Parts for Detroit Diesel 471 Non-Turbo - (4 Valve Head Type) for Canada - Engine Overhaul Kit Section

Loading...

Loading... Parts for Detroit Diesel 4-71 Non-Turbo (4-Valve Head Type) – Engine Overhaul Kit Section

The Detroit Diesel 4-71 engine is one of the most iconic powerplants in the Series 71 family, designed for consistent performance, long service life, and rugged dependability in both industrial and marine environments. When it’s time to bring this classic two-stroke engine back to peak condition, a properly matched engine overhaul kit provides everything needed to restore compression, eliminate wear, and renew essential sealing and lubrication integrity.

This section focuses on engine overhaul kits and in-frame rebuild components for the Detroit Diesel 4-71 Non-Turbo (4-Valve Head Type) engine. These components are selected for precision fit, OEM-level quality, and long-term reliability. Diesel Pro Power supplies all major rebuild parts, gasket kits, seals, filters, and tools necessary for a complete in-frame overhaul. With over 40,000+ satisfied customers worldwide, Diesel Pro has become the trusted source for Detroit Diesel replacement parts.

Detroit Diesel 4-71 Engine Overview

The Detroit Diesel 4-71 is a four-cylinder, inline, two-stroke diesel engine producing between 140 and 180 horsepower depending on application and configuration. The “71” in its name represents the cubic inches of displacement per cylinder, resulting in a total displacement of 284 cubic inches (4.65 liters).

The 4-valve head variant provides improved airflow and combustion efficiency over the earlier 2-valve models, resulting in smoother idle, better throttle response, and cleaner emissions. This configuration was widely used in construction equipment, generators, small vessels, and stationary industrial systems where long hours of operation demanded robust engineering and ease of service.

Because of its modular design, the 4-71 shares many components with other Series 71 engines such as the 6-71, 8V71, and 12V71, making part sourcing straightforward. The overhaul kits listed here are specifically tailored to the non-turbocharged 4-71 engines equipped with either one-piece or two-piece piston assemblies.

Engine Overhaul Kits for Detroit Diesel 4-71 Non-Turbo

Detroit 4-71 Engine Overhaul Kit – Non-Turbo (One-Piece Piston)

For standard naturally aspirated engines using one-piece pistons, this kit contains all the major internal components required for an in-frame rebuild. It’s the ideal choice when the pistons and liners are worn but the crankshaft remains serviceable.

Included Components:

-

Cylinder liners and seals

-

Pistons and piston rings (one-piece design)

-

Connecting rod bearings

-

Main bearings

-

Thrust washers

-

Full engine gasket set

-

Liner O-rings and seals

-

Pin bushings and retainers

Benefits:

-

Designed for fast in-frame overhaul with minimal downtime

-

OEM-quality metallurgy for high wear resistance

-

Restores compression and power output

-

Compatible with factory clearances and tolerances

This one-piece piston configuration was commonly found in industrial power units and stationary generators where simplicity and durability were preferred.

Detroit 4-71 Engine Overhaul Kit – Non-Turbo (Two-Piece Crosshead Piston)

For engines equipped with the crosshead two-piece piston design, this kit provides all equivalent components in the appropriate configuration. Crosshead pistons separate the crown and skirt portions, connected by a pin and guide, allowing better heat dissipation and reduced skirt wear.

Kit Features:

-

Two-piece piston assemblies with upper crown and lower skirt

-

Liner kits with precision-fit O-rings

-

Rod and main bearings, cam bushings, and thrust washers

-

Full gasket set for upper and lower engine rebuild

-

Designed for engines operating in heavy-duty or continuous-load applications

Advantages:

-

Improved heat control for long duty cycles

-

Reduced friction and wear in high-load applications

-

Suitable for marine auxiliary and industrial power equipment

Both overhaul kits are designed to restore engine performance, fuel efficiency, and reliability while meeting original Detroit Diesel engineering standards.

Supporting Components and Tools

To complement the overhaul process, Diesel Pro Power offers a complete range of service tools, seals, and accessories necessary for proper reassembly.

A cylinder liner puller is indispensable when removing old liners from the block during teardown. Designed specifically for Detroit Diesel Series 53 and 71 engines, this puller provides a secure grip and even extraction force without damaging the block bore. Using proper extraction tools prevents block distortion and ensures the new liners seat correctly with the proper interference fit.

Liner Inserts and Shims

Liner inserts and shims are critical for setting liner height and ensuring proper compression sealing between the cylinder head and block.

-

Standard Liner Inserts – Used when block counterbores remain within specification.

-

Oversize Inserts (.010–.030) – Installed when counterbores are slightly worn or have been machined.

-

Liner Shims (.002 or .003) – Fine-tune liner height to match Detroit Diesel’s required protrusion specification for optimal sealing.

Proper liner height adjustment prevents coolant leaks and ensures uniform combustion chamber pressure across all cylinders.

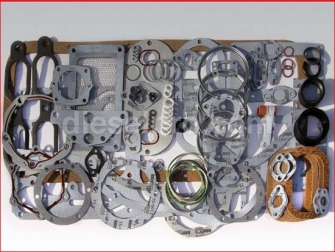

Complete Engine Gasket Kit

The Detroit Diesel 4-71 overhaul gasket kit includes all necessary gaskets and seals for the upper and lower engine assemblies. Components are made from premium materials resistant to oil, fuel, and coolant exposure.

Kit Contents Include:

-

Cylinder head gasket

-

Intake and exhaust manifold gaskets

-

Oil pan and rocker cover gaskets

-

Water pump seals

-

Fuel and oil pump gaskets

-

Injector O-rings

-

Crankshaft front and rear seals

Every gasket kit ensures leak-free reassembly and long-term reliability after a rebuild.

Crankshaft Seals and Sleeves

Maintaining oil retention at the crankshaft ends is essential. Diesel Pro offers front and rear crankshaft seals in standardand oversize dimensions, available in both single-lip and double-lip designs depending on application.

-

Front Seal – Standard Universal Rotation: Compatible with left- or right-hand rotation engines.

-

Rear Seal – Single or Double Lip: Available for 3-71 through 16V92 engines.

-

Seal Sleeve – Oversize: Used to repair worn seal surfaces on crankshaft journals.

Proper seal selection ensures longevity and eliminates oil seepage common in older two-stroke engines.

Filters, Fluids, and Routine Maintenance Components

During any major rebuild, filters and fluids should always be replaced to prevent contamination and premature wear.

Fuel Filters

Detroit Diesel 4-71 engines typically use a two-stage filtration system:

-

Primary Filter – Removes coarse contaminants from the fuel supply (available in spin-on or cartridge style).

-

Secondary Filter – Provides final filtration to protect injectors and fuel pumps.

Spin-on and cartridge options are offered for both configurations, each meeting or exceeding OEM filtration efficiency standards.

A clean oil supply is critical for new bearings and piston assemblies. Both spin-on and cartridge-type oil filters are available, designed for high flow rates and superior particle retention. Replacing the oil filter at every oil change maintains lubrication quality and extends bearing life.

The Detroit Diesel 4-71 thermostat (173°F) maintains optimal engine operating temperature, ensuring efficient fuel combustion and preventing cylinder glazing during light load operation.

Tools for Rebuilding

Proper tooling makes overhaul work efficient and precise.

-

Piston Ring Compressor – Ensures safe and even installation of piston assemblies into liners without ring damage.

-

Piston Ring Assembly Tool – Simplifies piston ring installation and removal for both Detroit and Cummins engines.

-

Fuel and Oil Filter Wrenches – Adjustable designs for secure grip and quick service.

-

Tune-Up Kit for Series 53, 71, and 92 Engines – Contains specialized service tools for injector calibration, governor adjustments, and timing checks.

Using the correct tools prevents costly mistakes and guarantees a factory-level rebuild.

Additional Components for Finishing the Rebuild

Block Heaters

For engines operating in cold climates, block heaters keep coolant and engine oil warm during downtime. Two models are available:

-

1500-Watt Standard Heater – For general applications.

-

750-Watt Air-Compressor Version – Designed for engines with auxiliary air systems.

Warm starts reduce wear on bearings and pistons, improving longevity.

Used to flush debris and corrosion from the cooling system before filling with fresh coolant. Maintaining a clean cooling system ensures uniform cylinder temperatures, preventing thermal distortion during operation.

Temperature Switch and Electrical Accessories

Temperature switches close at 205°F, protecting the engine from overheating by triggering alarms or automatic shutdown systems. Electrical gauges (mechanical, 12V, and 24V options) are also available to monitor oil pressure, coolant temperature, and voltage during engine operation.

Engine Finishing and Presentation

After completing a rebuild, a clean and properly finished engine not only performs well but also looks professional. Diesel Pro supplies Detroit Diesel Green Engine Paint and primer, both formulated for high-temperature resistance and protection against oil and chemical exposure.

Painting the block and components after assembly prevents corrosion and preserves the professional appearance associated with freshly rebuilt Detroit Diesel powerplants.

Best Practices for Overhauling a Detroit Diesel 4-71

-

Inspect Before Disassembly: Check compression, oil pressure, and coolant integrity to identify root causes of performance loss.

-

Follow Torque Specifications: Always adhere to Detroit Diesel torque values when reinstalling heads, rods, and main caps.

-

Cleanliness Is Key: Keep all parts and oil passages clean to prevent debris-related damage.

-

Pre-Lubricate Components: Use engine assembly lube on bearings, liners, and piston rings during installation.

-

Prime the Oil System Before Start-Up: Ensures immediate lubrication upon initial cranking.

-

Perform Post-Rebuild Adjustments: Set injector rack, valve lash, and governor linkages to factory specification.

Following these guidelines ensures that your rebuilt 4-71 performs with the same reliability and power that made Detroit Diesel famous.

Why Choose Diesel Pro Power for Your 4-71 Overhaul

-

Global Shipping and Support: Fast worldwide delivery ensures minimal downtime.

-

Over 40,000+ Satisfied Customers: Proven reputation in the marine and industrial engine market.

-

Comprehensive Inventory: Everything from overhaul kits to filters, seals, and gauges—available from one source.

-

Expert Customer Service: Technical representatives can guide you through part selection for your exact engine configuration.

-

Quality Assurance: All parts are tested and inspected to meet or exceed OEM standards.

Diesel Pro Power makes rebuilding a Detroit Diesel 4-71 straightforward, reliable, and cost-effective. Whether you are restoring a vintage generator, rebuilding a marine auxiliary engine, or servicing industrial power equipment, these complete overhaul kits and components ensure that your Detroit Diesel engine runs as powerfully and efficiently as the day it was new.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588