Cummins KTA 38 Engine Parts for Canada - Crankshaft Section

Loading...

Loading... Cummins KTA38 Crankshaft Parts Catalog – Extended Guide

The Cummins KTA38 engine is a powerhouse in industrial and marine applications, known for its rugged reliability and long-lasting performance in even the most demanding environments. At the heart of its performance lies the crankshaft—a massive forged steel component that converts linear piston motion into rotational force. This section covers everything you need to know about Cummins KTA38 crankshaft components, including replacement options, seal kits, bearing sets, sleeves, and supporting gaskets. Whether you're planning a complete rebuild or a focused bottom-end repair, Diesel Pro Power is your trusted source for high-quality aftermarket parts compatible with Cummins KTA38 engines.

Engine Overview: Cummins KTA38

Before diving into the crankshaft-specific components, it’s important to understand the engine’s scale. The Cummins KTA38 is part of the K-series heavy-duty diesel engines and features:

-

Configuration: V12, four-stroke

-

Displacement: 38 liters

-

Bore x Stroke: 159 mm x 159 mm

-

Aspiration: Turbocharged and aftercooled

-

Applications: Marine propulsion, power generation, mining, and locomotive operations

The crankshaft in the KTA38 is subjected to tremendous stress and rotational forces due to the size and power output of the engine, making it one of the most critical components in engine health.

New Crankshaft for Cummins KTA38

Heavy-Duty Construction for Long-Term Performance

The new crankshaft offered for the Cummins KTA38 is manufactured from forged steel, designed for superior durability under high-load conditions. Each crankshaft is machined to precise tolerances and undergoes quality control inspections to ensure consistent journal diameters and alignment.

-

Application: KTA38, K38 industrial and marine engines

-

Construction: Forged steel, nitrided surface

-

Benefits:

-

Reduced friction and wear on main bearings

-

Balanced for smooth operation at full load

-

Excellent torsional resistance

-

Corrosion protection coating (where applicable)

This crankshaft is a direct-fit replacement and requires no modification to the engine block or associated rotating assembly.

Crankshaft Bearings: Shell Sets for Every Rebuild Stage

Standard and Oversize Options

Every crankshaft relies on a precise interface with its main and rod bearings to rotate freely and absorb loads. Diesel Pro Power offers Cummins KTA38 crankshaft shell sets in both standard and oversize (0.010") configurations.

Standard Size Crankshaft Bearing Set

-

Includes upper and lower bearing halves for complete main bearing replacement

-

OEM-equivalent materials for long-lasting oil film protection

-

Perfect for standard journal crankshafts with no machining

Oversize Crankshaft Bearing Set (0.010”)

-

Used when the crankshaft has been ground down to a smaller diameter

-

Ensures tight oil clearance after journal machining

-

Compatible with factory torque specifications

When to Use Oversize Bearings

Oversize bearings are essential if you’ve had the crankshaft journals machined due to scoring, heat damage, or wear. Always confirm measurements with a micrometer before selecting bearing sizes.

Crankshaft Seal Kits: Front and Rear

Proper sealing at both ends of the crankshaft is critical for maintaining oil pressure and keeping contaminants out of the engine block. Diesel Pro Power carries both front and rear crankshaft seal kits, each including all necessary components for a complete seal replacement.

Front Crankshaft Seal Kit

-

Includes seal and wear sleeve

-

Available in multiple versions: dust-seal integrated or separate

-

High-temp, oil-resistant materials

-

Designed for extended service life in marine and industrial settings

Rear Crankshaft Seal Kit

-

Includes rear crankshaft seal and sleeve

-

Matches OEM specifications for ease of installation

-

Protects rear main journal from oil leaks and debris

Proper installation requires evenly torqued retaining hardware and care to avoid damaging the seal lip during assembly. Seal installers or proper guide tools are recommended.

Crankshaft Sleeves: Rear-Side Protection and Seal Seating

The crankshaft sleeve, particularly for the rear side, serves a critical function in sealing performance. The rear crankshaft sleeve fits over the shaft’s sealing surface and provides a smooth, hardened surface for the seal to mate against.

-

Rear Crankshaft Sleeve Features:

-

Hardened and ground for precision sealing

-

Helps reduce seal wear and extend replacement interval

-

Protects crankshaft from groove wear

Replace the sleeve any time a new rear crankshaft seal is installed, especially if there's visible scoring or wear lines.

Gear Cover Gaskets: Upper and Lower Crankshaft Support

While not part of the crankshaft itself, the gear cover gaskets are critical components surrounding the crankshaft front. These gaskets prevent oil seepage where the gear train interfaces with the block.

Upper Gear Cover Gasket

-

Designed for the front gear housing

-

Made from premium gasket materials resistant to oil and heat

Lower Gear Cover Gasket

-

Seals the bottom portion of the gear housing

-

Critical for crankshaft oil control and crankcase pressure balance

Both gaskets are important to replace during any crankshaft service where the timing gear housing is removed or serviced.

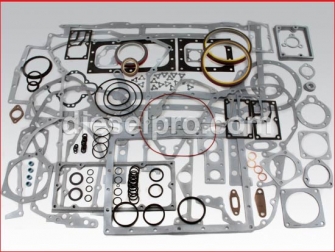

Gasket Sets: Upper and Lower for Complete Bottom-End Access

Major crankshaft work often requires removal of both the upper and lower engine components. Diesel Pro Power offers:

Upper Gasket Set

-

Includes cylinder head gaskets, valve cover gaskets, and intake/exhaust seals

-

Required when removing heads to access pistons or inspect rods connected to the crankshaft

Lower Gasket Set

-

Includes oil pan gaskets, gear cover seals, front/rear seals, and miscellaneous block gaskets

-

Essential for resealing the lower half after crankshaft removal

Use these gasket sets when performing a full in-frame overhaul or crankshaft replacement to ensure oil-tight reassembly.

Crankshaft Failure Symptoms in the KTA38 Engine

Being proactive with crankshaft inspection and replacement can prevent catastrophic engine failure. Look out for the following symptoms that may indicate crankshaft or bearing issues:

-

Low oil pressure: May indicate worn bearings or excessive journal clearance

-

Knocking noises: Rod or main bearing failure may produce rhythmic knocking sounds

-

Metal flakes in oil: A sign of journal scoring or bearing material breakdown

-

Crankshaft endplay: Excessive movement forward/backward can affect gear alignment and sealing

-

Oil leaks from front or rear seals: Can result from worn sleeves or failed seal lips

Installation Tips: Ensuring Long-Term Crankshaft Reliability

Installing a crankshaft in a KTA38 engine demands technical accuracy and clean working conditions. Follow these general tips for a successful installation:

-

Thorough Cleaning: Remove all debris, oil sludge, and old sealant from bearing saddles and oil passages.

-

Torque Specifications: Use a calibrated torque wrench to fasten main bearing caps.

-

Lubrication: Apply assembly lube to bearings and journals during installation.

-

Crankshaft Endplay Check: Use a dial indicator to confirm endplay is within specification.

-

Seal Installation Tools: Use a seal driver or appropriate tool to install front and rear seals evenly without lip deformation.

Maintenance Recommendations for a Healthy Crankshaft

To extend the life of your Cummins KTA38 crankshaft, follow these maintenance best practices:

-

Routine Oil Changes: Use high-quality diesel engine oil and change according to load and hours of operation.

-

Oil Sampling: Periodic oil analysis helps detect early bearing or crankshaft wear.

-

Monitor Oil Pressure: Consistent readings at startup and under load indicate healthy bearing clearances.

-

Vibration Analysis: Excessive vibration can point to imbalance or worn main bearings.

-

Avoid Overloading: Operate within manufacturer-recommended horsepower ratings to reduce crankshaft fatigue.

Why Choose Diesel Pro Power for KTA38 Crankshaft Parts?

With over 40,000 satisfied customers worldwide, Diesel Pro Power is a trusted supplier of high-quality aftermarket parts compatible with Cummins KTA38 engines. Here's why professional mechanics and fleet operators choose us:

-

Extensive Inventory: From full crankshafts to individual seals and gaskets

-

Competitive Pricing: High-value options without sacrificing quality

-

Worldwide Shipping: Fast delivery for urgent repairs and scheduled rebuilds

-

Expert Support: Our team understands heavy-duty diesel engines inside and out

Applications That Demand the Best: Where the KTA38 Crankshaft Matters Most

The Cummins KTA38 is relied on in high-output operations where crankshaft integrity is mission-critical. Typical applications include:

-

Marine propulsion: Ferries, tugboats, fishing vessels

-

Power generation: Stationary gensets for oil rigs, mines, and hospitals

-

Rail locomotives: Providing tractive effort in freight and passenger engines

-

Mining operations: Drills, pumps, and haul trucks in extreme conditions

In all of these environments, downtime is costly. That’s why our crankshaft solutions are engineered for durability, ease of installation, and long service intervals.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588