Parts For Detroit Diesel 8V92 Turbo for Canada - Oil Pump Section

Loading...

Loading... -

-

-

Detroit Diesel Oil Pump - 6V71,8V71,6V92,8V92,12V92,16V92

5128905

Scavenging type. Rebuilt - Sold with refundable deposit. See details.

Price: $ 5,353.89 -

-

-

-

-

-

-

-

-

-

-

Detroit Diesel Gasket, Oil Pressure Regulator Add Relief for V71, V92 Series

5117269

.Price: $ 3.82 -

-

-

Detroit Diesel Oil Filter Adaptor for Engine & Allison transmission

25010854

From cartridge to spin-on

Price: $ 208.96 -

-

-

Oil Filter Removal Wrench for Detroit Diesel, Caterpillar & Cummins

2321

4-21/32" to 5-5/32"Price: $ 63.29 -

-

-

-

-

-

Oil cooler installation kit for Detroit Diesel

2COOLERS-INS-K

For Double oil coolersPrice: $ 242.09 -

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Detroit Diesel Water Manifold to Oil Cooler Housing Seal

5159457

2 1/2" outside diameter, with inner lipPrice: $ 5.48 -

Detroit Diesel Seal, Water Manifold to Oil Cooler Housing

5156770

2 3/4" outside diameter, with inner lipPrice: $ 5.46 -

Detroit Diesel Seal for Oil Cooler Housing Water Inlet, Series V71 and 92

23501837

2 3/4" Inside diameterPrice: $ 6.39 -

-

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

Green Paint for Detroit Diesel Engines

26006

Available for ground shipping only in USA and CanadaPrice: $ 12.46 -

-

Parts for Detroit Diesel 8V92 Turbo – Oil Pump Section

The Detroit Diesel 8V92 Turbo engine represents one of the most advanced evolutions in the two-stroke V92 series. Known for its reliability, torque output, and efficiency under heavy load, this powerhouse has served in countless marine, industrial, and transportation applications. Maintaining the oil system of the 8V92 Turbo engine is critical for preserving engine longevity and peak performance.

This section provides an in-depth look at the complete oil system components available for the Detroit Diesel 8V92 Turbo, including rebuilt oil pumps, oil coolers, gaskets, seals, dipsticks, and accessories—all available from Diesel Pro Power. With over 40,000 satisfied customers worldwide, Diesel Pro Power ensures every component is engineered for a perfect fit and tested for quality and durability before shipping.

Overview of the 8V92 Turbo Engine Oil System

The oil system of the 8V92 Turbo plays a vital role in engine health and performance. Its function extends far beyond basic lubrication—it manages engine cooling, supports hydraulic operations, and stabilizes internal temperatures during prolonged operation.

Key components of this system include:

-

Oil Pump Assembly: Circulates oil throughout the engine at controlled pressure.

-

Oil Cooler: Regulates oil temperature to prevent overheating and viscosity breakdown.

-

Gaskets and Seals: Maintain pressure integrity and prevent leaks.

-

Pressure Regulators and Valves: Ensure proper flow under all load conditions.

-

Oil Filter Assemblies: Remove impurities to protect bearings and cylinder liners.

The 8V92 Turbo’s oil system uses high-capacity scavenging-type pumps to handle the added lubrication demands of turbocharging. It’s essential that each component—from pump to gasket—meets OEM specifications for reliable performance.

Detroit Diesel 8V92 Turbo Oil Pumps

Rebuilt Oil Pumps (Right Hand and Left Hand Rotation)

The 8V92 Turbo engine employs oil pumps available in both right-hand and left-hand configurations, depending on engine rotation. Each pump is fully rebuilt to precise Detroit Diesel standards and sold with a refundable core deposit.

These pumps feature hardened internal gears, precision-machined housings, and balanced shafts to maintain optimal oil pressure under high RPMs. Whether used in marine propulsion, generators, or industrial power units, these pumps ensure stable lubrication throughout the entire system.

Scavenging-Type Oil Pumps

The scavenging-type oil pump is essential for turbocharged Detroit Diesel engines. It recovers and circulates oil efficiently from multiple parts of the crankcase, preventing pooling and maintaining pressure consistency. Rebuilt scavenging pumps for the 8V92 Turbo are meticulously tested for flow rate and gear integrity, ensuring reliable performance under extended use.

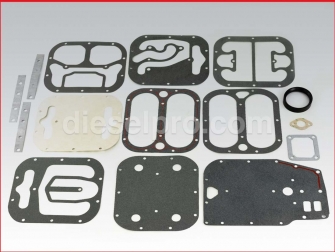

Oil Pump Gaskets and Sealing Components

Proper sealing is the foundation of an efficient oil system. For the 8V92 Turbo engine, Diesel Pro Power offers a full range of premium gaskets designed to withstand high pressure and extreme heat cycles.

Oil Pump Gasket and Pad Cover Gasket

The oil pump gasket provides a tight seal between the pump and the engine block, preventing leaks that could cause loss of oil pressure. The oil pump pad cover gasket reinforces the integrity of the pump assembly, ensuring that every drop of oil flows where it should.

Crankshaft Front Cover Gasket

This gasket seals the crankshaft housing, protecting internal bearings and gears from oil leaks. It’s designed to handle the vibration and thermal expansion common in V8 two-stroke diesel engines.

Oil Pressure Regulator Gasket and Valve Relief Seals

These components ensure precise control of oil flow and pressure. The oil pressure regulator valve maintains optimal PSI throughout the engine, while the relief valve prevents over-pressurization during peak load.

Each gasket and valve offered by Diesel Pro Power is produced using durable composite materials that exceed OEM standards for chemical and thermal resistance.

Oil Pressure Regulation and Control Components

The 8V92 Turbo’s lubrication system relies heavily on consistent oil pressure. The oil regulator valve and pressure spring combination ensures a steady oil supply to all moving parts, including camshafts, bearings, and turbocharger assemblies.

-

Oil Pressure Regulator Valve: Calibrated for optimal PSI management, maintaining engine stability.

-

Regulator Spring: Works in tandem with the valve to provide proper resistance and pressure balance.

-

Oil Relief Valve: Safeguards the system from excess pressure, protecting seals and gaskets from damage.

Maintaining or replacing these components regularly ensures longer bearing life and reduced wear on the crankshaft and connecting rods.

Oil Filtration System Components

Oil filtration is critical in any diesel engine, especially in a turbocharged application where heat and pressure levels are elevated.

Oil Filter Bases and Adaptors

The Detroit Diesel 8V92 Turbo can use either cartridge-style filters or spin-on filters, depending on the configuration. Diesel Pro Power supplies both original-style filter bases and modern adaptors that allow conversion from cartridge to spin-on filters.

Oil Filters (Spin-On and Cartridge Types)

Spin-on filters offer quick replacement and reliable filtration, while cartridge filters are favored for traditional setups that require periodic cleaning and reuse. Both types feature reinforced housings to withstand pressure surges.

Oil Filter Removal Tools

The catalog also includes professional-grade oil filter removal wrenches designed for Detroit Diesel, Caterpillar, and Cummins engines, ensuring maintenance efficiency and safety.

Oil Coolers and Thermal Management

Maintaining stable oil temperature is crucial for the 8V92 Turbo’s longevity. Diesel Pro Power offers a wide variety of oil coolers for single and double configurations, each tested for flow capacity and plate integrity.

Oil Cooler Plate Options:

-

16-Plate Oil Cooler: Compact and efficient for light-duty configurations.

-

18-Plate Oil Cooler: Balances cooling capacity with compact form factor.

-

24-Plate Oil Cooler (With or Without Nipples): Designed for heavy-duty and turbocharged applications.

-

32-Plate Oil Cooler: Maximum cooling efficiency for high-load continuous operation.

Each cooler is constructed from corrosion-resistant materials and brazed for leak-free performance. Diesel Pro Power also offers oil cooler installation kits for double coolers, simplifying retrofitting and replacement.

Oil Cooler Gasket Sets and Housing Seals

Every cooler installation requires multiple gaskets, including housing, water inlet, and cover gaskets. These prevent coolant and oil cross-contamination—one of the most damaging issues in diesel lubrication systems.

Dipsticks, Tubes, and Measurement Accessories

Accurate oil level monitoring ensures safe operation. Diesel Pro Power supplies multiple dipstick lengths for different 8V92 Turbo configurations:

-

27 ¼-inch dipstick for compact installations.

-

44 ¼-inch dipstick for marine or generator applications.

Complementary components such as dipstick tubes and guides are also available, ensuring accurate measurement and easy access during servicing.

Seals, Washers, and Housing Components

Seals and copper washers prevent leaks at critical junctions throughout the oil system.

Water Manifold to Oil Cooler Seals

Available in 2 ½” and 2 ¾” diameters, these seals prevent coolant and oil mixing—a crucial safeguard for engine health.

Oil Cooler Housing Seals

Ensure the connection between cooler plates and housing remains leak-free under constant vibration and heat cycles.

Copper Washers

Small but essential, these washers are used at high-pressure junctions to ensure airtight sealing and prevent oil seepage.

Pressure Switches and Monitoring Components

Monitoring oil pressure is essential for preventing engine damage. Diesel Pro Power offers fuel and oil pressure switches calibrated at 5, 10, 20, and 27 PSI make/break thresholds. These switches provide feedback to gauges or alarms, alerting operators of pressure deviations instantly.

Mechanical and Electrical Gauges

Choose from standard mechanical gauges or electrical versions (12V and 24V) with integrated alarms for marine and industrial systems.

Maintenance Tips for 8V92 Turbo Oil System

-

Monitor Oil Pressure Regularly: Sudden drops often indicate pump wear or clogged filters.

-

Inspect Seals and Gaskets: Replace them during every oil change to prevent gradual leaks.

-

Flush and Clean Coolers: Over time, sludge or scaling can reduce thermal transfer efficiency.

-

Use OEM-Grade Filters: Inferior filters may collapse under pressure, leading to oil starvation.

-

Keep the Oil System Balanced: Avoid mixing oil grades and ensure the regulator valve operates freely.

Why Choose Diesel Pro Power for Detroit Diesel 8V92 Turbo Oil System Parts

With over 40,000 satisfied customers worldwide, Diesel Pro Power has built its reputation on reliability, precision, and service excellence. Every oil system component offered—whether a rebuilt pump, new gasket set, or high-efficiency cooler—is inspected to meet or exceed OEM specifications.

Benefits of buying from Diesel Pro Power:

-

Expert-verified compatibility with the Detroit Diesel 8V92 Turbo engine.

-

Rapid worldwide shipping and secure packaging.

-

Dedicated customer support for technical and application questions.

-

Easy-to-navigate online catalog with clear descriptions and reference data.

-

Proven reliability in both marine and industrial fleets.

When you choose Diesel Pro Power, you’re not just purchasing a replacement part—you’re investing in continued performance, reduced downtime, and confidence that your Detroit Diesel 8V92 Turbo engine will continue to deliver the power and reliability it was designed for.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588