Parts for Detroit Diesel 671 Non-Turbo - (4 Valve Head Type) for Canada - Gasket Section

Loading...

Loading... Parts for Detroit Diesel 6-71 Non-Turbo (4-Valve Head) — Gasket Section

If you run a classic Detroit Diesel 6-71 naturally aspirated engine with the 4-valve cylinder head, keeping the sealing system healthy is non-negotiable. Gaskets and seals are what keep compression where it belongs, oil where it should stay, and coolant and raw water from wandering into places they absolutely shouldn’t. This page focuses exclusively on the 6-71 Non-Turbo (4-valve head type), tying every component back to real-world service tasks on this specific engine. While some items may physically interchange with other Detroit two-stroke models, our guidance below is written for the 6-71 owner, tech, or fleet manager who needs to identify, choose, and install the right gaskets the first time.

Gaskets for Cylinder Head & Upper Engine (6-71 Non-Turbo, 4-Valve)

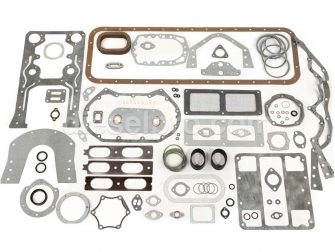

Head Gasket & Cylinder Head Gasket Set (Top-End Work)

When you’re refreshing valves, injector cups, or addressing coolant seepage along the deck, the cylinder head gasket set is the foundation of a reliable top-end reseal. On the 6-71 4-valve head, pay attention to coolant and oil transfer ports and ensure your set is matched to your head style (aluminum or cast rocker cover style influences other included pieces like rocker cover seals). A quality set will include the main head gasket(s), valve stem seals, injector tube seals, and the assortment of small profile gaskets that support thermostat housing, water manifold interfaces, and governor mounting to the head.

Rocker Cover Gaskets — Old Style vs. New Style

Detroit transitioned from tin (stamped steel) to aluminum rocker covers on many 71-series applications. Your 6-71 may use:

-

Old-style, black rubber rocker cover gasket for tin covers. These are slightly different in profile and compression behavior.

-

New-style, gray rubber rocker cover gasket tuned for aluminum covers.

If you’ve upgraded to aluminum covers for better sealing and rigidity, pair them with the new-style gasket to reduce weeping around the perimeter. Always inspect cover flatness; even a new gasket can’t compensate for a warped edge.

Governor-to-Head Sealing

Because the mechanical or hydraulic governor interfaces directly with the cylinder head on the 6-71, there are a few thin paper or fiber gaskets you’ll encounter:

-

Head-to-Governor gasket (seals the governor pad to the cylinder head).

-

Governor drive cover gasket (between blower cover and governor drive housing).

-

Governor spring cover and housing cap gaskets (small, easy-to-miss seals that prevent oil misting).

Replace these anytime the governor is removed for calibration, spring changes, or leak chasing. A minor seep here can coat the top of your engine with oil over time, and on marine installations that’s a housekeeping and safety issue.

Thermostat Housing & Thermostat Gaskets

Upper-engine coolant joints are notorious spots for crusting, pitting, and slow leaks. Replace the flat thermostat housing gasket and the thermostat gasket during any cooling service. If you see pitting on the housing flange, dress it lightly with a flat block; deep pitting calls for replacement of the housing itself, not just a thicker bead of sealant.

Water Rail (Water Manifold) Gasket

The long water manifold (often called the water rail) that runs along the cylinder head needs a dedicated gasket that matches the port spacing of the 6-71. Reuse is false economy here; a fresh cut gasket keeps coolant contained and helps your pump run a stable system without aeration.

Head-to-Exhaust Manifold Gaskets

Your naturally aspirated 6-71 breathes through the blower, but heat management still matters. Replace head-to-manifold gaskets whenever the manifold comes off, and tighten from the center outward in small increments after warm-up to account for expansion. If you run a marine manifold or riser, also check the marine manifold flange gasket sizing (OD/ID) so it fits the flange and doesn’t obstruct the flow.

Gaskets for the Blower & Air Handling (6-71 Non-Turbo)

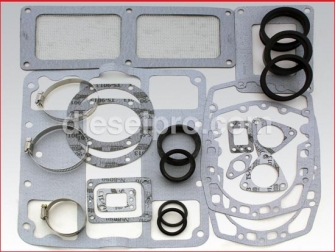

Blower Installation Gasket Kit

Even on a non-turbo 6-71, the Roots-type blower is the heart of scavenging. An installation kit simplifies resealing the blower to the block, the end plates, and the striker plate. Typical kit coverage for the 6-71 includes:

-

Blower-to-block gasket — the big one; leaks here cause oil smearing and low-grade air leaks that sap performance.

-

End plate gaskets — old-style blowers rely on these thin, precise seals; replace them if you open the blower.

-

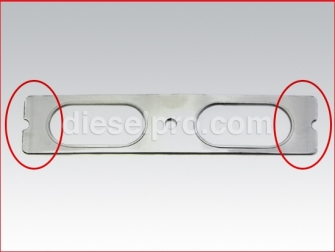

Striker plate gasket — often overlooked; keeps the assembly tight and prevents seepage at the interface.

-

Blower screen gasket — replaces the mesh cover seal to keep debris out and airflow consistent.

Inspection Cover & Front Lower Cover Gaskets

Use the inspection cover gasket on the block access plates and the front lower cover gasket anytime you pull those plates for blower or gear train checks. These are thin and inexpensive—don’t reuse old, compressed material. A clean, flat surface and a light film of high-tack gasket adhesive make for quick, drip-free reassembly.

Gaskets for Oil System & Bottom End (6-71 Non-Turbo)

Oil Pan Gasket

After decades of service, pan rails can show nicks and waves. The 6-71’s oil pan gasket is a robust, formed piece designed to seal even with minor rail imperfections—provided you properly torque in sequence and verify the pan lip is flat. Clean both rails, dry-fit the pan, and look for daylight with a feeler gauge. Correct the pan lip before installing the new gasket.

Oil Cooler Gaskets

The 6-71 uses stacked-plate oil coolers with dedicated end-cap gaskets. If you pull the cooler for flushing, pressure testing, or replacement, fit new gaskets on both ends. Watch for any corrosion on the cap faces and use the correct orientation; pinched oil cooler gaskets can cause cross-leaks between oil and coolant circuits.

Oil Filter Adapter Gasket

A small but critical seal. A tired adapter gasket can make it look like the rear main is weeping when the source is actually higher up. Whenever the adapter comes off for service, install a new gasket—cheap insurance against a messy bilge or shop floor.

Front & Rear Crankshaft Seals (6-71 Non-Turbo)

Standard vs. Oversize; Single-Lip vs. Double-Lip

The 6-71 sees a lot of hours, and crank hubs wear grooves. That’s why you’ll see:

-

Standard-size seals for unworn hubs.

-

Oversize seals (rear) to ride on a fresh surface if the hub is grooved.

-

Single-lip options (common, low friction) and double-lip options (extra exclusion of contaminants and better oil retention).

For the rear main, the 6-71 frequently benefits from the double-lip, standard option when the hub surface is in good shape, or the double-lip oversize with a matching rear sleeve if the sealing surface shows a groove. Always match an oversize rear seal with the specified sleeve to restore the sealing diameter correctly.

Front Main Seal

On the naturally aspirated 6-71, the front seal sees less splash than the rear but still ages out. Install the front, universal-rotation seal and verify the timing cover surface is flat and free of burrs. Inspect the wear sleeve or hub; replacing a $20–$50 seal without addressing a scored hub is a false fix.

Sleeves (Repair Rings) for Oversize Rear / Front

A repair sleeve lets a fresh seal ride on a clean, hardened surface. Press it square, seat fully, and confirm the new seal lip will land on the sleeve’s polished band. Lightly oil the lip at install; never run a lip seal dry.

Cooling System Gaskets (6-71 Non-Turbo)

Fresh Water (Engine Coolant) Pump Gasket

When removing the freshwater pump to change bearings or impeller, replace the cover gasket. A dripping cover after reassembly typically means either the flange has a ding or the old gasket was reused. Dress the surface and install a new gasket dry or with a light adhesive—avoid heavy RTV that can squeeze into the coolant passage.

Raw Water (Marine) Pump Gaskets

If your 6-71 is marinized, the raw water pump requires a set of thin paper gaskets at the inlet and outlet and often at an intermediate plate. Some pumps use two identical gaskets—one per port—so plan to buy them as a pair. Replace these anytime you service the impeller or the pump plate; a tiny vacuum leak on the suction side can cause aeration and overheating underway.

Heat Exchanger & End-Cap Gaskets (Marine)

A heat exchanger gasket kit covers end-caps and inspection plates. Replace these during cooler service, cleaning, or descaling. For best longevity, clean the grooves thoroughly and seat the new gaskets without twisting. Pressure-test if possible before buttoning up the system.

Thermostat & Housing

As mentioned above, these two gaskets are routine replacements during coolant service. Combine fresh gaskets with correct thermostat specs for the 6-71 to maintain stable head temperatures that protect the head gasket and reduce thermal cycling of the block deck.

Exhaust Interface Gaskets (6-71 Non-Turbo)

Head-to-Manifold

Two patterns are common across the 71-series; choose the one specified for the 6-71 port and bolt spacing you have. Heat-cycle and re-torque as required after initial run-in to prevent exhaust edge staining or ticking that hints at a leak.

Marine Manifold Flange Gasket

On marine conversions, the flange gasket between the manifold and riser or elbow must match the exact inner diameter to avoid choking the outlet. Verify outside and inside diameters against your flange; a mismatch can create hot spots and carbon build-up.

Insulation Tape (Manifold Wrap)

While not a gasket, high-temp insulation tape helps manage under-hood/engine-room temps and protects adjacent wiring and hoses. Install fresh wrap on clean, oil-free surfaces to keep radiant heat off your governor, fuel lines, and harness.

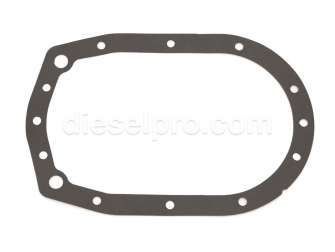

Flywheel Housing & Access Covers (6-71 Non-Turbo)

Flywheel Housing Perimeter Gasket & Large Service Cover

The flywheel housing uses both a full-profile gasket and a large removable cover with its own seal. If you pull the housing to access the rear seal or ring gear, replace both. Wipe surfaces with a lint-free towel and use a light spray tack to index the gasket; this minimizes creep during alignment.

Starter Mounting Gasket

Install a new starter gasket when replacing or shimming the starter. It helps control oil misting and protects the bore from grime. Oil seepage at the starter can masquerade as a rear main leak—fresh gasket, cleaned mating faces, and proper torque cure many “mystery” drips.

Flywheel-to-Raw-Water-Pump Adapter Gasket (Marine)

Many marine brackets pick up off the flywheel or housing. Where a gasket is specified between the adapter and the pump or housing, replace it on every service. A small leak here can fling salt water across the bellhousing—bad for everything.

Allison Marine Gear Interface (6-71 Non-Turbo)

SAE #2 Flywheel Housing-to-Transmission Gasket

On marinized 6-71s coupled to Allison M and MH gears with SAE #2 housings, use the correct flywheel housing-to-transmission gasket. This thin gasket helps ensure proper alignment and keeps oil mist from tracking along the joint. Confirm your housing size is SAE #2; if you’ve swapped housings, don’t assume—measure the bolt circle and opening. Proper alignment dowels must be present; a gasket can’t correct a missing dowel or bellhousing distortion.

General-Purpose & Accessory Gaskets (6-71 Non-Turbo)

Fuel & Water Pump Interface Gaskets

Small flat gaskets at the fuel pump and freshwater pump flanges are easy to tear during removal. Replace them proactively to avoid fuel weep or coolant drips. Use a thin film of high-tack adhesive on the part side to hold alignment; leave the block side dry for cleaner future removal.

Hydraulic Governor Cover & Drive Gasket

Hydraulic governor systems rely on tight covers. Replace the governor drive and cover gaskets whenever you’re inside to change springs or adjust rate. Keep mating surfaces immaculate; a single fiber under a cover can create a tiny gap that mists oil.

Adapter & Plate Gaskets (Raw Water Pump Plates, Adapters)

Wherever you see a plate on a pump body, there’s a thin gasket doing critical work. Replace plate gaskets during impeller service and inspect for plate warping. Likewise, adapter gaskets used to mate different accessory patterns should be refreshed when you change configurations.

Sealants, Dressings & Thread Treatments (Supporting the Gaskets)

High-Tack Gasket Adhesive (Spray)

Use high-tack spray to index broad, flat gaskets (oil pan, flywheel housing covers). It prevents slip during assembly and makes torque sequences more predictable. Apply a thin, even film; more is not better.

3H-Type Liquid Gasket Maker

A non-hardening liquid sealant has a place on certain Detroit two-stroke joints where OEM practice allows a film to augment a paper gasket. It stays pliable, resists vibration, and simplifies future disassembly.

Sensor-Safe RTV (Blue / Ultra Blue)

For joints near sensors or on modern retrofits with electronic senders, use sensor-safe RTV. Apply a narrow bead and keep it clear of oil passages and coolant ports. Allow proper skin-time and full cure per product instructions.

High-Temp RTV (Exhaust-Adjacent Joints)

High-temp RTV belongs near exhaust interfaces or hot covers—not inside coolant or oil passages. Use sparingly; the best practice is the correct gasket plus a tiny assist where the OEM joint is known to weep.

Non-Hardening Pliable Sealant

Great for thread sealing where a true pipe dope isn’t specified, or for dressing small cover gaskets. Stays flexible and helps when components see frequent maintenance.

Threadlocker (High-Strength Red)

Where Detroit specifies a locking compound (e.g., on fasteners that are vibration-prone), high-strength red is appropriate. Do not put threadlocker on fasteners that need routine adjustment or on studs that thread into aluminum—match the compound to the job.

Choosing the Right 6-71 Gaskets: Materials & Fit

Material Matters

-

Graphite/Composite head gaskets handle thermal cycling and slight surface imperfections better than old-style fiber alone.

-

NBR or Viton-based rocker cover gaskets resist oil swell.

-

Paper/fiber accessory gaskets seal well on flat, clean faces; dress lightly if a surface is not perfect.

-

Metal-reinforced seals (front/rear mains) with correct lip design stand up to the 6-71’s continuous-duty RPM.

Match the Head & Cover Style

On a 4-valve 6-71, your head architecture dictates rocker cover gasket selection and, in some sets, small variations in included seals. Confirm whether you run aluminum covers (new style) or tin covers (old style) and order to suit.

Standard vs. Oversize Seals

Rear main leaks that persist after a “standard” seal install often trace back to a grooved hub. That’s the moment to choose an oversize rear seal and repair sleeve. If you can catch a fingernail in the groove, plan on the sleeve.

Marine vs. Industrial Add-Ons

Heat exchanger kits, raw water pump gaskets, and marine manifold flange gaskets are specific to marinized 6-71s. Industrial and on-road engines won’t use them. Build your cart around your configuration.

Installation Best Practices (6-71 Non-Turbo)

Surface Prep

-

Scrape old gasket material with a plastic scraper or a new razor at a shallow angle.

-

Finish with Scotch-Brite on a flat block; avoid rounding edges.

-

Degrease with a lint-free towel and solvent that leaves no residue.

Dry vs. Dressed

-

Dry install: many paper gaskets seal perfectly when both faces are clean and flat.

-

Dressed: use high-tack spray to hold large gaskets in place or non-hardening sealant on known weepers.

-

RTV: only where OEM practice allows, and never in excess.

Torque, Sequence, and Re-Checks

-

Use Detroit-specified torque values and sequences for head, manifold, and pan fasteners.

-

After first heat cycle, re-check exhaust manifold and rocker cover fasteners to prevent edge weeps.

-

For the blower, torque in a crisscross, center-out pattern to keep the case parallel to the block.

Seal & Sleeve Install Notes

-

Lubricate lips lightly with clean engine oil.

-

Press repair sleeves square; confirm the seal lands on the polished band.

-

Inspect and replace worn wear rings or hubs—don’t ask a new seal to fix old metal.

Leak-Check Before Final Wrap-Up

-

Pressure test the coolant side if you serviced the heat exchanger or water rail.

-

Prime the oiling system and inspect for weeps around the filter adapter and cooler caps.

-

Run at fast idle and inspect the flywheel housing seam, rear pan edge, and starter joint.

Troubleshooting Common 6-71 Gasket & Seal Issues

Chronic Rear Main Drip

-

Check hub groove; oversize seal + sleeve may be required.

-

Verify crankcase pressure isn’t elevated (stuck breather can push oil past lips).

Oil Film on Governor & Top of Head

-

Replace the head-to-governor gasket and the small cap/spring cover gaskets.

-

Inspect rocker cover gasket and cover flatness (swap to new-style gasket if using aluminum cover).

Coolant Seep at Water Manifold

-

Replace the water rail gasket; inspect bolt torque and flange straightness.

-

Check for electrolysis pitting around ports—severe pitting needs component replacement.

Exhaust Tick After Manifold Service

-

Re-torque after heat cycle; ensure you used the correct head-to-manifold gasket pattern for your 6-71.

-

Inspect flange flatness and look for carbon trails to pinpoint the leak point.

Raw Water Drip in Bilge (Marine)

-

Confirm both inlet and outlet gaskets are new and seated.

-

Inspect plate gasket and pump face for wear tracks; dress or replace plate as needed.

Maintenance Strategy for Long-Life Seals on a 6-71

Proactive Gasket Refresh During Adjacent Work

Bundle small gaskets into any job that already exposes them: if the governor is off, refresh the drive and cover gaskets; if the blower comes off, do the end plates and striker plate; if the pan is down, replace the pan gasket and inspect rear main.

Use the Right Sealant in the Right Amount

A thin, even film beats big beads every time. Excess RTV becomes debris in oil galleries or cooling jackets—a serious risk on a two-stroke Detroit where flow areas are tight.

Monitor Fasteners After Heat Cycles

The 6-71’s castings move with heat. A quick re-check of exhaust and cover fasteners after the first few hours makes a big difference in long-term cleanliness.

Keep Paint & Cleanliness in Mind

A coat of Detroit green formulated for engines protects metal and makes leaks easier to spot. Degrease before painting; paint after you’ve verified joints are dry.

Why Buy Your 6-71 Gaskets from Diesel Pro Power

-

Focused 6-71 Coverage: Everything above is curated with the 6-71 Non-Turbo (4-valve head) in mind, so you don’t have to sift through generic lists.

-

Reliability at Sea and on Land: Marine-specific gaskets (raw water pump, heat exchanger, marine flange) and industrial essentials (oil cooler, starter, flywheel housing) are in one place—ready when your maintenance window opens.

-

Quality You Can Trust: Our replacement gaskets and seals meet or exceed OEM performance, with modern materials that stand up to heat, vibration, and continuous-duty service.

-

In-Stock, Fast Shipping: Most items on this page are in stock, so you can plan your service and keep downtime to a minimum.

-

Expert Support: Need to confirm rocker cover style, choose between standard vs. oversize rear seals, or identify a marine flange gasket by dimensions? We can help you match parts to your exact 6-71 configuration.

-

Proven Customer Satisfaction: Join 40,000+ satisfied customers who count on Diesel Pro Power for dependable parts and steady uptime.

-

Clear Fitment Notes: Where items also fit other Detroit two-stroke models, we make that clear—but our recommendations keep the spotlight on your 6-71.

Quick Selection Guide (6-71 Non-Turbo)

Top-End

-

Cylinder head gasket set for the 6-71 4-valve head

-

Rocker cover gasket matched to cover style (old tin vs. new aluminum)

-

Governor pad, drive, cap, and spring cover gaskets

-

Thermostat and housing gaskets

-

Water rail (manifold) gasket

Blower & Air Handling

-

Blower-to-block gasket

-

End plate gaskets (old-style blowers)

-

Striker plate gasket

-

Blower screen gasket

-

Inspection and front lower cover gaskets

Bottom End & Oil System

-

Oil pan gasket

-

Oil cooler end-cap gaskets

-

Oil filter adapter gasket

Crankshaft Seals

-

Front main seal (universal rotation)

-

Rear main seal (single-lip or double-lip; standard or oversize)

-

Repair sleeve for oversize rear/main as needed

Cooling & Marine

-

Freshwater pump cover gasket

-

Raw water pump inlet/outlet and plate gaskets (marine)

-

Heat exchanger gasket kit (marine)

-

Marine manifold flange gasket (verify ID/OD)

Flywheel & Interfaces

-

Flywheel housing perimeter gasket

-

Large flywheel service cover gasket

-

Starter mounting gasket

-

Flywheel-to-raw-water-pump adapter gasket (where used)

-

Allison marine gear SAE #2 housing-to-transmission gasket (for marinized 6-71s)

Dressings & Companions

-

High-tack gasket adhesive (spray)

-

Non-hardening pliable sealant

-

Sensor-safe RTV (blue / ultra blue)

-

High-temp RTV (for specific hot joints)

-

High-strength red threadlocker (where specified)

-

Detroit green engine paint

Installation Tips Specific to the 6-71 Non-Turbo

Setting the Head

Dry-fit the head gasket on a spotless deck; verify oil and coolant ports. Lower the head evenly to avoid scuffing the gasket. Follow Detroit torque steps carefully, and re-check after initial operation if your maintenance manual calls for it.

Blower Reseal

Clean the block pad thoroughly; a slight nick near an air passage can cause a subtle vacuum leak. Replace the blower-to-block gasket and striker plate gasket together. Check end-plate flatness on old-style blowers.

Rear Main Strategy

If the bellhousing is off for any reason, evaluate the rear seal. If the crank hub is grooved, plan a sleeve + oversize seal solution now rather than living with a drip later.

Cooling Interfaces

On marine engines, replace both raw water pump port gaskets at every impeller service. Use new heat exchanger end-cap gaskets after cleaning. Pressure-test the exchanger on the bench when possible.

Exhaust Manifold

Use the correct head-to-manifold gasket pattern for your 6-71, torque from center out, and re-check after warm-up. If you run a marine riser, confirm the flange gasket ID to avoid restriction.

Safety & Housekeeping

-

Wear eye protection when scraping gaskets and when using aerosol adhesives.

-

Keep oil and solvent off belts and hoses.

-

Dispose of old sealants and gaskets per local regulations.

-

Label and bag fasteners by component; the 6-71 is simple, but organization prevents mix-ups.

Frequently Asked Questions — 6-71 Non-Turbo Gaskets

Do I need sealant on the head gasket?

Follow Detroit service literature for your specific head gasket construction. Many modern composite head gaskets install dry on clean, flat surfaces.

How do I know which rocker cover gasket I need?

Check your cover material: tin (old style) uses the black rubber profile; aluminum (new style) uses the gray profile. If you’ve converted to aluminum covers, use the new-style gasket.

When should I choose a double-lip rear main seal?

When you want extra oil retention and contaminant exclusion—especially valuable on workboats or dusty industrial environments. If the hub is grooved, step up to oversize + sleeve.

Can a raw water pump leak air but not water?

Yes—on the suction side, a poor gasket can admit air without dripping. Symptoms include unexplained overheating or unstable raw water flow. Replace inlet/outlet and plate gaskets and inspect the plate face.

Why does my starter area look oily?

A tired starter mounting gasket or the flywheel housing service cover gasket can mist oil. Replacing these often cures what looks like a rear main problem.

Why Buy These 6-71 Gaskets from Diesel Pro Power

For owners and operators of Detroit Diesel 6-71 Non-Turbo engines, we provide a complete, curated lineup of gaskets and seals that match your exact configuration—from the 4-valve head top-end set and rocker cover gaskets to blower installation kits, rear main seal options (standard and oversize), and the marine-specific interfaces many 6-71s rely on. Our parts are engineered as high-quality replacement components and are not affiliated with any OEM brand. You get fast availability, clear fitment notes, and expert help if you need it—backed by 40,000+ satisfied customers who trust us to keep their Detroits clean, dry, and running strong.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588