Cummins ISB 4.5 Parts for Canada - Fuel Pump Section

Loading...

Loading... -

-

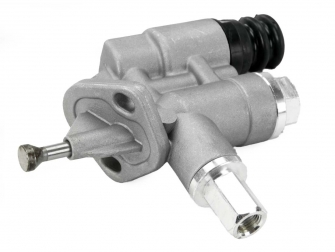

Cummins Fuel Transfer Pump

3936319

Pump Style Mechanical Piston, Used with non-rotary pumpsPrice: $ 101.38 -

-

-

-

-

-

Cummins Fuel Filter & Water Separator

3286503

3.02" diameter, 5.62" height, thread: M16 x 1.5" - 6H INTPrice: $ 44.78 -

-

-

-

1000 Racor Replacement fuel and water separator filter unit

1000

Filter element 2020 includedPrice: $ 449.65 -

-

-

-

-

-

-

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

Fuel System Components for Cummins ISB 4.5 Engines

The Cummins ISB 4.5 engine is widely used in marine and industrial applications, where reliable fuel delivery is essential for consistent performance and long service life. The fuel system in the ISB 4.5 is designed to provide clean, pressurized fuel to the injectors while filtering out contaminants and separating water that can cause corrosion or injector damage.

At Diesel Pro Power, we stock a full range of Cummins ISB 4.5 fuel pumps, gaskets, solenoids, manifolds, filters, and related hardware, ensuring you can source all the components you need from a single, trusted supplier with over 40,000 satisfied customers worldwide.

Mechanical Fuel Transfer Pumps

Lever-Style Mechanical Transfer Pump

This style of mechanical fuel pump uses a lever mechanism to transfer diesel from the tank to the injection system. It is a robust, manually actuated design ideal for ISB 4.5 applications where long-term durability and straightforward servicing are important. Lever-style pumps are preferred in some marine environments for their mechanical simplicity and ease of troubleshooting.

Piston-Style Mechanical Transfer Pump

The piston-style fuel transfer pump operates using a reciprocating piston action, providing consistent fuel pressure. This type is commonly paired with non-rotary fuel injection systems and offers superior sealing against fuel leakage. In industrial ISB 4.5 engines, this style of pump helps maintain reliable performance under varying load conditions.

Fuel Pump Gaskets and Seals

Fuel Transfer Pump Gasket

Every fuel pump installation requires precise sealing to prevent air intrusion and diesel leaks. The fuel transfer pump gasket for the ISB 4.5 is designed to handle high temperatures and continuous vibration, ensuring a long-lasting seal. Two gaskets are typically required per pump, and they should always be replaced when the pump is serviced or replaced.

Fuel Injection Pump Gasket

The fuel injection pump gasket sits between the pump housing and its mounting point, preventing leaks at high pressures. For the ISB 4.5, this gasket is engineered to withstand the pulsations and heat generated by the high-pressure injection process.

Fuel Shutoff Solenoids

The 12-volt fuel shutoff solenoid for the ISB 4.5 provides a critical safety function—cutting off fuel supply to the injectors when the engine is turned off or in an emergency stop scenario. This solenoid ensures precise control over engine shutdown, protecting both the engine and surrounding equipment.

Fuel Manifolds

The fuel manifold distributes diesel evenly to each injector, ensuring balanced combustion across all cylinders. In a marine ISB 4.5 engine, proper fuel distribution helps maintain smooth operation even at varying throttle settings and during prolonged idling.

Fuel Filtration Components

Standard Diesel Fuel Filters

Clean fuel is vital for injector longevity and engine performance. The ISB 4.5 fuel filter removes particles that can cause wear or clogging. Diesel Pro offers direct-fit filters with the correct diameter, height, and thread specifications for the ISB 4.5 fuel system.

Fuel Filter & Water Separator Units

Marine and industrial environments often expose fuel to moisture, which can cause severe damage to injectors and pumps. A fuel filter with an integrated water separator removes both particulates and water before fuel reaches the injection system. This is essential for Cummins ISB 4.5 engines operating in humid climates or offshore conditions.

Fuel Filter Removal Tools

A fuel filter removal wrench is a valuable addition to any Cummins ISB 4.5 maintenance kit. Designed to grip filters without slipping, this tool makes it easier to replace clogged filters without damaging the housing.

Racor-Style Fuel and Water Separators

For operators looking for superior water separation performance, Racor-style separators offer multi-stage filtration and moisture removal. Diesel Pro supplies units in various flow capacities (500, 900, 1000 series) to match different fuel consumption rates in ISB 4.5 engines.

These separators are ideal for marine diesel applications where water contamination risks are high. They also come with filter elements in multiple micron ratings for different operating conditions.

Replacement Racor Filter Elements

Brown-Top Elements – 2 Micron Filtration

For the highest level of filtration, 2-micron elements capture even the smallest particles. Recommended for final filtration before the injectors.

Red-Top Elements – 30 Micron Filtration

These elements serve as a pre-filter stage, removing larger debris before the fuel reaches finer filters. They are excellent for extending the life of downstream filtration components.

Filter elements are available for 2010, 2040, and 2020 series housings, ensuring compatibility with existing Racor setups.

Fuel & Oil Pressure Switches

Pressure switches are used in the ISB 4.5 fuel system for monitoring and control purposes. Diesel Pro offers multiple make/break pressure ratings to suit different application requirements:

-

5 PSI Make/Break – for low-pressure warning or pump control

-

10 PSI Make/Break – common for standard diesel monitoring

-

20 PSI Make/Break – used in higher-pressure systems

-

27 PSI Make/Break – for heavy-duty industrial or marine use

These switches help prevent engine damage by triggering alarms or shutoff functions if fuel or oil pressure drops below safe limits.

Gauges for Monitoring Fuel System Health

Mechanical Gauges

Direct-reading mechanical gauges provide real-time feedback on fuel and oil pressure without requiring electrical power.

Electrical Gauges (12V & 24V)

For ISB 4.5 installations with electrical systems, 12-volt and 24-volt gauges offer easy integration with control panels, allowing operators to monitor fuel system status from the helm or control station.

Why Choose Diesel Pro Power for ISB 4.5 Fuel System Parts

-

Global Shipping – We deliver Cummins ISB 4.5 fuel system components worldwide.

-

In-Stock Inventory – Fast dispatch from our warehouse.

-

Trusted by 40,000+ Customers – Proven reliability and customer satisfaction.

-

Expert Support – Our team can help you select the correct parts for your specific engine setup.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588