MG-514C Owners

Fewer variables. Faster turnarounds. Better outcomes.

Choose MG-514C-specific overhaul and service components, apply technician-ready guidance, and complete your maintenance window with confidence. Diesel Pro Power brings the parts, the clarity, and the experience to keep your Twin Disc MG-514C engaging cleanly and running strong.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588