Parts for Detroit Diesel 12V71 Turbo for Canada - Gasket Section

Loading...

Loading... Parts for Detroit Diesel 12V71 Turbo – Gasket Section

The Detroit Diesel 12V71 Turbo is a legend in heavy-duty marine and industrial applications, where sustained boost, high specific output, and long service intervals are the rule—not the exception. Gaskets and seals are the quiet heroes that keep this two-stroke V-12 dry, cool, and airtight under boost. Below you’ll find a comprehensive, technician-friendly expansion of the gasket components listed on this catalog page, organized by system so you can pinpoint what you need, understand why it matters on a turbocharged 12V71, and complete the job right the first time. We’ll cover material choices, standard vs. oversize seals, common leak sources on boosted setups, best-practice installation guidance, and how the individual items listed here work together during an overhaul or targeted repair.

Gaskets for Block & Core Plugs (12V71 Turbo)

Role & why it matters:

The seemingly simple block plug gasket keeps coolant where it belongs within the water jacket castings. On a turbocharged 12V71 that spends hours at elevated load, localized coolant pressure pulses and thermal cycling are more aggressive than on naturally aspirated engines. A tired plug gasket can mist coolant down the side of the block, invite corrosion, and disguise itself as a “mystery” leak from above.

When to replace:

-

Any time a core/block plug is disturbed.

-

During winterization or post-overheat inspections when plugs are removed for flushing.

-

When you see crusty green/white trails near a plug bore or smell sweet coolant after shutdown.

Installation tips:

-

Clean the plug bore with a Scotch-Brite pad until it’s bright metal and burr-free.

-

Dry fit to verify seating; use a thin, even film of coolant-safe gasket sealer only if the service manual allows.

-

Torque or stake per Detroit Diesel guidance; overtightening deforms the gasket and encourages seepage.

Front & Rear Crankshaft Seals (12V71 Turbo)

Understanding the choices:

You’ll notice several variants: single-lip vs. double-lip, standard vs. oversize, and orientation differences between front and rear applications across the 71- and 92-series families. On a 12V71 Turbo, crankcase pressure pulses can be higher because the engine is moving more air and fuel. That’s why lip design and condition of the seal journal are critical.

-

Single-lip (standard/oversize): Best for journals in excellent condition and engines within OE crankcase pressure spec.

-

Double-lip (rear, standard/oversize): Adds an auxiliary dust/secondary sealing lip—useful where environment is gritty or where the primary lip alone has struggled to maintain dryness over long intervals.

-

Oversize options & sleeves: If the crank’s seal journal is grooved or polished by years of service, an oversize seal or a thin repair sleeve restores the sealing surface without replacing the crankshaft.

Diagnosing before you buy:

-

Oil sling on the vibration damper or flywheel housing interior suggests front or rear main seepage.

-

Persistent weep at the same location after a fresh standard seal? Inspect journal OD; if out-of-round or grooved, step up to an oversize seal or install the recommended sleeve.

Installation best practices:

-

Use a proper driver to keep the seal square; never hammer on the lip area.

-

Lightly oil the lip; install with lips toward the oil side.

-

For sleeves, follow the kit’s depth stop and adhesive cure time; any raised seam will cut the new seal.

Cylinder Head & Upper Engine Gaskets (12V71 Turbo)

Head gasket strategy on a V-12 two-stroke:

The 12V71 Turbo uses modular head components that clamp combustion pressure, coolant passages, and oil returns at each bank. In boosted service, the heads experience greater thermal expansion and higher cylinder pressures, making flatness, surface finish, and torque sequence mission-critical.

-

Head gasket kits (two kits required): Each bank needs its own set. Replacing both during top-end work saves labor and prevents chasing cross-bank coolant or combustion leaks.

-

Rocker/valve cover seal kits (aluminum covers): New-style rocker cover kits resist seepage from valve gear oil splash and crankcase pulsing. On high-hour engines, hard gaskets are a top cause of top-side oil film.

Inspection checklist before reassembly:

-

Check deck and head surfaces with a straightedge and feeler gauges; follow Detroit Diesel flatness limits.

-

Chase head bolt threads and blow out holes; oil-contaminated wells can cause false torque.

-

Verify pushrod tube seals and injector tube seating to keep oil and fuel paths segregated.

Water Manifold & Cooling System Gaskets (12V71 Turbo)

Why coolant sealing is harder on boosted engines:

Turbocharging raises thermal load, so the water manifold (water rail) and outlet gaskets see more expansion/contraction cycles. A tiny seep here aerates the coolant, raising cavitation risk and complicating temperature control at idle.

-

Water manifold gasket: Replace any time the manifold is removed for cleaning or rust scale treatment.

-

Block water outlet & heat-exchanger outlet gaskets: If you see a white residue “crumb line” at the exit or a persistent drip after shutdown, refresh these thin paper/fiber gaskets.

-

Raw (salt) water pump gaskets & plate gaskets: Marine 12V71 Turbos live and die by reliable seawater flow to the heat exchanger. Inlet/outlet gaskets compress and take a set; reuse invites air leaks (which cause pump cavitation) or saltwater dribble.

Pro tips:

-

Lightly coat paper cooling gaskets with a non-hardening sealant for easier future removal.

-

Always true the flange faces on raw water components; warpage from overtightening is common.

Flywheel Housing, Rear End Plate & Interface Gaskets

Purpose & pitfalls:

The rear end plate, flywheel housing gasket, and housing covers trap engine oil while providing critical alignment for the transmission interface. Oil weeps here migrate along the bell housing seam and can be mistaken for rear main seal failures.

-

Replace the end plate and flywheel housing gaskets together when the driveline is uncoupled.

-

Inspect alignment dowels; missing or damaged dowels lead to misalignment, seal distress, and gear train noise.

Allison marine transmission interface (SAE 2):

A dedicated flywheel housing-to-transmission gasket for SAE #2 applications maintains the seal at the engine/gear junction. If you’re swapping or servicing an Allison M/MH marine gear commonly paired to the 12V71 Turbo, this gasket is the correct choice when the engine and transmission share the same housing size. Always verify bell size and register fit before ordering.

Fuel, Oil, and Lubrication System Gaskets (12V71 Turbo)

Small gaskets that prevent big messes:

-

Fuel or water pump mounting gaskets: Any time the pump comes off, a new gasket is cheap insurance against seepage that can contaminate paint and belts or dilute oil (in the case of fuel leaks).

-

Oil pump inlet & inlet pipe gaskets; oil pickup tube gasket: These are low-profile seals that must be absolutely tight. A tiny air leak at the pickup side can introduce aeration, dropping oil pressure at high RPM and causing lifter rattle or bearing distress.

-

Oil filter adaptor gasket: Replace if you remove the adaptor for cooler service or filter head repairs. Even slight warpage of the adaptor flange benefits from a fresh, quality gasket.

Technique reminders:

-

Clean, lint-free surfaces only; no silicone “worms” near oil galleries.

-

Torque evenly in sequence; recheck after heat-soak on initial run if the manual calls for it.

Oil Pan Gaskets (Small & Large) for 12V71

Choosing the correct profile:

The 12V71 uses different pan configurations; select the small or big oil pan gasket to match your sump. Always compare the old gasket’s outline to the new one before sealing.

Leak prevention:

-

Ensure the pan rail is dead flat—use a hammer and dolly to flatten bolt hole “mushrooms.”

-

Use correct torque; overtightening crushes the gasket and warps the rail.

-

Consider a thin film of non-hardening sealant at the end-cap joints only, not across the entire rail.

Turbocharger, Riser & Oil Line Gaskets (12V71 Turbo)

Boosted system specifics:

Turbo hardware on the 12V71 adds hot-side flange gaskets, oil feed/return gaskets, and riser gaskets that must seal under heat, vibration, and oil coking risks.

-

Turbo riser gasket: Sized precisely for the hot-side outlet geometry. Any exhaust leak here robs boost, raises EGTs, and introduces soot where you most don’t want it.

-

Oil supply & oil return gaskets: Oil cokes quickest at the turbo. Always replace these when the turbo is off; make sure the mating surfaces are spotless and flat.

-

High-temperature jointing compound: A purpose-built paste rated for turbo temperatures can augment seal reliability on certain flanges; use sparingly and only where appropriate.

Installation sequence:

-

Dry-fit turbo, elbow/riser, and clamps to confirm alignment.

-

Install fresh gaskets; torque per spec in cross-pattern.

-

Prime turbo with oil before first start; verify oil feed banjo/flare seating.

Intercooler (Aftercooler) Gaskets on Marine 12V71 Turbo

Why they’re critical:

Charge-air cooling (intercooler/aftercooler) gaskets must seal both air and water sides. Any leak can send saltwater into intake air or allow boost to bleed off, causing power loss, smoke, and higher fuel burn.

-

End plate gaskets (use two per unit): These frame the cooler core; replace any time the cooler is pressure-washed or boiled out.

-

Intermediate/core gaskets (multiple per unit): Designed to compress uniformly; set screws should be torqued in several passes to avoid bowing the plate.

-

Inspection routine: Pressure test both circuits. On the air side, listen for hiss around the gasket seams at 15–20 psi. On the water side, look for weeps after shutdown.

Exhaust Manifold & Marine Flange Gaskets (12V71 Turbo)

Sealing under thermal shock:

Turbocharged exhaust manifolds expand more, and studs see greater cyclic load. Fresh head-to-manifold gaskets and marine flange/flange-spacer gaskets are must-replace items when manifolds are off for cleaning, surfacing, or turbo service.

-

Head-to-manifold gasket: Replace in sets for the bank you service; torque hot and retorque per manual if required.

-

Marine manifold flange & spacer gaskets: Choose the correct inside/outside diameters to match risers and wet elbows. Spacers correct alignment and help thermal isolation; always pair them with the proper gasket.

Blower, Striker Plate & Governor Cover Gaskets

Two-stroke air system seals:

On a Detroit two-stroke, the blower is essential for scavenging. The blower installation kit consolidates the various seals you need when removing both blowers during a turbo or top-end service. The striker plate gasket sits between the blower and its striker plate—any leak here becomes an oily film below the assembly and can upset low-RPM scavenging efficiency.

Governor cover/spring cover gaskets:

These small, overlooked paper gaskets prevent oil misting from the governor housing and keep contaminants out. Always replace when setting rack or adjusting governor springs.

Raw (Salt) Water Pump & Heat Exchanger Gaskets

Marine-specific reliability:

Your raw water pump mounting and plate gaskets, plus the inlet/outlet pair, should be replaced whenever the pump is off for impeller service. A tiny suction-side leak introduces air, reducing cooling flow and raising engine temperature under boost.

Best practice:

-

Lap the cover plate on a flat surface with fine paper to remove grooves.

-

Replace both inlet and outlet gaskets every time; at this price point, reusing old paper isn’t worth the risk.

Starters, Covers & Miscellaneous Seals

Starter gasket:

Seals the bendix housing to keep oil mist from wicking into the starter cavity and to keep salt-laden air out. A fresh gasket is smart insurance after any starter service.

Flywheel housing cover (large cover):

This large access cover gasket is easy to damage during inspections. Replace on reassembly to keep the housing dry and clean.

Consumables & Sealants: What to Use Where

High-tack spray sealant:

Great for holding thin paper gaskets in place during assembly (e.g., water manifold, oil pan corners). Apply a light, even film—too much can squeeze into passages.

3H liquid gasket maker (non-silicone):

Useful where a non-hardening, fuel/oil-resistant film is recommended. Ideal for cover flanges with minor imperfections.

RTV silicone (sensor-safe / ultra-blue / high-temp):

Use sparingly and only where the manufacturer permits (end cap joints, certain covers). Avoid RTV near fuel or raw water passages and never rely on it to compensate for warped flanges.

Threadlocker (red, high-strength):

For critical studs/bolts exposed to vibration and heat cycling—think turbo hardware (where specified), riser brackets, or exhaust clamps. Use only on clean, dry threads; respect the service manual’s callouts.

J-B Weld (cold weld):

Handy for non-structural, off-engine repairs—mounting tabs or minor brackets. Not a substitute for a gasket or a flat sealing surface.

Detroit Green engine paint:

After the fixes, a fresh coat protects against corrosion and makes future leaks easier to spot. Degrease thoroughly before painting.

How to Choose: Standard vs. Oversize & Single vs. Double-Lip Seals

When standard works:

-

Journal within spec, no visible groove, and crankcase pressure normal.

-

Engine has a clean breather and no excessive blow-by.

When oversize or sleeve is smarter:

-

You can catch a fingernail on the journal groove.

-

A standard seal failed early without other root cause.

-

You want to extend service life on a high-hour crank without replacement.

Single-lip vs. double-lip:

-

Single-lip: Lower friction; fine for clean environments and healthy breathers.

-

Double-lip: Extra protection against dust/splash and minor crankcase pulsation. Often chosen at the rear on workboats where bilge conditions vary.

Surface Prep, Torque & Break-In Notes (12V71 Turbo)

Surface conditioning:

-

Scrape old gasket material carefully—avoid gouging aluminum.

-

Finish with solvent and lint-free wipes; no silicone “strings.”

Torque habits:

-

Follow the Detroit Diesel pattern, especially on heads, manifolds, intercooler end plates, and oil pan rails.

-

Use calibrated torque wrenches; re-torque hot only if the manual calls for it.

First run checklist:

-

Prime the turbo with oil and crank for oil pressure.

-

Watch for seepage at the turbo oil lines, water manifold ends, and raw water pump flanges during the first 30 minutes.

-

After cooldown, re-inspect clamps and fasteners you disturbed.

Troubleshooting Common 12V71 Turbo Gasket/Seal Issues

Persistent oil film at bell housing seam:

-

Could be rear main seal, but also end-plate/flywheel housing gasket. Clean thoroughly, run under load, trace the source with UV dye if needed.

Soot around turbo riser joint:

-

Riser gasket crushed or misaligned; fasteners may have relaxed after heat cycles. Replace gasket, clean faces, and re-torque in sequence.

Low oil pressure at high RPM after pan service:

-

Suspect air leak at oil pickup tube/inlet gasket. Re-seal and confirm pickup tube seating depth.

Coolant odor after shutdown:

-

Check block plug gasket and water manifold ends first; small seeps leave white deposits.

Oil drips at the front pulley:

-

Front seal lip hardened or journal grooved; consider oversize seal or sleeve solution.

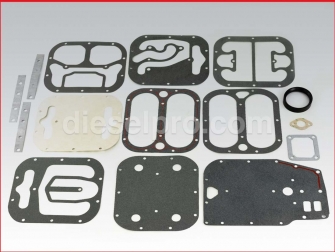

Overhaul & Top-End Planning for a 12V71 Turbo

Bundle your gaskets intelligently:

-

Overhaul gasket kit: The comprehensive path during in-frame rebuilds—minimizes downtime and ensures you’re not reusing aged paper/fiber seals.

-

Head gasket kits (two required): Ideal for top-end refresh with injector and rack work, valve service, and blower off/on.

While you’re in there:

-

Inspect exhaust manifold flatness; resurface if pitted from salt or heat.

-

Replace all intercooler gaskets and pressure-test the cooler.

-

Refresh raw water pump plate and both in/out gaskets; lap the plate.

-

Fit new turbo oil feed/return gaskets and verify oil supply cleanliness to protect the turbo.

Quick Cross-Reference by System (What the Catalog Items Cover)

-

Block/Core Plugs: Block plug gasket.

-

Crankshaft Seals: Front and rear, single/double lip, standard/oversize, plus repair sleeve where applicable.

-

Upper Engine: Head gasket kits (two per engine), rocker cover kit (aluminum cover).

-

Cooling System: Water manifold, heat-exchanger outlet, block heater outlet, raw water pump mount/plate/inlet-outlet pair.

-

Rear of Engine: Rear end plate gasket, flywheel housing gasket, flywheel housing cover, SAE 2 transmission interface gasket.

-

Fuel & Oil: Pump mounting gasket, oil pump inlet, inlet pipe, oil pickup tube, oil filter adaptor.

-

Turbo & Charge-Air: Turbo riser gasket, oil supply and return gaskets, high-temperature jointing compound; intercooler end-plate and core gaskets.

-

Exhaust (Hot-Side & Marine): Head-to-manifold gasket; marine flange and spacer gaskets sized for 12V71-compatible elbows.

-

Blower & Governor: Blower installation kit (covers two blowers), striker plate gasket, governor spring/top cover gaskets.

-

Oil Pan: Small and big oil pan gaskets.

-

Service Consumables: Gasket sprays, RTVs (sensor-safe and high-temp), non-hardening sealants, threadlocker, cold weld; Detroit Green paint.

-

Electrical/Accessory: Starter gasket.

Fitment & Selection Tips Specific to the 12V71 Turbo

-

Two head kits: Always plan on two when doing both banks.

-

Choose the correct oil pan gasket: Visually confirm small vs. big before sealing.

-

Match exhaust gasket diameters: Marine flange and spacer gaskets must match the wet elbow/flange sizes used on your installation.

-

Mind the environment: If your vessel sees silty or gritty bilge conditions, consider double-lip at the rear main.

-

Repair sleeves are your friend: If you can feel a groove on the seal journal, a sleeve plus a fresh seal is more reliable than another standard seal.

Step-By-Step: Replacing Turbo Oil Feed/Return Gaskets (Mini Guide)

-

Prep: Drain down only as needed. Cool engine fully.

-

Remove lines: Mark orientation; cap open ports to keep debris out.

-

Clean surfaces: Use a plastic scraper and solvent; finish lint-free.

-

Install new gaskets: Dry or per the gasket maker’s recommendation; do not glob RTV.

-

Torque & prime: Torque to spec; syringe some clean oil into the turbo feed.

-

Test: Idle 5–10 minutes while watching for weeps; inspect again after a short sea trial.

Step-By-Step: Intercooler End Plate Gasket Service (Mini Guide)

-

Isolate & drain: Close seawater valves, drain the cooler water side.

-

Remove end plates: Loosen in a star pattern to prevent warping.

-

Clean & inspect: Check for corrosion tracks where old gaskets seated.

-

New gaskets (use two where specified): Align carefully; start all fasteners by hand.

-

Torque sequence: Snug in three passes, finish to spec.

-

Pressure test: Water side and air side separately; re-torque if required after first heat cycle.

Maintenance Intervals & Spares to Keep Aboard

-

Annually: Inspect raw water pump gaskets/plate, intercooler joints, and turbo oil line gaskets.

-

Every major service: Replace head-to-manifold gaskets if manifolds come off; renew oil pickup and inlet gaskets when the pan is down.

-

Spares: Keep at least one set of turbo oil feed/return gaskets, a pair of raw water pump inlet/outlet gaskets, one water manifold gasket, and a small supply of approved sealants.

Why Buy These 12V71 Turbo Gaskets & Seals from Diesel Pro Power

When uptime matters, you need gasket materials and seal profiles that match Detroit Diesel’s demands under boost. Diesel Pro Power curates components that install cleanly, torque down predictably, and hold up under the heat-soak cycles unique to turbocharged two-strokes. You’ll find:

-

Precisely matched fitment for the 12V71 Turbo, including correct diameters and outlines for marine flanges, risers, and intercooler end plates.

-

Coverage for the entire job, from the overhaul gasket kits and dual head kits you need for both banks to the small but essential pieces—oil pickup gaskets, governor cover paper seals, and turbo oil line gaskets—that frequently derail timelines when overlooked.

-

Marine-ready focus, with raw water pump, heat-exchanger, and wet exhaust gasket options sized and stocked for common 12V71 Turbo installations.

-

Quality consumables, so you can select the right high-tack spray, non-hardening sealant, sensor-safe RTV, threadlocker, and finishing paint without a separate supply run.

-

Expert support, swift shipping, and inventory visibility—so you’re not waiting on a $2 gasket to finish a $20,000 overhaul.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588