Cummins QSM Parts for Canada - Piston Kit Section

Loading...

Loading... Piston Kits for Cummins QSM11 Engines

The Cummins QSM11 is a high-performance, mid-range diesel engine widely used in marine, industrial, and heavy-duty applications. Designed for durability and clean power, the QSM11 features advanced fuel systems and precision internal components—including high-strength pistons engineered to withstand demanding environments. At Diesel Pro Power, we carry top-quality piston kits and related parts that support a complete in-frame or out-of-frame rebuild of the QSM11 engine platform.

All piston kits listed here are ready to ship, carefully matched by CPL (Control Parts List) numbers, and designed for OEM-quality fit and function.

Overview of Cummins QSM11 Piston Kit Options

The Cummins QSM11 engine can be equipped with either a two-piece or one-piece piston depending on the specific CPL configuration and application type. Both configurations are engineered to meet the high demands of marine and industrial engines.

Two-Piece Pistons for QSM11

Two-piece pistons are commonly found in high-output versions of the QSM11 engine. These pistons include a forged steel crown and an aluminum skirt—offering high thermal resistance and reduced skirt wear over extended operating intervals.

Key Features:

-

Forged steel crown for extreme pressure tolerance

-

Aluminum alloy skirt for reduced friction

-

Piston pin included in kit

-

Engineered for marine and industrial QSM11 applications

-

Compatible with CPLs such as 2828, 2829, 8062, 8409, 8753

One-Piece Pistons for Marine Engines

For certain marine QSM engines, a one-piece piston design is used. These pistons are cast from a monolithic alloy, offering an integrated, simplified solution ideal for controlled thermal environments like marine propulsion systems.

Key Features:

-

One-piece casting for thermal stability and simplicity

-

Ideal for marine-specific applications

-

Piston pin included

-

Compatible with CPLs such as 2199, 2200, 2350, 2376, 2477, 2562, 2563, 2576, 2607, 2608, 2610, 2611, 2612, 2614, 2615

Included Components in QSM11 Piston Kits

Pistons

Each QSM11 piston kit includes a high-quality piston matched to OEM specs. Whether your engine uses a two-piece steel-aluminum piston or a one-piece alloy piston, our kits guarantee reliable combustion sealing, optimal heat transfer, and long wear life.

Benefits:

-

Designed to handle high cylinder pressures

-

Coated skirts reduce scuffing and wear

-

Oil gallery cooling when required by CPL

-

Lightweight for improved response and fuel economy

Piston Pins

The piston pin—also known as a wrist pin—connects the piston to the connecting rod and must be able to withstand tremendous load without deformation. All QSM11 kits include a fully machined piston pin, heat-treated for durability.

-

Precision ground for tight tolerances

-

Compatible with full-floating configurations

-

Engineered for high-duty cycles

Piston Ring Sets

Each piston requires a dedicated set of piston rings to manage compression, oil control, and blow-by. We offer piston ring sets specifically designed for QSM11’s cylinder geometry and operating conditions.

Ring Set Includes:

-

Compression rings for top-end sealing

-

Intermediate scraper/wiper rings

-

Oil control rings with expanders

-

One set required per piston

Cylinder Liners for Cummins QSM11

Cylinder liners—or sleeves—are critical for establishing a clean, wear-resistant cylinder surface. Cummins QSM11 engines use wet-type, replaceable liners that can be serviced independently of the block. Our QSM liners are manufactured to OEM specifications and available in standard sizing.

Features:

-

Honed surface for optimal ring seating

-

Compatible with all standard QSM11 pistons

-

Easy installation in both in-frame and out-of-frame rebuilds

Liner Seal Rings

To ensure coolant and combustion isolation, each cylinder liner uses dedicated seal rings. These rings sit at the base of the liner and form a critical barrier between the cooling system and combustion chamber.

-

High-quality elastomeric design

-

Compatible with QSM11, ISM, M11, and L10 engines

-

Sold per liner—multiple required for full rebuild

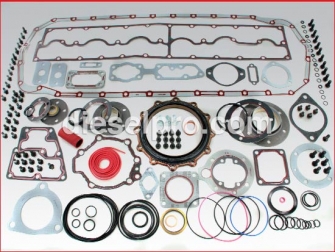

Lower Gasket Sets

While not part of the piston itself, a lower gasket set is essential when rebuilding the bottom end of your QSM11 engine. The set includes oil pan gaskets, front/rear seals, and other vital seals needed for reassembly.

Contents May Include:

-

Oil pan gasket

-

Crankshaft seals

-

Rear gear housing gasket

-

Sealant instructions and installation notes

Using a complete lower gasket set ensures your rebuilt engine won’t suffer from premature oil leaks or seal failures.

CPL Compatibility and Engine Matching

When choosing a piston kit for a Cummins QSM11, it’s critical to verify compatibility using the Control Parts List (CPL) number. Diesel Pro Power provides piston kits for dozens of CPLs, each with exact matching for compression ratio, skirt profile, pin bore, and ring design.

Examples of Supported CPL Numbers:

-

Two-Piece Piston Kits: CPL 2828, 2829, 8062, 8409, 8753

-

One-Piece Marine Kits: CPL 2199, 2200, 2350, 2376, 2477, 2562, 2563, 2576, 2607, 2608, 2610, 2611, 2612, 2614, 2615

If you’re unsure of your CPL number, Diesel Pro Power offers technical support to help identify the correct match based on your engine serial number.

Compression Ratios for Cummins QSM11 Pistons

Cummins QSM11 engines are offered in several compression ratios, each tailored to a specific operational profile. Selecting the correct compression ratio ensures proper combustion efficiency, emissions compliance, and longevity.

-

Typical Ratios Include:

-

16.1:1 (common in marine engines)

-

17.0:1 (for industrial or over-the-road use)

Compression ratio affects ignition timing, cylinder temperature, and fuel consumption. Matching your replacement piston to the original ratio is essential to avoid issues like knocking or low-end torque loss.

Marine vs. Industrial QSM11 Piston Kits

While many internal parts are similar, marine and industrial QSM engines differ in piston design and cooling requirements.

Marine Pistons:

-

Often feature one-piece construction

-

Designed for consistent thermal environments

-

Tuned for lower RPM torque and high idle stability

Industrial Pistons:

-

Typically two-piece for higher strength

-

Optimized for frequent load changes and variable RPMs

-

Heavier crown designs to handle thermal shock

Diesel Pro Power provides both configurations—ensuring your engine receives the correct piston type for its specific working conditions.

Why Diesel Pro Power?

With over 40,000 satisfied customers across the globe, Diesel Pro Power is a trusted name in Cummins engine parts. When you order piston kits from us, you get:

-

Guaranteed CPL-match accuracy

-

In-stock availability for faster delivery

-

Expert customer service for technical support

-

Kits engineered to meet or exceed OEM standards

-

Access to all related rebuild components

Whether you’re rebuilding a marine QSM11 for commercial fishing or refreshing a standby generator engine, we deliver the parts you need—quickly and reliably.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588