Parts for Detroit Diesel 6V71 Non-Turbo for Canada - Engine Water Pump Section

Loading...

Loading... Detroit Diesel 6V71 Non-Turbo – Engine Water Pump & Cooling System Parts Catalog

The Detroit Diesel 6V71 Non-Turbo engine remains one of the most durable and respected powerplants ever produced in the two-stroke diesel family. Found in marine propulsion, industrial, generator, and heavy-duty truck applications, it’s a workhorse known for longevity and distinctive performance.

At the heart of that reliability is an efficient cooling system—anchored by the engine’s fresh water pump. The water pump and its surrounding components are responsible for maintaining optimal temperature, preventing overheating, and ensuring consistent performance in both marine and land-based environments.

This catalog presents the complete range of Detroit Diesel 6V71 Non-Turbo engine water pump and cooling system components, all offered by Diesel Pro Power, the most trusted online source for Detroit Diesel parts. Every component listed here is built to factory specifications or higher, engineered for perfect fitment, and supported by the confidence of more than 40,000 satisfied customers worldwide.

The Importance of the Water Pump in the Detroit Diesel 6V71 Cooling System

The 6V71 engine is a V-6, two-stroke diesel engine from Detroit Diesel’s legendary 71-series line. It’s designed to operate under extreme loads and temperatures, and as such, depends heavily on precise temperature regulation. The fresh water pump circulates coolant throughout the cylinder block, cylinder heads, and oil cooler assembly to keep engine temperature within safe limits.

A properly functioning pump ensures:

-

Stable engine temperature during continuous heavy load operation.

-

Reduced wear on pistons, liners, and valve assemblies.

-

Protection against heat stress on head gaskets and seals.

-

Extended engine life in marine, industrial, and transport equipment.

When the pump’s seals or bearings wear out, or when flow rate declines due to impeller wear, overheating or coolant leakage can occur. Regular inspection and timely replacement are essential for maintaining reliable performance—especially in marine applications where downtime can be costly.

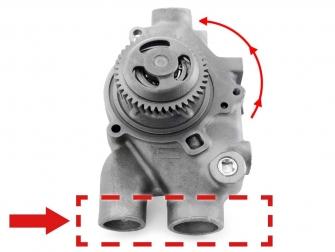

Complete Water Pump Options for the 6V71 Engine

Diesel Pro Power provides rebuilt and new water pumps for the 6V71 engine, available in both right-hand (RH) and left-hand (LH) rotation models to suit marine and industrial configurations.

Rebuilt Right-Hand (RH) Rotation Marine Water Pump

The right-hand rotation pump is specifically designed for starboard-side or clockwise-rotating marine engines. Each pump is fully remanufactured by professional technicians, tested under pressure, and balanced for optimal coolant circulation.

Key Features:

-

Factory-standard flow capacity to ensure consistent cooling.

-

Pre-installed seals, bearings, and impeller assemblies.

-

Ideal for direct replacement in marine propulsion systems.

-

Backed by Diesel Pro Power’s rebuild quality assurance.

This pump restores original cooling efficiency, eliminates leaks, and ensures that the marine-grade Detroit Diesel 6V71 remains protected under demanding sea conditions.

Rebuilt Right-Hand Rotation Water Pump for Industrial & Truck Engines

For land-based applications—such as generators, stationary compressors, and trucks—the RH rotation water pump provides reliable performance with consistent flow characteristics.

Highlights:

-

Precision-machined impeller for optimal flow balance.

-

Suitable for long-hour industrial operation and fleet service.

-

Designed for both dry-cooled and heat-exchanger systems.

-

Compatible with various V71-series engine models.

This pump helps maintain consistent cooling cycles, even under the most demanding workloads, and is a perfect choice for operators seeking longevity and OEM-equivalent reliability.

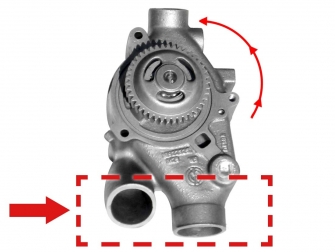

Rebuilt Left-Hand (LH) Rotation Marine Water Pump

The LH rotation pump is commonly used for port-side engines in twin-engine marine setups. Correct rotation ensures the coolant circulates in the proper direction through the block and heat exchanger, preventing reverse flow issues that can cause overheating.

Product Overview:

-

Designed for marine propulsion engines running counter-clockwise.

-

Completely rebuilt with new seals, bearings, and balanced impeller.

-

Compatible with heat exchanger and keel cooling configurations.

-

Tested to meet Detroit Diesel flow and pressure standards.

This LH rotation pump maintains the correct balance between port and starboard systems, helping twin-engine configurations maintain synchronized cooling efficiency.

Water Pump Repair Kits

For operators who prefer to rebuild existing pumps, Diesel Pro Power offers complete water pump repair kits. These kits include every major wear component—seals, bearings, bushings, gaskets, and hardware—to restore original flow and pressure characteristics.

Marine Pump Repair Kit

Designed for both LH and RH marine pumps used on Detroit Diesel V71-series engines. It includes:

-

Replacement bearings and shaft seals.

-

Internal gaskets and retaining rings.

-

Precision components for restoring impeller clearance.

This kit is ideal for scheduled maintenance programs or for rebuilding pumps during engine overhauls.

Industrial Pump Repair Kit

For industrial and truck applications, the repair kit includes:

-

High-temperature bearing assemblies.

-

Oil-resistant seals.

-

Reinforced gaskets for long-term reliability.

Each kit allows in-house technicians to restore water pumps quickly without requiring specialized equipment, minimizing downtime and extending component life.

Seals and Rings for the Cooling System

The water pump and related manifolds rely on multiple seals to maintain system pressure. Over time, seals degrade due to temperature cycling and coolant chemistry. Diesel Pro Power provides premium replacements that maintain proper elasticity and sealing performance.

Water Pump Seal Rings

These are installed between the pump and the engine block to prevent coolant leakage. Each ring is made of reinforced elastomer designed for continuous contact with antifreeze and corrosion inhibitors.

Manifold to Oil Cooler Seals

The connection between the water manifold and the oil cooler housing uses large-diameter seals to maintain coolant separation from the lubrication circuit. Using quality replacements prevents cross-contamination between coolant and engine oil—an issue that can lead to severe damage if left unchecked.

All seals are engineered for a perfect fit and long service life, ensuring a leak-free system across thousands of operating hours.

Thermostats and Temperature Regulation Components

Thermostats play a crucial role in controlling coolant flow. When the engine is cold, the thermostat remains closed to allow faster warm-up. Once optimal temperature is reached, it opens gradually to regulate flow through the radiator or heat exchanger.

Available Thermostat Temperature Ratings

Diesel Pro Power offers multiple thermostat temperature ranges to match different environments and duty cycles:

-

160-degree thermostats for cold-climate or intermittent use.

-

170-degree thermostats as standard settings for most marine and industrial operations.

-

180-degree thermostats for high-efficiency or continuous heavy-load applications.

Each thermostat features a fast-response wax element calibrated to Detroit Diesel specifications, providing precise temperature control for smooth engine operation and optimal fuel efficiency.

Thermostat Seals and Gaskets

Thermostat assemblies require sealing rings and housing gaskets to maintain coolant pressure. Diesel Pro Power provides durable replacements built from heat-resistant materials that prevent leaks and deformation. These gaskets are shaped for direct fitment into Detroit Diesel thermostat covers and upper housings, ensuring a secure and long-lasting seal.

Radiator Caps and Necks

Maintaining proper coolant system pressure is vital to prevent boiling and maintain flow through the engine. Diesel Pro Power supplies radiator caps and necks designed for both marine and industrial Detroit Diesel applications.

Radiator Caps

Each radiator cap maintains a specific pressure rating—commonly 7 pounds for Detroit Diesel 71-series engines—to raise the boiling point of coolant and prevent vapor lock.

Radiator Necks

Available in multiple inside and outside diameters, these necks are built from corrosion-resistant alloys and precision-machined for a tight seal with OEM-style caps. The necks ensure smooth coolant expansion and contraction cycles without leaks or pressure loss.

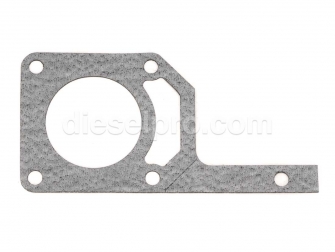

Water Pump Seals and Gaskets for Block and Housing Connections

The connection between the water pump, block, and outlet housing is sealed with reinforced gaskets that prevent coolant seepage and air intrusion. Diesel Pro Power supplies direct-fit gaskets designed to maintain consistent pressure and temperature across all mounting surfaces.

These components are critical during pump replacement or when performing top-end rebuilds, ensuring the system remains perfectly sealed once assembled.

Cooling System Service Accessories

Radiator Cleaner

Keeping the cooling system free of corrosion and scale is essential. Diesel Pro Power’s radiator cleaning solution is formulated to remove mineral deposits, rust, and biological buildup without harming copper, aluminum, or brass components. It’s safe for use in both closed and open systems and is ideal for seasonal maintenance.

Temperature Switches

Temperature switches help monitor coolant temperature and activate warning lights or fans when preset limits are reached. Diesel Pro Power provides universal switches compatible with Detroit Diesel, Cummins, and Caterpillar engines. Each switch activates at approximately 205 degrees Fahrenheit, ensuring timely alerts for overheating prevention.

Detroit Diesel Green Engine Paint

An authentic finishing touch, Detroit Diesel green engine paint restores the original look of the engine after maintenance or overhaul. The high-temperature enamel is resistant to oil, fuel, and coolant exposure and helps prevent corrosion on exposed metal surfaces.

Premium Silicone Coolant Hoses

The Detroit Diesel 6V71 cooling system requires multiple hose diameters to connect the water pump, thermostat housing, radiator, and oil cooler. Diesel Pro Power provides a complete range of premium silicone coolant hoses, each reinforced for high-temperature and high-pressure operation.

Available Sizes:

-

From ¾ inch up to 4 inches in inside diameter.

-

Sold by the foot for custom installations or system upgrades.

-

Reinforced with multiple layers of fabric for flexibility and burst protection.

Silicone hoses outperform standard rubber in marine environments, offering resistance to heat, oil mist, and coolant additives. They maintain elasticity even after prolonged exposure to engine heat, reducing maintenance frequency and preventing unexpected failures.

Hose Clamps for Coolant and Fuel Lines

To secure silicone hoses properly, Diesel Pro Power offers a full line of stainless-steel hose clamps. Each clamp provides even pressure distribution around the hose, preventing leaks and ensuring a long-lasting connection.

Clamp Features:

-

Smooth inner bands to avoid hose damage.

-

Rust-resistant construction for marine conditions.

-

Available in a variety of effective diameter ranges to fit all coolant and fuel hoses on the 6V71 engine.

These clamps are essential for maintaining secure connections under pressure and vibration, whether the engine is powering a vessel at sea or running a generator onshore.

Gauges and Temperature Monitoring

Monitoring coolant temperature is key to preventing overheating and ensuring consistent performance. Diesel Pro Power supplies a range of mechanical and electric gauges compatible with Detroit Diesel engines.

Gauge Options

-

Mechanical temperature gauges for direct-reading applications.

-

Mechanical gauges with integrated alarms for added safety.

-

Electrical gauges available in both 12-volt and 24-volt configurations.

By installing accurate temperature monitoring equipment, operators can detect early signs of cooling system failure, allowing timely intervention before serious damage occurs.

Cooling System Maintenance Tips for the Detroit Diesel 6V71

Regular preventive maintenance extends engine life and helps maintain efficiency. Below are the key service guidelines for operators and maintenance technicians:

-

Inspect the water pump regularly for leaks, bearing noise, or coolant residue.

-

Replace seals and gaskets during every major service to prevent pressure loss.

-

Flush the cooling system annually using a non-corrosive cleaner to remove buildup.

-

Check thermostat function to ensure proper temperature control.

-

Replace old hoses and clamps before signs of swelling or cracking appear.

-

Monitor coolant pressure and maintain appropriate radiator cap ratings.

-

Use only approved antifreeze and corrosion inhibitors to protect internal components.

-

Paint and protect exposed surfaces to prevent rust and maintain professional appearance.

By following these steps, operators can achieve thousands of additional service hours from their Detroit Diesel 6V71 engines.

The Diesel Pro Power Advantage

Diesel Pro Power isn’t just a supplier—it’s a partner dedicated to keeping classic Detroit Diesel engines running strong for decades. The company supports owners of legacy two-stroke engines around the world, providing access to quality parts, expert support, and fast delivery.

Why professionals choose Diesel Pro Power:

-

Proven experience: Trusted by more than 40,000 customers across over 180 countries.

-

Expert assistance: Knowledgeable staff ready to guide you through rotation selection, compatibility, and installation.

-

Global logistics: Reliable worldwide shipping to marinas, ports, industrial facilities, and fleets.

-

Complete catalogs: Parts organized by engine model and system for quick and accurate identification.

-

Guaranteed quality: Each rebuilt pump and component undergoes detailed inspection and testing.

When you purchase Detroit Diesel 6V71 cooling system parts from Diesel Pro Power, you invest in longevity, performance, and confidence.

Conclusion

Maintaining the Detroit Diesel 6V71 Non-Turbo cooling system requires attention to every detail—from the water pump itself to the smallest seal or hose clamp. Diesel Pro Power’s complete catalog includes everything needed for a full refresh or targeted repair.

Whether your engine powers a vessel, generator, or industrial unit, every component in this catalog—water pumps, thermostats, hoses, clamps, and gauges—has been chosen for quality, reliability, and precision fit.

By choosing Diesel Pro Power, you ensure that your Detroit Diesel 6V71 continues to operate with the same dependable performance that made it an industry legend. The right parts, expert guidance, and global support all come together here—helping you keep your engine running cool, efficient, and ready for any challenge ahead.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588