Cummins 6B Engine Parts for Canada - Crankshaft Section

Loading...

Loading... Cummins 6B Engine Parts – Crankshaft & Related Components

The Cummins 6B series—covering the naturally aspirated 6B, turbocharged 6BT, and aftercooled 6BTA variants—has earned a global reputation for durability, power, and long service life in both marine and industrial applications. At the heart of every one of these engines lies the crankshaft: a precision-balanced, high-strength steel component responsible for converting the linear motion of the pistons into the rotational force that drives your propeller, pump, or machinery.

When the crankshaft is properly maintained and paired with high-quality related components—bearings, seals, dampers, and gaskets—your Cummins 6B will deliver reliable performance for thousands of hours. Below, you’ll find a detailed breakdown of the crankshaft and every associated part in our catalog, along with technical considerations, replacement guidelines, and compatibility notes for the B Series platform.

Crankshaft for Cummins 6B, 6BT, and 6BTA Engines

The crankshaft for the Cummins 6B series is a forged steel component, precision-machined to exacting tolerances to ensure smooth rotation, minimal vibration, and maximum durability. For the B Series, the crankshaft is typically supplied new and includes the front gear pre-installed for ease of installation. The front gear drives critical components such as the camshaft, oil pump, and in some configurations, accessory drives.

Key Features:

-

Designed for standard journal sizes with factory machining precision.

-

Balanced to minimize vibration and extend bearing life.

-

Supplied with front gear installed to reduce installation time and eliminate gear press-fitting errors.

-

Manufactured to meet or exceed OEM specifications for the 6B, 6BT, and 6BTA engines.

Applications:

-

Marine propulsion engines powering fishing vessels, tugboats, and workboats.

-

Industrial engines driving compressors, generators, and pumps.

-

Agricultural and construction equipment powered by the Cummins B Series.

Crankshaft Bearing Sets (Shell Sets)

The crankshaft rides in the main bearings located within the engine block, and these bearings must maintain the correct oil film thickness to prevent metal-to-metal contact. Over time, wear can occur due to normal operation, inadequate lubrication, or contamination.

We offer crankshaft bearing sets in standard and oversize options to match your engine’s condition and machining requirements. Each set includes upper and lower halves for all main bearing positions in the engine.

Standard Size Bearing Sets

Ideal for engines with crankshaft journals still within factory tolerances. Standard size bearings restore the correct oil clearance without requiring machining.

Oversize 0.25 mm Bearings

Used when the crankshaft has been reground to 0.25 mm undersize. Provides the correct oil clearance after journal material removal.

Oversize 0.50 mm Bearings

For crankshafts reground to 0.50 mm undersize. Suitable for heavy rebuilds or engines that have suffered bearing damage requiring deeper material removal.

Installation Note:

Always measure crankshaft journals with a micrometer before ordering bearings. Even a small deviation from specification can affect oil pressure and bearing life.

Crankshaft Seal Kits – Front

The front crankshaft seal prevents oil from leaking past the front of the crankshaft where it exits the block to drive accessory pulleys or gear train components. Two main variations are available:

-

Seal with Dust Shield: Includes both the sealing lip and a protective dust shield to block contaminants from reaching the seal.

-

Seal with Sleeve: Includes a wear sleeve for the crankshaft snout, restoring a smooth sealing surface if grooves or wear marks are present.

Pro Tip: When replacing the front seal, inspect the vibration damper hub for wear. A damaged hub can quickly ruin a new seal.

Crankshaft Seal Kits – Rear

The rear main seal is one of the most critical oil-retention components in the engine, particularly in marine applications where oil loss can be catastrophic. Our kits include both the seal and sleeve, ensuring a tight fit even on crankshafts with minor wear.

Marine 6B applications often use a dry clutch housing configuration, so the correct seal kit ensures compatibility with that setup.

Vibration Dampers for Cummins B, ISB, and QSB Engines

Vibration dampers—also known as harmonic balancers—are mounted on the front of the crankshaft to absorb torsional vibrations generated by the combustion process. Without a properly functioning damper, crankshaft fatigue and gear train wear can occur prematurely.

Two sizes are available for the B Series:

Maintenance Tip:

Dampers should be inspected at every major service interval. Rubber isolation material can harden over time, reducing damping effectiveness.

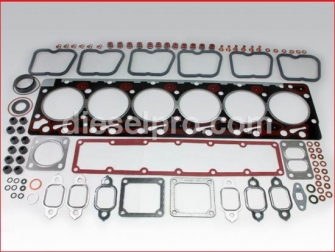

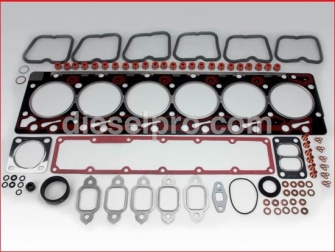

Lower and Upper Gasket Sets

While not crankshaft components themselves, the upper and lower gasket sets are essential when performing a crankshaft replacement or bottom-end rebuild.

-

Lower Gasket Set: Includes oil pan gaskets, crankshaft seals, and other components necessary for bottom-end reassembly.

-

Upper Gasket Set: Covers the top end of the engine and is often replaced during a full rebuild.

Available in standard and oversize configurations to suit different rebuild needs.

Expansion Plug Kit for Block

Also called freeze plugs or core plugs, expansion plugs seal the holes left in the block casting during manufacturing. During a crankshaft or bottom-end overhaul, it is wise to replace these plugs to prevent coolant leaks in the future.

How the Cummins 6B Crankshaft Works

The crankshaft converts the up-and-down motion of the pistons into rotational torque. Each piston connects to the crankshaft via a connecting rod, which rides on crankpins offset from the crankshaft centerline. As combustion forces push the piston downward, the connecting rod pushes against the crankpin, rotating the crankshaft.

Main Functions:

-

Convert linear motion into rotational motion.

-

Transfer torque to the flywheel, transmission, or marine gear.

-

Drive engine accessories via timing gears and belts.

Common Causes of Crankshaft Wear or Failure

-

Insufficient Lubrication: Low oil pressure or dirty oil can rapidly damage bearings and journals.

-

Overloading: Excessive torque demand in marine applications can stress the crankshaft.

-

Improper Machining: Incorrect regrinding tolerances can lead to premature wear.

-

Torsional Vibrations: Running without a proper vibration damper can cause fatigue cracks.

-

Seal Failure: Oil leakage at the crankshaft ends can lead to oil starvation.

Signs Your 6B Crankshaft May Need Replacement

-

Knocking sounds from the bottom end.

-

Low oil pressure despite correct oil levels.

-

Visible scoring or grooves on crankshaft journals.

-

Excessive metal particles in the oil filter.

-

Persistent oil leaks from the front or rear main seals.

Best Practices for Crankshaft Replacement in a Cummins 6B

-

Inspect the Block and Main Bearing Caps – Ensure there is no distortion or cracking.

-

Measure All Journals – Use a precision micrometer and compare against factory specifications.

-

Select Correct Bearing Size – Based on measured journal diameter.

-

Lubricate Bearings Properly – Use assembly lube during installation.

-

Check Endplay – Ensure correct axial movement to avoid thrust bearing failure.

-

Replace Seals and Dampers – Prevent oil leaks and reduce torsional stress.

Marine vs. Industrial 6B Crankshaft Considerations

-

Marine Engines: Operate under sustained high load; crankshaft bearings may require more frequent inspection.

-

Industrial Engines: Often experience more variable load cycles, but dust and debris can increase contamination risk.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588