Parts For Detroit Diesel Series 60 11.1 Ltrs for Canada - Cylinder head Section

Loading...

Loading... -

-

-

-

-

-

-

-

Detroit Diesel Rocker cover gasket for series 60

23516322

1 per engine with head with 4 bolts

Price: $ 46.60 -

-

-

-

-

-

-

-

-

-

Detroit Diesel Valve Kit, Exhaust for 60 Series Engines - for ERG engines only

23501577P

12 per engine

Price: $ 31.55 -

-

-

-

-

Detroit Diesel Guide, exhaust valve for engine series 60

23518571

14.30 - 14.32 diameter. 24 per engine

Price: $ 4.38 -

Detroit Diesel Guide, exhaust valve for engine series 60

23518572

14.43 - 14.45 diameter. 24 per engine

Price: $ 5.88 -

-

-

-

-

-

-

-

-

Detroit Diesel Series 60 11.1L Cylinder Head Parts Catalog

The Detroit Diesel Series 60 11.1L engine is a proven workhorse that has powered a wide range of heavy-duty and continuous-duty applications worldwide. Known for its reliability, fuel efficiency, and innovative design, the Series 60 platform introduced many features that redefined diesel performance, including advanced electronic fuel control and modular component design.

Among its most critical systems, the cylinder head assembly plays a central role in ensuring the proper operation of the combustion process. The cylinder head on the Series 60 11.1L not only seals the combustion chambers but also houses the intake and exhaust valves, injector components, valve springs, rocker assemblies, and critical gasket interfaces. Keeping this system properly serviced is essential for maintaining compression, fuel efficiency, and overall engine life.

Diesel Pro Power offers a complete catalog of Detroit Diesel Series 60 11.1L cylinder head parts, including new and rebuilt heads, gasket sets, valve train components, and supporting hardware. With over 40,000+ satisfied customers worldwide, we specialize in providing marine and industrial engine solutions that keep your equipment running with minimal downtime.

Complete Cylinder Head Assemblies for Detroit Diesel Series 60 11.1L

The heart of the catalog begins with the cylinder head itself. Customers can choose between new heads preassembled with valves and springs or professionally rebuilt heads designed to OEM standards.

-

New Cylinder Heads: Delivered ready to install, these heads include new valves and springs for quick turnaround.

-

Rebuilt Cylinder Heads: Non-EGR heads rebuilt to original specifications, offering a cost-effective alternative without sacrificing quality.

Each head undergoes rigorous inspection, ensuring precision valve seat machining, proper valve guide installation, and accurate spring tensioning. For operators running continuous-duty applications—such as marine propulsion, power generation, or heavy equipment—the condition of the cylinder head can dramatically affect performance.

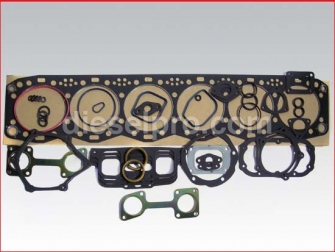

Cylinder Head Gaskets and Gasket Kits

A cylinder head is only as reliable as the gasket sealing it to the block. Diesel Pro Power provides:

-

Head Gaskets – Single replacement gaskets engineered to maintain compression and prevent coolant or oil leaks.

-

Head Gasket Sets – Kits containing the necessary gaskets to reseal the head after servicing valves or injectors.

-

Overhaul Gasket Kits – Comprehensive sets designed for full engine rebuilds, including every gasket needed for cylinder head installation and other upper and lower engine components.

These gaskets are manufactured to withstand the high pressures and thermal stresses of the Series 60 11.1L’s combustion cycle, ensuring long-term reliability in demanding marine and industrial conditions.

Rocker Arm and Valve Train Adjusting Components

Precise valve and injector adjustment is critical to engine efficiency. The Series 60 11.1L uses rocker arm assemblies with dedicated adjustment screws for intake valves, exhaust valves, and injectors.

-

Exhaust Rocker Arm Adjusting Screws – Allow accurate calibration of exhaust valve timing.

-

Intake Rocker Arm Adjusting Screws – Provide fine-tuning of intake valve lift and seating.

-

Injector Adjustment Screws – Essential for proper injector calibration and fuel delivery balance.

Regular inspection and replacement of these screws prevent excessive wear, misadjustment, and uneven combustion, which can lead to reduced power or increased emissions.

Rocker Cover Gaskets

To protect the valve train, rocker covers must remain sealed under vibration and temperature fluctuations. Diesel Pro Power supplies rocker cover gaskets in different configurations:

-

Four-Bolt Rocker Cover Gaskets – Designed for earlier Series 60 variations.

-

Ten-Bolt Rocker Cover Gaskets – Designed for later 11.1L and other Series 60 configurations.

These gaskets prevent oil leaks, reduce contamination, and keep maintenance areas clean.

Cylinder Head Bolts and Fastening Hardware

Cylinder head bolts are among the most stressed fasteners in any diesel engine. Proper torque and stretch characteristics are essential for sealing the head to the block. Diesel Pro Power provides OEM-spec head bolts that ensure proper clamping force across the combustion chambers.

Each 11.1L engine requires a full set of bolts, which should always be replaced during a top-end rebuild or head replacement to ensure even sealing and prevent future failures.

Isolators and Isolator Washers

The Detroit Diesel Series 60 11.1L uses isolator components to reduce vibration transfer between the head assembly and other engine components.

-

Early-Design Isolators – Installed on engines manufactured up to the mid-1990s.

-

Later-Design Isolators (1996–1999) – Updated designs featuring washer assemblies for improved vibration dampening.

Maintaining these components reduces stress on gaskets, fasteners, and surrounding engine hardware.

Intake and Exhaust Valves

The cylinder head of the Series 60 11.1L contains intake valves and exhaust valves, each with critical functions:

-

Intake Valves – Allow the air-fuel mixture into the combustion chamber.

-

Exhaust Valves – Release exhaust gases post-combustion.

Diesel Pro Power provides:

-

Bare replacement valves

-

Complete intake and exhaust valve kits for 12-valve and 24-valve configurations

-

Specialized kits designed for EGR-equipped engines

Ensuring the correct valve kit is installed helps maintain precise combustion timing and efficiency.

Valve Seats, Guides, Locks, and Seals

The life of a cylinder head depends on supporting components that ensure valves operate smoothly:

-

Valve Seats – Intake and exhaust inserts engineered for durability against high-heat environments.

-

Valve Guides – Maintain valve alignment while controlling lubrication. Available in multiple diameter ranges for precision fitting.

-

Valve Locks – Secure valves within the retainer assembly.

-

Valve Stem Seals – Prevent oil leakage into the combustion chamber, reducing smoke and oil consumption.

Replacing these parts during top-end service extends the head’s lifespan and restores performance.

Valve Springs, Rotocoils, and Spring Seats

Valve motion depends on the reliability of springs and their supporting hardware:

-

Valve Springs – Ensure consistent closing pressure.

-

Valve Spring Seats – Provide a stable base for spring operation.

-

Rotocoils – Allow controlled rotation of valves to distribute wear evenly.

These components are especially critical in high-RPM or continuous-duty marine conditions, where valve train stability directly influences performance.

Injector Tubes and Fuel Sealing Components

The Series 60 11.1L uses dedicated injector tubes to deliver fuel to each cylinder. These tubes must maintain a perfect seal to avoid compression loss or fuel leakage.

Diesel Pro Power supplies precision-engineered injector tubes that restore proper fuel delivery and protect against injector seat erosion.

Exhaust Manifold Gaskets and Hardware

The cylinder head connects directly to the exhaust manifold, requiring robust sealing solutions:

-

Head-to-Manifold Gaskets – Maintain airtight exhaust flow.

-

Exhaust Manifold Mount Gaskets – Ensure proper fit and prevent leaks at mounting points.

-

Exhaust Manifold Screws – OEM-quality fasteners designed to handle extreme heat cycles.

Failure in this area can lead to power loss, increased fuel consumption, and higher exhaust temperatures.

Tools for Cylinder Head Maintenance

Special tools are required to correctly service the Detroit Diesel Series 60 cylinder head. Among the most important:

-

Feeler Gauges – Used for calibrating valve clearances. Diesel Pro Power offers gauges ranging from .002" to .025", covering all adjustment needs.

Using the correct tool ensures valves are set to precise factory specifications, improving fuel efficiency and extending engine life.

Gauges and Monitoring Instruments

No cylinder head rebuild is complete without proper monitoring. Diesel Pro Power carries a range of mechanical and electrical gauges for oil pressure, coolant temperature, and exhaust readings.

Options include:

-

Standard mechanical gauges

-

Alarm-equipped mechanical gauges

-

12-volt and 24-volt electrical gauges

Installing high-quality gauges helps operators protect their investment by detecting issues before they become catastrophic.

Why Choose Diesel Pro Power for Series 60 11.1L Cylinder Head Parts

When maintaining or rebuilding your Detroit Diesel 11.1L, choosing the right supplier is just as important as choosing the right part. Diesel Pro Power provides:

-

Global Shipping – Fast delivery to over 180 countries.

-

Trusted by 40,000+ Customers – Proven reliability with decades of service.

-

Complete Catalog – From cylinder heads to the smallest valve lock, every part is available in one place.

-

Marine & Industrial Focus – Unlike general suppliers, Diesel Pro Power specializes in continuous-duty diesel engines.

-

Expert Support – Assistance in selecting the correct head, gasket set, or valve kit based on your engine’s build date and serial number.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588