Cummins 6C Engine Parts for Canada - Crankshaft Section

Loading...

Loading... Cummins 6C Engine Parts – Crankshaft Section

The crankshaft is the foundation of the Cummins 6C’s power delivery system, responsible for translating the vertical motion of the pistons into smooth, rotational torque that drives marine propellers or industrial machinery. In heavy-duty environments, from ocean-going vessels to stationary power units, the crankshaft must endure constant stress, high combustion forces, and varying loads. Maintaining this component, along with its bearings, seals, dampers, and associated gaskets, is critical to preserving engine health, performance, and longevity.

At Diesel Pro Power, we offer a complete selection of Cummins 6C crankshaft parts engineered to meet or exceed original specifications. Every item is selected for durability in challenging marine and industrial environments, ensuring reliability in high-humidity, high-load, and continuous-duty operations.

New Crankshaft Assemblies for Cummins 6C

Cummins 6C Crankshaft – Standard Marine & Industrial Configuration

Our new Cummins 6C crankshaft assembly is engineered for precise fit and long-lasting performance in marine propulsion and stationary industrial applications. Each unit is manufactured to match the exact dimensions and journal specifications of the Cummins 6C engine block, ensuring correct alignment, smooth rotation, and dependable power delivery under demanding operating conditions.

Every crankshaft is machined with strict tolerances and then dynamically balanced to OEM specifications to help reduce vibration throughout the powertrain. This balancing not only improves operator comfort but also reduces stress on main bearings, connecting rods, and gear trains. Journal surfaces are prepared for consistent contact with the bearings, promoting a stable oil film and reducing the risk of scoring or premature wear.

Key Features:

-

Manufactured to precise Cummins 6C specifications for proper fit and function

-

Journal surfaces treated for durability and extended service life

-

Dynamic balancing for smoother operation and reduced vibration

-

Protective finish suitable for marine and industrial operating environments

This crankshaft is an ideal choice for replacing an original component damaged by bearing failure, lubrication issues, or mechanical impact. When installed correctly, it helps restore the Cummins 6C’s smooth operation, fuel efficiency, and torque delivery.

Cummins 6C Crankshaft – CM-Compatible Configuration

This Cummins 6C crankshaft is designed for engines that incorporate certain advanced control setups often found in marine and industrial installations. While it shares the same dimensional accuracy, journal preparation, and balancing process as the standard configuration, it includes specific machining details that allow it to integrate with specialized control and sensor arrangements.

The journals are finished to provide stable and consistent bearing support, while the overall balancing process helps minimize torsional vibration. These qualities are important in applications where sensitive monitoring equipment depends on accurate rotational signals from the crankshaft. A protective exterior coating helps guard against environmental factors such as humidity, salt air, and extended storage conditions.

Applications:

-

Commercial fishing vessels that require steady torque output for long periods

-

Harbor workboats that experience frequent load changes and extended idle time

-

Industrial pumping stations operating under continuous duty

-

Standby and prime power generation units where reliability and smoothness are essential

This configuration is a strong choice for Cummins 6C owners operating in electronically monitored systems where crankshaft precision plays a direct role in performance and operational stability.

Gasket Sets for Cummins 6C Crankshaft Service

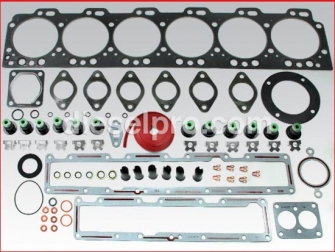

Upper Gasket Set – Cummins 6C

The upper gasket set provides all the top-end seals required when servicing the crankshaft alongside major engine work such as head removal. It includes cylinder head gaskets, intake and exhaust manifold gaskets, valve cover gaskets, and other seals.

Benefits:

-

Maintains combustion pressure

-

Prevents coolant and oil leaks from the top end

-

Designed to handle high-heat marine environments

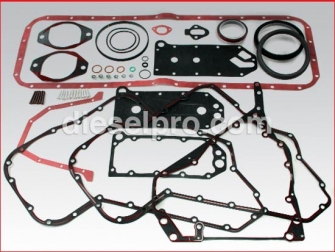

Lower Gasket Set – Cummins 6C

The lower gasket set covers all sealing points in the crankshaft and bottom-end area. It includes oil pan gaskets, timing cover gaskets, and lower crank seals.

Benefits:

-

Prevents oil leaks and contamination

-

Withstands continuous heavy-load operation

-

Essential when removing or replacing the crankshaft

Crankshaft Bearings for Cummins 6C

Standard Size Crankshaft Bearing Set

For crankshafts within OEM journal specifications, these standard-size bearings provide a precise oil clearance, supporting smooth rotation and protecting against wear.

Features:

-

Tri-metal or bi-metal bearing construction

-

Includes both upper and lower shells

-

Optimized for high-load marine operation

Oversize 0.25 mm Crankshaft Bearing Set

For crankshafts that have been lightly reground to the first undersize specification, this bearing set restores proper oil clearance.

Benefits:

-

Precision machining for reconditioned journals

-

Prevents metal-to-metal contact under load

Oversize 0.50 mm Crankshaft Bearing Set

For crankshafts that have undergone a heavier regrind due to significant wear, the 0.50 mm oversize set maintains oil film integrity even under high load.

Benefits:

-

Provides correct clearance after heavy reconditioning

-

Ideal for older marine and industrial 6C engines undergoing major rebuilds

Crankshaft Seals for Cummins 6C

Front Crankshaft Seal Kit

Includes a high-durability front seal and wear sleeve to keep oil inside the engine where the crankshaft exits the timing cover.

Benefits:

-

Protects against oil leaks in marine humidity

-

Long-life elastomer for extended service intervals

Front Crankshaft Seal Kit – Marine/Industrial Specification

A variation of the front seal kit engineered specifically for marine and industrial use, with sealing materials resistant to saltwater exposure and high-RPM continuous operation.

Rear Crankshaft Seal Kit

Seals the crankshaft at the flywheel end to prevent oil leakage into the bellhousing.

Benefits:

-

Includes seal and wear sleeve

-

Protects clutch and marine transmission components from oil contamination

Rear Crankshaft Seal Kit – Dry Clutch

Designed for Cummins 6C engines connected to dry clutch housings, preventing oil intrusion into the clutch mechanism.

Rear Crankshaft Seal Kit – Wet Clutch

For 6C engines paired with marine gear wet clutch systems, this seal features a double-lip design for maximum oil retention and protection.

Vibration Dampers for Cummins 6C

9.67" Outside Diameter Damper

A heavy-duty harmonic balancer engineered to absorb torsional vibrations and prevent damage to the crankshaft and bearings.

Features:

-

Four-bolt mounting

-

Ideal for higher-horsepower marine configurations

8.97" Outside Diameter Damper

A slightly smaller damper, suitable for mid-range power setups where reduced rotational mass is beneficial.

Features:

-

Four-bolt mounting

-

Optimized for certain marine propulsion and industrial generator setups

Expansion Plug Kit – Cummins 6C

This kit includes all expansion (freeze) plugs for the 6C engine block, sealing casting holes and protecting against block damage from freezing coolant.

Benefits:

-

Corrosion-resistant materials for saltwater environments

-

Ensures complete sealing during crankshaft or block service

Installation Best Practices for Cummins 6C Crankshaft Components

-

Always measure journal diameters and check tolerances before selecting bearings.

-

Use assembly lube on bearings and seals to prevent dry starts.

-

Follow proper torque sequences for main bearing caps.

-

Replace vibration dampers showing rubber degradation or cracks.

-

Inspect expansion plugs during crankshaft removal to prevent future leaks.

Common Crankshaft Issues in Cummins 6C Engines

-

Low Oil Pressure: Often caused by worn bearings or excessive clearance.

-

Knocking Noise: May indicate bearing failure or crankshaft scoring.

-

Oil Leaks: Frequently traced to worn front or rear seals.

-

Excessive Vibration: Can result from a damaged crankshaft or worn vibration damper.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588