Cummins NT855 Engine Parts for Canada - Crankshaft Section

Loading...

Loading... Crankshaft Components for Cummins NT855 Engines

The crankshaft is the heart of the Cummins NT855 engine’s rotating assembly. It converts the linear motion of pistons into rotational power that drives industrial equipment, marine propulsion systems, and heavy-duty generators. Whether you're performing a full rebuild or addressing vibration issues or bearing wear, Diesel Pro Power offers a complete selection of OEM-quality crankshaft components for Cummins NT855 and related models, including the NH855 and N14.

Backed by over 40,000 satisfied customers and decades of experience in diesel engine parts, Diesel Pro Power ensures you have everything you need for a long-lasting, precision-balanced crankshaft rebuild.

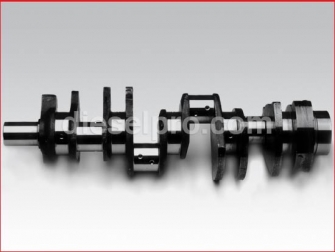

Cummins NT855 Crankshaft Assemblies

Snub-Nose (Bull-Nose) Crankshaft for Big Cam Engines

This new crankshaft is designed specifically for NT855 Big Cam engine configurations. Known for its "snub-nose" or "bull-nose" profile, this crankshaft style is commonly used in later-model NT855 engines, offering improved balance and performance. It is precision-machined to exact Cummins specifications, ensuring compatibility and smooth operation with existing engine blocks and bearing surfaces.

Applications:

-

NT855 Big Cam engines in marine propulsion systems

-

Industrial NT855 gensets with Big Cam configuration

-

High-output applications requiring superior rotational balance

Key Features:

-

Ready to install out of the box

-

Compatible with standard and oversized bearing sets

-

Forged steel construction for durability in harsh operating environments

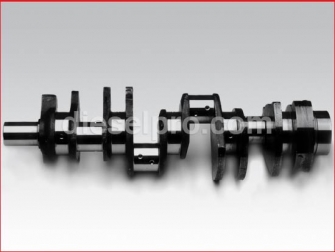

Tapered Nose Crankshaft for Standard NT855 Engines

The tapered nose version of the Cummins NT855 crankshaft is used in earlier engine models or where specific accessory drive configurations are required. This new crankshaft is engineered for reliability and fits seamlessly into NH855 and NT855 blocks with matching taper drives.

Ideal For:

-

Legacy NT855 and NH855 marine engines

-

Dry clutch systems or equipment with tapered nose damper compatibility

-

Power units with mechanical accessory drives

Highlights:

-

Balanced and magnaflux-tested to ensure integrity

-

Works with standard or oversized crankshaft bearing shells

-

Supported by front and rear seal kits for leak-free installation

Crankshaft Bearings for NT855 and NH855 Engines

Proper crankshaft bearing clearance is critical to the longevity of your Cummins NT855 engine. At Diesel Pro Power, we offer full bearing sets in standard and oversize options to match your journal dimensions after machining.

Standard Size Crankshaft Shell Set

Our standard size shell set includes both upper and lower main and rod bearings to complete the crankshaft bearing replacement. These shells are ideal for engines with minimal journal wear or for installations using a new crankshaft.

Features:

-

Engineered to match Cummins OEM tolerances

-

Excellent load-carrying capacity and wear resistance

-

Pre-lubed with assembly lube for easy installation

Oversize .010" Bearing Set

Used after the crankshaft journals have been machined down 0.010", this bearing set restores proper oil clearance and maintains consistent lubrication.

Use Cases:

-

Crankshaft journal repair after scoring or ovality

-

Industrial engine rebuilds with moderate wear

Oversize .020" Bearing Set

When your crankshaft journals have been reground to 0.020" undersize, this bearing set ensures reliable operation under high-stress applications.

Best For:

-

High-hour marine propulsion engines

-

Rebuilt NT855 blocks with heavy wear on journals

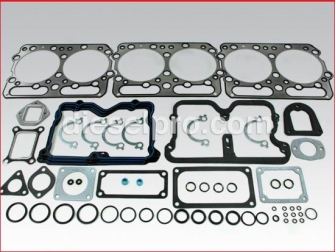

Crankshaft Seal Kits for NT855 Engines

A leaking front or rear crankshaft seal can lead to low oil pressure, contamination, and crankcase vacuum issues. Diesel Pro Power provides high-quality crankshaft seal kits for both dry and wet clutch applications, ensuring compatibility and long-term sealing performance.

Front Crankshaft Seal Kit

This complete kit includes the front crankshaft oil seal and an installation sleeve. Designed for both NH and NT855 engines, it prevents front main seal leaks and extends the service life of the front cover assembly.

Advantages:

-

Seal constructed from high-temperature elastomers

-

Installation sleeve included for accurate fitment

-

Designed to withstand crankcase pressures in high-load environments

Rear Crankshaft Seal Kit – Dry Clutch Configuration

This version is designed specifically for NT855 engines with dry clutch setups. It includes all necessary components to stop rear main leaks without requiring extensive downtime.

Includes:

-

Rear oil seal

-

Metal wear sleeve for shaft protection

-

Compatible with Cummins rear housings used in dry clutch systems

Rear Crankshaft Seal Kit – Wet Clutch Configuration

For marine engines or industrial systems that use a wet clutch, this rear seal kit is the correct choice. It provides a superior seal against both oil leakage and external contamination.

Key Characteristics:

-

Engineered for engines using wet flywheel housings

-

Delivers leak-proof operation under extreme operating conditions

-

Kit includes everything for installation in confined spaces

Rear Crankshaft Wear Sleeve

This precision sleeve is used in conjunction with the rear crankshaft seal kits. It restores the crankshaft’s sealing surface without the need to replace or regrind the crankshaft. Ideal for engines that have worn or grooved sealing surfaces from prolonged operation.

Why Install a Wear Sleeve?

-

Prevents leaks without crankshaft replacement

-

Easy to install during rear main seal servicing

-

Adds years of service life to older engines

Vibration Damper for Cummins NT855 and N14 Engines

A properly functioning vibration damper is essential for reducing torsional vibration in the crankshaft. The 13.54” diameter damper available from Diesel Pro Power fits both Cummins NT855 and N14 engines, helping to protect the crankshaft and internal components from harmonic failure.

When to Replace a Damper:

-

Visible rubber deterioration or separation

-

Audible noise or vibration at idle

-

Damper has exceeded manufacturer’s recommended service interval

Benefits:

-

Reduces crankshaft torsional fatigue

-

Improves engine balance and longevity

-

Bolts directly onto snub-nose and tapered crankshafts

Fan Hub Oil Seal

Located at the front of the engine, this oil seal prevents leaks where the fan hub shaft meets the front gear cover. It is compatible with NT855, NH855, and N14 engine models and should be replaced during crankshaft or front cover servicing.

Installation Tip:

Always inspect the fan hub shaft surface for scoring or wear when replacing this seal. Use a wear sleeve if needed to extend service life.

Complete Crankshaft Rebuild Solutions for NT855 Engines

At Diesel Pro Power, we supply everything required for a complete crankshaft overhaul or repair:

-

New crankshafts for both Big Cam and tapered nose configurations

-

Main and rod bearing sets in standard and oversize dimensions

-

Front and rear seal kits for both dry and wet clutch configurations

-

Rear crankshaft wear sleeves to extend crankshaft life

-

Vibration dampers and oil seals to reduce wear and prevent leakage

Whether you're working on a marine propulsion system, a standby generator, or an industrial pump setup, our crankshaft components are trusted by diesel professionals around the globe. With fast shipping and dedicated support, we make it easy to get your Cummins NT855 engine back to peak performance.

Compatible Engine Models

All components in this catalog are compatible with:

-

Cummins NT855 (All variants, including Big Cam)

-

Cummins NH855

-

Cummins HT855

-

Select N14 engines (bearing sets, vibration damper, and seals)

When to Rebuild the Crankshaft Assembly

Rebuilding the crankshaft system is essential in the following situations:

-

Oil Pressure Drop: Worn crankshaft bearings can result in lower oil pressure and increased bearing clearance.

-

Crankshaft Vibration or Knocking: Often caused by a failing vibration damper or bearing misalignment.

-

Oil Leaks: Leaks at the front or rear seals typically indicate worn seal surfaces or failed gaskets.

-

Engine Overhaul: A crankshaft inspection and possible replacement is standard during complete rebuilds.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588