Cummins KTA 19 Engine Parts for Canada - Cylinder Head Section

Loading...

Loading... Cylinder Heads & Related Components For Cummins KTA19

The Cummins KTA19 engine is a powerhouse in heavy-duty industrial, power generation, and marine applications. As a robust 6-cylinder, turbocharged, and aftercooled diesel engine, it demands a reliable and durable cylinder head assembly to ensure maximum performance. Whether you're performing a full top-end rebuild or replacing worn components, this section covers all essential cylinder head components compatible with the KTA19. Every product is selected for precision fitment, durability under extreme pressure, and performance integrity. All references to other models like the KTA38 or KTA50 are included only when parts are shared across platforms.

Complete Cylinder Heads for Cummins KTA19

We offer two main types of new cylinder heads for the Cummins KTA19, each assembled with valves and valve springs:

Standard Cylinder Head (with Valves and Washers)

This version includes a fully assembled cylinder head with valve springs seated on traditional spring washers. It’s a reliable choice for standard-duty industrial operation and marine propulsion systems where durability and consistent valve seating pressure are needed. These heads are designed to match the factory specifications of original KTA19 engines, ensuring straightforward installation and optimal combustion performance.

Premium Cylinder Head (with Valves and Rotocoils)

The premium head includes rotocoils installed under the valve springs. Rotocoils help reduce valve wear by spinning the valve slightly during operation, distributing heat and stress more evenly. This design is ideal for applications running under heavier loads or at higher RPMs, especially in marine generators and drilling rigs where continuous performance is critical.

Both versions are manufactured to exacting OEM standards and arrive ready to install, eliminating the need for time-consuming valve train setup.

Cylinder Head Bolts

Cylinder head bolts are crucial for securing the head to the engine block and maintaining proper sealing under extreme compression. For the KTA19 engine, each head requires a specific number of heavy-duty bolts, each engineered to withstand high torque and thermal expansion. Replacing head bolts during a cylinder head replacement is strongly recommended, as used bolts may have stretched or lost clamping force over time.

Valve Train Components for KTA19

Rebuilding a cylinder head often requires refreshing the valve train system. We offer a complete suite of compatible components:

Intake and Exhaust Valves

-

Intake Valves: Standard intake valves for the KTA19 are designed for optimal airflow and combustion efficiency.

-

Exhaust Valves: Available in both stellite and Inconel versions. Stellite valves resist erosion and wear, while Inconel options withstand higher exhaust gas temperatures—ideal for high-performance and marine engine variants.

The KTA19 uses high-precision valve guides for both intake and exhaust valves. These guides maintain proper valve alignment under constant motion and high-temperature cycling.

Valve Inserts (Seats)

We carry exhaust and intake valve inserts (seats) that press into the cylinder head to provide a hardened sealing surface for the valves. These are critical wear components that should be replaced whenever the head is being rebuilt.

Valve Springs, Retainers, and Guides

Valve springs ensure consistent seating pressure. We supply both top spring retainers and bottom guides engineered for high-RPM durability. These components are essential in preventing valve float and maintaining valve timing integrity.

The KTA19 supports the use of rotators (rotocoils) on exhaust valves, particularly for marine and heavy-duty generator applications. These components extend valve life by rotating the valve during operation, which evens out heat distribution and minimizes carbon buildup.

Crosshead Components and Push Rods

Valve crossheads distribute rocker arm pressure evenly across the valve stems. Each KTA19 valve train assembly includes a crosshead bracket to ensure proper contact and even actuation.

Both injector and valve push rods are available, manufactured with hardened steel to resist bending or warping under high-pressure operation. It’s important to inspect and replace push rods during any head or camshaft service.

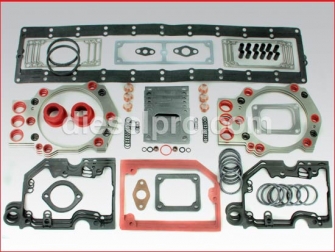

Gaskets & Seals for KTA19 Cylinder Head Service

A successful top-end rebuild depends heavily on high-quality sealing components. We provide everything you need for full resealing:

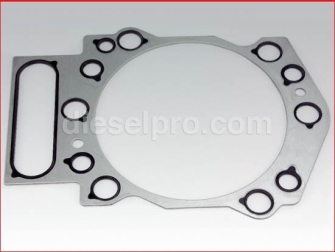

Each KTA19 engine requires six individual head gaskets, one for each cylinder head. These multilayer steel gaskets are designed to maintain compression and coolant separation under high temperatures and cylinder pressures.

We offer two types of upper gasket sets depending on your engine configuration:

-

Non-aftercooled KTA19: Designed for turbo-only engines with three push rod holes.

-

Aftercooled KTA19: Designed for engines with an integrated intercooler for enhanced air intake efficiency.

Both sets include all the necessary O-rings, seals, gaskets, and washers for a complete top-end reseal.

Rocker Lever Housing and Cover Gaskets

Proper sealing around the rocker arm assembly and cam follower covers prevents oil leaks and ensures longevity. We offer exact-fit gaskets for:

-

Rocker lever covers

-

Rocker lever housings

-

Cam follower covers

Cam Follower & Roller Assemblies

The KTA19 valve actuation system includes cam followers and precision rollers, which convert camshaft motion into valve movement:

Cam Follower Rollers and Pins

Rollers are available for both valve and injector cam followers. We recommend inspecting and replacing the roller and associated pin if any pitting or wear is observed, as these can lead to valve timing issues or injector misfires.

Fasteners and Hardware

Heavy-duty hex nuts are used to adjust rocker arms and secure various head components. Always replace worn or rounded fasteners during service.

Thermostatic Components

While not a direct cylinder head component, temperature switches play a crucial role in protecting the head from overheating. Our universal temperature switch closes at 205°F and fits Cummins as well as other diesel engines. This is ideal for monitoring cylinder head temperature in marine applications or industrial gensets.

Why Replace All Cylinder Head Components During a Rebuild?

Rebuilding the cylinder head on a Cummins KTA19 engine is a significant maintenance task—especially for operators relying on this engine in mission-critical environments. Replacing all associated components during the service can:

-

Prevent premature failure

-

Restore lost horsepower and compression

-

Improve fuel efficiency

-

Minimize oil leakage or coolant seepage

-

Extend engine life under full load conditions

It also reduces the likelihood of having to pull the head again shortly after installation—an especially critical factor for marine or offshore platforms where downtime is costly.

How Many Cylinder Heads Does the Cummins KTA19 Use?

Unlike the KTA38 or KTA50, the KTA19 uses a total of six individual cylinder heads—one per cylinder. These heads are independently mounted and sealed using individual gaskets. This modular approach simplifies repairs and allows for targeted service if one cylinder shows symptoms of failure.

Common Applications That Depend on Proper Cylinder Head Function

-

Marine propulsion (workboats, tugboats, fishing trawlers)

-

Offshore drilling platforms

-

Power generation stations

-

Industrial pump systems

-

Heavy-duty construction and mining equipment

In these environments, a malfunctioning cylinder head doesn’t just cause downtime—it can jeopardize contracts, safety, and regulatory compliance.

Tips for a Successful Top-End Overhaul

-

Inspect the Cylinder Block Deck Surface: A warped or damaged deck can cause sealing issues.

-

Torque Head Bolts in Sequence: Always follow Cummins’ recommended torque sequence and use a calibrated torque wrench.

-

Use Anti-Seize on Threads Where Recommended: Especially in high-humidity marine environments.

-

Replace All Related Gaskets and Seals: Old gaskets are prone to leakage and failure.

-

Prime the Lubrication System: Prevent dry starts by ensuring oil reaches the head and rocker assembly before cranking.

Additional Resources

-

KTA 600 Cummins Marine Engine: Specs and Performance Insights

-

A Step-by-Step Guide to Installing a Cummins KTA19 Sea Water Pump

-

Engine Testing and Performance Optimization for Cummins KTA19

-

Mounting Adaptations and Custom Installations for Cummins KTA19

-

Brake System Interfaces for Cummins KTA19 (For Vehicle Applications)

-

Special Tools and Service Equipment Overview for Cummins KTA19

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588