Parts for Detroit Diesel 6V92 Non-Turbo for Canada - Marine Water Pump Section

Loading...

Loading... -

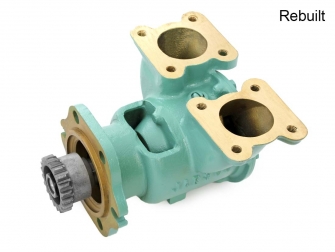

Marine Water Pump for Detroit Diesel 53, 71 and 92 Series Marine Engines, Rebuilt

23507971R

Sold with refundable core deposit. See details

Bidirectional Pump (It Turns Right or Left)

Port Type: 1 1/2” Flange. Includes Adapter & Drive Gear.

Impeller Height: 2 1/2”

Price: $ 892.00 -

Marine Water Pump for Detroit Diesel 53, 71 and 92 Series Marine Engines

23507971

Bidirectional Pump (It Turns Right or Left)

Port Type: 1 1/2” Flange. Includes Adapter & Drive Gear.

Impeller Height: 2 1/2”

Price: $ 1,068.69 -

Impeller for Caterpillar, Detroit Diesel, and Volvo Penta Marine Water Pumps

8924838

Impeller with 12 Blades and 12 Spline Drive.

Diameter: 3 3/4” - Height: 2 1/2”

Price: $ 96.73 -

Detroit Diesel Marine Water Pump repair kit 6V53, 6V71, 6-71, 6V92

5197224P

For 2 1/2" impeller height

Price: $ 630.32 -

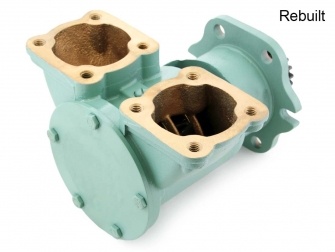

Marine Water Pump for Detroit Diesel 71 and 92 Series Marine Engines - Rebuilt

23507972R

Sold with refundable core deposit. See details

Bidirectional Pump (It Turns Right or Left)

Port Type: 2” Flange. Includes Adapter & Drive Gear.

Impeller Height: 3 1/2” - Splined Shaft.

Price: $ 939.00 -

Marine Water Pump for Detroit Diesel 71 and 92 Series Marine Engines

23507972

Bidirectional Pump (It Turns Right or Left)

Port Type: 2” Flange. Includes Adapter & Drive Gear.

Impeller Height: 3 1/2” - Splined Shaft.

Price: $ 1,124.90 -

Detroit Diesel Marine Water Pump repair kit for 6-71, 8V71, 8V53, 12V71, 6V92, 8V92

5197222

For 3 1/2" height impeller - spline pump shaft

Price: $ 739.75 -

Impeller for Detroit Diesel, Scania and Volvo Penta Marine Water Pumps

8924839

Impeller with 12 Blades and 12 Spline Drive.

Diameter: 3 3/4” - Height: 3 1/2”

Price: $ 145.72 -

Detroit Diesel Gasket, Marine Water Pump

5115395

Each pump uses 2 of this gasket. Water inlet and outletPrice: $ 4.38 -

-

-

Impeller Puller for Marine Water Pumps

50070

Fit range: 2 9/16" to 4 5/8" diameter impeller puller for marine water pumps.

Price: $ 345.12 -

-

-

-

-

-

-

-

-

-

Detroit Diesel Heat Exchanger Gasket Kit for Marine Engines for Series 53, 71 and 92

5192637

.Price: $ 97.18 -

-

-

-

-

-

-

Zinc for Marine Engine - for Heat Exchangers

E4C

Brass plug NPT 3/4", zinc length 3 3/8"Price: $ 33.43 -

Zinc for Marine Engine - for Marine Water Pumps

E3C

Brass plug NPT 3/4", zinc length 2"Price: $ 32.05 -

Zinc for Marine Engine - for Marine Water Pumps

E2C

For Detroit heat exchanger For Cummins heat exchanger and aftercooler For Brass plug NPT 1/2", zinc length 2"Price: $ 27.53 -

Zinc for Marine Engine - for Fuel Coolers & Oil Coolers

E1C

Brass plug NPT 3/8", zinc length 2"Price: $ 24.54 -

Zinc for Marine Engine - for Fuel Coolers & Oil Coolers

E00

Brass plug NPT 1/8", zinc length 2"Price: $ 18.72 -

Detroit Diesel Cam for Marine Water Pump or Marine Water Pump

5193554

For 2 1/2" dia raw water pump

Price: $ 168.90 -

-

Detroit Diesel Cover for Marine Water Pump with 2 1/2 and 3 1/2 inch dia impeller

5193555

For 2 1/2" and 3 1/2 impeller

Price: $ 94.00 -

-

-

-

-

-

-

-

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

-

-

-

-

-

-

-

-

-

-

-

Clamp for a coolant and fuel Hose

10H

Effective Diameter Range:

Minimum 9/16", Maximum 1-1/16"

Price: $ 3.04 -

Clamp for a coolant Hose

4920417

Effective Diameter Range:

Minimum 13/16", Maximum 1-3/4"

Price: $ 15.78 -

Clamp for a coolant Hose

3412320

Effective Diameter Range:

Minimum 11/16", Maximum 1-1/4"

Price: $ 14.76 -

Clamp for a coolant Hose

3922846

Effective Diameter Range:

Minimum 1-5/16", Maximum 2-1/4"

Price: $ 16.50 -

Clamp for a coolant Hose

3922847

Effective Diameter Range:

Minimum 1-9/16", Maximum 2-1/2"

Price: $ 16.68 -

Clamp for a coolant Hose

3922849

Effective Diameter Range:

Minimum 2-5/16", Maximum 3"

Price: $ 17.19 -

-

Controls Cables & More...

-

Marine Control

-

Industrial Cable

-

Marine Cables 1/16 thread

-

Marine Cables 1/4 thread

-

Marine Steering

-

Rubber Bearing

-

Searchlight

-

Marine Bulb

-

Navigation Light

-

Parts for Detroit Diesel 6V92 Non-Turbo – Marine Water Pump Section

Overview of the Detroit Diesel 6V92 Cooling System

The Detroit Diesel 6V92 non-turbo marine engine is a legendary two-stroke diesel built for reliability, power, and endurance in heavy-duty marine service. Whether installed in commercial vessels, workboats, tugs, or pleasure craft, its ability to maintain consistent operating temperature is critical for long-term performance.

At the heart of the cooling system is the raw (sea) water pump, which draws cool seawater through the hull and circulates it through the heat exchanger, aftercooler, and exhaust manifold. This process keeps the engine temperature stable and prevents overheating in continuous operation.

Because marine environments are harsh, Detroit Diesel engineered the 6V92’s sea water pump to withstand salt exposure and corrosion. The pump uses bronze housings, stainless-steel shafts, and neoprene impellers designed to perform even in demanding conditions. Diesel Pro Power supplies both new and rebuilt marine water pumps that meet or exceed OEM standards, ensuring that your Detroit Diesel 6V92 performs efficiently for years to come.

Marine Water Pumps for Detroit Diesel 6V92 Non-Turbo Engines

Diesel Pro Power carries both rebuilt and new bidirectional water pumps for Detroit Diesel Series 53, 71, and 92 marine engines, including the 6V92 non-turbo configuration. Each pump is precision-assembled, dynamically balanced, and pressure-tested for marine endurance.

Rebuilt Marine Water Pump – 1½” Flange

This pump is ideal for Detroit Diesel 6V92 and other 92-series non-turbo marine engines that require a compact cooling configuration. It includes the adapter and drive gear, and uses a 2½” impeller height.

-

Bidirectional rotation (right or left hand) makes installation flexible for twin-engine vessels.

-

Precision-fit bronze housing ensures longevity and corrosion resistance.

-

Fully rebuilt and sold with a refundable core deposit, each unit undergoes flow testing before shipment.

New Marine Water Pump – 1½” Flange

A brand-new version of the 6V92 raw water pump, built to original Detroit Diesel marine specifications.

-

Constructed with new shafts, seals, and gaskets to ensure zero leakage.

-

Compatible with Detroit Diesel 53, 71, and 92-series engines.

-

Designed for continuous duty, capable of operating under heavy sea loads.

Rebuilt Marine Water Pump – 2” Flange

For high-capacity applications or larger cooling systems, this bidirectional pump features a 3½” impeller height and splined shaft.

-

Suited for larger Detroit Diesel 71 and 92-series installations.

-

Includes adapter and drive gear for plug-and-play replacement.

-

Rebuilt and tested to exceed OEM flow standards.

New Marine Water Pump – 2” Flange

A direct-fit replacement for Detroit Diesel 6V92 and 8V92 marine engines that use the larger 2” flange housing.

-

Heavy-duty bronze construction and stainless hardware.

-

Bidirectional operation for port or starboard configuration.

-

Ready for installation—no machining or modification required.

Impellers for Detroit Diesel 6V92 Marine Water Pumps

The impeller is the key moving component inside the raw water pump, responsible for drawing and circulating seawater throughout the cooling system. Diesel Pro Power offers two impeller sizes compatible with the 6V92 non-turbo configuration.

-

12-blade neoprene impeller with 12-spline drive.

-

3¾” overall diameter.

-

Compatible with Detroit Diesel, Caterpillar, and Volvo Penta pumps using the 2½” housing.

-

Flexible and durable design ensures smooth water flow even when small debris enters the line.

-

Heavy-duty 12-blade impeller with spline drive for larger capacity pumps.

-

Ideal for engines running at higher sustained loads or in warmer waters.

-

Designed for maximum flow efficiency and extended life between maintenance intervals.

Repair Kits and Seal Components

Every marine cooling system eventually needs attention. Diesel Pro Power supplies complete water pump repair kitsdesigned for Detroit Diesel Series 53, 71, and 92 marine engines.

Repair Kit for 2½” Impeller Pumps

-

Includes seals, bearings, wear plate, and gaskets.

-

Restores full pumping efficiency to smaller Detroit Diesel marine pumps.

-

Ideal for preventative maintenance during seasonal overhauls.

Repair Kit for 3½” Impeller Pumps

-

Contains all critical seals, gaskets, and bearings for spline-shaft pumps.

-

Designed for heavy-duty marine operation with long-life materials.

-

Prevents leaks, shaft wear, and flow loss.

Gaskets and Sealing Components

A watertight cooling system relies on the proper gasket configuration. Diesel Pro Power provides all required sealing components for installation or rebuild of 6V92 water pumps, heat exchangers, and related fittings.

-

Marine Water Pump Gaskets – Used at the inlet and outlet of the raw water pump; each pump requires two.

-

Mounting Gaskets – For secure, leak-proof installation of the pump to the flywheel housing.

-

Cover Plate and Flywheel Gaskets – Maintain pressure integrity and protect from seawater intrusion.

-

Plate and Housing Gaskets – Designed for corrosion-resistant sealing between metal surfaces.

All gaskets are precision-cut from marine-grade materials to resist heat and saltwater corrosion.

Thermostats and Seals for Temperature Regulation

Detroit Diesel 6V92 engines operate best when maintaining a steady temperature. Diesel Pro Power offers thermostats calibrated for 160° and 170° Fahrenheit, ensuring proper coolant flow during warm-up and under load.

-

160° Thermostat – Commonly used for cooler ambient conditions or engines operating at lower RPM ranges.

-

170° Thermostat – Ideal for heavy-load applications or tropical climates where maintaining higher temperature aids efficiency.

-

Thermostat Seals – Provide leak-free seating in the housing.

These components ensure accurate temperature control, preventing overheating and improving overall performance.

Heat Exchangers and Related Gaskets

The heat exchanger functions as the heart of the closed cooling system. It allows seawater to cool the engine coolant without direct contact. Diesel Pro Power supplies new and remanufactured cores, gasket kits, and sealing accessories for the Detroit Diesel 6V92.

-

Heat Exchanger Core – Manufactured from copper-nickel alloy for superior heat transfer and corrosion resistance.

-

Heat Exchanger Gasket Kit – Includes all seals required for tank assembly and end cap installation.

-

Individual Gaskets and Seals – For quick replacement of worn components during maintenance.

-

Glands and Tank Seals – Ensure a perfect watertight fit and maintain coolant separation.

Routine inspection of the heat exchanger assembly is essential—cleaning and replacing gaskets every two years is recommended to prevent salt buildup or leaks.

Anodes (Zincs) for Corrosion Protection

Marine engines operate in conductive seawater environments, which can cause galvanic corrosion. To counteract this, Detroit Diesel cooling systems use sacrificial zinc anodes. Diesel Pro Power provides a complete range for all cooling components:

-

Zinc for Heat Exchangers – Protects internal copper tubes from electrolysis.

-

Zinc for Raw Water Pumps – Prevents corrosion in the bronze impeller housing.

-

Zinc for Fuel and Oil Coolers – Shields sensitive metal surfaces from saltwater exposure.

Each zinc is threaded with a brass plug and available in various NPT sizes for direct replacement. Regular inspection and replacement of anodes every six months will extend the service life of the entire cooling system.

Hoses and Clamps for Marine Cooling Systems

Diesel Pro Power offers premium silicone coolant hoses designed for high-temperature and pressure applications. These hoses resist cracking, collapse, and saltwater damage—making them ideal for Detroit Diesel 6V92 engines.

-

Available in multiple inner diameters ranging from 1” to 4”.

-

Sold by the foot for customizable installation.

-

Reinforced for long life and consistent coolant flow.

Each hose can be secured with stainless-steel hose clamps, available in multiple effective diameter ranges to match coolant and fuel lines. All clamps are corrosion-resistant and meet marine safety standards.

Bearings, Seals, and Internal Pump Components

For complete overhauls, Diesel Pro Power carries all internal service parts for the Detroit Diesel raw water pump, including:

-

Mechanical Seals – Prevent leakage along the pump shaft.

-

Ball Bearings – Designed for high-speed marine rotation.

-

Bearing Oil Seals – Protect internal components from water intrusion.

-

Shaft Seals – Maintain smooth operation and prevent coolant contamination.

-

Wear Plates – Extend housing life by reducing friction and erosion.

-

Pump Covers and Screws – Secure the impeller housing and ensure proper compression on gaskets.

-

Pump Cams – Precisely machined to deliver optimal water flow and impeller engagement.

These parts ensure that your pump maintains proper flow and efficiency even after years of service.

Radiator Components and Engine Paint

Diesel Pro Power also provides the finishing touches for Detroit Diesel 6V92 marine engine cooling systems:

-

Radiator Gaskets and Cap Necks – Maintain pressure integrity in closed cooling systems.

-

Green Detroit Diesel Engine Paint – Authentic OEM-style finish, resistant to heat and corrosion. Available for ground shipping within the U.S. and Canada.

Maintaining your engine’s original Detroit Diesel green coating protects it from oxidation and preserves resale value.

Maintenance Recommendations for the Detroit Diesel 6V92 Cooling System

To ensure maximum performance and longevity of your 6V92 non-turbo marine engine:

-

Inspect Impellers Every 12 Months – Replace if blades show cracking or distortion.

-

Check Zinc Anodes Every 6 Months – Replace when more than 50% deteriorated.

-

Flush Cooling System Annually – Remove scale or salt buildup from heat exchangers.

-

Lubricate Pump Bearings and Seals During Overhauls – Prevent premature wear.

-

Inspect Gaskets and Hoses Regularly – Replace any components showing swelling or corrosion.

Following these simple steps will preserve your engine’s cooling efficiency and prevent overheating in demanding marine environments.

Why Choose Diesel Pro Power for Your Detroit Diesel 6V92 Marine Water Pump and Cooling System Parts

Diesel Pro Power has earned the trust of over 40,000 satisfied customers worldwide, supplying Detroit Diesel engine parts with unmatched reliability and service. Choosing Diesel Pro Power means you benefit from:

-

All parts in stock and ready for global shipment.

-

Real-time order tracking and transparent logistics.

-

Expert technical support from Detroit Diesel-trained specialists.

-

Comprehensive product warranties and satisfaction guarantees.

-

Proven reliability in commercial, military, and recreational marine applications.

Every pump, impeller, gasket, and seal sold by Diesel Pro Power is inspected, pressure-tested, and packaged for marine service. With fast worldwide shipping and a reputation built on precision, Diesel Pro Power remains the preferred source for Detroit Diesel 6V92 marine cooling components.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588