Parts for Detroit Diesel 671 Non-Turbo - (4 Valve Head Type) for Canada - Exhaust Section

Loading...

Loading... Parts for Detroit Diesel 6-71 Non-Turbo (4-Valve Head Type) – Exhaust Section

The Detroit Diesel 6-71 engine, part of the legendary Series 71 family, has been one of the most reliable and widely used two-stroke diesel engines ever produced. Renowned for its simplicity, ruggedness, and service life, the 6-71 non-turbo (naturally aspirated) configuration continues to power countless vessels, generators, and industrial machines worldwide. In marine applications, proper exhaust system maintenance is essential to prevent overheating, maintain optimal backpressure, and ensure the engine’s longevity. This section focuses exclusively on high-quality exhaust components for the Detroit Diesel 6-71 non-turbo 4-valve head type — including manifolds, elbows, flanges, mufflers, gaskets, and all necessary hardware.

Detroit Diesel Marine Water-Cooled Exhaust Manifold

The Detroit Diesel Marine Manifold for the 6-71 and 12V71 is a robust, water-cooled exhaust manifold engineered to handle the extreme heat generated in continuous-duty marine operation. Built from heavy cast iron and precision-machined to factory tolerances, this manifold ensures effective heat dissipation through internal water passages.

For marine operators, water-cooled manifolds are essential because they prevent radiant heat from damaging nearby components and reduce engine room temperatures. This manifold includes provisions for 1-inch threaded fittings, allowing easy connection to the raw water system. Diesel Pro Power supplies these manifolds new and ready for installation—ideal for refit projects or preventive maintenance programs on older vessels.

Applications include:

-

Detroit Diesel 6-71 non-turbo engines used in marine propulsion and auxiliary power generation

-

Commercial fishing boats, tugs, and trawlers

-

Yacht main propulsion systems

Each manifold is inspected for casting integrity and hydro-tested to ensure zero leakage in the cooling jacket.

Head to Manifold Gaskets

Two variations of Detroit Diesel Head to Manifold Gaskets are available, depending on the series and application.

-

Gasket for 6-71 and 12V71 – Designed to create a perfect seal between the cylinder head and the exhaust manifold, this gasket prevents exhaust leaks that can affect engine performance. Manufactured using heat-resistant materials and reinforced steel cores, these gaskets endure constant high-temperature cycles.

-

Gasket for Series 71 and 92 Engines (4-71, 6-71, 8V71, 12V71, 16V71, 8V92, 16V92) – Ideal for multi-engine fleets or operations maintaining different Detroit Diesel models. This gasket type ensures uniform fitment and reliable sealing across a range of engines, making it a versatile option for marine service shops and fleet engineers.

Proper sealing between the head and manifold ensures accurate backpressure, optimal scavenging, and reduced exhaust noise. Regular replacement during overhauls is recommended to maintain system integrity.

Marine Exhaust Manifold Flange and Gasket

The Detroit Diesel Marine Exhaust Manifold Flange connects the water-cooled manifold to the exhaust riser or outlet system. Constructed with a 4-inch NPT thread, this component ensures a secure connection that can withstand high vibration and thermal expansion common in marine engines.

Complementing the flange is the Marine Manifold Flange Gasket, designed with an outer diameter of 6.25 inches and an inner diameter of 4.25 inches. This gasket provides a gas-tight seal, preventing leaks at the junction where exhaust gases and cooling water merge. Diesel Pro Power supplies both components new and ready for installation, ensuring precise fitment and long-lasting service.

Manifold Insulation Tape

To control surface temperatures and protect the surrounding engine compartment, Manifold Insulation Tape is essential. Available in 3-inch and 4-inch widths, this high-quality fiberglass tape is designed to wrap exhaust manifolds, elbows, and pipes. It reduces radiant heat loss, prevents burns, and improves overall thermal efficiency.

-

3” x 100’ x 1/8” Thickness – Ideal for tight spaces or smaller diameter pipes.

-

4” x 100’ x 1/8” Thickness – Best for large manifold assemblies or wide exhaust runs.

By keeping exhaust heat inside the piping, insulation tape can also improve exhaust flow velocity, slightly boosting efficiency in naturally aspirated engines like the 6-71.

Manifold Hardware: Studs, Crabs, Washers, and Nuts

Reliable hardware ensures secure attachment and even clamping pressure across the manifold assembly. Diesel Pro Power supplies OEM-grade replacements for all critical fasteners:

-

Manifold Studs (7/16"–14/20 x 2.10") – Heat-treated for strength and corrosion resistance.

-

Manifold Crabs – These clamps distribute torque evenly, reducing the risk of warping during installation.

-

Washers and Nuts – Zinc-coated and engineered for high-temperature service. Proper torque application with these parts prevents exhaust leaks and gasket blowouts.

When reassembling any Detroit Diesel exhaust system, always use new hardware to maintain correct torque retention, especially after thermal cycling.

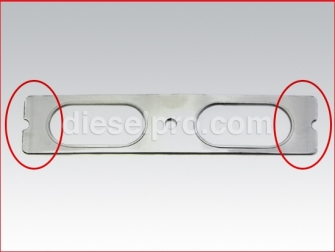

Marine Manifold Plates and Gaskets

The Marine Manifold Water Outlet Plate and Threaded Plates are designed to close or connect water passages on the manifold. These plates include:

-

A Water Outlet Plate with its corresponding gasket (Series 71/92 type) for a tight seal.

-

A Threaded Plate with a 3/4-inch threaded opening, used to attach fittings for cooling water hoses or sensors.

Constructed from corrosion-resistant metal and machined for perfect flatness, these plates maintain the internal water pressure necessary for even manifold cooling.

Exhaust Elbows and Connectors

The exhaust elbows are critical junctions between the manifold outlet and the downstream exhaust piping. Diesel Pro offers:

-

90° Elbows (1” and 3/4” thread) – Commonly used in tight marine spaces to route exhaust water efficiently.

-

45° Elbows (3/4” thread) – Used where a more gradual exhaust bend is needed to minimize restriction and backpressure.

All elbows are precision-cast for strength and threaded for direct installation on marine manifolds. These fittings resist corrosion from saltwater and maintain full flow under load.

Industrial Flanges and Mufflers

For stationary or generator applications using the Detroit Diesel 6-71, Diesel Pro Power provides industrial exhaust flanges, gaskets, and mufflers compatible with 4-inch exhaust systems.

-

Industrial Exhaust Flange (4” ID) – Provides a sturdy connection point for the exhaust outlet.

-

Flange Gasket (4” ID) – Designed for heat resistance and sealing under high vibration.

-

Industrial Muffler (4” NPT Inlet/Outlet) – Reduces exhaust noise while maintaining appropriate flow characteristics. Available with precise dimensional charts to ensure fitment.

These components are frequently used on generator sets, compressors, and stationary equipment where exhaust routing must comply with safety and noise standards.

Muffler Caps

Protective Muffler Caps prevent water, dust, or debris from entering the exhaust pipe when the engine is not running. Available in multiple sizes — 3”, 3.5”, 4.5”, and 5” diameters — these caps are crucial for maintaining the longevity of marine and industrial exhaust systems.

Each cap is made from stainless or galvanized steel for corrosion protection. They automatically lift when exhaust pressure increases and close tightly when the engine stops, providing maintenance-free protection in all weather conditions.

Flexible Metal Exhaust Hoses

The Flexible Metal Exhaust Hose (4” diameter x 18” length) allows for movement and vibration absorption between rigid exhaust components. This flexibility is especially vital in marine and industrial installations where engines vibrate or expand thermally during operation.

Constructed from interlocked stainless steel, these hoses resist heat, corrosion, and mechanical stress. Proper installation of flexible sections prevents cracking or misalignment in manifolds and flanges, extending exhaust system life.

Temperature Switch for Exhaust Systems

The Temperature Switch (Closes at 205°F, 1/2" NPT) is a simple yet critical component for safety monitoring. Installed near the manifold or cooling circuit, it signals when the temperature exceeds safe operating limits. Compatible with Detroit Diesel, Cummins, and Caterpillar engines, it helps prevent overheating in both marine and industrial systems.

Integrating this sensor with your alarm panel ensures early detection of restricted water flow or cooling issues—an essential safeguard for engines operating in continuous-duty environments.

Detroit Diesel Green Paint

Once the exhaust system is reassembled, Detroit Green Paint provides the finishing touch. This industrial-grade enamel protects against corrosion, heat, and oil contamination while restoring the iconic Detroit Diesel color. Only available for ground shipping within the U.S. and Canada, this paint ensures long-term durability and a professional finish for restorations and rebuilds.

Gauges and Monitoring Accessories

Monitoring exhaust temperature and engine performance is essential for reliability. Diesel Pro Power offers:

-

Mechanical Gauges (Standard and with Alarm)

-

Electrical Gauges for both 12V and 24V systems

These instruments allow operators to maintain optimal exhaust temperatures, ensuring proper cooling and combustion efficiency.

Why Buy Detroit Diesel 6-71 Non-Turbo Exhaust Parts from Diesel Pro Power

Trusted Worldwide Since 1989

Diesel Pro Power has proudly served more than 40,000 satisfied customers across over 200 countries. The company has become the go-to source for legacy Detroit Diesel engine parts—especially for the 6-71 non-turbo models that continue to power fleets, vessels, and industrial units decades after production ceased.

OEM-Grade Quality You Can Depend On

Every exhaust component listed—whether a manifold, gasket, or muffler—is tested for quality and fitment. Diesel Pro Power ensures each part meets or exceeds OEM specifications, providing the reliability professional operators expect.

Fast Global Shipping and Real-Time Tracking

With strategically located warehouses and streamlined logistics, Diesel Pro Power delivers parts quickly anywhere in the world. Customers can track their orders in real time and receive prompt updates.

Comprehensive Technical Support

Diesel Pro’s expert staff understands the Series 71 engine line inside and out. Whether you’re restoring a vintage vessel or maintaining a workboat fleet, you can count on professional guidance for selecting and installing the right exhaust parts.

Simplified Online Ordering

The DieselPro.com platform makes finding, identifying, and purchasing Detroit Diesel parts fast and intuitive. Each listing includes clear specifications, dimensions, and compatibility information to ensure perfect fitment on your 6-71 non-turbo engine.

Maintaining the Detroit Diesel 6-71 Exhaust System

Regular maintenance of the exhaust system is vital to keep your engine performing at its best. Over time, heat and vibration can cause gaskets to deteriorate, flanges to corrode, and manifolds to develop cracks. Inspecting and replacing worn components helps prevent exhaust leaks, which can cause power loss, overheating, and noise.

Key Maintenance Tips:

-

Inspect manifolds annually for signs of leakage or warping.

-

Replace gaskets whenever manifolds are removed.

-

Check all threaded fittings for corrosion and re-torque hardware after 25 hours of operation following installation.

-

Wrap manifolds with insulation tape to reduce heat transfer and prevent burns.

-

Keep muffler caps functional to block water ingress during idle periods.

By following these steps, you can extend the service life of your Detroit Diesel 6-71 exhaust system and maintain optimal engine performance.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588