Parts for Detroit Diesel 6V92 Non-Turbo for Canada - Gasket Section

Loading...

Loading... Parts for Detroit Diesel 6V92 Non-Turbo — Gasket Section

Built for durability and serviceability, the Detroit Diesel 6V92 non-turbo (naturally aspirated) engine depends on a complete network of gaskets, seals, and related consumables to keep oil, coolant, air, and exhaust exactly where they belong. This expanded guide organizes the gasket section of the 6V92 Non-Turbo parts catalog into easy-to-scan categories, explains where each component lives, what it does, and how to select the right option for your specific configuration—without forcing you to wade through unrelated engines or parts. When a part is also used on other Series 92 or V-series engines, we’ll note the cross-compatibility briefly—but the emphasis stays squarely on the 6V92 Non-Turbo.

Below you’ll find practical installation notes, torque and prep considerations, and pro tips gathered from years of field experience supporting professional mechanics, fleet managers, commercial vessel operators, and hands-on owners.

Gaskets for the Cylinder Block & Lower End (6V92 Non-Turbo)

Block Plug Gasket (2.5" Diameter)

The block plug gasket seals the core/freeze plug opening on the 6V92 block, preventing coolant seepage at one of the simplest—but most overlooked—interfaces on the engine. On older castings, corrosion and pitting around the plug bore can challenge sealing; always clean and inspect the bore, lightly dress any high spots, and verify the plug fits squarely before tightening. A thin, even film of the correct sealant on the gasket face can assist where surface condition is marginal, but the core of the job is cleanliness and proper seating. Replace any plug that shows deformation or rust scaling.

Liner Seal (Cylinder Liner Lower Seal)

On the wet-liner 6V92, the liner seal keeps coolant out of the crankcase and maintains a stable interface between the liner and block counterbore. If you’re seeing unexplained coolant loss, milky oil, or combustion gases in the cooling system, the liner seal is on the shortlist of suspects. During a refresh, replace these seals as a set, keep the liner and block counterbores clean and dry, and lubricate per spec at assembly. Pay attention to seal orientation and avoid twisting the seal as the liner is lowered—using guide studs and a proper lifting tool makes the difference between a one-time job and a re-do.

Oil Pan Gasket

The 6V92’s oil pan gasket seals the entire lower sump perimeter. If you work in marine or heavy-duty environments, heat-soak cycles and hull vibration can gradually relax fasteners and compress the gasket. After installation, re-torque fasteners in the specified criss-cross pattern once the engine has reached operating temperature and cooled back down. Inspect the pan flange for bends—straighten gently on a flat surface before installing the new gasket.

Starter Gasket

The starter gasket provides a neat, oil-tight seal at the starter mounting pad—especially helpful on engines with high crankcase ventilation rates where misting can accumulate near penetrations. Clean both surfaces and avoid over-applying sealant; a thin film is plenty.

Flywheel Housing Gasket (End Plate to Housing)

This large-format gasket sits between the end plate and the flywheel housing. Any leak here tends to travel and masquerade as a rear main seal failure. Before you assume the rear crankshaft seal is the culprit, clean the area thoroughly, run the engine, and trace the oil trail back to its highest, driest point. If it’s the housing interface, replace this gasket and verify dowel alignment.

Flywheel Housing Cover (Large Cover)

The housing cover seals service openings at the rear of the engine. It’s essential for keeping oil inside and debris outside, especially on engines that see dusty or salty environments. Replace the cover gasket whenever the plate comes off.

Gaskets for the Cylinder Head & Upper Engine (6V92 Non-Turbo)

Cylinder Head Gasket Kit (6V92)

For the 6V92, two head-gasket kits are required per engine—one per cylinder bank. These kits bundle the head gaskets and commonly replaced upper-end seals for a thorough top-end service. When doing head work, always check deck flatness and head surface finish, verify liner height (protrusion) is within spec across all cylinders, and clean the fire ring lands meticulously. Uneven liner heights are a leading cause of repeat head-gasket failures on two-stroke Detroit Diesels; shim or correct as required before buttoning up.

Inspection/Block Cover Gaskets

The 6V92 uses inspection cover gaskets to seal service plates along the block. These plates permit internal checks and maintenance without full disassembly. If you spot weeping or oil mist along the cover edges, replace the gaskets and inspect the plate for warpage. A flat file and surface plate can true minor distortion. Install covers evenly and re-torque in small increments.

Front End Plate Gasket

Sitting between the block and front end plate, this gasket seals multiple fluid passages and timing spaces at the nose of the engine. Oil drips at the front can be deceptive because a moving crank pulley throws oil wide; confirm the leak source with UV dye or a clean/observe routine. Replace this gasket when front accessory service exposes the plate.

Thermostat Housing Cover Gasket

Coolant leaks at the thermostat housing can quickly travel onto belts and alternators, leading to squeal and charging issues. Replace the housing cover gasket any time the thermostat is serviced. A small bead of RTV at the corners (per spec) helps in older housings with minor pitting.

Air Inlet Housing Gasket

On naturally aspirated 6V92 engines, the air inlet housing mates tightly to the blower side to feed the cylinders. Unmetered air at this flange can disrupt scavenging and reduce cylinder filling. Replace the gasket whenever the housing is removed, and check for flange flatness and cleanliness.

Gaskets & Seals for the Crankshaft (Front & Rear)

Front Crankshaft Seal — Right-Hand Rotation (Teflon)

Front Crankshaft Seal — Left-Hand Rotation (Teflon)

The 6V92 family can be built in right-hand or left-hand rotation configurations. Using the correct front seal for your rotation is essential—the lip and dust-excluder profiles are direction-sensitive. Teflon front seals tolerate heat and shaft speed well, but they demand proper installation: use a guide sleeve, keep the sealing lip clean, and allow the PTFE to “set” per instructions before running the engine. Wipe the balancer hub and inspect for grooves; if you can feel it with a fingernail, address it before installing a new seal.

Rear Crankshaft Seals — Single Lip, Double Lip, Standard & Oversize

Rear main sealing on a working 6V92 lives a hard life: heat, clutch or coupling loads, and flywheel harmonics all conspire against it. Double-lip variants add an extra barrier when conditions are dusty, wet, or the shaft shows slight wear. Oversize rear seals are designed for housings that have worn beyond standard tolerance; confirm oversize need with a bore gauge, don’t guess. If the crank’s seal land is grooved, pair the replacement seal with a dedicated sleeve.

Crankshaft Seal Sleeve — Rear (for Oversize Seal)

A seal sleeve restores a smooth, concentric sealing surface on a worn crank. Clean the land, align the sleeve with the installer tool, and drive it square. A light smear of non-hardening sealant between sleeve and crank helps prevent micro-weeping.

Gaskets for the Cooling System (6V92 Non-Turbo)

Water Manifold (Water Rail) Gasket

The water rail manifold ties coolant flow across cylinders; a leak here will often appear as a slow, chalky residue line along the rail. Replace the gasket at the first sign of seepage—coolant loss adds up, and hot-running Detroits are not forgiving.

Block Water Outlet (Block Heater) Gasket

This gasket seals the block heater or block outlet plate. Before installation, clean the block face meticulously and remove old gasket material. A film of appropriate sealant helps on older castings. After installation, pressurize the cooling system and check for dry joints.

Heat Exchanger Gasket (Marine 6V92 Applications)

For marine-configured 6V92 engines, the heat exchanger gasket keeps raw water and coolant in their proper circuits. If you’re refitting or servicing a marine system, always replace this gasket when opening the exchanger end caps. Once reassembled, pressure-test both sides (coolant and raw water) independently for peace of mind.

Thermostat Housing Cover Gasket (Revisited)

Because thermostat service is routine, keep a spare cover gasket handy. Pair it with new thermostats and fresh O-rings as part of seasonal maintenance.

Gaskets for the Lubrication System (6V92 Non-Turbo)

Oil Cooler Gaskets (Two Styles Listed)

Oil-to-coolant heat exchangers rely on clean, intact gaskets to keep lube oil and coolant separate. A breach can cross-contaminate both systems—foamy oil or oily sheen in coolant are red flags. When servicing, flush both circuits, replace the gaskets, inspect the cooler core, and use a calibrated torque wrench on the cover bolts to avoid warping.

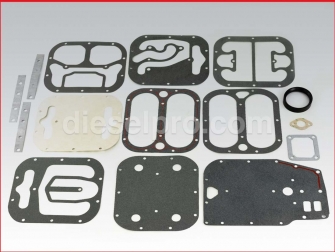

Oil Cooler Installation Kit (Double Oil Coolers)

Some duty cycles call for a dual-cooler setup. This installation kit brings together the gaskets and hardware you’ll need to mount and seal double oil coolers on the 6V92. Lay out the parts before disassembly, note cooler orientation, and torque in stages to keep covers flat.

Turbo Oil-Return Gasket (Also Used on NA for Return Flanges in Certain Configurations)

Even on non-turbo engines, return-line style gaskets show up at specific oil drain interfaces. Keep the mating faces clean and flat; use the correct fastener length to avoid bottoming out the threads and losing clamp load.

Gaskets for the Air System & Blower (6V92 Non-Turbo)

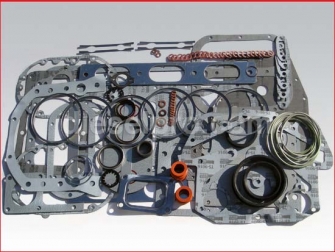

Blower Installation Gasket Kit

The two-stroke Detroit Diesel relies on the Roots-type blower for scavenging. Proper sealing at the blower base, striker plate, and related interfaces maintains air flow and keeps oil inside the case. This installation kit covers the blower-to-block and blower accessory sealing points you’ll disturb during removal. After installation, hand-rotate the engine to ensure no contact or binding exists before first start.

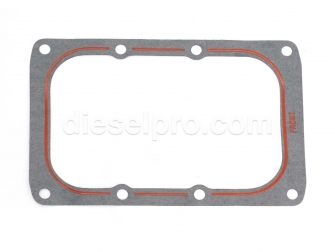

Striker Plate Gasket (Between Blower and Striker Plate)

A small gasket with an outsized impact: a leak here compromises scavenging efficiency and can create oil haze near the blower. Replace anytime the blower comes off, and keep surfaces surgically clean.

Governor Gaskets (Top Cover & Spring Cover)

The mechanical governor’s top and spring covers seal with dedicated gaskets. Any oil seep here tends to drip along the throttle linkage. Replace the gaskets and verify that breather passages are clear—excess crankcase pressure will drive oil past even brand-new gaskets.

Hydraulic Governor Gaskets (Governor to Drive & Cover)

If your 6V92 uses a hydraulic governor, two interfaces need attention: the gasket between governor and drive, and the governor cover gasket. Replace both when servicing the governor to keep oil where it belongs and to ensure stable, vibration-resistant mounting.

Air Inlet Housing Gasket (Revisited)

A clean seal at the inlet keeps the blower fed without bypass. During reassembly, lightly oil the fastener threads and torque evenly.

Gaskets for the Exhaust Interface (6V92 Non-Turbo)

Exhaust Manifold Gaskets (Head-to-Manifold)

A proper seal at the head-to-manifold interface keeps exhaust gas energy directed through the manifold and out the system, minimizing under-hood heat and protecting nearby wiring and hoses. If you see black soot prints along the joint, replace the gaskets and inspect for warped runners. On reassembly, tighten in sequence from the center out, then re-check torque after a heat cycle.

Marine Manifold & Flange Gaskets (Where Applicable)

Marine-configured 6V92s use water-cooled manifolds and specific flange gaskets to connect to risers or elbows. Always replace flange gaskets after disturbing the joint. If reusing a manifold, pressure-test the water jacket for pinholes or internal corrosion.

Turbo Inlet Connection Gasket (Catalog Listing)

Although this catalog section includes a turbo inlet gasket, keep in mind this specific page is focused on the 6V92 Non-Turbo. If you maintain a mixed fleet that includes turbocharged 92-series engines, the inlet gasket listed may cross over. For a strictly naturally aspirated 6V92, you won’t use this item—but it commonly appears in universal V-/Series-92 gasket assortments.

Gaskets for Pumps & Accessories (6V92 Non-Turbo)

Fuel/Water Pump Plate & Mounting Gaskets

These small-format gaskets seal the pump bodies and plates to the engine. Even a slight weep can attract grime and hide larger issues. Replace gaskets as soon as staining appears and verify pump shaft seals at the same time.

Raw Water Pump Plate & Mounting Gaskets (Marine)

For marine 6V92 installations, the raw water pump requires both a plate gasket and a mounting gasket. When servicing the impeller, it’s good practice to replace the plate gasket to maintain proper suction. A clean, flat plate improves impeller life and priming reliability.

Gasket for Thermostat Housing Cover (Cooling Accessory)

Covered above in the cooling section, but worth repeating here: always have a spare. You’ll be glad you did during a mid-season thermostat swap.

Transmission Interface Gaskets (Allison Marine Pairings)

Flywheel Housing-to-Transmission Gasket — SAE 1

Flywheel Housing-to-Transmission Gasket — SAE 2 (Most Common)

Many 6V92 Non-Turbo engines are mated to Allison M or MH marine gears. The flywheel housing-to-transmission gasket matches the SAE housing size. Using the correct SAE size is critical; SAE 2 is common, but verify your bellhousing tag before ordering. These gaskets seal the large annulus between engine and gear to prevent oil transfer or seawater ingress near the coupling. When rejoining engine and transmission, confirm dowel alignment and never “draw” the halves together with bolts—if alignment is off, you’ll damage the pump drive or distort the housing.

Universal & Miscellaneous Gaskets and Supplies (Used on 6V92)

General-Purpose Series 71/92 Gasket (Utility Seal)

A commonly used flat gasket in the 71/92 ecosystem, handy for servicing auxiliary covers and plates on the 6V92. Keep a few on hand; they’re the “fuses” of the sealing world—cheap insurance against a comeback.

Gasket for Hydraulic Governor Cover (53/71/92 Series)

If your fleet spans multiple Detroit families, this cover gasket simplifies stocking. It fits the 6V92 application and related series cover patterns.

Gasket Spray — High-Tack Sealant

Ideal for holding paper gaskets in place during tricky assemblies and for improving seal at slightly imperfect surfaces. Use sparingly; a thin, uniform coat is all you need. Excessive spray can squeeze out and contaminate nearby passages.

Liquid Sealant (3H-Type)

A classic, petrol- and oil-resistant non-hardening sealant. Perfect for threads, minor surface imperfections, and select joints that benefit from flexible sealing. Do not use where RTV or dry install is specified.

Threadlocker — High Strength (Red)

Use high-strength threadlocker only where the service manual calls for it or where fasteners are not intended to be removed frequently (e.g., select driveline or coupling hardware). Degrease threads thoroughly before application for best results.

RTV Gasket Makers — Sensor-Safe & High-Temp Variants

Sensor-safe RTVs are formulated to avoid harming oxygen or other sensors—while not strictly relevant on the 6V92, these formulas provide excellent general sealing without corrosive by-products. High-temp RTV is your go-to around exhaust adjacencies and other hot spots. Apply in a continuous bead on clean, oil-free surfaces and allow proper skin time before assembly.

J-B Weld (Cold Weld Epoxy)

A useful field repair material for non-structural, non-pressurized components. While not a replacement for proper part replacement or welding, it can get you back to port or to the yard. Follow cure times and surface prep instructions closely.

Engine Paint — Detroit Green

Finish your service with a protective coat. Besides aesthetics, paint helps highlight fresh leaks since oil will discolor bright paint quickly, guiding diagnostics. For safety and compliance, note shipping restrictions and use only in ventilated spaces.

Selection & Installation Best Practices (6V92 Non-Turbo)

Match the Part to Your Configuration

The 6V92 family has variations—industrial, on-highway, and marine. Verify rotation (right-hand vs. left-hand) before ordering front seals, confirm SAE housing size before transmission-interface gaskets, and note whether your setup uses single or double oil coolers. A quick ID checklist at the engine saves downtime and returns.

Prep Is Everything

Gaskets don’t seal dirt, corrosion, or scratches. Clean both surfaces with solvent, chase threads with a tap if needed, and wipe with lint-free cloths. For aluminum mates, use plastic scrapers to avoid gouging. Where the manual calls for “dry” installation, follow it—over-sealing can be as problematic as under-sealing.

Use the Right Sealant, Sparingly

High-tack gasket spray helps hold thin paper gaskets; non-hardening sealant is great for threads and adjustable joints; RTV belongs where specified (sensor-safe around air systems, high-temp near exhaust). Too much sealant can squeeze into passages and create bigger problems.

Torque in Sequence & Re-Check

Large covers (oil pan, flywheel housing cover, manifolds) demand an even, staged torque pattern. After the first heat cycle, re-check torque where recommended—especially on marine engines that see continuous heavy loads.

Look for the Root Cause

If a gasket has failed prematurely, ask why. Was a breather clogged, spiking crankcase pressure? Was a mating flange warped? Did a vibration issue loosen hardware? Solving the underlying cause saves you from a repeat repair.

Stock the “Usual Suspects”

Downtime is expensive. Keep common 6V92 gaskets on hand: oil pan, thermostat housing cover, water rail, inspection covers, governor covers, blower base kit, and front/rear main seals matched to your rotation. Add universal supplies—high-tack spray, non-hardening sealant, RTV, threadlocker—and you’ll be ready for most on-engine sealing work.

Troubleshooting Common Leak Points on a 6V92 Non-Turbo

Front of Engine (Accessory Drive Area)

A film of oil around the crank pulley often points to the front main seal, but verify the front end plate gasket and timing cover joints. UV dye in the oil can highlight the true source.

Rear of Engine (Bellhousing Area)

Oil inside the bellhousing suggests a rear main seal or the flywheel housing gasket, but don’t ignore breather performance or overfilled crankcases—both can push oil past sound gaskets.

Upper Engine (Head & Inspection Covers)

Soot tracks along the exhaust manifold interface indicate gasket leaks or warped flanges. Oil mist along the inspection covers calls for new gaskets and flatness checks.

Cooling System Seepage

Chalky white residue around the water rail or thermostat housing indicates small leaks that will grow under pressure. Address immediately to protect liners and bearings.

How These Gaskets Fit Real-World 6V92 Service Scenarios

Top-End Refresh

Pair two cylinder head gasket kits with inspection cover gaskets, thermostat housing cover gasket, air inlet housing gasket, and exhaust manifold gaskets. If you disturbed the blower, add the blower installation kit and striker plate gasket.

Bottom-End Reseal

Combine oil pan gasket, front and rear main seals (correct rotation), and flywheel housing gasket. If the crank seal land is worn, include the rear seal sleeve.

Cooling System Rehab (Marine or Industrial)

Select water manifold gasket, block outlet (block heater) gasket, heat exchanger gasket (marine), thermostat cover gasket, and appropriate sealants. Pressure-test after assembly.

Transmission Pull & Refit (Allison Marine)

Choose the correct SAE flywheel housing-to-transmission gasket and a flywheel housing cover gasket. Check dowels and alignment before torque.

Oil Cooler Service

Pick the appropriate oil cooler gasket set (or the double-cooler installation kit), inspect cores, and torque evenly. After running, re-check for seepage along the cover edges.

Additional Resources (to be linked)

-

How to Identify Right-Hand vs. Left-Hand Rotation on a 6V92

-

Step-by-Step Guide: Replacing a 6V92 Front Main Seal

-

Pressure-Testing a Marine Heat Exchanger on a Series 92

-

Diagnosing Exhaust Manifold Leaks on Detroit Two-Stroke Engines

Why Buy 6V92 Non-Turbo Gaskets from Diesel Pro Power

When you’re maintaining a Detroit Diesel 6V92, you don’t have time for guesswork. Diesel Pro Power curates gasket and seal components that match the fit and materials you expect for hard-working two-stroke Detroits. From front and rear crankshaft seals (in both rotations) to complete head-gasket kits, water rail and thermostat gaskets, blower installation kits, oil cooler gasket sets, and Allison marine interface gaskets, you’ll find the exact pieces you need—organized specifically for the 6V92 Non-Turbo.

What sets Diesel Pro Power apart:

-

Engine-Specific Organization: This catalog section is purpose-built for the 6V92 Non-Turbo, so you’re not sifting through unrelated parts. Cross-compatibility is noted only where it helps you, not to distract you.

-

Field-Ready Quality: Materials and construction meet the demands of commercial duty and marine environments—heat-resistant composites, correct thickness and compressibility, and precise cut patterns.

-

Installation Confidence: The right accessory consumables—high-tack spray, non-hardening sealant, sensor-safe and high-temp RTVs, threadlocker—are stocked alongside your gaskets to streamline the job.

-

Experience You Can Call On: If you need help confirming rotation, SAE housing size, or the correct configuration for single vs. double oil coolers, expert support can help you identify the right parts the first time.

-

Fast, Reliable Fulfillment: In-stock items ship quickly so you can keep vessels earning and equipment running.

Whether you’re resealing the bottom end, refreshing the top end, or chasing down a stubborn coolant weep, Diesel Pro Power makes it straightforward to source every gasket and seal you need for your 6V92 Non-Turbo—organized, vetted, and ready to go.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588