Parts For Detroit Diesel 16V92 Turbo for Canada - Oil Pump Section

Loading...

Loading... -

Detroit Diesel Oil Pump for 12V92, 16V92 Marine Engine

5129876

Rebuilt - Sold with refundable core deposit. See details.

Price: $ 3,896.32 -

Detroit Diesel Oil Pump - 6V71,8V71,6V92,8V92,12V92,16V92

5128905

Scavenging type. Rebuilt - Sold with refundable deposit. See details.

Price: $ 5,353.89 -

-

Detroit Diesel Oil Pan Gasket for 371,16V92,16V71

5150115

For 3-71 and front lower oil pan gasket for 16V71 (2 per engine) & 16V92 (2 per engine)Price: $ 32.02 -

Detroit Diesel Oil Pan Gasket for 471,16V71,16V92

5150116

For 4-71 and rear lower oil pan gasket for 16V71 (2 per engine), 16V92 (2 per engine)

Price: $ 27.07 -

-

-

-

-

-

-

-

Detroit Diesel Oil Filter Adaptor for Engine & Allison transmission

25010854

From cartridge to spin-on

Price: $ 208.96 -

-

-

Oil Filter Removal Wrench for Detroit Diesel, Caterpillar & Cummins

2321

4-21/32" to 5-5/32"Price: $ 63.29 -

-

-

-

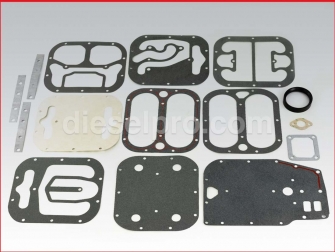

Oil cooler installation kit for Detroit Diesel

2COOLERS-INS-K

For Double oil coolersPrice: $ 242.09 -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Detroit Diesel Water Manifold to Oil Cooler Housing Seal

5159457

2 1/2" outside diameter, with inner lipPrice: $ 5.48 -

Detroit Diesel Seal, Water Manifold to Oil Cooler Housing

5156770

2 3/4" outside diameter, with inner lipPrice: $ 5.46 -

Detroit Diesel Seal for Oil Cooler Housing Water Inlet, Series V71 and 92

23501837

2 3/4" Inside diameterPrice: $ 6.39 -

-

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

-

Detroit Diesel 16V92 Turbo – Oil Pump and Lubrication System Parts

The Detroit Diesel 16V92 Turbo is one of the most powerful engines ever produced in the 92-Series family. Designed for heavy marine propulsion, industrial power generation, and demanding commercial duty, this 16-cylinder, two-cycle V-engine requires a precise and durable lubrication system to perform at its peak.

At the heart of this system lies the oil pump assembly, supported by a series of high-efficiency filters, coolers, and pressure-control components that keep the engine’s vital internals protected under extreme load and temperature conditions.

Diesel Pro Power provides a full selection of oil system components for the Detroit Diesel 16V92 Turbo, each manufactured or rebuilt to meet OEM specifications and thoroughly tested for marine-grade reliability. Whether you’re performing a full overhaul, replacing a damaged pump, or addressing low oil-pressure readings, this catalog offers everything you need in one place.

The Role of the Oil Pump in the 16V92 Turbo Engine

The oil pump is the foundation of the engine’s lubrication circuit. In the Detroit Diesel 16V92 Turbo, the pump draws oil from the oil pan and distributes it under pressure through galleries to crankshaft bearings, connecting rods, camshafts, and turbocharger bearings. The design uses dual scavenging and pressure sections to ensure continuous oil circulation, even during high-RPM operation and heavy load conditions typical of marine propulsion systems.

Rebuilt Detroit Diesel 16V92 Turbo Oil Pump

Each rebuilt oil pump offered through Diesel Pro Power is fully disassembled, inspected, and precision-machined to factory tolerances. The housing is resurfaced, gear end-play is corrected, and relief valves are recalibrated to maintain consistent oil pressure across varying RPM ranges.

This pump is delivered ready to install, sold with a refundable core deposit to encourage sustainable component reuse. Every rebuilt unit undergoes bench testing to confirm proper oil flow and pressure performance before shipping.

Scavenging-Type Oil Pumps

For high-capacity engines like the 16V92 Turbo, scavenging-type oil pumps are used to reclaim oil from the crankcase and return it efficiently to the oil pan. These pumps prevent oil accumulation within the blower compartment and ensure complete lubrication coverage across all cylinders. Each scavenging pump features heavy-duty gears, precision-sealed housings, and wear-resistant shafts capable of withstanding long-term marine operation.

Oil Pan and Gasket Components

The oil pan assembly at the base of the 16V92 Turbo engine serves as both a reservoir and a cooling aid for the circulating lubricant. Over time, heat cycling and vibration can degrade the oil pan gaskets, leading to seepage or leaks that compromise oil pressure.

Oil Pan Gaskets for the 16V92 Turbo

Diesel Pro Power supplies the complete range of main and lower oil pan gaskets required for the 16V92 Turbo. These gaskets are precision-cut for proper alignment and use high-temperature-resistant composite materials that maintain sealing integrity under continuous thermal expansion and contraction.

For the 16V92 Turbo, two lower oil pan gaskets are used per engine—one for the front section and one for the rear. Each gasket is designed to withstand the pressures of marine environments, ensuring a tight, leak-free seal between the oil pan and block surfaces.

Installation Notes

Before installing new gaskets, the oil pan mating surfaces should be thoroughly cleaned and checked for warping or scoring. A thin layer of oil-resistant sealant is recommended for perfect sealing. Always torque bolts to factory specifications in a cross-pattern to prevent uneven pressure.

Oil Pump Inlet, Pickup Tube, and Related Gaskets

To maintain proper oil flow, the inlet and pickup assembly of the 16V92 Turbo ensures the pump receives a steady supply of oil from the sump. Diesel Pro Power offers inlet gaskets and pickup tube seals that are precision-formed to OEM standards, eliminating suction loss that could lead to cavitation or reduced lubrication performance.

Gasket for Oil Pump Inlet

These gaskets are crafted from oil-resistant materials to maintain a consistent seal between the oil inlet flange and the pump housing. Regular inspection of the inlet gasket is recommended during oil pump maintenance, especially if the engine operates in high-vibration marine environments.

Gasket for Oil Pickup Tube

The oil pickup gasket ensures the suction tube connecting the sump to the pump remains airtight. Replacing this gasket during pump servicing is essential to maintain prime and prevent aeration within the lubrication circuit.

Oil Relief and Regulator Valves

Oil pressure regulation is critical in the 16V92 Turbo engine. The oil relief valve prevents excessive pressure buildup that could damage seals or filters, while the regulator valve ensures consistent pressure delivery throughout the system.

Oil Relief Valve for 16V92 Turbo

This valve automatically opens at a specified threshold, diverting excess oil back to the sump to stabilize pressure. Precision-machined internals ensure rapid response and long-term reliability, even after thousands of operating hours.

Oil Regulator Valve

Installed within the oil pump assembly, the regulator valve maintains the optimal oil pressure range for high-output turbocharged operation. Diesel Pro Power’s replacement regulator valves are built to match factory settings, providing consistent pressure across the engine’s load curve.

Oil Filter Bases and Adaptors

The 16V92 Turbo engine uses a high-capacity oil filtration system to trap contaminants before they reach bearings and turbocharger components.

Oil Filter Base Assembly

The oil filter base is designed for cartridge-type filters, featuring precision-machined ports and mounting surfaces. Each base undergoes leak testing and surface inspection to ensure a secure connection between the oil galleries and filter housing.

Spin-On Filter Adaptor

To modernize maintenance and reduce service time, Diesel Pro Power also offers an adaptor that converts the traditional cartridge-type filter setup into a spin-on configuration. This adaptor allows quick filter changes while maintaining full filtration efficiency and flow consistency.

Oil Filters for Detroit Diesel 16V92 Turbo

Spin-On Oil Filters

These premium filters use multi-layer filtration media capable of capturing microscopic particles and sludge. Designed to fit perfectly with the adaptor assembly, they provide superior oil purity and minimize flow restriction.

Cartridge-Type Oil Filters

For applications maintaining the original filter setup, Diesel Pro Power supplies cartridge-type filters engineered for high flow rates and marine oil viscosity. These filters ensure clean lubrication for critical moving parts, including the crankshaft, camshaft, and turbo bearings.

Oil Filter Removal Tools

An oil filter removal wrench is available to simplify maintenance. It accommodates the size range of Detroit Diesel filters and provides a firm grip without damaging the housing.

Oil Coolers and Gasket Kits

The oil cooler plays a crucial role in managing the 16V92 Turbo’s oil temperature. Excessive heat reduces oil viscosity and leads to accelerated wear. Diesel Pro Power offers several configurations of oil coolers designed for this engine, including 24-plate and 32-plate models.

Oil Coolers – 24 and 32 Plate Designs

The plate-type oil coolers use stacked copper-alloy plates to transfer heat efficiently between oil and coolant. They are ideal for marine installations where space efficiency and maximum cooling capacity are vital. The 32-plate version provides enhanced cooling for high-performance configurations.

Oil Cooler Installation Kits

For dual-cooler setups, Diesel Pro Power provides installation kits that include gaskets, seals, and mounting components necessary for a complete replacement or rebuild. Proper installation ensures optimal temperature regulation, extending engine life.

Oil Cooler Gaskets and Seals

A variety of gaskets are available for the oil cooler housing, cover, and water inlet connections. These gaskets are precision-cut and heat-resistant, preventing cross-contamination between oil and coolant circuits. Each gasket maintains a perfect seal under vibration and high thermal stress.

Dipsticks, Tubes, and Filler Components

Oil Dipsticks and Tubes

Accurate oil level monitoring is essential in a large-capacity engine like the 16V92 Turbo. Diesel Pro Power offers dipsticks in multiple lengths to match various marine configurations, along with precision-fitted dipstick tubes that ensure accurate readings and a leak-free seal at the crankcase.

Dipstick Guides

Each dipstick guide helps align and protect the measurement rod from wear during repeated use. These are designed to fit the standard 1-1/2” dipstick port common to Detroit Diesel engines.

Oil Filler Caps

Durable oil filler caps prevent contamination from entering the lubrication system. They are machined from corrosion-resistant materials, suitable for the marine environment, and ensure an airtight closure at the head cover.

Seals and Gaskets for Oil-to-Water Connections

The 16V92 Turbo’s integrated oil-to-water cooling system requires numerous seals and gaskets to prevent fluid crossover and leakage.

Water Seals and Manifold Gaskets

Diesel Pro Power carries all seals connecting the water manifold to the oil cooler housing. These seals are engineered with an inner lip design for superior grip and leak protection under varying temperatures. Proper sealing ensures oil and coolant remain in separate channels for maximum efficiency.

Oil Cooler Housing Seals

The oil cooler housing seal maintains isolation between oil passages and coolant flow. Regular replacement during cooler servicing is recommended to prevent cross-leakage that can lead to emulsified oil or overheating.

Oil Pressure Switches and Monitoring Components

Reliable oil pressure monitoring is critical for protecting the 16V92 Turbo engine. Diesel Pro Power provides a full range of fuel and oil pressure switches designed for different make/break settings, allowing operators to match system needs with specific alarm thresholds.

5 PSI to 27 PSI Make/Break Switches

Available configurations include 5, 10, 20, and 27 PSI switches, each designed with precision-calibrated diaphragms for accurate readings. These switches can be installed in oil or fuel lines and connect easily to existing marine instrumentation panels.

Gauge Options

Mechanical and electrical gauges are also available, including 12-volt and 24-volt variants with or without built-in alarms. These gauges provide continuous monitoring of oil pressure, giving operators real-time protection against lubrication loss.

Why Choose Diesel Pro Power for Detroit Diesel 16V92 Turbo Oil System Parts

With over 40,000 satisfied customers worldwide, Diesel Pro Power has earned a reputation for reliability, technical expertise, and outstanding customer support. Each component in this catalog is verified for accuracy and compatibility with the Detroit Diesel 16V92 Turbo engine. Customers benefit from:

-

Fast global shipping with reliable delivery tracking.

-

24/7 online ordering with clear, high-resolution diagrams for easy identification.

-

Expert technical assistance from experienced diesel specialists.

-

Guaranteed quality through stringent testing and rebuild protocols.

Whether maintaining a commercial vessel, offshore generator, or industrial power unit, Diesel Pro Power ensures you receive the correct part the first time—ready to install and built to last.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588