Cummins QSC Parts for Canada - Fuel Pump Section

Loading...

Loading... -

-

Cummins Fuel Transfer Pump

3936319

Pump Style Mechanical Piston, Used with non-rotary pumpsPrice: $ 101.38 -

-

Cummins Fuel Filter

3890017

3.7" diameter, 5.46" height, thread: + 13/16- 18" - 14 UNF-28Price: $ 32.59 -

-

-

-

-

-

-

-

1000 Racor Replacement fuel and water separator filter unit

1000

Filter element 2020 includedPrice: $ 449.65 -

-

-

-

-

-

-

Zinc for Cummins Marine Engine Fuel and Oil Coolers

3957921

Brass plug NPT 3/8”, zinc length 1”Price: $ 20.77 -

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

Cummins QSC Parts – Fuel Pump & Fuel System Components

The Cummins QSC engine series is widely respected for its efficiency, durability, and adaptability in both marine and industrial applications. At the heart of its performance lies a dependable fuel system. The fuel pump and related components ensure consistent delivery of clean diesel fuel at the correct pressure, helping the QSC maintain reliable combustion and long service life.

This section of the catalog highlights all the essential fuel pumps, filters, gaskets, solenoids, and accessories available for the Cummins QSC engine platform.

Fuel Transfer Pumps for Cummins QSC Engines

Fuel transfer pumps are critical to the proper operation of Cummins QSC engines. They move diesel fuel from the tank to the injection system at the right pressure and flow rate. Over time, pumps can wear out due to internal stress, fuel contamination, or simple age. Replacing a failing pump ensures reliable starting, smooth idling, and efficient fuel combustion.

Mechanical Lever-Style Transfer Pump

This pump is designed with a manual lever for durability and simplicity. Its mechanical action provides consistent fuel delivery, making it ideal for QSC engines operating in demanding environments. The lever design also makes priming easier when servicing or after replacing filters.

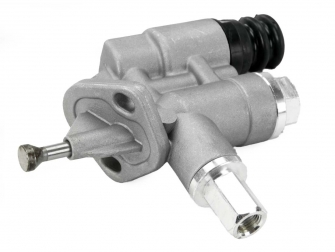

Mechanical Piston Transfer Pump

The piston-style fuel pump is engineered for QSC engines using non-rotary injection systems. Known for its rugged design, this pump delivers stable fuel pressure even under heavy load conditions. It is often preferred in marine applications where constant fuel flow is critical to engine reliability.

Fuel Transfer Pump Gaskets

Every fuel pump installation requires quality gaskets to prevent leaks and maintain pressure. For the Cummins QSC engine, the cover plate gasket is specifically designed to fit securely, sealing the fuel pump assembly. Using the correct gasket prevents air intrusion into the system—a common cause of poor engine starting and inconsistent operation.

Each pump installation typically uses two gaskets, ensuring a complete seal and long-term durability.

Fuel Filters for Cummins QSC Engines

Clean diesel fuel is essential for extending the life of injectors and pumps. The QSC’s fuel filters capture contaminants such as dirt, rust, and water, preventing them from reaching sensitive fuel system components.

Spin-On Fuel Filter

The spin-on filter design allows for fast, easy replacement. With high dirt-holding capacity and precise filtration, these filters ensure that only clean fuel reaches the injectors. Their compact size fits perfectly within the QSC engine layout, making them an ideal choice for quick service intervals.

Standard Canister-Style Fuel Filters

Some QSC configurations utilize canister-style fuel filters with threaded connections. These filters are slightly larger in capacity and designed for extended service intervals. Depending on application, you may see variations in filter diameter, height, and thread specifications.

Fuel Pump Solenoids

The Cummins QSC relies on fuel shut-off solenoids to control the flow of fuel when starting or shutting down the engine. These electrical components are essential for safe operation, preventing fuel from entering the system when the engine is not running.

-

12-Volt Solenoid – Designed for smaller marine or industrial applications using standard 12-volt electrical systems.

-

24-Volt Solenoid – Common in heavy-duty marine and commercial QSC installations requiring 24-volt setups for enhanced electrical reliability.

Both solenoids are engineered for long life and reliable operation, ensuring the engine responds instantly to start and stop commands.

Fuel Filter Tools & Removal Accessories

Changing a QSC fuel filter is straightforward with the right tools. A specialized fuel filter removal wrench allows technicians to quickly and safely remove filters without damaging the housing. This tool is designed to fit common Cummins and Detroit Diesel filter sizes, providing flexibility across multiple engines in a fleet.

Racor Fuel & Water Separators

Marine and industrial Cummins QSC engines often operate in environments where fuel contamination is common. Racor fuel/water separators are the industry standard for removing moisture and debris before fuel enters the QSC system.

-

500, 900, and 1000 Series Units – These complete assemblies filter diesel fuel while separating water. Each unit includes a filter element matched to its size and flow capacity.

-

Replacement Filter Elements – Available in 2-micron (brown top) and 30-micron (red top) variations. The 2-micron filters provide ultra-fine protection for injection systems, while the 30-micron elements allow higher flow in less demanding applications.

Installing a Racor system alongside Cummins QSC filters adds another layer of protection, extending injector and pump life.

Fuel Cooler Zinc Anodes

Marine QSC engines are often equipped with fuel and oil coolers to maintain stable operating temperatures. Inside these systems, zinc anodes are used to prevent corrosion. Over time, the zinc is consumed, sacrificing itself to protect vital components from saltwater damage. Regular inspection and replacement of zinc anodes ensures long-term protection for the cooling and fuel systems.

Fuel & Oil Pressure Switches

Pressure switches are small but essential parts of the QSC’s fuel system. They monitor system pressures and activate alarms or shutdown functions if pressures fall outside safe ranges.

-

5 PSI Make/Break Switch – Used to monitor low-pressure conditions.

-

10 PSI Switch – Provides additional sensitivity for early warning.

-

20 PSI Switch – Often applied in heavy-duty industrial settings.

-

27 PSI Switch – For high-performance applications requiring tighter control.

Maintaining functional pressure switches ensures that operators are alerted to potential fuel system issues before they become critical.

Gauges for Monitoring Fuel System Performance

Accurate monitoring is essential for keeping a Cummins QSC running at peak performance. Fuel pressure, oil pressure, and other system parameters can be tracked using high-quality gauges. Options include:

-

Mechanical Gauges – Simple, direct-reading gauges with rugged reliability.

-

Mechanical Gauges with Alarm Functions – Provide both a visual reading and audible warning.

-

Electrical Gauges (12V and 24V) – Designed for modern control panels in both marine and industrial environments.

These gauges ensure operators can quickly assess engine performance and take corrective action when needed.

Why Choose Diesel Pro Power for Cummins QSC Fuel System Parts

With more than 40,000 satisfied customers worldwide, Diesel Pro Power is the trusted source for Cummins QSC parts. All fuel pumps, filters, solenoids, gaskets, and accessories are stocked, tested, and ready to ship. Whether maintaining a single vessel or managing a fleet of industrial engines, Diesel Pro Power ensures you have access to reliable, high-quality components when you need them.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588