Parts for Detroit Diesel 8V71 Turbo for Canada - Engine Water Pump Section

Loading...

Loading... -

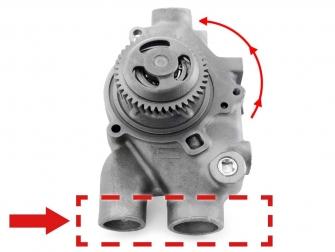

Detroit Diesel Water Pump for 6V71, 6V92, 8V71, 8V92 - RH - Rebuilt

23506790

RIGHT hand rotation - for marine application. Sold with refundable core deposit. See details

Price: $ 1,549.76 -

Detroit Diesel Water Pump for 6V71, 6V92, 8V71, 8V92 - Rebuilt

23506602

RIGHT hand rotation - for truck, Industrial and also in some marine applications. Sold with refundable core deposit. See details

Price: $ 1,592.61 -

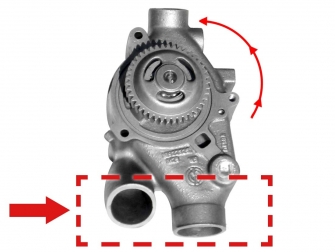

Detroit Diesel Water Pump for 6V71, 6V92, 8V71, 8V92 - LH - Rebuilt

23506670

LEFT hand rotation - for marine application. Sold with refundable core deposit. See details

Price: $ 1,667.96 -

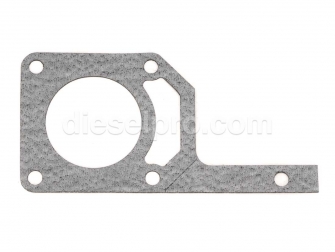

Detroit Diesel Engine Water Pump repair kit for 6V71,8V71, 6V92, 8V92

5197509

Repairs pumps shown in picture 1 and 3 of this page

Price: $ 277.20 -

Detroit Diesel Engine Water Pump repair kit for 6V71, 8V71, 6V92, 8V92

5149407

Repairs pump shown in picture 2 of this page

Price: $ 308.45 -

-

-

Detroit Diesel Water Manifold to Oil Cooler Housing Seal

5159457

2 1/2" outside diameter, with inner lipPrice: $ 5.48 -

Detroit Diesel Seal, Water Manifold to Oil Cooler Housing

5156770

2 3/4" outside diameter, with inner lipPrice: $ 5.46 -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $ 97.19 -

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

-

-

-

-

-

-

-

-

-

-

-

-

Clamp for a coolant and fuel Hose

10H

Effective Diameter Range:

Minimum 9/16", Maximum 1-1/16"

Price: $ 3.04 -

Clamp for a cooland and fuel Hose

5104592

Effective Diameter Range:

Minimum 1", Maximum 1.5"

Price: $ 4.52 -

Clamp for a coolant Hose

3412320

Effective Diameter Range:

Minimum 11/16", Maximum 1-1/4"

Price: $ 14.76 -

Clamp for a coolant Hose

4920417

Effective Diameter Range:

Minimum 13/16", Maximum 1-3/4"

Price: $ 15.78 -

Clamp for a coolant Hose

3922846

Effective Diameter Range:

Minimum 1-5/16", Maximum 2-1/4"

Price: $ 16.50 -

Clamp for a coolant Hose

3922847

Effective Diameter Range:

Minimum 1-9/16", Maximum 2-1/2"

Price: $ 16.68 -

Clamp for a coolant Hose

3922849

Effective Diameter Range:

Minimum 2-5/16", Maximum 3"

Price: $ 17.19 -

Clamp for a coolant Hose

5188036

Effective Diameter Range:

Minimum 2-7/8", Maximum 3.5"

Price: $ 5.16 -

-

Parts for Detroit Diesel 8V71 Turbo – Engine Water Pump Section

The Detroit Diesel 8V71 Turbo engine is a legendary workhorse of the two-stroke Series 71 family, known for its powerful performance, compact V8 design, and exceptional durability in both marine and industrial settings. One of the most vital systems ensuring the reliability and long life of these engines is the cooling system — and at the center of that system is the engine’s fresh water pump.

This catalog provides a comprehensive guide to the Detroit Diesel 8V71 Turbo water pump and related cooling components, focusing on the high-quality rebuilt water pumps available from Diesel Pro Power. These pumps are engineered to OEM standards and backed by decades of expertise supporting Detroit Diesel operators around the world.

Overview: The Importance of the Fresh Water Pump in Detroit Diesel 8V71 Turbo Engines

The fresh water pump plays a central role in the 8V71 Turbo’s cooling system. It circulates coolant through the engine block, cylinder heads, turbocharger cooling passages, and heat exchanger (in marine setups) to regulate temperature and prevent overheating under high-load conditions.

A malfunctioning or inefficient water pump can quickly lead to dangerous temperature spikes, reduced power, and in extreme cases, catastrophic engine failure. For this reason, operators maintaining Detroit Diesel 8V71 Turbo engines—whether in tugboats, yachts, power generators, or industrial machinery—depend on high-quality rebuilt pumps and proper cooling system components to ensure consistent, reliable performance.

Rebuilt Water Pumps for Detroit Diesel 8V71 Turbo Engines

Right-Hand Rotation Marine Water Pump – Rebuilt

This right-hand rotation water pump is designed specifically for Detroit Diesel 6V71, 6V92, 8V71, and 8V92 engines used in marine applications. Each pump is professionally rebuilt to restore original flow capacity and durability while ensuring a perfect fit with Detroit Diesel’s factory cooling system specifications.

-

Application: Marine engines (right-hand rotation)

-

Condition: Rebuilt, tested, and ready for installation

-

Includes: Full impeller assembly, shaft, seals, and bearings

-

Core Deposit: Sold with a refundable core charge — the old pump is returned to Diesel Pro Power for remanufacture, promoting sustainability and cost savings.

-

Quality Guarantee: Each rebuilt pump is inspected and pressure-tested to ensure leak-free operation and consistent coolant circulation under demanding conditions.

These rebuilt units are trusted by commercial marine operators who rely on 8V71 Turbo engines for continuous-duty service. The high-flow impeller design supports optimal temperature control during prolonged operation, ensuring consistent power delivery in hot and high-load environments.

Right-Hand Rotation Water Pump – Truck and Industrial Applications

The second option in the catalog is the right-hand rotation rebuilt water pump for industrial and truck enginespowered by Detroit Diesel’s V71 or V92 series. Though similar to the marine version, this pump is configured for land-based cooling systems that typically use radiators rather than heat exchangers.

-

Application: Industrial engines, stationary power units, and heavy trucks

-

Condition: Rebuilt to OEM standards

-

Rotation: Right-hand rotation (standard for most configurations)

-

Durability: Reinforced housing and high-grade seals handle continuous operation in high-temperature, high-dust environments.

Industrial and trucking applications demand uninterrupted performance under varying loads and ambient conditions. A properly rebuilt water pump from Diesel Pro Power ensures that the 8V71 Turbo engine maintains steady coolant flow—extending lifespan and reducing unplanned downtime.

Left-Hand Rotation Marine Water Pump – Rebuilt

The left-hand rotation rebuilt pump is engineered for marine engines that require counter-rotation to match specific gear train and propeller setups. Like the right-hand rotation version, it is fully rebuilt, tested, and backed by Diesel Pro Power’s quality guarantee.

-

Application: Marine propulsion and auxiliary engines requiring LH rotation

-

Condition: Fully rebuilt

-

Key Features: OEM-quality bearings, precision-balanced impeller, new seals, and corrosion-resistant housing

-

Core Program: Old cores are returned for full deposit credit once inspected

Left-hand pumps are commonly used in dual-engine marine setups where engines are installed in mirror-image configurations to achieve balanced thrust. Diesel Pro Power’s rebuilt LH 8V71 Turbo pump offers identical flow rates and reliability as its right-hand counterpart, ensuring matched cooling efficiency across both engines.

The Diesel Pro Power Rebuild Process

Diesel Pro Power’s remanufacturing process for Detroit Diesel water pumps is what sets these components apart. Every pump undergoes a rigorous multi-step process designed to restore original Detroit Diesel performance:

-

Core Inspection: Each returned pump core is visually and dimensionally inspected. Housings are checked for cracks, corrosion, and warpage.

-

Disassembly & Cleaning: The pump is completely disassembled and cleaned using industrial-grade ultrasonic and chemical processes to remove old scale, rust, and debris.

-

Component Replacement: Bearings, seals, O-rings, gaskets, and impellers are replaced with brand-new OEM-equivalent components.

-

Precision Machining: The shaft bore and impeller surfaces are machined to factory specifications, ensuring perfect balance and alignment.

-

Assembly & Calibration: Each unit is reassembled under controlled conditions using precision torque settings.

-

Testing: Rebuilt pumps are pressure- and flow-tested to guarantee proper coolant delivery and seal integrity before packaging.

This attention to detail ensures that rebuilt Detroit Diesel 8V71 Turbo water pumps perform as reliably as new units—often at a fraction of the replacement cost.

Repair Kits for Detroit Diesel 8V71 Turbo Water Pumps

For operators capable of performing in-house rebuilds, Diesel Pro Power also offers complete repair kits. These kits include seals, bearings, O-rings, and gaskets needed to overhaul an existing pump.

Repair Kit for Marine Water Pump (LH & RH Applications)

This kit is compatible with both left-hand and right-hand marine pumps and provides all necessary components to restore water-tight integrity and impeller performance. Ideal for mechanics seeking to rebuild pumps without replacing the full assembly.

Repair Kit for Truck & Industrial Water Pump

This version is designed for the truck and industrial application pumps. It features heavy-duty bearings and high-temperature seals suitable for long-term use in high-heat environments.

Supporting Components for the Cooling System

A successful cooling system overhaul for a Detroit Diesel 8V71 Turbo requires more than just the water pump. Diesel Pro Power stocks every complementary part to ensure the entire system functions flawlessly:

Seals and Gaskets

Proper sealing prevents coolant leaks and maintains internal pressure balance. The catalog includes:

All gaskets and seals are made of high-quality, heat-resistant materials suitable for marine and industrial coolant formulations.

Thermostats and Temperature Control Components

Maintaining correct operating temperature is critical for turbocharged two-stroke engines. Diesel Pro Power offers thermostats rated at 160°, 170°, and 180° Fahrenheit, allowing operators to choose the ideal setting for their environment.

Each thermostat is precision-calibrated to open and close at the specified temperature, ensuring rapid warm-up and consistent cooling under heavy loads.

For industrial versions of the 8V71 Turbo, the radiator is the key heat exchanger. Diesel Pro Power supplies OEM-quality radiators specifically built for the 8V71. These units are heavy-duty and engineered for efficient heat dissipation in stationary and vehicle-mounted applications.

Marine versions of the 8V71 rely on heat exchangers coupled with seawater-cooled systems—both of which depend on the fresh water pump’s performance to move coolant efficiently through the engine block and core tubes.

Coolant Hoses and Clamps

Silicone coolant hoses are essential for maintaining consistent pressure and temperature resistance. Diesel Pro Power’s hoses are available in a variety of inner diameters ranging from 3/4" to 4", each designed to resist collapse under suction and withstand temperatures well above conventional rubber hoses.

Paired with precision hose clamps, these components form secure connections throughout the cooling circuit, preventing leaks and ensuring smooth coolant flow.

Temperature Switches and Monitoring

To complement the cooling system, Diesel Pro Power also provides temperature switches and mechanical or electrical gauges. These allow real-time monitoring of coolant temperature and early detection of potential overheating before damage occurs.

-

Temperature switch closes at 205°F (1/2" NPT thread size)

-

Compatible with Detroit Diesel, Cummins, and Caterpillar engines

-

Available in both 12V and 24V gauge configurations

Why Choose Diesel Pro Power for Detroit Diesel 8V71 Turbo Cooling System Parts

When it comes to rebuilding or maintaining a Detroit Diesel 8V71 Turbo engine, Diesel Pro Power stands as the global leader in reliable replacement parts and rebuilt components.

Key Advantages

-

40,000+ Satisfied Customers Worldwide: Trusted by marine engineers, fleet managers, and industrial operators in over 180 countries.

-

Comprehensive Online Catalog: Every component is clearly organized by engine model and system type for quick and accurate selection.

-

Quality Assurance: Each rebuilt pump undergoes strict inspection and testing to meet or exceed OEM performance.

-

Core Exchange Program: Return your old pump and receive a full core credit — reducing waste and cost.

-

Expert Technical Support: Knowledgeable staff provide guidance on pump rotation, gasket compatibility, thermostat calibration, and installation best practices.

-

Fast Global Shipping: Diesel Pro Power ships daily to marinas, industrial sites, and ports around the world, minimizing downtime.

When you purchase a rebuilt Detroit Diesel 8V71 Turbo water pump from Diesel Pro Power, you’re not only buying a component — you’re investing in longevity, efficiency, and the continued performance of one of the most dependable diesel engines ever built.

Maintenance Tips for Detroit Diesel 8V71 Turbo Cooling Systems

To maximize pump life and engine performance, Diesel Pro Power recommends the following best practices:

-

Flush the Cooling System Regularly: Remove debris, corrosion, and scale deposits that can restrict coolant flow.

-

Inspect Seals and Gaskets: Replace worn or leaking seals promptly to avoid coolant loss and cavitation damage.

-

Use Proper Coolant Mix: Always use coolant approved for Detroit Diesel engines with the correct ratio of antifreeze and corrosion inhibitors.

-

Monitor Operating Temperature: A sudden rise in temperature may indicate a failing impeller or clogged coolant passages.

-

Replace Thermostats Periodically: Over time, thermostats can stick or lose calibration, leading to poor temperature regulation.

The Diesel Pro Power Difference

Every rebuilt Detroit Diesel 8V71 Turbo water pump sold by Diesel Pro Power represents a commitment to precision craftsmanship, sustainable engineering, and customer satisfaction. From the moment you place your order to installation and beyond, Diesel Pro Power ensures your experience is seamless, professional, and backed by decades of diesel engine expertise.

Whether maintaining a classic twin 8V71 marine setup, a generator unit, or an industrial power source, trust Diesel Pro Power for the highest quality rebuilt pumps and cooling system components available anywhere online.

Diesel Pro Power — Trusted Worldwide by Detroit Diesel Operators Since 1989.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588