Cummins QSB 4.5 Parts for Canada - Fuel Pump Section

Loading...

Loading... -

-

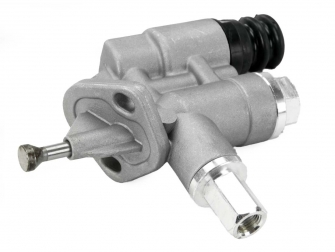

Cummins Fuel Transfer Pump

3936319

Pump Style Mechanical Piston, Used with non-rotary pumpsPrice: $ 101.38 -

-

-

-

-

Cummins Fuel Filter & Water Separator

3286503

3.02" diameter, 5.62" height, thread: M16 x 1.5" - 6H INTPrice: $ 44.78 -

-

-

-

1000 Racor Replacement fuel and water separator filter unit

1000

Filter element 2020 includedPrice: $ 449.65 -

-

-

-

-

-

-

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

Cummins QSB 4.5 Fuel Pump & Fuel System Components

The Cummins QSB 4.5 diesel engine is a proven workhorse across both marine and industrial applications, delivering reliable power with exceptional fuel efficiency. A key factor in this performance is the fuel delivery system — from transfer pumps to filters, solenoids, and pressure switches — each component ensures the engine receives clean, consistent fuel at the correct pressure. Whether used in a workboat, passenger vessel, generator, or heavy-duty industrial machine, maintaining the fuel system is critical for preventing downtime and maximizing service life.

At Diesel Pro Power, we supply a full range of Cummins QSB 4.5 fuel pumps, filters, and related components, all backed by fast worldwide shipping and the trust of over 40,000+ satisfied customers. Our selection includes OEM-style mechanical fuel transfer pumps, shutoff solenoids, Racor-style water separators, filter elements, and fuel pressure switches — all designed for durability in demanding environments.

Fuel Transfer Pumps for Cummins QSB 4.5

The fuel transfer pump is the first step in ensuring your Cummins QSB 4.5 receives an uninterrupted supply of diesel from the tank to the high-pressure injection system. A reliable transfer pump ensures consistent starting performance, stable engine operation, and prevents fuel starvation under load.

Mechanical Lever-Style Fuel Transfer Pump

A rugged mechanical lever fuel transfer pump is ideal for QSB 4.5 engines in applications where mechanical reliability is preferred over electrical operation. Built for long service life, this pump efficiently moves fuel at the correct pressure while withstanding vibration, saltwater exposure (in marine setups), and the high temperatures found in engine compartments.

Mechanical Piston-Style Fuel Transfer Pump

For QSB 4.5 engines using non-rotary injection pumps, the mechanical piston fuel transfer pump is a high-durability choice. With fewer moving parts and a proven design, it excels in continuous-duty applications such as commercial vessels, dredging equipment, or industrial generators.

Gaskets for Fuel Pump Installation

Even the most robust pump can suffer performance issues if gaskets are not sealing properly. Over time, exposure to heat, fuel, and vibration can degrade these seals.

-

Fuel Transfer Pump Gasket – Typically used in pairs for each pump, these precision-cut gaskets prevent fuel leakage and maintain proper pump mounting alignment.

-

Fuel Injection Pump Gasket – Designed to withstand the pressures of the injection system while preventing leaks between the pump and mounting surface.

Fuel Shutoff Solenoid – 12 Volt

The fuel shutoff solenoid is a critical safety and control device for the QSB 4.5. When de-energized, it cuts fuel flow to the engine, allowing for emergency shutdown or normal stop procedures. The 12-volt configuration is standard for many marine and stationary industrial setups, ensuring rapid response and reliable operation even after thousands of cycles.

Cummins Fuel Filters & Water Separators

Contaminated fuel is one of the leading causes of diesel engine problems. The QSB 4.5 benefits from a dual-layer defense: primary filtration via water separation and fine filtration before fuel enters the injection pump.

-

Designed for quick replacement.

-

Micron ratings ensure the removal of fine contaminants that could damage injectors.

-

Heavy-duty metal casing for marine and industrial environments.

Fuel Filter & Water Separator Units

Water in fuel can cause injector damage, corrosion, and poor combustion. A fuel/water separator removes both free and emulsified water before it can enter the injection system. Diesel Pro Power offers Racor-style replacements for QSB 4.5 systems, compatible with standard marine mounting arrangements.

Racor-Style Fuel & Water Separator Replacement Units

We carry complete fuel and water separator assemblies in various flow ratings to match your application:

-

500 Series – Ideal for smaller QSB 4.5-powered vessels and generators.

-

900 Series – Designed for medium-duty setups requiring higher flow rates.

-

1000 Series – High-capacity option for heavy marine or industrial use.

Each comes complete with the required filter element for easy installation.

Replacement Filter Elements for Racor Units

To maintain peak filtration, replace elements at recommended service intervals. We supply multiple micron ratings to match your fuel quality and OEM recommendations:

-

2010 Series – Available in 2 Micron (Brown Top) for ultra-fine filtration or 30 Micron (Red Top) for primary filtering.

-

2040 Series – Medium-flow element, also available in 2 or 30 Micron.

-

2020 Series – High-capacity element, with the same micron options.

Selecting the correct micron rating ensures your filtration setup is properly staged: larger micron elements for primary separation, finer elements for secondary protection.

Fuel & Oil Pressure Switches

Monitoring system pressure is essential for detecting fuel starvation, filter blockage, or oil pressure loss. We offer make/break pressure switches in multiple ratings for QSB 4.5 systems:

-

5 PSI Make/Break

-

10 PSI Make/Break

-

20 PSI Make/Break

-

27 PSI Make/Break

Each switch uses a 1/8" NPT fitting for compatibility with standard Cummins housings and can be integrated with alarms or shutdown systems.

Fuel Filter Removal Tools

To make filter service easier, we supply a fuel filter removal wrench sized for standard Cummins and Detroit Diesel fuel/water separator filters. This prevents over-tightening damage and speeds up maintenance in tight spaces.

Marine & Industrial Maintenance Tips for Cummins QSB 4.5 Fuel Systems

-

Prime After Service – Always prime the fuel system after replacing pumps or filters to prevent air lock.

-

Use Quality Diesel – Even with advanced filtration, poor-quality fuel accelerates wear on injectors.

-

Monitor Pressure Regularly – Installing a gauge alongside a pressure switch provides early warning of restrictions or pump wear.

-

Replace Elements Proactively – Don’t wait for engine performance to drop; follow a scheduled filter change routine.

-

Check Gaskets – Small leaks can introduce air into the fuel system, causing hard starts or stalling.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588