The Detroit Diesel 6-71 Turbo is a high-performance evolution of the time-tested 71 Series two-stroke diesel platform. With a robust inline 6-cylinder layout and the addition of a turbocharger, this engine delivers enhanced power, torque, and efficiency while retaining the rugged simplicity and modular design that define the Detroit Diesel legacy. Widely used in marine vessels, power generation, and heavy-duty industrial equipment, the 6-71 turbocharged version provides a dependable boost in output for operations demanding more performance without stepping up to a larger engine footprint. While maintaining mechanical fuel injection and modular head design, the turbo variant allows operators to move heavier loads, climb steeper grades, or cruise at higher speeds—especially in challenging marine conditions. At Diesel Pro Power, we offer the full spectrum of aftermarket parts for the Detroit 6-71 Turbo engine, including turbochargers, overhaul kits, fuel injectors, gaskets, cooling system parts, and more. Our parts are built to OEM-match or exceed original specs, and we ship worldwide with expert support to ensure your turbocharged 6-71 delivers power reliably for years to come. Engine Series: Detroit Diesel 71 Series Model: 6-71 Turbocharged Cylinder Arrangement: 6-cylinder inline Cycle: 2-Stroke Diesel Aspiration: Turbocharged, non-intercooled (stock) Valvetrain: Typically 4 valves per cylinder (2 intake, 2 exhaust) Fuel System: Mechanical unit injectors (pressure-timed) Firing Order: 1-5-3-6-2-4 Compression Ratio: ~16.5:1 (reduced to support forced induction) Governor Options: Mechanical, variable or limiting speed Bore: 4.25 inches (108 mm) Stroke: 5.00 inches (127 mm) Total Displacement: 426 cubic inches (6.99 liters) The core engine dimensions remain unchanged from the naturally aspirated 6-71, but the turbocharging system adds forced air induction to increase cylinder pressure and fuel efficiency. Injector Size Approx. Horsepower @ RPM N65 ~260 HP @ 2,100 RPM N70 ~275 HP @ 2,100 RPM N75 ~290 HP @ 2,100 RPM N80 ~300+ HP @ 2,100 RPM Industrial Rating: Often governed at 1,800 RPM for generators Torque Output: 625–750 lb-ft depending on load and injector size The turbocharger boosts power output by up to 30–40% compared to the naturally aspirated version without requiring a major increase in engine size or fuel flow under light load. Turbo Type: Fixed-geometry, exhaust-driven Mounting: Exhaust manifold-mount Boost Pressure Range: 8–15 PSI typical Intercooler: Not included in stock configuration (intercooler optional in retrofits) Wastegate: Not common in stock systems Oil Capacity with Filter: ~10 gallons (37.9 liters) Coolant Capacity: ~7.5 gallons (28.4 liters) Operating Oil Pressure: 40 – 60 PSI Standard Operating Temp: 170°F – 195°F Max Coolant Temp: 200°F Turbocharged engines run hotter than non-turbo configurations, making proper cooling system maintenance and high-quality coolant components essential. Dry Weight: ~2,250–2,350 lbs depending on turbo and accessories Length: ~67 inches (170 cm) Width: ~32 inches (81 cm) Height: ~42 inches (107 cm) Despite the addition of a turbo system, overall size remains compact enough to fit engine rooms, machinery enclosures, and marine engine bays without major modifications. The turbocharged 6-71 offers as much as 100 more horsepower than the non-turbo 2-valve or 4-valve variants—without requiring additional displacement or engine mounts. Turbocharging increases the mass of air in each combustion cycle, resulting in a more complete burn of injected fuel. This means more power is produced per unit of fuel—especially during high-load operations. The turbo helps compensate for air density losses at higher altitudes and ensures more consistent performance in tropical or desert climates, making it an excellent choice for global marine and industrial operators. This is especially useful in marine towing, heavy lifting, or uphill operations, where the engine needs torque more than speed. Turbocharged 6-71 engines are commonly used in marine environments where horsepower, reliability, and parts availability are critical. Fishing Vessels (Crabbers, Shrimpers, Gillnetters): Delivers the torque needed to haul full nets while cruising efficiently to and from fishing grounds. Tugboats & Push Boats: Popular in shallow-draft, harbor-assist tugboats, especially in small fleets. Barge Pusher Boats: Capable of pushing heavier loads through inland rivers or coastal areas. Tour and Charter Boats: Offers smoother throttle response, better economy, and higher cruise speed. Dredgers and Support Vessels: Supports hydraulic systems and propulsion in demanding operations. Large Trawlers and Liveaboard Boats: The 6-71 Turbo offers the perfect power upgrade for boaters who want better cruising speeds without sacrificing longevity. Converted Workboats: Many ex-commercial vessels converted for private use retain their 6-71 turbo engines for their blend of power and serviceability. The 6-71 turbocharged engine also performs reliably in land-based applications where consistent power is needed for long hours. Prime and Standby Generators (80–125 kW): A top choice for field generators in remote oilfields, mines, and military operations. Hydraulic Pump Systems: Used in pipeline and industrial fluid control where boost in engine output enhances flow volume. Large Compressors: Powers drilling rig air systems and portable high-pressure compressors. Construction Equipment: Found in older cranes, pile drivers, and rock-crushing equipment. Mobile Utility Platforms: Trucks and trailers with PTO-driven accessories benefit from high torque at moderate RPM. Boost in Performance Without Changing the Engine Block Reliable, Proven Platform with Decades of Field Use Still 100% Mechanically Controlled—No Electronics Extremely Easy to Service with Widely Available Parts Can Be Retroactively Installed in Place of NA Engines Diesel Pro Power carries turbo kits, manifolds, and head gaskets for customers converting their naturally aspirated 6-71 engines to turbocharged configurations. Marine Detroit Diesel 6-71 Component Maintenance Life Engine Components and Their Roles (Covering Detroit Diesel 271, 371, 471, 671 Engines) Key Maintenance Procedures (Covering Detroit Diesel 271, 371, 471, 671 Engines) Assembly and Disassembly Guidelines (Covering Detroit Diesel 271, 371, 471, 671 Engines) Safety Protocols for Technicians (Working On Detroit Diesel 271, 371, 471, 671 Engines) Torque Specifications And Wear Limits (Covering Detroit Diesel 271, 371, 471, 671 Engines) Disassembly Of Throttle Controls For Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671) DISASSEMBLY OF AIR BOX COVERS FOR DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671) Disassembly Of The Blower For Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671) Removing Air Box Drains For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) REMOVING THE VALVE ROCKER COVER ON A DETROIT DIESEL 71 SERIES INLINE ENGINE (271, 371, 471, 671) Torque Specifications Of 71 Series Inline Engines (271, 371, 471, 671) Disassembly Of Components For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Key Components of the Oil Pump and Model-Specific Variations (271, 371, 471, 671) INSIGHTS FROM THE DETROIT DIESEL 71 SERIES INLINE ENGINE MANUAL VOLUME 2 (271, 371, 471, 671) LUBRICATION SYSTEM FOR DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671) Disassembly of the Oil Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Reassembly of the Oil Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Oil Filters For Detroit Diesel 71 Series Inline Engines (271,371, 471, 671) LUBRICATING OIL PRESSURE REGULATOR FOR DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671) Oil Cooler For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Oil Pan For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Ventilating System for Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Oil Pump Maintenance For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Radiator Cooling For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Cooling System and Heat Exchanger For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Cooling System Configurations For 71 Series Inline Engines (271, 371, 471, 671) Types of Coolant for Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Chemicals & Coolant For Your Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671) Maintaining The Heat Exchanger Core For Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671) Guidelines for Coolant For Detroit 71 Series Inline Engines (271, 371, 471, 671) Introduction to the Water Pump System for the 71 Series Inline Engine (271, 371, 471, 671) Disassembly of the Freshwater Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Reassembly of the Freshwater Pump For Detroit Diesel 71 Series Inline (271, 371, 471, 671) Freshwater Pump Maintenance For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Raw Water Pump Maintenance (Marine Application) For 71 Series Inline Engines (271, 371, 471, 671) Disassembly of the Raw Water Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Reassembly of the Raw Water Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Water Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Thermostat Operation For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) SYSTEMATIC APPROACH TO TROUBLESHOOTING DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671) Cooling System Troubleshooting For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Troubleshooting Tips for Improved Efficiency In Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Detroit Diesel 271,371,471,671 Inline Engine Tune Up Guide Disassembly Turbocharger (If Equipped) For Detroit Diesel 71 Series Inline Engines (471, 671) Disassembly Of Turbochargers For Detroit Diesel 71 Series Inline Engines – (471, 671)

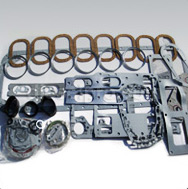

Parts for Detroit Diesel 671 Turbo

-

Select Parts Category

Loading...

Loading... Detroit Diesel 6-71 Turbo Engine Specifications & Applications

Introduction to the Detroit Diesel 6-71 Turbocharged Engine

Engine Configuration and Core Specs

Bore, Stroke, and Displacement

Performance and Power Output

Typical Marine Rating: 250–300 HP

Turbocharger System Details

Oil and Cooling System Capacities

Physical Dimensions and Weight

Key Benefits of the 6-71 Turbocharged Engine

More Power with the Same Footprint

Improved Fuel Efficiency Under Load

Better High-Altitude and High-Heat Performance

More Torque at Mid-Range RPMs

Marine Applications of the Detroit Diesel 6-71 Turbo Engine

Commercial Use

Recreational Marine Use

Industrial and Generator Applications

Why Choose the Turbocharged 6-71?

Additional Resources

The Legacy of the Detroit Diesel Marine 671 Engine & Its Use Today

Detroit Diesel 6-71 Marine Engine Specifications (2 Valve, 4 Valve Non-Turbo & Turbo)

The History of the Detroit Diesel 671 Quad Engine Setup

Assembling The Detroit Diesel 671 Long Block

Aftermarket Parts For Detroit Diesel 671 Engines

Everything You Need to Know About the Detroit Diesel 671 Blower

Practical Guide To Servicing Your Detroit Diesel 71 Series Inline (271, 371, 471, & 671 ) – Part 1

AIR SCAVENGING AND BLOWER SYSTEM FOR DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671)

Best Practices for Keeping Air Intake and Exhaust Systems Clean For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Cleaning and Inspection Processes For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Safe Cleaning Procedures Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671)

Critical Inspection Points For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Valve and Injector Maintenance For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Checking Valve Clearance and Injector Timing For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Tools and Equipment For Maintaining Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Detailed Overhaul Process For Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671)

Common Troubleshooting Tips For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Disassembly Of Fuel Lines For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Disassembly Of Exhaust Manifold For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Disassembling The Air Cleaner & The Air Shutdown Housing For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Summary of Troubleshooting and Specifications In Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

FAQ From Detroit Diesel 71 Series Inline Engine Service Manual (271, 371, 471, 671)

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588