Parts for Detroit Diesel 16V71 Non-Turbo for Canada - Exhaust Section

Loading...

Loading... Parts for Detroit Diesel 16V71 Non-Turbo – Exhaust Section

The Detroit Diesel 16V71 is one of the most iconic large-displacement two-stroke engines ever produced. Found in heavy industrial, marine, and power generation applications, this engine delivers rugged dependability and high torque output. Its exhaust system plays a vital role in maintaining efficiency, power, and temperature control across all sixteen cylinders. At Diesel Pro Power, we provide a complete range of exhaust parts specifically designed for the Detroit Diesel 16V71 Non-Turbo engine, ensuring precise fit, durability, and OEM-grade performance. Every product in this catalog has been inspected, tested, and packaged for worldwide shipping to over 40,000 satisfied customers.

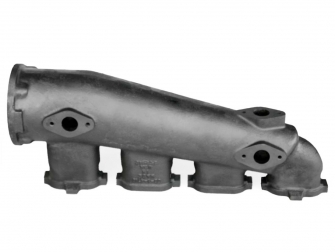

Marine Exhaust Manifold

The Detroit Diesel marine exhaust manifold channels exhaust gases from multiple cylinders into a single outlet. For the 16V71 Non-Turbo, Diesel Pro Power offers precision-machined marine manifolds compatible with other large V-series engines such as the 8V92 and 16V92. Each manifold is built from heavy-duty cast iron for superior resistance to cracking and corrosion in high-temperature marine environments.

Manifolds are pressure-tested to prevent internal leaks that could allow seawater intrusion. Designed for straightforward installation, they include correct port alignment and mounting geometry for seamless integration with existing cylinder heads and exhaust risers.

Head to Manifold Gasket

Between the cylinder head and exhaust manifold lies the head-to-manifold gasket, which ensures the gas path remains sealed under extreme pressure. This gasket prevents exhaust gas blow-by that could erode metal surfaces or reduce backpressure balance.

For the Detroit Diesel 16V71, Diesel Pro Power supplies OEM-grade gaskets compatible with all series 71 and 92 engines. Each piece is cut to exact dimensions for a reliable fit across the sixteen-cylinder layout. Replacing these gaskets during routine maintenance helps maintain compression, reduce soot accumulation, and extend manifold life.

Marine Exhaust Manifold Flange & Gasket

The manifold flange and flange gasket form the crucial connection between the exhaust manifold and downstream piping or elbows. The marine environment demands absolute tightness and corrosion resistance at this junction. Our flanges are machined with NPT threading to provide secure coupling for marine piping, and paired with precision gaskets to maintain seal integrity.

Using a fresh flange gasket at each service interval prevents the escape of hot exhaust gases and protects nearby components from heat damage. Diesel Pro’s gasket materials are formulated to resist salt exposure and repeated thermal cycling.

Insulation Tape

Proper insulation of exhaust manifolds is essential in marine engine rooms, where controlling radiant heat prevents component wear and maintains safe ambient temperatures. Diesel Pro Power offers insulation tape in 3-inch and 4-inch widths, each roll 100 feet long and 1/8-inch thick.

This fiberglass-based wrap withstands continuous high temperatures, reducing surface heat and protecting surrounding wiring or hoses. It also helps improve exhaust flow efficiency by maintaining hotter internal gas velocity. Technicians can easily cut and wrap the tape around manifolds, elbows, and risers for a professional, long-lasting finish.

Manifold Studs, Crabs, Washers, and Nuts

Securing the exhaust manifold properly ensures the system remains sealed even under vibration and temperature fluctuations. Diesel Pro Power supplies studs, crabs (clamps), washers, and nuts that replicate OEM strength and geometry.

-

Manifold studs provide even torque distribution and prevent stripping in cast iron heads.

-

Crabs (the curved clamps) apply balanced pressure across manifold flanges.

-

Hardened washers and locking nuts maintain tightness through countless heat cycles.

Using a full set of new fasteners during overhaul minimizes the risk of manifold warping or leaks—a small investment that protects major components.

Marine Manifold Water Outlet Plate & Gasket

Cooling water circulates through the manifold on marine engines to maintain safe exhaust temperatures. The manifold water outlet plate and its gasket form the seal between the water jacket and outlet fittings. Diesel Pro Power’s outlet plates are machined from corrosion-resistant metal and designed for perfect fitment on the 16V71.

The companion gasket ensures a leak-free seal that can handle continuous exposure to saltwater and high pressure. These components help maintain balanced cooling, preventing hot spots and extending manifold service life.

Threaded Plates and Elbows for Marine Manifolds

Threaded plates and elbows allow secure routing of cooling water or exhaust gases in marine installations. The threaded plate provides a 3/4-inch NPT connection point, while 90-degree and 45-degree elbows adapt piping for confined spaces within the engine room.

These fittings are made from high-grade brass or marine bronze to resist corrosion. The elbows’ precision threading ensures no leaks in the cooling system, while their angled designs improve space efficiency around bulkheads and deck fittings.

Gasket for Marine Manifold Flange Spacer

The marine manifold flange spacer gasket is another critical sealing element, designed to handle both temperature and vibration. It’s often used when aligning exhaust components that require spacing adjustments between manifold and riser. The gasket’s composite material tolerates continuous exposure to exhaust temperatures and moisture, maintaining flexibility and preventing exhaust gas seepage over time.

Muffler Caps

Muffler caps are essential protective components for stationary or marine engines exposed to the elements. These caps prevent water, debris, and insects from entering the exhaust system when the engine is off. Available in multiple diameters—4.5-inch, 5-inch, and 6-inch—they are crafted from stainless or galvanized steel with a pivoting design that automatically opens with exhaust pressure.

For the 16V71 Non-Turbo engine, properly sized muffler caps prevent rust and internal corrosion, especially on boats or outdoor generator installations.

Flexible Metal Exhaust Hoses

Vibration and thermal expansion demand flexibility in exhaust systems. Diesel Pro Power provides reinforced metal exhaust hoses in 6-inch and 8-inch diameters, both 18 inches long. These hoses connect rigid manifold outlets to mufflers or discharge piping while absorbing vibration and movement.

Constructed of interlocked stainless steel, the hoses resist high heat, saltwater, and exhaust corrosion. Their flexibility also simplifies installation in tight marine compartments and prevents stress on manifold flanges or gaskets.

Temperature Switch

Maintaining proper engine temperature is vital for exhaust system performance. Diesel Pro Power’s temperature switchfits multiple engine families, including Detroit Diesel, Cummins, and Caterpillar. It closes at 205°F to signal potential overheating, allowing early intervention before exhaust components sustain heat damage.

This reliable, NPT-threaded switch helps protect against high temperature conditions that can degrade manifold insulation, gaskets, and paint coatings.

Detroit Green Paint

After servicing or rebuilding your 16V71 exhaust system, the finishing touch is Detroit Green paint—the traditional factory color for Detroit Diesel engines. This high-temperature enamel resists oil, fuel, and heat, keeping your engine looking professional and corrosion-free.

Diesel Pro Power ships this paint within the USA and Canada for ground delivery. It’s ideal for restoring engine rooms, power units, or generators to OEM appearance.

Mechanical & Electrical Gauges

Monitoring exhaust and coolant temperatures is crucial in large Detroit Diesel engines. Diesel Pro Power carries a full range of mechanical and electrical gauges, available in both 12-volt and 24-volt configurations. These gauges allow operators to maintain real-time awareness of exhaust gas temperatures, coolant pressure, and system health.

Choose between standard mechanical designs or units equipped with alarms for added protection in critical marine or industrial setups.

Why Buy Detroit Diesel 16V71 Exhaust Parts from Diesel Pro Power

Global Reach and Trusted Experience

Diesel Pro Power has served over 40,000 customers worldwide, delivering Detroit Diesel parts to fleets, shipyards, and independent owners. Our commitment to quality, reliability, and customer support has made us the world’s leading online source for Detroit Diesel components.

OEM-Level Quality You Can Trust

Every exhaust manifold, gasket, hose, and fastener is designed to meet or exceed original specifications. This ensures perfect compatibility, efficient gas flow, and long-term durability under heavy use.

Fast Shipping and Expert Support

All items listed in this catalog are stocked and ready for immediate dispatch. Our warehouse staff and technical experts provide accurate guidance for installation and compatibility, ensuring you get the right part the first time.

Built for Legacy Engines

The Detroit Diesel 16V71 Non-Turbo remains in service worldwide thanks to its robust design. Diesel Pro Power continues to support these legacy engines with parts that allow operators to maintain performance without compromise—keeping fleets running for decades to come.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588