Parts for Detroit Diesel 6V71 Non-Turbo for Canada - Gasket Section

Loading...

Loading... Parts for Detroit Diesel 6V71 Non-Turbo – Gasket Section

Built on the rugged two-stroke 71 Series architecture, the Detroit Diesel 6V71 non-turbo remains a workhorse in marine, industrial, and off-highway applications. Keeping it leak-free and correctly sealed is essential for reliable oil pressure, stable coolant temps, clean exhaust paths, and a tidy engine room. This expanded gasket guide is written specifically for the 6V71 naturally aspirated engine and organizes the components you’ll find on this catalog page into clear categories, with practical fitment notes and installation best practices. Where components are shared across other 71/92-Series engines, we’ll mention that briefly for context—but the focus here stays on the 6V71 non-turbo so you can choose confidently and get back to work.

Block, Core & General Engine Plate Gaskets (6V71 Non-Turbo)

Block plug gasket (core/freeze plug seal)

The humble block-plug gasket keeps coolant where it belongs by sealing the service plug in the water jacket. On a 6V71 that sees frequent thermal cycling (daily start/stop, seasonal layups), these gaskets can harden and weep first. If you notice a faint coolant crust around the plug perimeter, replace the gasket rather than overtightening the plug—over-torque can distort the seat in the block. Prep matters: wire-brush any scale from the counterbore, wipe clean with solvent, then install the new gasket dry unless your service manual calls for a thin film of non-hardening sealant.

Front end plate gasket (between block and front plate)

This gasket closes the front accessory cavity where the cam gear train and front seal live. A smear of oil around the lower corners often traces back to an aging front plate gasket. When you service the front crank seal or water pump drive, budget time for the plate gasket as well. The key to success is flat, squeaky-clean mating faces—use a plastic scraper on aluminum, chase bolt holes, and torque the plate evenly in several passes.

Rear end plate gasket (between block and rear plate)

At the flywheel end, the rear plate gasket prevents seepage from the crankcase. It’s common to refresh this gasket during clutch, flywheel housing, or marine gear interface work. If you’ve pulled the housing for ring-gear or rear main service, replace the rear plate gasket too—reusing a compressed gasket here is false economy.

Flywheel housing gasket (between end plate and flywheel housing)

This large perimeter gasket seals the interface between the rear plate and bell housing. Oil mist from the crankcase breather can accumulate along this seam over time, so it’s smart to renew the gasket whenever the housing is off. Degrease the flange thoroughly; any residual oil film under the gasket can create a path for seepage later.

Flywheel housing cover (inspection cover) & cover gasket

Your 6V71 uses an inspection cover on the bell housing to access the ring gear and coupling. Replacing the cover and its gasket together prevents drip lines that masquerade as “rear main leaks.” Confirm the cover is flat; if it’s been overtightened and dished, straighten or replace it before installing the fresh gasket.

Crankshaft Front & Rear Seals, Carriers & Sleeves (6V71 Non-Turbo)

Front crankshaft seal (standard, universal rotation)

Whether your 6V71 turns left-hand or right-hand, the standard front seal is designed for universal rotation. A weeping front seal leaves telltale sling marks around the vibration damper and a film down the front plate. Inspect the damper hub for a wear groove; if the hub is scored, fit a wear sleeve or replace the hub so the new seal has a clean running surface. Lightly oil the seal lip at install—running a dry lip even for a minute can glaze it and cause an immediate seep.

Rear crankshaft seal – single lip (standard & oversize)

The rear seal keeps engine oil out of the flywheel housing. On older hubs with a polished groove, oversize or sleeve-type solutions restore proper sealing. Single-lip designs reduce friction and heat; standard size fits a healthy hub, while oversize pairs with a specific sleeve/carrier. Always verify hub diameter with a micrometer rather than guessing—“close enough” here is a guaranteed comeback.

Rear crankshaft seal – double lip (standard & oversize)

Double-lip rear seals add a dust-exclusion or backup lip that helps in gritty environments (dredges, quarries, forestry). They’re great for long service intervals because the second lip provides redundancy as the primary lip wears. If your application idles for long periods or runs in dusty air, a double-lip seal can keep the bell housing clean for years.

Oversize seal sleeve (rear for 71-Series)

When a hub is grooved and you don’t want to pull the crank, an oversize sleeve provides a fresh, concentric surface. Cleanliness and concentricity are everything—use the correct driver to seat the sleeve square and at the correct depth. A light coat of non-hardening sealant under the sleeve helps fill microscopic pores, but do not slather; excess can migrate to the seal lip.

Pro tips for crank seals

-

Check crank endplay before and after—excess thrust can eat seals.

-

Inspect the breather/airbox drain system; crankcase pressure will push oil past a perfect seal.

-

Lubricate the lip and run a small sleeve over the keyway to protect the lip during installation.

Cylinder Head, Rocker Cover & Upper Engine Gaskets (6V71 Non-Turbo)

Head gasket kits (two required per 6V71)

Your V-6 uses one head per bank, so you’ll need two head gasket kits to service both sides. Modern composite head gaskets handle the two-stroke’s pulsing, especially at long idle. When you’re in here, measure liner heights (“protrusion”) and verify proper fire-ring crush. Two-stroke Detroits reward meticulous surface prep: a flat deck, correct torque sequence, and re-torque after the first heat cycle if your service spec calls for it.

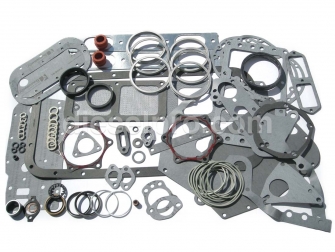

Overhaul gasket kit (complete upper & lower)

When you’re refreshing the 6V71 end-to-end—liners, pistons, heads, blower—the complete overhaul gasket set bundles the major seals and gaskets you’ll touch. That saves hunting for small consumables (thermostat cover, accessory pads, oil cooler, governor covers, blower base, water manifolds). It’s the cleanest path to a leak-free rebuild and simplifies inventory management on a busy job.

Rocker (valve) cover gasket kit – new style for aluminum covers

New-style gaskets for aluminum covers resist compression set better than old cork styles and make valve set or injector rack adjustments less messy. If your covers have been off multiple times, inspect the bolt grommets; tired grommets allow overtightening, which can bow the cover and create ghost leaks.

Inspection block cover & inspection cover gaskets

Those small tin covers along the block are there for a reason—inspection and cleaning of airbox drains. Their gaskets are easy to ignore, but replacing them during any top-end work keeps oil mist inside where it belongs and prevents salt-air corrosion lines on marine engines.

Air Handling, Blower Base & Inlet Gaskets (6V71 Non-Turbo)

Blower installation gasket set (6V71)

On a naturally aspirated 6V71, the Roots-type blower is essential to scavenge spent gases and charge fresh air. Sealing at the blower base, striker plate, and end plates prevents airbox leaks that can upset idle quality and smoke. The dedicated installation set includes the base, side, and end gaskets you’ll disturb when swapping or resealing the blower.

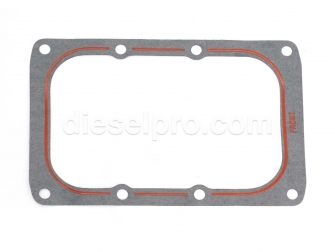

Striker plate gasket (between blower and striker plate)

Think of the striker plate as part of the blower mounting stack. A clean, flat striker plate mated with a fresh gasket helps maintain proper airbox pressure. If you find oily residue at the rear of the blower, don’t forget this gasket; leaks here are frequently misdiagnosed as rear main issues.

Air inlet housing gasket

This gasket seals the inlet housing to the blower body, preventing unmetered air and oil haze. If you hear a faint whine or feel a suction leak with a smoke pen around the inlet, the gasket may be crushed or the surface dinged by past tool slips. Dress minor high spots with a fine file and install a new gasket.

Fuel System & Governor Cover Gaskets (6V71 Non-Turbo)

Fuel pump / water pump shared gasket

Some accessory pads use a common pattern. Always compare the old gasket to the new before torquing the pump—rotated patterns can bolt up yet cover a passage. A proper gasket prevents both oil weeps and coolant seep at the pump body.

Governor spring cover gasket & governor top cover gasket

On mechanically governed 6V71 engines, the spring cover and top cover keep the governor oil tight and free from dust. Oil mist here can drip along control linkages and collect grime, leading to sticky throttle response. Replace both gaskets when you have the covers off for rack or buffer adjustments so everything goes back clean and dry.

Hydraulic governor gaskets (drive-to-governor and cover)

Where a hydraulic governor is fitted, you’ll have a gasket between the drive and governor plus a separate cover gasket. Renewing both prevents cross-contamination and keeps the governor body clean for visual leak checks. After reassembly, check for clean oil at the weep holes and verify the governor is venting properly.

Cooling System Gaskets: Water Rail, Thermostat, Oil Cooler & Marine Heat Exchanger (6V71 Non-Turbo)

Water manifold (water rail) gasket

The long water manifold distributes coolant along the cylinder head. Weeps here leave a clean “washed” line along the block with green or pink residue at bolt heads. Replace the gasket if you’ve removed the rail for thermostat or hose service; torque the rail evenly so the long flange doesn’t bow.

Thermostat housing cover gasket

A fresh gasket under the thermostat cover prevents the classic crusty halo on the housing. During service, clean the mating faces and verify the thermostat jiggle pin (if used) is oriented per spec to bleed air.

Block water outlet gasket (block heater port)

Engines equipped with a block heater rely on a flat, sealed outlet. If you’re upgrading heaters before winter layup, install a new gasket and lightly coat the fastener threads with sealant rated for coolant.

Oil cooler gaskets (6V71)

Your lube oil cooler sits in the coolant stream and uses dedicated gaskets at the housing interfaces. A compromised cooler gasket can put oil in the coolant or coolant in the oil—both costly. When renewing, flush both circuits, pressure-test the cooler core if possible, and replace the end gaskets as a set to protect the new oil.

Marine heat exchanger gasket kit (for 6V71 with marine cooling hardware)

On marine 6V71s, the heat exchanger and raw-water components have several small gaskets and plates. This kit bundles the common seals so you can service end caps, zinc plugs, and intermediate plates in one go. Always tighten end-cap fasteners in a crisscross pattern to keep the cap square and avoid pinching the gasket.

Raw (salt) water pump gaskets: body, plate & mounting

Raw water pumps rely on paper/fiber gaskets to seal the end plate and to mount the pump to the flywheel housing or bracket. Replace plate and mounting gaskets whenever you change impellers; a flat, lightly lapped plate extends impeller life and ensures prime is maintained after shutdown.

Gasket—flywheel housing to salt-water pump

Where the raw water pump mounts directly to the housing, a dedicated gasket prevents both oil mist leaks from the housing and air ingress on the pump side (which can cause priming issues). Make sure both faces are oil-free before assembly.

Lubrication System: Oil Pan, Filter Adapter & “Universal” Gasket Stock (6V71 Non-Turbo)

Oil pan gasket (6V71/6V92 pattern)

The pan perimeter on a two-stroke is notorious for weeping if overtightened. Use a calibrated inch-pound wrench, flatten any pulled bolt holes (“dimpling”) with a hammer and dolly, and install the new gasket dry unless the manual calls for a dab of sealant at corner joints. Re-check torque after a thermal cycle.

Oil filter adapter gasket

A small but high-stakes gasket—if it fails, you’ll lose oil fast. Replace it when you remove the adapter for filter base servicing or remote-mount upgrades. Clean both faces until they feel like glass; a single grit can create a leak path.

General-purpose 71/92-Series gasket sheet

Keeping one or two universal gasket pieces in the toolbox is smart insurance. They’re cut to common patterns and save a trip when a small cover gasket tears during unrelated service.

Exhaust & Turbo Inlet Connection (Context for Non-Turbo 6V71)

Turbo exhaust inlet connection gasket (for retrofits or mixed fleets)

This catalog includes the turbo inlet connection gasket used upstream of a turbocharger. While a non-turbo 6V71 doesn’t use this part, many fleets mix NA and turbo engines, and some owners retrofit. If you are converting or servicing a turbo-equipped variant, this heavy-duty fire-ring style gasket handles heat and flange movement. On NA engines, simply ignore this item.

Starters, Paints & Consumables (Useful While You’re There)

Starter gasket

The starter flange gasket prevents splash oil and dust from migrating through the interface. If you’ve had the starter off for bench service, replace this gasket on re-install—it’s inexpensive insurance against grime accumulating on the ring gear and bendix.

Detroit Green engine paint

After gasket work, a quick degrease and repaint of touched-up areas keeps corrosion at bay and makes future leaks easy to spot. Paint only on oil-free, dry metal; masking around seams provides clean inspection lines.

Sealants, Gasket Makers & Thread Treatments (Approved Companions)

High-tack gasket adhesive (spray)

Ideal for thin paper gaskets that tend to slip (water rail, inspection covers). Apply a light even coat to the gasket, let it tack, then assemble. More is not better—excess can squeeze into passages.

3H-type liquid sealant (non-hardening)

Great for fine-thread plugs, small covers, and places you may service again. It remains pliable, making future disassembly easier without tearing fibers from the gasket.

High-strength red threadlocker

Reserve for fasteners you do not expect to remove frequently (coupler bolts, certain bracket bolts). Clean threads thoroughly; oil-soaked fasteners defeat the chemistry.

Sensor-safe silicone RTV (general & ultra blue)

Use sparingly at corners where multiple gaskets meet (pan rails at timing cover, rear plate corners), and around formed joints. “Sensor-safe” means it won’t outgas corrosives—handy if your application uses nearby electronics. Allow proper skin-time before torque.

High-temp RTV silicone

For flanges that see exhaust-related heat or hot oil splash, high-temp RTV withstands the environment better. Again, a thin film is enough—RTV should not replace a primary paper/composite gasket unless the OEM procedure specifies it.

Non-hardening pliable sealant

Perfect under oversize sleeves, around core plugs, and under cover screw heads where a flexible seal is preferred. It stays elastic so vibration doesn’t crack the seal.

J-B Weld (cold-weld epoxy)

Not a replacement for a gasket, but invaluable for repairing a nicked pan rail or filling a small casting divot outside of a sealing surface. Let it cure fully, then level it flush before gasket install.

Marine Driveline Interface: Allison M/MH Flywheel Gaskets (When Applicable)

Flywheel housing-to-transmission gasket – SAE #2 pattern

Many 6V71 marine installations pair with Allison M or MH gears. When housing size matches the transmission adapter, the SAE #2 interface gasket prevents oil mist and salt-air ingress. Always dry-fit the gasket to confirm bolt pattern alignment and dowel fit. Lightly oil the locating dowels to prevent galling, and torque the housing in a star pattern to avoid warping the flange.

Choosing the Right Kit: What to Buy for Each Job on a 6V71 Non-Turbo

Top-end refresh (valve sets, rack, blower reseal)

-

Two head gasket kits (one per bank)

-

Rocker cover gasket kit (aluminum cover style)

-

Blower installation gasket set + striker plate gasket

-

Intake (air inlet housing) gasket

-

Water rail and thermostat cover gaskets

-

Inspection cover gaskets

Front-of-engine leak cure

-

Front crankshaft seal (verify hub condition)

-

Front end plate gasket

-

Water pump/fuel pump gasket as needed

-

Paint and high-tack spray for clean reassembly

Rear-of-engine leak cure / driveline service

-

Rear crank seal (choose single vs. double lip, standard vs. oversize)

-

Oversize sleeve if hub is grooved

-

Rear end plate and flywheel housing gaskets

-

Flywheel housing cover gasket

-

Allison SAE #2 interface gasket (if marine gear is removed)

Cooling circuit overhaul

-

Water manifold (rail) gasket

-

Oil cooler gaskets (both ends)

-

Thermostat housing gasket

-

Block water outlet gasket (heater port)

-

Marine heat-exchanger gasket kit (if so equipped)

-

Raw water pump body/plate/mounting gaskets

Bottom-end tidy-up

-

Oil pan gasket

-

Oil filter adapter gasket

-

Universal 71/92 gasket sheet stock for small covers

Consumables to keep on the bench

-

High-tack gasket adhesive spray

-

Non-hardening liquid sealant

-

High-temp RTV and sensor-safe RTV

-

High-strength threadlocker (red) for select fasteners

-

J-B Weld for small non-critical casting blemishes

-

Detroit Green paint for inspection-clean seams

Installation Best Practices for a Leak-Free 6V71

Cleanliness is king

Oil and RTV don’t mix. Degrease, rinse, and dry all mating surfaces. Use lint-free wipes; paper towel fibers trapped under a gasket become capillary leak paths.

Flatness and fastener prep

Check covers and pans for “pulled” bolt holes. A few taps with a flat punch levels the land so the new gasket compresses evenly. Chase threads in the block and covers; thread friction dramatically changes clamp load.

Dry vs. sealant-assisted

Follow the service procedure. Many paper/cellulose gaskets are designed to be installed dry with only a touch of RTV in corner joints. Over-sealing can cause gasket creep and squeeze-out. Use high-tack adhesive sparingly on vertical surfaces to keep the gasket from walking while you align bolts.

Torque in stages and patterns

Large flanges (water rail, flywheel housing, pan rails) should be tightened in a crisscross pattern and in stages. Final torque should be with a calibrated wrench. Re-check after the first heat cycle if the procedure calls for it.

Vent & drain checks

A clogged breather or airbox drains will raise crankcase pressure and force oil past perfect seals. After reseal work, verify the breather element is clear and the airbox drains are open.

Cooling system test

Pressure-test the coolant side to spec before first start. A quick pressure test finds weeps at the water rail, thermostat cover, and heat-exchanger caps while you can still reach everything.

Oil system verification

Prime the oil system, then crank with fuel disabled to confirm pressure before lighting off. Watch for any seep at the filter adapter and cooler ends.

Troubleshooting Common 6V71 Non-Turbo Leak Points

Oil at bell housing weep hole

-

Likely rear main seal or flywheel housing gasket. Confirm by cleaning thoroughly, running at fast idle, and observing fresh oil trails with a UV dye if necessary.

-

Check crankcase pressure; excessive pressure will overcome new seals.

Oily film on blower and rear of intake

-

Frequently the striker plate or blower base gasket. Less commonly, governor cover gaskets mist oil forward.

-

Dye check and a bright light along the blower perimeter will pinpoint the culprit.

Coolant crust along head/block seam

-

Could be a water rail gasket seep running down and collecting.

-

Clean, dry, and pressure-test; the head gasket fire-ring rarely leaks coolant externally unless there’s a deck/liner protrusion issue.

Persistent oil pan drips after reseal

-

Inspect pan flange for dimpling near bolt holes; even new gaskets can’t seal a wavy flange.

-

Verify corner joints where pan meets front and rear plates got a pea-size dab of RTV.

Why Experienced Technicians Choose Diesel Pro Power for 6V71 Gaskets

When uptime matters, parts quality and logistics make all the difference. Diesel Pro Power backs each 6V71 non-turbo gasket and seal with real-world testing and fast fulfillment, so your engine goes back together once, and stays dry.

Purpose-built kits that match how you actually work

Complete head, blower, and overhaul kits bundle the exact gaskets you’ll disturb during common service jobs—no last-minute runs for a forgotten cover gasket.

Tight quality control on materials

From fiber composition and coating to embossing and crush, gasket materials are specified for the 6V71’s two-stroke dynamics—steady scavenging pulses, hot oil splash, and marine-grade corrosion exposure.

Expert guidance when you need it

Not sure whether to choose single-lip or double-lip on the rear main? Unsure about oversize sleeve vs. hub replacement? You’ll get straight answers that match your application (workboat, industrial, on-highway) and your schedule.

Fast, reliable shipping worldwide

Downtime is expensive. We stock the 6V71 gaskets techs order most, ship quickly, and package to survive shop handling and rough transit environments.

Trusted by 40,000+ satisfied customers

Fleet managers, yard foremen, and owner-operators choose Diesel Pro Power because the parts fit, the engines seal up, and the service is consistent.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588