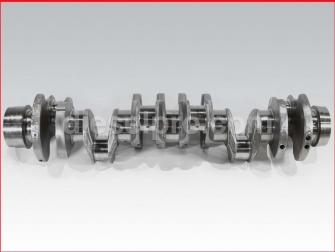

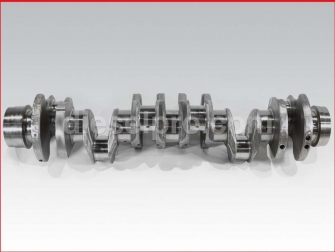

Parts for Caterpillar 3406E for Canada - Crankshaft Section

Loading...

Loading... Parts for Caterpillar 3406E – Crankshaft Section

The Caterpillar 3406E engine is one of the most trusted heavy-duty diesel platforms ever built, powering trucks, marine vessels, construction equipment, and industrial machines across the globe. At the heart of this legendary engine lies the crankshaft—an essential rotating assembly that transforms the linear force of piston movement into rotational torque. Without a healthy, properly balanced crankshaft, the 3406E cannot deliver the horsepower, durability, or fuel efficiency that operators expect.

Diesel Pro Power provides a complete range of aftermarket replacement crankshaft components for the Caterpillar 3406E and other 3400-series engines. From new crankshafts in both wide and narrow bearing designs to main bearings, thrust washers, dampers, gears, dowel pins, and crankshaft seals, our catalog is organized to give operators every component required for a top-tier rebuild.

The Role of the Crankshaft in the Caterpillar 3406E Engine

The crankshaft is more than just a rotating piece of forged steel—it is the backbone of the engine’s power delivery. In the 3406E:

-

Conversion of Energy – As pistons travel downward under combustion, connecting rods transmit force to the crankshaft journals, which convert that linear energy into torque.

-

Synchronization of Engine Timing – The crankshaft works in tandem with the camshaft and timing gear train to keep valve events and injection cycles precisely aligned.

-

Balance and Smoothness – A properly balanced crankshaft prevents harmful vibration, reduces stress on bearings, and ensures even power delivery across all cylinders.

-

Durability in Heavy Duty Use – Caterpillar engines are designed for high-load applications; the crankshaft must endure millions of cycles while resisting fatigue, wear, and torsional stress.

A compromised crankshaft or related component—whether from wear, improper lubrication, or imbalance—can result in catastrophic engine failure. That’s why rebuilding with quality crankshaft parts is crucial.

Crankshaft Options for Caterpillar 3406E

New Crankshaft – Wide Bearing Design

The wide bearing version is engineered to distribute load over a larger surface area. This reduces wear on journals, helps maintain oil film integrity, and enhances overall service life. It is favored in high-duty cycles such as over-the-road trucking, mining, and marine propulsion, where continuous load and long operating hours demand maximum durability.

New Crankshaft – Narrow Bearing Design

The narrow bearing version is lighter and allows for reduced internal friction. It is often selected for applications prioritizing fuel efficiency and quicker revving response. While still highly durable, the narrow bearing design may offer a performance advantage in certain industrial engines where weight and rotational inertia are critical considerations.

Main Bearings for Caterpillar 3406E

Main bearings support the crankshaft inside the engine block. They prevent direct metal-to-metal contact and allow the crankshaft to rotate freely under heavy load. Diesel Pro Power offers a full range of main bearing sizes, ensuring a precise fit for any rebuild scenario:

-

Standard Size Bearings – Ideal when journals remain within factory tolerance.

-

Oversized Bearings (.010, .025, .050) – Designed for use after crankshaft journals are ground undersize during machining. Oversized bearings restore correct oil clearance and maintain pressure balance across all mains.

Using the proper main bearing size is essential for longevity. Installing a bearing with too much clearance leads to oil pressure loss, while too little clearance risks overheating and seizure.

Thrust Washers for Crankshaft Endplay

The crankshaft must not only rotate smoothly but also remain within a specified range of axial movement (endplay). Thrust washers provide the necessary control, preventing the crankshaft from shifting forward or backward under heavy load. Without properly functioning thrust washers, premature wear on the block and transmission components can occur.

In the Caterpillar 3406E, two thrust washers are used per engine, working in tandem with main bearings to stabilize axial loads.

Vibration Damper – Protecting Against Harmful Oscillation

Torsional vibration is a hidden threat to any diesel crankshaft. Each combustion event sends shock waves through the crankshaft, and over time, these pulses can cause fatigue cracks, keyway damage, or outright failure. The vibration damper (also called a harmonic balancer) absorbs and neutralizes these oscillations.

By maintaining crankshaft stability, the vibration damper:

-

Prevents main bearing wear

-

Extends crankshaft life

-

Reduces gear train noise

-

Ensures smoother engine operation

Operators rebuilding a 3406E should never overlook the vibration damper. Replacing it alongside the crankshaft and bearings ensures long-term reliability.

Crankshaft Gears and Dowel Pins

Crankshaft Gear

The gear affixed to the front of the crankshaft is a vital component of the engine’s timing assembly. With its precisely machined teeth, it drives the camshaft gear and ensures perfect synchronization of valve timing and fuel injection events. A worn or damaged gear can lead to misalignment, noise, or catastrophic engine timing issues.

Dowel Pin

Small but critical, the dowel pin ensures that the crankshaft gear is properly aligned on the shaft. Without a secure dowel, even the strongest crankshaft gear can slip, leading to timing failure. This inexpensive part is an insurance policy against major downtime.

Crankshaft Seals – Front and Rear

The crankshaft must pass through the front and rear covers of the engine block. At these exit points, specialized seals prevent oil leakage.

-

Front Crankshaft Seal – Maintains a tight seal between the rotating crankshaft nose and the timing cover.

-

Rear Crankshaft Seal – Protects the flywheel side of the crankshaft, ensuring oil stays inside the block and away from the clutch or transmission.

Oil leaks at either end can quickly lead to low oil levels, clutch contamination, or environmental hazards. Replacing seals during every major rebuild is strongly recommended.

Why Choose Diesel Pro Power for Caterpillar 3406E Crankshaft Parts

Trusted by 40,000+ Customers Worldwide

Diesel Pro Power has earned the confidence of more than 40,000 satisfied customers across 180+ countries. From long-haul trucking companies to ship captains navigating global trade routes, operators rely on us for dependable parts that keep their Caterpillar 3406E engines running at peak performance. Our reputation is built on consistency, service, and a proven track record of delivering the right parts, on time, to the people who need them most.

Premium Aftermarket Quality

Every crankshaft, bearing, thrust washer, seal, and gear we supply is built to meet or exceed Caterpillar performance requirements. This ensures that each part offers proper fit, durability, and compatibility with the 3406E platform. Our strict quality standards mean you can rebuild your engine with confidence, knowing that components will withstand the stresses of heavy-duty use in trucking, marine, construction, and industrial environments. By choosing Diesel Pro Power, you are investing in components designed for long-term service life and reduced maintenance costs.

Fast Worldwide Shipping

Downtime is the enemy of productivity. A grounded truck, stalled excavator, or idle generator can result in lost revenue and missed deadlines. That’s why Diesel Pro Power prioritizes rapid order processing and expedited global delivery. Whether your Caterpillar engine is powering equipment in North America, a vessel in South America, or an industrial plant in Asia, we ship quickly and efficiently to minimize costly delays. Our logistics expertise ensures that parts arrive on schedule—no matter how remote your operation may be.

Dedicated Caterpillar 3406E Catalog

Our Caterpillar 3406E catalog is carefully organized by engine system and component type, eliminating the frustration of sifting through unrelated parts. Need a wide-bearing crankshaft? Searching for an oversize bearing set? Looking for a replacement vibration damper? Our streamlined catalog design makes locating the right component fast and simple. This saves operators valuable time and reduces the risk of ordering errors, ensuring you get the exact parts your rebuild requires.

Expert Technical Support

Rebuilding a Caterpillar 3406E engine often involves critical decisions—selecting between wide or narrow bearing crankshafts, verifying main bearing clearances, or determining the best practices for installing seals and dampers. Diesel Pro Power’s expert support team is here to help. With decades of combined experience in diesel engines, our specialists can provide guidance on measurement, installation, and component selection. This hands-on support helps operators avoid costly mistakes, extend engine life, and ensure that rebuild projects are completed smoothly and successfully.

The Diesel Pro Power Advantage

Choosing Diesel Pro Power means more than just buying parts—it means partnering with a supplier dedicated to keeping your engines running. Our combination of global reach, premium aftermarket quality, fast shipping, organized catalog design, and expert technical support gives operators a clear advantage. Whether you manage a single truck or a global fleet of marine vessels, you can depend on Diesel Pro Power to deliver reliability, efficiency, and peace of mind with every order.

Applications of the Caterpillar 3406E Crankshaft Assembly

The 3406E engine powers some of the hardest-working machines in the world. The crankshaft components provided by Diesel Pro Power are relied upon in:

-

On-Highway Trucks – Freight haulers, logging trucks, and vocational vehicles depend on crankshaft durability for long miles between rebuilds.

-

Marine Engines – Commercial vessels, tugboats, and fishing fleets require stable torque delivery and vibration-free operation.

-

Construction Equipment – Bulldozers, excavators, and loaders rely on smooth crankshaft function to deliver power under variable load.

-

Industrial Power Units – Generators, compressors, and pumps powered by the 3406E depend on crankshaft reliability for continuous uptime.

Best Practices for Replacing or Servicing a 3406E Crankshaft

-

Measure Journal Wear – Always use micrometers to check for taper or out-of-round conditions.

-

Match Bearings Correctly – Use standard bearings for in-spec journals and oversized bearings after machining.

-

Check Endplay – Verify thrust washers are controlling axial movement within factory specifications.

-

Inspect Vibration Damper – Replace if worn or if the rubber isolator shows signs of cracking.

-

Renew Seals – Always install new front and rear crankshaft seals during major service.

-

Balance the Assembly – Proper dynamic balancing reduces stress on bearings and prolongs life.

Long-Term Value of Using Quality Crankshaft Parts

Investing in high-quality crankshaft components during a rebuild pays dividends:

-

Extended Engine Life – Proper bearings and seals prevent premature wear.

-

Reduced Downtime – Reliable parts minimize the risk of mid-operation failure.

-

Improved Efficiency – Balanced and sealed crankshafts maintain fuel economy.

-

Lower Total Cost of Ownership – Spending on quality upfront reduces the frequency of overhauls.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588