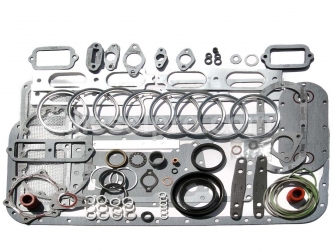

Parts for Detroit Diesel 8V71 Turbo for Canada - Gasket Section

Loading...

Loading... -

-

-

-

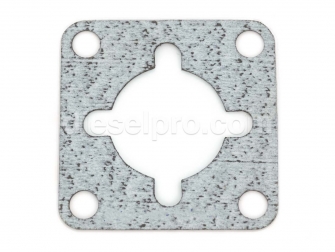

Detroit Diesel Inspection Cover Gasket for Series V71, V92 and for 6V53, 8V53 new style

8923792

.

Price: $ 8.61 -

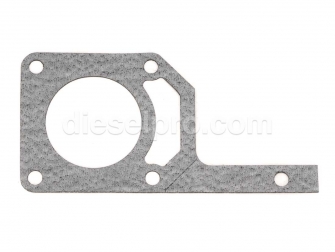

Detroit Diesel Front End Plate Gasket for Series V71 & V92

5144901

Located between the block and end platePrice: $ 20.15 -

Detroit Diesel Crankshaft seal for 8V53, 3-71, 4-71, 6-71, 6v71, 8v71, 12v71 engines

5115454

Front - Standard - Universal rotation

Price: $ 22.56 -

Detroit Diesel Rear Crankshaft seal

5114335

Rear for 271, 371, 471, 671,6V71, 8V71, 12V71, 8V53 and Front for 16V71, 12V92, 16V92. - Standard - Single Lip

Price: $ 33.18 -

Detroit Diesel Rear Crankshaft seal.

5197860

Rear - Oversize - Single Lip for 271, 371, 471, 671, 6V71, 8V71, 8V53 and Front for 16V71,12V92, 16V92 Engines

Price: $ 45.45 -

Detroit Diesel Crankshaft seal for 3-71, 4-71, 6-71, 6v71, 8v71, 12v71 engines

5127821

Rear - Standard - Double lip

Price: $ 41.05 -

Detroit Diesel Rear seal for 3-71, 4-71, 6-71, 6v71, 8v71, 12v71 engines

5196927

Real - Oversize - Double Lip.

Price: $ 119.36 -

Detroit Diesel Sleeve seal

5197159

Oversize - Rear for 71 series and Front for 16V71, 12V92 and 16V92 engines.

Price: $ 55.43 -

Detroit Diesel Head gasket kit for 8V71 and 16V71

5196381P

8V71 engine requires 2 kits

16V71 engine requires 4 kits

Price: $ 81.00 -

Detroit Diesel Rocker cover kit, for 4-71, 8V71, 16V71, 8V92, 16V92

5149511

For use with aluminum rocker covers. New stylePrice: $ 68.65 -

-

Detroit Diesel Rocker cover gasket , gray

5104081

For use with aluminum rocker covers. New stylePrice: $ 22.35 -

Detroit Diesel Flywheel Housing Gasket for V71 and V92

5144875

Gasket located between end plate and flywheel housingPrice: $ 30.84 -

-

-

Allison Flywheel Gasket for Marine Transmission M and MH - SAE 2 (Most Common)

29503155

Use when engine housing size is the same as transmission

Price: $ 102.60 -

-

-

Detroit Diesel Blower installation gasket kit for turbo engines 8V71, 16V71, 8V92 and 16V92

5149643

This kit covers one blowerPrice: $ 98.27 -

-

-

Detroit Diesel Head to Manifold Gasket for 471, 671, 8V71, 12V71, 16V71, 8V92, 16V92

5120224

Click on + Pictures below to see how many are needed per engine

Price: $ 13.74 -

Detroit Diesel Gasket for marine manifold flange

23504701

Outside diameter 6.25", inside diameter 4.25"

Price: $ 31.22 -

Detroit Diesel Turbo riser gasket

8923492

Inner width 2”, Inner Length 3.75”, Outer width 3.75”, Outer Length 5.5”Price: $ 9.08 -

762 Hi-Temperature jointing compound for Detroit Diesel and Cummins turbos

762

225 gm tube - Temp range 550C to 760CPrice: $ 188.19 -

-

-

-

Detroit Diesel Gasket for Hydraulic Governor

23509675

Gasket between Governor and DrivePrice: $ 5.50 -

-

-

-

-

-

-

Detroit Diesel Marine Water Pump gasket

5112143

Each pump uses 2 of this gasket. Water inlet and outletPrice: $ 4.59 -

-

-

Detroit Diesel Heat Exchanger Gasket Kit for Marine Engines for Series 53, 71 and 92

5192637

.Price: $ 97.18 -

-

Detroit Diesel Gasket, marine manifold flange spacer

5101914

Outside diameter 6.25", inside diameter 3.50"Price: $ 69.50 -

-

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

Gasket Spray -High Tack Sealant (Hold & Seals Cut Gaskets)

99MA

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 20.55 -

3H Gasket Maker

3H

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 17.46 -

-

-

-

Gasket Maker - Ultra Blue RTV Silicone Sensor Safe

77BR

For Detroit Diesel & Cummins enginesPrice: $ 11.03 -

-

Parts for Detroit Diesel 8V71 Turbo — Gasket Section

Keep your Detroit Diesel 8V71 Turbo dry, tight, and performing at its best with a complete selection of gaskets, seals, and sealants chosen specifically for the turbocharged 8V71 configuration. This page explains what each gasket does on the 8V71 Turbo, where it installs, and best practices to prevent leaks and repeat repairs. Some components also fit other Detroit Diesel two-stroke families, but all guidance below is written for the 8V71 Turbo so you can confirm fit and install with confidence.

Gaskets for Cylinder Head & Upper Engine (Detroit Diesel 8V71 Turbo)

Head & Upper Engine Overview

The turbocharged 8V71 uses a V-8 block with loop scavenging and a turbo-assisted Roots blower. A leak-free top end is essential: even minor seepage at rocker covers, head-to-manifold joints, or the water rail can create oil mist, coolant staining, and gradual power loss. The parts below address the high-temperature, high-vibration environment of an 8V71 Turbo’s upper engine.

Head Gasket Kits (one kit per cylinder head)

Use head gasket kits any time a cylinder head comes off—for injector sleeve work that requires head removal, correcting coolant or compression leaks at fire rings, or during a full top-end refresh. The 8V71 Turbo uses two cylinder heads, so you’ll typically need two kits. Preparation is everything: clean the deck and head to bare metal, verify flatness with a straightedge, chase threads, and torque in the Detroit sequence in stages. After the first heat cycle, recheck for seepage around coolant and oil feed points.

Rocker Cover Gaskets — New-Style Gray for Aluminum Covers

Turbocharged engines move more crankcase vapor. A weeping rocker cover gasket sends oil across the valve cover and onto heat shields. Choose the new-style gray gasket matched to aluminum covers; it resists compression set and heat cycling. Inspect cover flange straightness, replace distorted grommets or hardware, and avoid over-torquing which crushes the gasket and invites leaks.

Complete Rocker Cover Service Kits

If you’re chasing persistent top-end misting or renewing the look of the engine, a matched rocker cover service kit bundles the correct gaskets and seals for a reliable, uniform clamp load. It’s a smart add-on during head service.

Head-to-Exhaust Manifold Gaskets

These gaskets seal the exhaust ports to the manifold. Turbo heat, pulse pressure, and cycles demand a crisp surface finish. On 8V71 Turbo engines, even slight manifold warp can create soot tracks at port joints—check with a straightedge and resurface if needed. Use proper torque from the inner ports outward, and re-torque if your service literature calls for it after heat soak.

Water Manifold (Water Rail) Gasket

Coolant distribution along the head water rail depends on flat mating surfaces and correct gasket compression. In marine environments, salt and heat accelerate corrosion and pitting along the rail. Wire-brush scale, treat pitting, and replace the water rail gasket during any top-end service to prevent weeping that can travel down the block and masquerade as a hose leak.

Bottom End & Crankshaft Seals (Detroit Diesel 8V71 Turbo)

Why Main Seals Matter on an 8V71 Turbo

Front and rear main seals contain oil under splash and windage—not pressure—but turbocharged setups heighten crankcase pulsation. A hardened, glazed, or under-size seal can mist oil onto the damper, flywheel, or housing; any oil near the marine coupling or transmission bell deserves immediate attention.

Front Crankshaft Seal — Standard, Universal Rotation

The front seal sits at the damper end. On the 8V71 Turbo, check the hub for a wear groove; if you can feel it with a fingernail, combine your new seal with a wear sleeve to restore a smooth sealing land. Confirm the lip orientation for your rotation and apply a light film of clean oil on the lip before installation.

Rear Crankshaft Seals — Single-Lip and Double-Lip Options

Single-lip, standard size: Choose when the crank sealing surface is within spec and free of grooves.

Single-lip, oversize: Use with a sleeve or where a slightly larger interference fit is needed due to wear.

Double-lip, standard or oversize: Adds redundancy and better exclusion of contaminants—ideal for harsh duty cycles and marine service. Many technicians upgrade to double-lip on in-frame overhauls for added insurance.

Oversize Seal Sleeves

When the sealing land shows a minor groove, an oversize sleeve restores the surface. Press to the correct depth so the lip rides on a clean, cylindrical section—not a chamfer. Misplacement is a common cause of immediate re-leak.

Front End, Rear End Plate & Flywheel Housing (8V71 Turbo)

Front End Plate Gasket

At the front of the 8V71 block, the end-plate gasket seals accessory drive cavities and oil passages. Oil mist at the front cover that isn’t the main seal may trace back here. Clean the surfaces, align dowels, and torque evenly to prevent plate distortion. Replace any bent or nicked dowels.

Rear End Plate Gasket

This sits between the block and the rear end-plate. On marine 8V71 Turbos, leaks here are often misdiagnosed as a rear main seal. If you see a film along the plate perimeter, remove the flywheel housing for access and renew the gasket. UV dye makes source tracing easier before teardown.

Flywheel Housing Gasket & Flywheel Housing Cover

The housing gasket seals the interface between the rear plate and the flywheel housing; the large access cover allows clutch or coupler service. If you take the housing off for ring gear, clutch, or coupling work, replace both the perimeter gasket and the cover gasket. Clean the mating groove thoroughly and inspect for corrosion pitting.

Allison Marine Gear Housing-to-Transmission Gasket — SAE #2

Many 8V71 Turbo marine installations pair with Allison M or MH marine gears using an SAE #2 housing size. The correct housing-to-gear gasket prevents oil migration between housings and maintains alignment when you draw the gear to the bell. Confirm your housing size before ordering; SAE #2 is common on these engines.

Blower & Turbo Interface Gaskets (8V71 Turbo)

Why These Interfaces Are Critical

The turbo uses exhaust energy to supercharge inlet air, but the Roots blower remains the scavenging pump. Any leak at the blower base or turbo oil lines shows up as oil on the case, smoke, or soot at joint lines.

Blower Installation Gasket Kit — For Turbo Engines

A dedicated blower installation kit covers one blower and includes the base and associated interface gaskets. Inspect alignment dowels, verify gear end play per spec, and review crankcase breather condition—excess blow-by elevates crankcase pressure and can push oil past fresh gaskets.

Turbo Riser Gasket

This high-temperature gasket sits at the turbo riser/hot-side flange. It must withstand thermal shock and pulsation without crushing. If you find uneven clamp marks, dress the flange faces and replace distorted studs or nuts. Confirm dimensions against your riser before installation and tighten in a crisscross pattern.

Turbo Oil Feed & Return Gaskets

Oil supply gasket: Prevents pressure-side seepage at the turbo bearing housing. Any shine near the feed fitting can drip onto hot components—replace at the first sign of dampness.

Oil return gasket: The return is gravity-aided; even pinhole paths will weep. Keep the return line free of kinks or coke build-up to avoid forcing oil past the turbo seals.

High-Temperature Jointing Compound for Turbo Flanges

A thin, even film on stubborn high-temp joints can help seal minor surface imperfections. Use sparingly—excess compound can squeeze into the gas path.

Oil System Gaskets (8V71 Turbo)

Oil Cooler Gaskets

Cooler cover and core interfaces are frequent sources of oil film along the block. Replace both gaskets whenever the cooler is off, and verify studs are straight so the cover clamps squarely. Tighten fasteners evenly in stages to avoid pinching the gasket.

Oil Filter Adaptor Gasket

A hardened adaptor gasket can seep when the engine is hot and oil is thin and high-volume. Clean threads, install the gasket dry unless the procedure specifies otherwise, and torque to spec.

Oil Pan Gasket — 8V71 Turbo

Harmonic vibration and deep-sump marine pans make small imperfections matter. Flatten pan rail “dishes” at bolt holes with a body hammer and dolly, clean thoroughly, and torque in a crisscross pattern. After the first run-in, inspect for weeping around corners.

Cooling System Gaskets (8V71 Turbo)

Thermostat Housing Cover Gasket

Prevents seepage at the thermostat cover. Staining at the housing often looks like a hose leak; wipe the joint clean, pressure test, and confirm the true source before parts shotgun-ing.

Block Water Outlet (Block Heater) Gasket

If your 8V71 Turbo has a block heater, this is the seal behind it. White deposits around the outlet indicate long-term weeping—replace the gasket and clean both faces until they’re bright and smooth.

Marine Heat Exchanger Gasket Kit

Raw-water-cooled installations rely on a tight heat exchanger. A dedicated gasket kit includes the seals needed when you descale, re-tube, or service the end caps. Reassemble with flawless surfaces, correct torque, and a recheck after thermal cycling.

Marine Water Pump & Connection Gaskets

Marine water pump face gasket: Seals the pump body to its mounting surface.

Mounting gasket: Cushions and seals the mount to prevent fretting and seepage.

Plate gasket: Seals the pump cover plate—replace any plate with deep scoring.

Inlet/outlet gaskets (two per pump): Renew both to prevent air ingress that can trigger overheat at idle.

Flywheel-to-salt-water-pump gasket: Used where the pump couples to the flywheel housing; precise alignment prevents eccentric wear and early seal failure.

Marine Manifold Flange Gaskets & Spacers

Marine exhaust manifold flange gasket: Seals the interface at the marine manifold flange; confirm outer and inner diameters before installation.

Flange spacer gasket: For joints using spacer rings. Thermal cycles and salt cause flange face corrosion—dress surfaces flat and replace hardware as needed.

Governor, Fuel & Accessory Gaskets (8V71 Turbo)

Governor Spring Cover & Top Cover Gaskets

A precise governor needs clean, sealed covers. Replace the spring cover gasket after any spring adjustment and the top cover gasket after flyweight or linkage inspection. Oil mist here runs down and is often mistaken for a rear plate weep.

Hydraulic Governor Gasket & Governor Cover Gasket

Hydraulic governors rely on stable internal pressure. Air leaks through aged gaskets cause erratic idle and response. Renew the governor-to-drive gasket and the cover gasket during service and confirm clamp load evenly across the perimeter.

Fuel/Water Pump Gasket

This multi-purpose pump gasket is frequently disturbed during maintenance. Always install a fresh one to avoid weeping that looks like a timing cover leak.

Starter Gasket

For marine 8V71 Turbos, keeping moisture out of the starter housing is essential. Replace the starter gasket whenever the starter is serviced or replaced.

Inspection & Service Covers (8V71 Turbo)

Block Inspection Cover Gaskets

These seal the block inspection panels. On older engines, cover plates can warp—check flatness with a straightedge and replace plates that won’t hold even compression. Fresh gaskets plus straight plates eliminate the faint oil tracks that love to return.

Front End Plate & Flywheel Housing Access Gaskets

Anytime you open the front or rear access points for timing checks, coupling inspections, or clutch work, replace the associated gaskets. Small seep lines that appear later are often from reused, compressed access gaskets.

Block Plug & Ancillary Seals (8V71 Turbo)

Gasket for the Block Plug — 2.5" Diameter

This circular gasket seals coolant or gallery plugs with a 2.5-inch interface. Replace it anytime the plug is removed to drain or clean passages. Apply anti-seize to the plug threads if specified, and torque to spec to avoid twisting or distorting the gasket face.

Surface Prep, Sealants & Consumables for the 8V71 Turbo

High-Tack Gasket Spray

Use high-tack spray to hold cut gaskets in place during vertical assembly—water rails, inspection covers, and similar. Apply a light, even coat; too much can cause the gasket to “hydroplane” and extrude.

Non-Hardening Gasket Maker

A pliable, non-hardening sealant is ideal for thin cover plates that will be reopened later. It maintains a seal through heat cycles without bonding aggressively to the surface.

Ultra-Blue RTV, Sensor-Safe

When the procedure specifies RTV near sensors, choose sensor-safe formulas that resist oil and heat. Do not substitute RTV where a composite gasket is required; follow the service manual.

High-Strength Red Threadlocker

Use on clean, dry fasteners where a locking compound is called for (studs in vibration-prone areas). Avoid on hardware requiring periodic removal unless specified.

Cold-Weld Epoxy

Useful for temporary, non-structural repairs of minor casting porosity or incidental damage in the field. Not a substitute for proper gasket replacement or welding.

Detroit Green Engine Paint

After degreasing and leak repair, a fresh coat of engine paint makes it easier to spot new seepage during inspections and leaves the engine bay looking professional.

Troubleshooting Leak Paths on an 8V71 Turbo (Field Tips)

Oil at the Flywheel Housing

Don’t assume the rear main seal first. Clean the area, run the engine, and trace with UV dye. It could be the rear end-plate gasket, the flywheel housing perimeter, an access cover, or the governor-to-drive gasket wicking along a seam.

Oil Mist Near the Damper

Verify the front main seal and the front end-plate gasket. Check the damper hub for a groove; if present, add a sleeve and a fresh seal. Confirm crankcase ventilation is clear to avoid pressure buildup.

Sooty Streaks at Exhaust Ports

Replace the head-to-manifold gaskets, inspect manifold flatness, and tighten fasteners evenly. Warped manifolds will re-leak even with new gaskets.

Coolant Drips on the Side of the Block

Common sources are the water rail gasket, the thermostat housing cover, or the block heater outlet. White, chalky deposits indicate long-term weeping.

Oily Turbo Footing

Usually the turbo oil return gasket or a kinked return hose. Less often the supply gasket. Address promptly to protect the turbo’s bearings.

Blower Base Oil

Renew the blower installation gaskets and verify crankcase breathers aren’t restricted. Elevated crankcase pressure encourages leaks at the blower base and inspection covers.

Installation Best Practices (8V71 Turbo Gaskets & Seals)

Surface Preparation

Scrape old material with plastic or brass tools to avoid gouging aluminum or cast iron. Finish with solvent on lint-free rags. Avoid abrasive discs that shed grit into the engine.

Dry vs. Dressed

Install most composite gaskets dry unless the procedure calls for a specific sealant. Where RTV is specified, lay a narrow, continuous bead, respect skin-time, and avoid over-application.

Torque Patterns & Sequencing

Follow published patterns—usually center-out or crisscross—and torque in stages. Re-torque after heat cycles only where the manual specifies.

Hardware Health

Replace stretched, corroded, or rounded fasteners. Uneven clamp load is a common cause of recurring leaks.

Thermal Cycle Check

After the first heat cycle, inspect oil pan rails, water rails, and exhaust joints. Early detection prevents soot baking and oil staining.

Documentation

Record what you replaced and when. If a leak returns, your notes help correlate to operating hours, thermal cycles, or component warp.

Quick Reference: Common 8V71 Turbo Gaskets & Their Locations

Block plug gasket (2.5") — Coolant/gallery plugs in the block.

Head gasket kits — One per head; the 8V71 uses two heads.

Rocker cover gaskets/kits (new-style for aluminum covers) — Top-end sealing and vapor control.

Head-to-manifold gaskets — Exhaust interface; high heat and pulsation.

Water manifold (water rail) gasket — Coolant distribution along the head.

Front and rear main seals — Standard or oversize; single or double lip.

Front/rear end-plate and flywheel housing gaskets — Structural sealing at the rear and access points.

Allison SAE #2 housing-to-transmission gasket — For common marine pairings.

Blower installation gasket kit — Blower base and related interfaces.

Turbo oil feed/return and riser gaskets — Turbo lubrication and hot-side flange.

Oil cooler and oil pan gaskets — Lube system sealing hotspots.

Thermostat cover, block water outlet, heat exchanger kit — Cooling system interfaces.

Governor and accessory cover gaskets — Mechanical and hydraulic governor sealing.

Marine manifold flange and spacer gaskets — Exhaust flange joints in marine service.

Why Buy Your 8V71 Turbo Gaskets & Seals from Diesel Pro Power

Application-Focused Selection

Every gasket and seal featured here is curated for Detroit Diesel 8V71 Turbo reliability in demanding environments—workboats, commercial fleets, standby power, and heavy-duty vehicles.

Proven Materials for Two-Stroke Turbos

We prioritize materials that handle heat, vibration, and pressure dynamics unique to a turbocharged two-stroke.

Marine-Ready Experience

From flange corrosion to salt-fog staining, we stock what actually solves problems in real-world bays and engine rooms.

Clear Fitment Guidance

Descriptions emphasize location, function, and quantity notes (like one head kit per head) so you buy once and install confidently.

Fast Fulfillment

Most items are in stock, minimizing downtime and helping you complete repairs on schedule.

Seasoned Support

If you’re battling an elusive oil mist, recurring exhaust leak, or a stubborn coolant seep, our team can help you select the right gasket, seal, or kit the first time.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588