Parts for Detroit Diesel 471 Non-Turbo - (2 Valve Head Type) for Canada - Engine Overhaul Kit Section

Loading...

Loading... Parts for Detroit Diesel 4-71 Non-Turbo (2-Valve Head Type) – Engine Overhaul Kit Section

The Detroit Diesel 4-71 Non-Turbo engine is one of the most reliable and enduring power units in diesel history. Known for its two-stroke design, robust construction, and mechanical simplicity, the 4-71 earned its reputation in marine, industrial, and on-highway applications worldwide. Whether powering tugboats, generators, cranes, or construction equipment, this four-cylinder engine has proven itself as a powerhouse that can outlast generations when maintained properly.

At the heart of every long-lasting Detroit Diesel 4-71 is a properly built bottom end, and that begins with a high-quality engine overhaul kit and cylinder kit. These parts restore compression, improve performance, and ensure your engine continues running smoothly under heavy load conditions. Diesel Pro Power supplies complete, premium-quality kits designed to OEM specifications—used by professional rebuilders and operators around the globe.

Detroit Diesel 4-71 Cylinder Kits

The cylinder kit is the most critical part of any Detroit Diesel 4-71 rebuild. It directly determines how well the engine will seal compression, manage combustion temperatures, and maintain oil control. Each kit from Diesel Pro Power includes a precision-engineered cylinder liner, piston, piston rings, piston pin, and retainers—everything required for a single cylinder rebuild.

These components are manufactured to the same tolerances as the original Detroit Diesel specifications, ensuring seamless fit and reliable operation. Every liner is honed for the correct cross-hatch pattern, every piston is balanced for uniform combustion across cylinders, and every ring is engineered for proper sealing during high-pressure operation.

Features and Benefits of 4-71 Cylinder Kits

-

OEM-Quality Fitment: Designed to fit Detroit Diesel 2-71, 3-71, 4-71, and 6-71 engines, ensuring compatibility across the Series 71 line.

-

Precision Machining: Each piston and liner is machined to exact dimensions for optimal compression and oil control.

-

Improved Durability: Built from high-grade alloys to resist scuffing, corrosion, and thermal stress.

-

Pre-Matched Components: All kit elements—liner, rings, piston, and pin—are pre-matched to ensure correct clearances and compression ratio.

-

Ready for Marine, Industrial, and Generator Use: Suitable for both continuous-duty and intermittent-duty applications.

Rebuilding with a complete cylinder kit restores the performance of a worn 4-71 engine to factory-like condition. It’s the most cost-effective way to regain power and reliability without replacing the entire engine assembly.

Cylinder Liners for the Detroit Diesel 4-71

Each liner in a 4-71 engine serves as the wear surface for the piston rings. Over time, liners develop scoring, glazing, or out-of-round wear that can lead to blow-by and power loss. Diesel Pro Power offers standard and oversize liners for precise rebuild applications.

Standard liners are ideal for engines with normal wear and no significant damage to the cylinder bore.

Oversize liners, available in incremental dimensions, allow for restoration of worn or re-machined block counterbores.

All liners are induction-hardened, honed for consistent oil retention, and manufactured to exact surface roughness tolerances for ring seating.

Additional liner components include:

-

Liner inserts for proper seating in the block counterbore.

-

Liner shims available in multiple thicknesses (.002 and .003) to fine-tune liner protrusion height. Correct liner height ensures even head gasket compression, preventing coolant or combustion gas leaks.

Proper liner installation ensures the heart of the engine—the combustion chamber—remains airtight and thermally balanced.

Piston Rings for the 4-71 Engine

Piston rings play a key role in sealing the combustion chamber, transferring heat, and controlling oil. In the Detroit Diesel 4-71 Non-Turbo engine, rings are designed to handle high temperatures and pressures associated with two-stroke operation.

Each ring set includes compression rings and an oil control ring engineered for efficient sealing and long service life. Diesel Pro Power’s replacement ring sets use advanced metallurgy and precision grinding for smooth break-in and consistent performance.

Benefits of high-quality piston rings:

-

Restores compression and power output

-

Reduces oil consumption and exhaust smoke

-

Improves thermal transfer from piston to liner

-

Minimizes blow-by and fuel dilution

Pairing these rings with new liners and pistons ensures your rebuilt engine maintains correct compression across all cylinders, eliminating imbalance and improving fuel efficiency.

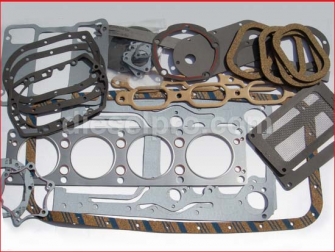

Gasket Sets for Complete Overhaul

Every complete rebuild requires replacing all gaskets and seals to prevent leaks and maintain internal pressure. Diesel Pro Power’s complete overhaul gasket kit for the 4-71 low block engine includes every major seal needed to reassemble the engine: head gaskets, blower housing seals, oil pan gaskets, and crankcase seals.

These gaskets are made from high-temperature, oil-resistant materials that provide long-term sealing under heavy load conditions. Whether you’re working on an older marine configuration or an industrial application, a full gasket set ensures that your rebuild is leak-free from day one.

Key inclusions:

-

Head and manifold gaskets

-

Crankshaft seals (front and rear)

-

Blower and oil pan gaskets

-

Fuel system and water jacket seals

Replacing all gaskets together ensures proper torque sealing across components, protecting your investment in the overhaul.

Crankshaft Seals & Sleeves

Oil sealing is another vital aspect of the rebuild. Diesel Pro Power offers front and rear crankshaft seals designed for both left-hand and right-hand rotation engines. These are available in single- and double-lip designs, with standard and oversize options depending on wear in the housing bore.

Front crankshaft seals prevent oil leakage at the blower drive end, while rear crankshaft seals keep the flywheel housing area dry and oil-free.

In some engines with worn housings, sleeve seals may be required to restore proper fitment. These sleeves ensure consistent oil sealing even in older engines with minor wear on the crankshaft or housing surfaces.

Piston Pin Retainers and Related Components

When rebuilding an engine, attention to small parts like piston pin retainers is crucial. These retainers secure the wrist pin within the piston, preventing it from sliding laterally and damaging the liner walls.

Diesel Pro Power’s retainers are built from durable spring steel and tested for the high vibration environment of Detroit Diesel’s two-stroke engines. Replacing them during a rebuild is a low-cost measure that prevents major mechanical failure down the road.

Specialized Tools for Installation

Proper installation of liners, rings, and pistons requires the right tools. Diesel Pro Power supplies professional-grade equipment to simplify rebuild tasks:

-

Cylinder liner puller: Safely extracts liners from the block without scoring the bore.

-

Piston ring compressor: Compresses rings uniformly for smooth piston insertion into the liner.

-

Tune-up kits: Includes essential tools for setting injector racks, adjusting valves, and tuning engine timing.

Using the correct tools not only speeds up the rebuild process but also protects precision-machined parts from accidental damage.

Filters and Maintenance Components

After a major overhaul, it’s vital to protect the new internals with clean oil and fuel. Diesel Pro Power supplies premium filters designed for the Series 71 engines:

Fuel filters: Available in both spin-on and cartridge styles for primary and secondary filtration. The primary filter removes larger particles before the fuel reaches the injection pump, while the secondary filter captures finer contaminants to protect injectors.

Oil filters: Offered in spin-on and cartridge types, ensuring consistent oil flow and protection of bearings and cylinder components.

Air filters (not shown): Should be inspected or replaced at each overhaul to ensure proper airflow and combustion efficiency.

Together, these filters maintain the clean operating environment your rebuilt engine requires for maximum service life.

Cooling System Components

Proper cooling is essential for engine longevity. Rebuilt engines need to maintain steady operating temperatures, and Diesel Pro Power offers several components to assist:

-

Thermostats calibrated to open at approximately 173°F for optimal coolant flow.

-

Block heaters available in 750-watt and 1500-watt versions for cold weather or marine startup assistance.

-

Radiator cleaner formulated to remove scale and rust from cooling passages safely.

A clean, well-maintained cooling system prevents overheating, reduces wear on liners and pistons, and ensures consistent operating temperatures throughout the engine.

Accessories & Finishing Touches

Once the mechanical rebuild is complete, attention to finishing details enhances both performance and appearance:

-

Detroit Diesel green paint restores the iconic factory color while providing corrosion resistance.

-

Primer coatings help paint adhere to cast iron surfaces and resist oil penetration.

-

Temperature switches protect against overheating by activating alarms or shutdown systems at preset temperatures.

These finishing steps are often overlooked but contribute to the professional quality of a rebuild, preserving both function and appearance for years to come.

Why Choose Diesel Pro Power for Your Detroit Diesel 4-71 Cylinder Kits

Comprehensive Selection: Diesel Pro Power stocks everything from cylinder kits and liners to seals, filters, and installation tools—making it the single source for Detroit Diesel rebuild parts.

OEM-Level Quality: Each component is built to meet or exceed original specifications, ensuring perfect fit and reliable operation.

Global Reputation: With over 40,000 satisfied customers worldwide, Diesel Pro Power has become a trusted name for Detroit Diesel replacement parts in marine, industrial, and on-highway sectors.

Fast Worldwide Shipping: All products are in stock and ready to ship, reducing downtime and helping you complete your rebuild faster.

Expert Support: Whether you’re an experienced mechanic or performing your first rebuild, Diesel Pro’s technical staff provides expert assistance to guide you through the process.

Rebuilding Tips for the Detroit Diesel 4-71 Non-Turbo

-

Inspect the Block Carefully: Clean and inspect the block’s liner bores, counterbores, and oil passages before installing new components.

-

Check Liner Protrusion: Measure liner height to ensure it meets Detroit Diesel’s specifications—improper height can cause head gasket failure.

-

Install Rings Correctly: Stagger ring gaps around the piston to prevent compression leakage.

-

Torque in Stages: Use a calibrated torque wrench and follow the proper tightening sequence when installing the cylinder head.

-

Prime the Oil System: Before the first start-up, always prime the oil pump and filters to prevent dry starts.

-

Use Genuine Gaskets and Seals: Inferior sealing materials can compromise your rebuild quickly.

-

Tune the Engine Properly: Set injector rack and valve lash according to manufacturer guidelines for smooth performance.

A correctly rebuilt Detroit Diesel 4-71 can deliver thousands of additional hours of dependable service when maintained with quality parts and proper procedures.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588