Parts for Detroit Diesel 12V71 Non-Turbo for Canada - Oil Pump Section

Loading...

Loading... -

Detroit Diesel Oil Pump for 12V71 - Rebuilt

5122233

For marine engines. Sold with refundable core deposit. See details

Price: $ 2,651.25 -

Detroit Diesel Oil Pump for 12V71 - Rebuilt

5122230

For truck and industrial engines. Sold with refundable core deposit. See details

Price: $ 6,715.10 -

-

-

-

-

-

-

-

-

-

Detroit Diesel Gasket, Oil Pressure Regulator Add Relief for V71, V92 Series

5117269

.Price: $ 3.82 -

-

-

-

-

Detroit Diesel Oil Filter Adaptor for Engine & Allison transmission

25010854

From cartridge to spin-on

Price: $ 208.96 -

-

-

-

Oil Filter Removal Wrench for Detroit Diesel, Caterpillar & Cummins

2321

4-21/32" to 5-5/32"Price: $ 63.29 -

-

-

-

-

Oil cooler installation kit for Detroit Diesel

2COOLERS-INS-K

For Double oil coolersPrice: $ 242.09 -

-

-

-

-

-

-

-

-

Detroit Diesel Seal - Water Manifold to Oil Cooler Housing for 12V71

5102098

OD:3 5/8” , ID: 3”Price: $ 4.68 -

-

-

-

-

-

-

-

-

-

-

-

Detroit Diesel Water Manifold to Oil Cooler Housing Seal

5159457

2 1/2" outside diameter, with inner lipPrice: $ 5.48 -

Detroit Diesel Seal, Water Manifold to Oil Cooler Housing

5156770

2 3/4" outside diameter, with inner lipPrice: $ 5.46 -

Detroit Diesel Seal for Oil Cooler Housing Water Inlet, Series V71 and 92

23501837

2 3/4" Inside diameterPrice: $ 6.39 -

-

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

-

Parts for Detroit Diesel 12V71 Non-Turbo – Oil Pump Section

The Detroit Diesel 12V71 Non-Turbo engine is one of the most recognized power units in the Series 71 family, known for its robust performance and legendary reliability. Designed for heavy-duty marine, industrial, and truck applications, the 12-cylinder two-stroke engine depends heavily on a precise and durable lubrication system. Every oil pump, gasket, seal, and filter in this system plays a vital role in maintaining oil pressure, regulating flow, and ensuring engine longevity.

This section of the Diesel Pro Power catalog is dedicated to oil system components for the Detroit Diesel 12V71 Non-Turbo engine, offering both rebuilt OEM-grade pumps and premium replacement accessories designed for optimal fit, reliability, and performance.

Oil Pumps for the Detroit Diesel 12V71 Non-Turbo

The oil pump is the heart of the lubrication circuit in the Detroit Diesel 12V71 engine. It’s responsible for moving oil throughout the block, crankshaft, bearings, camshaft, and cylinder liners, ensuring consistent lubrication and preventing wear caused by friction and heat. Diesel Pro Power offers both marine and industrial versions of rebuilt oil pumps for the 12V71 Non-Turbo, each engineered to meet factory specifications.

Marine Application – Rebuilt Oil Pump

The marine version of the 12V71 oil pump is built to endure the constant demands of seawater-cooled environments, extended operation, and variable engine loads. Each pump is fully disassembled, cleaned, and reassembled with precision-measured clearances and new internal components. After reassembly, it undergoes a performance test to confirm flow rate and pressure. This process guarantees that your Detroit Diesel 12V71 marine engine continues to deliver stable oil circulation whether your vessel is idling in port or pushing at full throttle offshore.

Industrial and Truck Application – Rebuilt Oil Pump

For land-based operations such as trucks, power generators, and stationary equipment, the industrial version provides the same dependability and pressure consistency. It’s designed for engines subjected to heavy torque and extended operation at variable RPMs. Diesel Pro’s rebuilt oil pumps restore OEM flow characteristics, ensuring the oil reaches every critical bearing and moving part even under high load conditions.

Quality Assurance and Rebuild Standards

Every rebuilt Detroit Diesel oil pump from Diesel Pro Power goes through rigorous testing. Housing dimensions, gear clearances, and pressure relief valves are measured to OEM standards. Internal surfaces are refinished for proper oil sealing, and each rebuilt unit is inspected for surface wear, gear alignment, and proper rotation (left-hand or right-hand orientation).

Advantages of a Rebuilt Detroit Diesel 12V71 Oil Pump:

-

Precision rebuilt to original factory tolerances

-

Tested for oil pressure performance before shipping

-

Compatible with both mechanical and electronic gauge systems

-

Backed by a refundable core program

-

Available for both marine and industrial configurations

Oil Pump Shims and Pressure Calibration

To achieve proper oil pressure in a Detroit Diesel 12V71 Non-Turbo engine, oil pump shims are used to fine-tune gear clearance and pressure regulation. Diesel Pro Power carries multiple shim thicknesses to accommodate varying setup requirements:

-

.005" (0.05 mm) Shim – Ideal for minor clearance adjustments or rebuilding pumps to tighter tolerances.

-

.010" (0.10 mm) Shim – Used to restore pressure balance when replacing worn internal pump gears.

-

.020" (0.20 mm) Shim – Helps achieve factory-recommended oil pressure in engines with higher wear or after block resurfacing.

These shims are essential for ensuring the oil pump maintains proper suction and delivery pressure throughout the lubrication circuit. Even small variations in gear clearance can result in a significant difference in oil volume delivery per revolution.

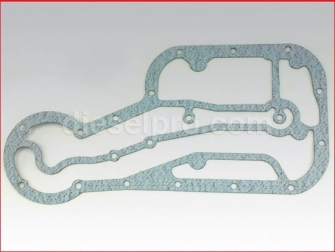

Oil Pressure Regulation and Relief Components

Maintaining consistent oil pressure is critical in the 12V71 engine. Diesel Pro Power provides genuine-fit oil pressure relief valves and regulators that work in conjunction with the pump to prevent over-pressurization and oil starvation.

Oil Relief Valve for 12V71

The relief valve opens automatically if oil pressure exceeds the calibrated limit, redirecting excess oil back into the sump. This prevents bearing overload and seal blow-outs, which are common in older engines with high viscosity oils.

Oil Regulator Valve for 12V71 & 12V92

This valve ensures a stable pressure curve across different engine speeds, keeping the lubrication consistent from idle to full throttle. These regulator assemblies are precision-machined and pressure-tested for leak-free performance.

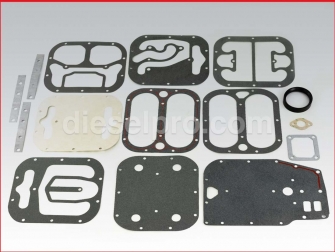

Gaskets and Seals for the Oil Pump and Lubrication System

A tight, leak-free seal is fundamental for maintaining oil system efficiency. Diesel Pro Power provides a full selection of oil pump gaskets, oil cooler gaskets, and oil pan seals specifically for the 12V71 Non-Turbo engine.

Oil Pump Gasket & Inlet Gaskets

The oil pump gasket seals the mating surface between the pump housing and the engine block, preventing oil seepage. Complementary inlet pipe gaskets ensure a proper seal at the suction tube connection, preventing air intrusion which could lead to cavitation and pressure loss.

Oil Pan Gaskets – Small and Large

The 12V71 uses different sizes of oil pan gaskets depending on the configuration. The smaller version fits shallow sump designs, while the larger one accommodates deep oil pan applications. Both are cut from heat-resistant materials and designed to resist shrinkage, oil saturation, and cracking under long-term exposure.

Oil Cooler Gaskets and Adaptor Seals

A variety of oil cooler gaskets are available, ensuring proper sealing between the cooler core, housing, and water manifold. Each gasket is manufactured to exact tolerances to prevent cross-contamination between oil and coolant passages.

Common Gaskets in the 12V71 Lubrication System Include:

-

Oil pump to block gasket

-

Oil inlet and suction tube gaskets

-

Oil cooler housing gasket

-

Oil pressure regulator gasket

-

Oil filter adaptor gasket

These parts help maintain full system integrity, preventing the minor leaks that can compromise pressure stability and cause gradual oil loss over time.

Oil Filters and Adaptors

The 12V71 Non-Turbo engine uses both cartridge-type and spin-on oil filters, depending on configuration and upgrades. Diesel Pro Power offers options for both:

Cartridge-Type Oil Filter and Base

This classic design uses a replaceable element housed within a metal canister. The oil filter base ensures a tight seal and even flow distribution through the element.

Spin-On Conversion Adaptor

For easier maintenance, Diesel Pro offers an adaptor that converts older cartridge systems into modern spin-on style filters. This reduces service time and ensures cleaner oil changes.

Spin-On Filters

Spin-on oil filters are built with high-efficiency media capable of trapping microscopic contaminants, maintaining oil purity, and protecting bearings from wear.

Accessories and Maintenance Tools

An adjustable oil filter wrench compatible with 4-21/32" to 5-5/32" filters is available to simplify filter removal, especially in tight engine compartments.

Oil Coolers and Cooling System Integration

Because the 12V71 Non-Turbo engine is a two-stroke diesel that operates at high combustion temperatures, oil cooling is critical. Diesel Pro Power offers several types of oil coolers to match your setup:

24-Plate and 12-Plate Oil Coolers

These compact, high-capacity coolers are available with or without nipples, allowing integration with either single or double-cooler configurations. The 24-plate version provides enhanced cooling for marine engines operating at high loads, while the 12-plate variant is perfect for auxiliary systems or low-duty applications.

Double Cooler Installation Kits

For vessels or industrial units that use dual oil coolers, Diesel Pro provides installation kits that include seals, mounting gaskets, and connectors.

Oil Cooler Housing and Water Manifold Seals

Oil and water circuits must remain completely isolated. Diesel Pro Power’s housing gaskets, seals, and manifold rings ensure leak-free performance even after repeated heat cycles.

Dipsticks, Tubes, and Measurement Components

To accurately monitor oil levels in the 12V71 Non-Turbo engine, Diesel Pro Power supplies dipsticks, tubes, and guides designed specifically for Detroit Diesel configurations.

Dipsticks in Various Lengths

Available in multiple lengths, including the 44.25-inch and 27.25-inch versions, each dipstick is calibrated for specific sump depths and oil pan configurations.

Dipstick Tubes and Guides

The tube provides a precise alignment for the dipstick, preventing scraping or bending. The guide, usually 1-1/2" in length, ensures consistent depth readings and secure sealing.

Pressure Switches and Monitoring Components

The oil pressure switches for the Detroit Diesel 12V71 Non-Turbo engine play an essential role in safety and monitoring. These switches activate alarms or gauge readings if oil pressure drops below safe operating levels.

Available pressure ratings include:

-

5 PSI make/break – for basic low-pressure warnings

-

10 PSI make/break – standard for most marine applications

-

20 PSI make/break – for high-pressure or turbo conversions

-

27 PSI make/break – for engines requiring precise monitoring at elevated pressure ranges

Each pressure switch is built with brass fittings and NPT threads, ensuring secure installation and electrical reliability.

Maintenance and System Performance

Routine oil system maintenance is essential to the longevity of the 12V71 engine. Replacing the oil pump, inspecting shims, checking pressure valves, and renewing gaskets are part of scheduled service intervals that keep the system functioning efficiently. Key steps include:

-

Inspecting oil pump pressure output during each major overhaul.

-

Replacing gaskets at every disassembly to prevent leaks.

-

Monitoring oil temperature and pressure using mechanical or electrical gauges.

-

Cleaning or replacing the oil cooler core if oil temperatures exceed standard operating ranges.

-

Using high-quality marine-grade oil to ensure consistent lubrication in both fresh and saltwater environments.

Why Choose Diesel Pro Power for Detroit Diesel 12V71 Oil System Components

With over 40,000 satisfied customers worldwide, Diesel Pro Power stands as the leading online distributor for Detroit Diesel parts. Our reputation is built on reliability, verified compatibility, and professional customer service.

Benefits of Ordering from Diesel Pro Power:

-

Expert-verified compatibility for every 12V71 Non-Turbo component

-

Rebuilt and new parts backed by quality assurance and warranty

-

Global shipping with real-time inventory and fast processing

-

Technical support from diesel engine specialists

-

Secure online ordering, available 24/7

Whether you’re maintaining a commercial vessel, an industrial generator, or an older truck application, Diesel Pro Power ensures that your Detroit Diesel 12V71 Non-Turbo engine receives the highest-quality oil system components available. Each part—whether it’s an oil pump, cooler, gasket, or valve—is designed to deliver durability, reliability, and long-term performance.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588