Parts For Detroit Diesel 12V92 Turbo for Canada - Cylinder head Section

Loading...

Loading... -

-

-

-

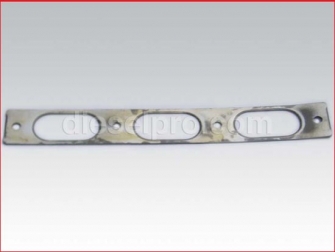

Detroit Diesel Head gasket for 6V92 and 12V92

5199673

6V92 requires 2 kits

12V92 requires 4 kits

Price: $ 70.14 -

-

-

-

-

-

-

Detroit Diesel Connector Assembly - 16V71, 12V92, 16V92

23514887

Fuel connector located between Cylinder HeadsPrice: $ 56.78 -

Cylinder head plug for Detroit Diesel 16V71, 12V92 and 16V92 engines

5126389

4 plugs per enginePrice: $ 65.75 -

-

Detroit Diesel Rocker cover gasket kit, for 3-71, 6V71, 6V92, and 12V92

5149510

For use with aluminum rocker covers. New stylePrice: $ 70.50 -

-

-

-

-

-

-

-

-

-

-

Regulator screw for Detroit Diesel valve bridge

5129101

Precision-threaded - for valve bridge; fits Detroit Diesel 71 & 92 Series.Price: $ 8.88 -

-

Kent Moore flaring die for Detroit injector tube installation

J-5286-6

This flaring die is part of an injector tube reconditioning kit.Price: $ 191.25 -

-

-

Detroit Diesel Air Box Modulator Cylinder, Bracket for Series 71 and 92

5148882

Cylinder for the throttle delayPrice: $ 865.37 -

-

Spring, Push Rod for Detroit Diesel 53, 71 & 92 series engines

5186858

2 5/8" Free Length, .177" Wire Dia., 11 Coils, R.H. HelixPrice: $ 9.03 -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

O Ring Seal for Detroit Diesel New Style Fuel Jumper Lines

8928676

Use 2 per fuel linePrice: $ 4.25 -

Detroit Diesel Fuel Line (Long) for Series 71 and 92

5111527

Long. Each engine uses short and long fuel lines

Price: $ 11.97 -

Socket To Install & Remove Injector Fuel Lines For Detroit Diesel 53, 71, 92

J8932B

.Price: $ 154.53 -

-

-

Detroit Diesel Elbow

8924161

45 degree Inverted flare elbow - with no restriction - 1/4 X 3/8

Price: $ 22.48 -

Detroit Diesel Suction Elbow for Engine

8924155

Fuel pump 90 degree Inverted flare elbow - with no restriction - 3/8 x 1/2

Price: $ 20.28 -

-

-

-

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $ 97.19 -

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

Detroit Diesel 12V92 Turbo – Cylinder Head & Related Components Catalog

The Detroit Diesel 12V92 Turbo engine belongs to the legendary Series 92 family, a line of two-stroke diesel engines known for their rugged construction, high output, and enduring popularity in marine, industrial, and heavy equipment applications. With twelve cylinders in a 90-degree V configuration and turbocharging to boost air intake efficiency, the 12V92T is an engine built for continuous power and reliability.

At the heart of this engine’s performance lies the cylinder head assembly. A well-maintained and properly sealed cylinder head ensures optimal combustion, heat management, and durability. This catalog covers the full range of Detroit Diesel 12V92 Turbo cylinder heads, gasket kits, valves, guides, seals, springs, fasteners, and associated hardware required to keep your engine running at peak efficiency.

Cylinder Heads for Detroit Diesel 12V92 Turbo

Bare Cylinder Head

The bare cylinder head is the foundation for a top-end rebuild. Supplied without valves or springs, this option is ideal for operators who wish to re-use or install custom valve components.

-

Precision-cast and machined for Series 92 fitment.

-

Designed to handle turbocharged combustion pressures.

-

Provides the base structure for complete rebuild customization.

Cylinder Head with Valves & Springs

A convenient option that comes pre-assembled with valves and springs. This reduces installation time and ensures critical components are factory-aligned for proper operation.

-

Eliminates guesswork in valve spring tension and seating.

-

Ideal for reducing downtime during maintenance.

-

Popular in marine fleets where service speed is critical.

Complete Cylinder Head Assembly

This fully-assembled unit includes valves, springs, seats, and other critical components. It offers a plug-and-play solution for operators needing quick replacement with minimal setup.

-

Pre-assembled to OEM specifications.

-

Ensures optimal combustion chamber sealing.

-

Ideal for vessels and industrial operations on strict maintenance schedules.

Head Gaskets & Cylinder Head Sealing Components

A proper seal between the cylinder head and engine block is critical in preventing coolant, oil, and compression leaks. For the 12V92T, four head gaskets are required per engine.

-

Designed to withstand the extreme pressures of turbocharged operation.

-

Manufactured with multi-layer construction to resist warping and blow-outs.

-

Available in complete gasket kits for convenience.

Operators should always replace gaskets when performing top-end overhauls to ensure reliable sealing and avoid repeat failures.

Valves, Guides, Seals & Springs

Exhaust & Intake Valves

The 12V92 Turbo relies on robust valves to control airflow in and out of the combustion chamber. Exhaust valves are designed to endure extreme heat, while intake valves manage the precise introduction of air.

-

Heat-treated for maximum durability.

-

Available individually or as part of a complete head assembly.

-

Compatible with both 6V92 and 12V92 configurations.

Valve Guides

Valve guides ensure smooth valve travel and maintain proper alignment. Excessive wear here can lead to poor compression and oil leakage.

-

Machined for precision fitment.

-

Manufactured from hardened alloys for extended life.

Valve Seals

Critical for preventing oil seepage into the combustion chamber, seals must be replaced whenever valves are serviced.

-

Designed to handle high-temperature, high-pressure operation.

-

Installed in sets—four per cylinder on Series 92 engines.

Valve Springs

Valve springs control timing and ensure valves close under turbocharged conditions.

-

Built to resist fatigue under continuous duty.

-

Should always be inspected for cracking or uneven pressure.

Cylinder Head Hardware & Fasteners

Cylinder Head Bolts & Washers

Strong, reliable head bolts and washers are essential for keeping the head clamped under combustion loads.

-

Precision-threaded for Series 92 torque specs.

-

Hardened steel ensures long service life.

-

Should be replaced during rebuilds to prevent uneven clamping.

Fuel Connector Assemblies

Located between cylinder heads, fuel connectors ensure even distribution of fuel across banks.

-

Designed for tight sealing and proper flow.

-

Available for multiple Series 92 configurations.

Rocker Cover Components

Rocker Cover Gaskets

These seals prevent oil leakage at the rocker arm covers. Available in old and new styles, including gray rubber gasketsfor aluminum covers.

-

Heat-resistant rubber for long-lasting performance.

-

Designed for easy installation and re-use in maintenance cycles.

Rocker Arm Brackets & Shafts

These parts maintain proper movement of the rocker arms and injectors. Worn brackets can cause valve timing issues and uneven fuel delivery.

-

Precision-machined brackets for Series 71 and 92 engines.

-

Hardened rocker shafts to withstand long-term load stresses.

Cooling System Connections

Water Manifold Gaskets & Plates

Proper sealing of the water rail manifold is essential to prevent coolant leaks that could lead to overheating.

-

Gaskets designed for high-pressure water circulation.

-

Plates and studs available for long-term reliability.

Fuel System Connectors & Injector Tubes

Fuel lines and injector tubes play a key role in delivering precise amounts of fuel under pressure.

-

Injector tubes designed for tight fit and durability.

-

Connector elbows and tees available in restricted and unrestricted styles for specific system requirements.

-

O-ring seals provided for new style jumper lines.

Valve Train & Cam Components

Rocker Arms

Both left-hand and right-hand rocker arms are available for Series 92 engines. Specialized injector rocker arms are also included for proper fuel delivery.

Cam Followers

Responsible for translating camshaft rotation into valve movement, cam followers must be kept in top condition to ensure proper engine timing.

Push Rods & Springs

Push rods transfer cam motion to rocker arms. Springs and retainers maintain correct seating under continuous operation.

-

Precision-engineered to resist bending.

-

Should be replaced in sets to maintain even wear.

Specialty Tools

To properly service Detroit Diesel 12V92 Turbo cylinder heads, specialized tools are recommended:

-

Feeler Gauges – For accurate valve lash calibration.

-

Injector Tube Flaring Dies – Ensures correct seating during injector tube installation.

-

Fuel Line Socket Wrenches – Designed specifically for injector fuel line removal and installation.

Additional Components

-

Valve Bridges & Guides – For proper synchronization of dual valve operation.

-

Valve Seats – Hardened inserts to ensure airtight sealing under high compression.

-

Breather Seals – Prevent crankcase pressure from escaping through valve covers.

-

Head to Manifold Gaskets – Seals exhaust gas flow between head and manifold.

-

Oil Filler Caps – Designed to withstand vibration and seal oil fill openings.

Applications of the Detroit Diesel 12V92 Turbo

The 12V92T engine powered countless applications:

-

Marine propulsion – Tugboats, ferries, fishing vessels, and patrol craft.

-

Industrial equipment – Pumps, compressors, and drilling rigs.

-

Heavy vehicles – Buses, fire trucks, and specialized construction equipment.

-

Military service – Widely used in armored vehicles and landing craft.

Operators in these demanding environments rely on quality cylinder head components to minimize downtime and extend service intervals.

Maintenance Best Practices

-

Always replace gaskets, seals, and fasteners during cylinder head service.

-

Perform valve lash adjustments with feeler gauges after installation.

-

Pressure-test heads before final assembly to check for cracks or leaks.

-

Use OEM-spec torque patterns and values for bolts to ensure proper seating.

-

Replace fuel line seals and connectors when servicing injectors.

Why Choose Diesel Pro Power

When you are searching for reliable diesel engine parts, whether for marine, industrial, or heavy equipment applications, the supplier you choose matters as much as the parts themselves. Diesel Pro Power has built a reputation as the most trusted online source for Cummins, Detroit Diesel, Caterpillar, Twin Disc, Allison, and other leading brands. With more than 40,000 satisfied customers worldwide, we understand what professionals in shipping, construction, mining, oilfield, and power generation need: dependable parts, fast delivery, and expert guidance.

Below, we expand on the key reasons why customers consistently turn to Diesel Pro Power for their engine rebuilds, maintenance, and upgrades.

Global Shipping – Fast Delivery to More Than 180 Countries

One of the greatest challenges in marine and industrial operations is downtime. A vessel at port or a generator offline means lost revenue, interrupted schedules, and costly delays. Diesel Pro Power eliminates these challenges with global shipping to more than 180 countries.

-

Worldwide Reach: Whether you are operating a tugboat in the Gulf of Mexico, a cargo vessel in Europe, a fishing trawler off the coast of South America, or a power plant in Africa, you can depend on Diesel Pro Power to deliver genuine and aftermarket parts directly to your location.

-

Streamlined Logistics: We partner with leading freight and courier services to minimize customs delays and provide tracking from warehouse to final delivery.

-

Emergency Support: For urgent breakdowns, expedited shipping options are available so critical components like cylinder heads, water pumps, gasket kits, and injectors arrive in days, not weeks.

This global shipping network is one of the main reasons our customers rely on us year after year. No matter where you operate, Diesel Pro Power makes sure your parts are never out of reach.

Trusted Supplier – Serving Over 40,000 Satisfied Customers Worldwide

With more than 40,000 satisfied customers across marine and industrial markets, Diesel Pro Power has become synonymous with trust and reliability.

-

Proven Track Record: From small family-owned fishing businesses to multinational shipping fleets, customers repeatedly choose Diesel Pro Power because of our consistency in delivering the right parts, the first time.

-

Decades of Expertise: Our team is composed of specialists who understand not only the parts we sell but also the engines and transmissions they belong to. This depth of knowledge helps reduce costly errors and ensures that every order is correct.

-

Customer Loyalty: Many of our clients have been purchasing from Diesel Pro Power for years, relying on us as their single source for Detroit Diesel 71 Series, Cummins B Series, Caterpillar 3400 Series, and countless other platforms.

Trust is not built overnight—it is earned through years of reliable service, correct orders, responsive customer care, and consistent product quality.

Comprehensive Catalog – From Bare Heads to the Smallest Valve Lock

One of the biggest frustrations for fleet managers and engineers is having to shop in multiple places for related parts. Diesel Pro Power eliminates that problem by providing a comprehensive catalog that includes everything you need, all in one place.

-

Complete Cylinder Head Assemblies: Options range from bare heads to heads pre-assembled with valves and springs.

-

Gasket Sets and Seals: Engine-specific kits designed for overhaul or top-end rebuilds, ensuring proper fit and reliable sealing.

-

Fuel System Components: Injectors, fuel pumps, filters, and related hardware to restore efficiency and meet OEM specifications.

-

Cooling System Parts: Marine raw water pumps, fresh water pumps, thermostats, and related gaskets for Cummins, Detroit Diesel, Caterpillar, and more.

-

Small Essentials: Even the smallest items, like valve locks, seals, and fasteners, are available so you never have to search elsewhere.

This all-in-one solution simplifies procurement, reduces downtime, and ensures that customers always find what they need, no matter the size of the project.

Marine & Industrial Focus – Unlike Automotive Suppliers

Most suppliers cast a wide net, trying to cover automotive, light-duty trucks, and passenger vehicles. Diesel Pro Power is different—we focus exclusively on marine and industrial diesel engines. This specialization sets us apart and provides unique benefits:

-

Continuous-Duty Expertise: Marine engines and industrial generators often run for thousands of hours at a time under high loads. Parts must meet higher durability standards compared to automotive applications.

-

Engine Coverage: We stock parts for iconic engines like the Detroit Diesel 6V92, Cummins 6CTA, Caterpillar 3406, and Twin Disc marine transmissions—components that automotive-focused suppliers simply do not carry.

-

Industry Knowledge: Our team understands the operational pressures in shipping, dredging, offshore drilling, and power generation. This insight translates into better recommendations and more reliable results for our customers.

By staying focused on heavy-duty engines, Diesel Pro Power ensures that every product in our catalog is relevant, dependable, and built for demanding environments.

Expert Support – Guidance on Identifying the Correct Parts

Selecting the correct part is not always straightforward. Engine models have multiple arrangements, configurations, and updates across years of production. Choosing the wrong gasket or head can result in wasted time and money. That is why Diesel Pro Power provides expert support at every step.

-

Arrangement & Serial Number Assistance: Our team can help decode Cummins CPL numbers, Detroit Diesel arrangement numbers, and Caterpillar prefixes to ensure accuracy.

-

Technical Knowledge: If you’re unsure whether you need a bare head or a complete assembly, or if you are replacing just a gasket kit versus a full overhaul set, we guide you through the decision.

-

Marine & Industrial Context: We understand that a part needed for a genset running in an oilfield is not the same as a part needed for a tugboat engine. That context ensures you always get the correct recommendation.

With Diesel Pro Power, you’re not just buying a product—you’re getting expert technical support that saves time, money, and stress.

Additional Advantages of Choosing Diesel Pro Power

Beyond the core benefits listed above, customers also gain other advantages that make us the preferred supplier in the marine and industrial diesel industry:

-

Competitive Pricing: Fair and transparent pricing without the hidden markups common in niche markets.

-

Consistent Availability: A large in-stock inventory ensures faster shipping and fewer delays.

-

Easy Online Ordering: A modern e-commerce platform that makes finding and purchasing parts simple, whether you’re onshore or offshore.

-

Core Exchange Programs: On certain components like blowers, turbos, and transmissions, core programs reduce cost and keep supply chains moving.

-

Bilingual Support: Customer service available in English and Spanish for better communication with our global audience.

Conclusion

When you choose Diesel Pro Power, you’re not just purchasing parts—you’re securing peace of mind. With global shipping to 180+ countries, 40,000 satisfied customers, a complete catalog of parts, exclusive marine and industrial focus, and expert technical support, Diesel Pro Power remains the most trusted source for heavy-duty diesel engine parts worldwide.

Whether you need a single head gasket for a Detroit Diesel 8V71, a complete overhaul kit for a Cummins 6CTA, or a new cylinder head for a Caterpillar 3406, Diesel Pro Power ensures you get the correct part, delivered quickly, backed by expertise.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588