Parts for Caterpillar 3412B for Canada - Cylinder Head Section

Loading...

Loading... Caterpillar 3412B Cylinder Head Parts Catalog

The Caterpillar 3412B engine is a legendary V12 powerhouse, trusted across marine, industrial, and power generation applications. At the heart of this engine lies its cylinder head system—a complex assembly that regulates airflow, combustion, and exhaust. Maintaining this system with genuine, high-quality replacement parts is essential for reliability, efficiency, and engine longevity.

This catalog covers cylinder heads, gasket sets, valves, springs, push rods, lifters, and all associated hardware designed for the Caterpillar 3412B engine. While some components overlap with 3412, 3412C, and even 3408 models, the emphasis here is on the 3412B platform.

Cylinder Heads for Caterpillar 3412B

Bare Cylinder Heads

The bare cylinder head for the Caterpillar 3412B is supplied without valves or springs. This option is ideal for rebuilds where existing hardware is still serviceable, or when an engine specialist prefers to install custom or upgraded valve components. Precision machining ensures perfect sealing surfaces, durability under high compression, and compatibility with Caterpillar’s demanding specifications.

Assembled Cylinder Heads

For a faster turnaround, fully assembled cylinder heads are available with valves, springs, and retainers pre-installed. These are ready-to-install units designed to minimize downtime, a critical factor in marine or industrial operations where lost hours equal lost revenue. Each head is engineered to withstand high operating pressures and extreme thermal cycling, ensuring long service life even under continuous duty.

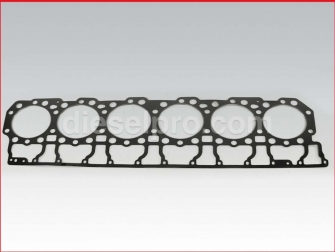

Cylinder Head Gasket Sets

Complete Gasket Sets

Every 3412B rebuild requires new gaskets to maintain compression and prevent coolant or oil leaks. The cylinder head gasket set is designed to cover both heads of the V12 configuration. These gaskets are multi-layered and engineered for heat resistance, pressure retention, and long-term reliability.

Serial Number Coverage

The gasket sets for the 3412B are matched to specific serial number prefixes including 3JK, 7BL, 7HG, 9KS, and 9PW. Ensuring serial number compatibility is essential to prevent mismatches that could compromise sealing integrity or performance.

Head Bolts and Washers

Heavy-Duty Head Bolts

The cylinder head bolts secure the head to the engine block, maintaining the clamping force necessary for consistent compression. The 3412B uses precision-threaded bolts capable of withstanding immense thermal expansion and contraction cycles. Proper torque sequencing is vital, and replacement bolts are strongly recommended during any rebuild to ensure maximum sealing.

Head Bolt Washers

Washers distribute clamping loads evenly across the cylinder head surface. Using fresh washers prevents uneven tightening, head warping, or premature gasket failure. Caterpillar specifies hardened washers designed to resist deformation even under the extreme loads of the 3412B.

Valves and Related Components

Intake Valves

The intake valves control airflow into the combustion chambers. For the 3412B, intake valves are precision-ground for maximum airflow, seating accuracy, and heat resistance. Caterpillar offers intake valves specific to certain arrangement numbers, ensuring proper fitment across the diverse range of 3412B configurations.

Exhaust Valves

Exhaust valves endure some of the harshest operating conditions within the engine, exposed to extreme heat and corrosive exhaust gases. Replacement exhaust valves for the 3412B are manufactured with hardened faces and high-temperature alloys, ensuring long-term durability.

Rotocoils

Rotocoils (or rotators) are critical in extending valve life by rotating the valve slightly with each opening and closing cycle. This prevents uneven wear, improves seating, and reduces the risk of hot spots. For the 3412B, rotocoils are used on both intake and exhaust valves.

Valve Guides

Valve guides keep the valve stems aligned, ensuring smooth operation and minimal wear. For the 3412B, intake and exhaust valve guides are engineered to withstand constant lubrication flow and thermal stress. Worn guides can cause oil leakage into the combustion chamber, leading to excessive smoke and oil consumption.

Valve Guide Oil Shields

These small yet vital components prevent oil from leaking past the valve guides into the combustion chamber. Oil shields extend valve life and ensure proper combustion by preventing contamination of the air-fuel mixture.

Valve Seats and Inserts

Valve inserts provide hardened surfaces for intake and exhaust valves to seat against. In high-duty applications like marine propulsion or continuous power generation, these inserts must resist both mechanical pounding and thermal cracking.

Valve Springs and Locks

Valve Springs

Valve springs are responsible for returning the valves to their closed position under high-speed operation. The springs in the 3412B are built for durability under high RPMs and extended continuous operation. Weak or fatigued springs can lead to valve float, poor combustion, or catastrophic piston-valve contact.

Valve Locks

Valve locks (or keepers) secure the valve spring retainer to the valve stem. Although small, they are critical in preventing valve train failure. Every valve in the 3412B requires two locks, making it important to replace them whenever valves or springs are serviced.

Head Gaskets and Sealing Components

Cylinder Head Gaskets

Each 3412B engine requires two head gaskets—one for each bank of the V12 configuration. These gaskets are designed to seal combustion pressures while also preventing cross-contamination of coolant and oil. Modern gasket materials ensure excellent heat resistance and long-term sealing reliability.

Precombustion Chamber Gaskets

Precombustion chamber gaskets ensure a tight seal between the chamber and the head. These small gaskets are vital for maintaining proper combustion dynamics and preventing compression leakage.

Adaptor Nozzles and O-Rings

Adaptor nozzles connect the fuel injection system to the cylinder head, delivering precise fuel spray into the chamber. O-rings are used to seal the nozzle adaptors, preventing fuel or compression leaks. These seals should always be replaced during rebuilds.

Valve Train Components

Push Rods

Push rods transfer motion from the camshaft and lifters to the rocker arms, ultimately actuating the valves. Caterpillar 3412B push rods are built from hardened steel tubing, capable of withstanding the high stresses of industrial operation.

Valve Lifters

Valve lifters (or tappets) ride on the camshaft lobes, transmitting motion to the push rods. In the 3412B, these lifters must operate smoothly to prevent camshaft wear and maintain precise valve timing.

Cylinder Head System Reliability

Maintaining the cylinder head system in peak condition is critical for the Caterpillar 3412B engine. A failing valve, a cracked gasket, or a stretched bolt can lead to significant downtime and costly repairs. Routine inspections during scheduled overhauls should include:

-

Measuring valve stem wear

-

Checking spring pressure and height

-

Inspecting head surface flatness

-

Replacing all sealing gaskets

-

Verifying torque on head bolts

By replacing these components with high-quality parts, operators ensure that their 3412B engines deliver maximum power, efficiency, and reliability.

Applications of Caterpillar 3412B Cylinder Head Parts

The Caterpillar 3412B is used in a wide range of demanding environments, including:

-

Marine propulsion and auxiliary engines – commercial vessels, workboats, and fishing fleets

-

Power generation – diesel generator sets for prime and standby power

-

Industrial applications – pumps, compressors, and heavy-duty machinery

-

Oilfield and mining equipment – continuous-duty operations requiring uncompromising durability

The cylinder head components in this catalog are specifically tailored for these tough environments, where downtime is not an option.

Why Choose Diesel Pro Power for Caterpillar 3412B Cylinder Head Parts

Selecting the right supplier for your Caterpillar 3412B parts is as critical as the parts themselves. Diesel Pro Power is trusted by operators worldwide because we deliver:

-

Global Reach – Fast shipping to over 180 countries.

-

Proven Reliability – More than 40,000 satisfied customers worldwide.

-

Complete Catalog – From full cylinder heads to the smallest valve lock, all in one place.

-

Specialization – Exclusive focus on marine and industrial diesel engines, not automotive.

-

Expert Support – Our team helps match heads, gaskets, and valves to your arrangement number or serial prefix.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588