Twin Disc MG 506 Marine Transmission Parts for Canada - Rebuilt MG506 Gear Section

Loading...

Loading... Twin Disc MG506 Rebuilt Marine Transmission Parts — Rebuilt MG506 Gear Section

Welcome to the dedicated rebuilt section for the Twin Disc MG506 marine transmission. This page is organized to help you quickly choose the correct rebuilt MG506 ratio for your vessel and then match it with the most common supporting components used on MG506 installations—such as ring drives, rubber blocks, and output shaft couplings. Each rebuilt MG506 transmission we offer is spin tested prior to shipment for functional verification, and most units are sold on an exchange basis with a refundable core deposit. The goal here is simple: make it easy to identify, select, and order the exact MG506 configuration you need with confidence.

How to Use This Section

-

Start with the Rebuilt MG506 transmissions below—organized by reduction ratio (1.5:1, 2.0:1, 2.5:1, 3.0:1).

-

Then review the MG506-compatible accessories (ring drive, rubber block, output coupling) that commonly pair with MG506 gears.

-

If you’re unsure about fitment, use the identification checklist and selection tips further down.

-

When in doubt, share your dataplate info with our team—we’ll confirm fitment before you buy.

Rebuilt Twin Disc MG506 Marine Transmissions — Ratio Selector

Below you’ll find the four most-requested MG506 reduction ratios. All MG506 transmissions in this section are spin tested to verify reliable operation before they leave our facility. They are typically supplied as exchange units with a refundable core deposit; details appear on each product page. Availability indicators (e.g., “In Stock”) and images are included where applicable to streamline your decision-making and order process.

MG506 Rebuilt — 1.5:1 Reduction

The MG506 in a 1.5:1 ratio is a versatile choice for operators targeting a balance of engine RPM, propeller load, and vessel speed. This ratio often suits lighter boats or applications where quick throttle response and midrange efficiency are favored.

Where this ratio shines

-

Planing or semi-planing hulls seeking brisk acceleration and responsive handling.

-

Applications where propeller diameter is limited, and slightly higher shaft RPM is acceptable.

Selection notes

-

Confirm your bell housing pattern (many MG506 units have been produced with different SAE housing options over the years).

-

Verify the input coupling specs and flywheel pattern to match your engine.

-

Match the output coupling to your shaft flange (bolt circle, pilot, and overall diameter).

-

Check rotation requirements for your driveline (LH/RH). The MG506 family includes variants for different rotation configurations; confirm what your installation requires.

Good practice

-

Compare your current dataplate (model, ratio, serial) with the ratio you’re ordering.

-

Validate case style (some MG gears are referred to as “shallow” or “deep” case by installers). If you’re replacing like-for-like, note what you have now and keep components consistent when possible.

What you can expect

-

A spin-tested MG506 1.5:1 that has been functionally verified.

-

Clear details on the core exchange so you know exactly how to secure your refundable deposit.

MG506 Rebuilt — 2.0:1 Reduction

The 2.0:1 MG506 is popular across a wide range of working and pleasure craft for its balanced torque multiplication and propeller loading, especially when upsizing prop diameter for better bite and low-speed control.

Where this ratio shines

-

General-purpose marine service seeking smoother low-speed maneuvering without sacrificing cruise efficiency.

-

Operators wanting more propeller authority for docking, towing, or frequent load changes.

Selection notes

-

Confirm shaft coupling pattern and output flange dimensions (ensure the output coupling you select matches the 2.0:1 variant of the MG506 you’re ordering).

-

Review your existing mount geometry (height and footprint) to keep alignment swift during change-out.

-

Cross-check cooling and oil line routing on your vessel to avoid surprises at install.

What you can expect

-

Fully spin-tested MG506 2.0:1.

-

Exchange terms with refundable core deposit clearly disclosed on the product page.

MG506 Rebuilt — 2.5:1 Reduction

Stepping to 2.5:1 gives you more torque multiplication at the shaft, which is helpful for heavier vessels, workboats, or applications prioritizing push, grip, and controlled low-speed handling over top-end speed.

Where this ratio shines

-

Heavier displacement vessels and utility craft that need strong low-end thrust.

-

Situations where a larger-diameter propeller is desired for better grip and station-keeping.

Selection notes

-

Confirm propeller sizing targets (diameter/pitch) with your naval architect or prop shop and ensure your ratio selection supports those goals.

-

Match your output coupling to the 2.5:1 unit you’re purchasing; coupling specs vary by model iteration.

-

Keep an eye on gear oil cooler capacity and plumbing layout; verify compatibility with your existing cooling circuit.

What you can expect

-

A spin-tested MG506 2.5:1 built to deliver reliable torque transfer.

-

Standard core exchange process with a refundable deposit, presented up front.

MG506 Rebuilt — 3.0:1 Reduction

The 3.0:1 variant emphasizes low-speed authority and high-thrust scenarios. It’s a go-to for operators who value push over speed—tug operations, certain fishing applications, and vessels frequently working against wind, current, or load.

Where this ratio shines

-

Displacement and heavy-duty service where controlled, deliberate thrust is mission-critical.

-

Operators counting on precise maneuverability and strong bite at low speeds.

Selection notes

-

Double-check rotation and case style. As MG506 models span production years, variants exist; aligning these details shortens downtime.

-

Match your output flange and shaft hardware to avoid delays; consider replacing aged couplings and mounts at the same time for best results.

-

If you’re moving from a different ratio to 3.0:1, revisit propeller specifics to avoid overloading the engine.

What you can expect

-

A spin-tested MG506 3.0:1 ready for service.

-

Clear core return and refund steps to protect your deposit.

MG506-Compatible Accessories & Hardware

Matching accessories to your MG506 reduces vibration, protects the drivetrain, and speeds up change-outs. Below are items commonly paired with MG506 transmissions in the field. Confirm measurements and patterns from your existing components (or provide your dataplate and photos) so we can verify compatibility before you order.

Ring Drive — MG506 (also used on MG507 & MG507-1) — Housing Size SAE #2

This ring drive matches MG506 installations that use an SAE #2 housing. It’s also shared across related models such as MG507 and MG507-1 in many configurations, which is why it’s a frequent choice for MG506 users standardizing spares across fleets.

Key considerations

-

SAE #2 housing spec: verify your bell housing size on the dataplate or by measurement.

-

Check tooth form, pitch diameter, and mounting points if you are replacing only the ring and not the full coupling assembly.

-

If your existing setup is SAE #1, do not assume interchangeability—ask us to confirm the correct ring drive for your exact MG506 variant.

Why this matters

-

Using the correct ring drive maintains concentricity and balance at the engine-to-gear interface, reducing wear and vibration while preserving seal life.

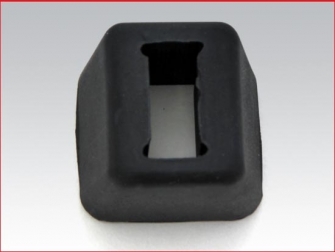

Rubber Block — Vibration Isolation for MG506 (also used across MG507/MG509 in many setups)

The rubber block supports torsional damping and reduces transmitted vibration. Even small amounts of degradation in the rubber can show up as chatter, clunking, or premature wear elsewhere in the driveline.

Key considerations

-

Replace in sets when practical. Mixing old and new isolators can create uneven support and misalignment under load.

-

Verify the block’s dimensions and hardness rating against your existing mount design.

-

If your vessel operates at extended idle or under frequent gear-shifting (e.g., harbor work), proactive replacement pays dividends in noise reduction and component life.

Why this matters

-

Healthy isolation protects the transmission, reduces operator fatigue, and keeps interior noise in check—particularly noticeable in enclosed pilot houses and cabins.

Output Shaft Coupling — MG506 (for 1.50:1, 1.97:1, 2.50:1 ratios)

This MG506 output coupling is designed for gears with the following ratios: 1.50:1, 1.97:1, and 2.50:1. Matching the coupling to your specific ratio and flange geometry is essential for proper shaft alignment and load transfer.

Key considerations

-

Confirm bolt circle, pilot bore, register, and overall diameter.

-

If your current flange shows fretting or ovalized holes, replacing the coupling during the transmission swap can prevent recurring alignment issues.

-

Consider new fasteners and locking hardware to maintain clamp load over time.

Why this matters

-

A correct, tight, and true coupling preserves bearing life and minimizes vibration. It also makes future service work (like alignment checks) faster and more predictable.

MG506 Identification & Selection Checklist

Choosing the right MG506 is straightforward when you gather a few details up front. Use this checklist to confirm fitment:

Dataplate Essentials

-

Model: “MG506” should be clearly shown on the plate.

-

Ratio: 1.5:1, 2.0:1, 2.5:1, or 3.0:1 (or 1.97:1 on certain variants tied to specific couplings).

-

Serial / Spec: Helps us pinpoint build differences across production years.

Bell Housing & Flywheel Interface

-

SAE size: Many MG506 installations use SAE #2; some installations may differ. Confirm what you have.

-

Flywheel pattern: Match engine flywheel drilling and pilot dimensions.

-

Ring drive: Verify the correct ring drive for your housing size and engine flywheel.

Rotation & Case Considerations

-

Rotation: Confirm LH/RH requirements for your driveline.

-

Case style: Some installers refer to “shallow” vs. “deep” case variants; note what you’re replacing.

Output Side

-

Coupling: Identify bolt circle, pilot, and OD; confirm compatibility with your shaft flange.

-

Shaft alignment: Plan to check alignment after install to protect bearings and seals.

Mounting & Isolation

-

Rubber blocks/isolators: Inspect condition; consider replacing in sets.

-

Mount height/footprint: Verify dimensions to reduce alignment time.

Practical Ordering Tips for MG506 Replacements

Confirm Before You Click

-

A quick photo of your dataplate plus a shot of the output flange can eliminate guesswork.

-

If you’re converting ratios (e.g., 2.0:1 to 2.5:1), consult your propeller specialist to avoid over- or under-loading the engine.

Plan for the Core Exchange

-

Your rebuilt MG506 comes with a refundable core deposit. Keep the crate and follow the return instructions to process your refund smoothly.

-

Drain fluids and cap ports to comply with carrier rules and protect the crate.

Bundle the Smarts

-

Pair your rebuilt gear with a new ring drive, fresh rubber blocks, and the correct output coupling to minimize vibration and future service.

-

Proactively replacing aged hardware (studs, bolts, lock washers) prevents fastener stretch and loosening over time.

Performance & Application Guidance for Each Ratio

1.5:1 — Balanced RPM & Speed

-

Use case: Lighter boats and operators who value quick response.

-

Prop notes: Slightly higher shaft RPM; ensure the prop diameter/pitch is matched to prevent cavitation.

-

Telltales you chose right: Clean acceleration, stable cruise, no chronic overloading alarms.

2.0:1 — The All-Rounder

-

Use case: Broad application coverage with comfortable docking behavior and cruise efficiency.

-

Prop notes: Supports a modest prop size increase for better bite.

-

Telltales you chose right: Positive station-keeping, predictable throttle response, reasonable fuel economy.

2.5:1 — Thrust-Forward Thinking

-

Use case: Heavier displacement vessels or duties demanding more low-end torque.

-

Prop notes: Enables larger diameter propellers for grip and control.

-

Telltales you chose right: Strong push against wind/current, cooler gear temps under load, calmer low-speed operation.

3.0:1 — Low-Speed Authority

-

Use case: Workboats, tow applications, or frequent heavy-load conditions.

-

Prop notes: Prioritize thrust over top speed; revisit propeller specs to keep engine in its power band.

-

Telltales you chose right: Confident handling in tight quarters, immediate bite, steady RPMs under strain.

Troubleshooting Fitment Questions (Before You Buy)

“My plate says MG506 but the bolt pattern looks off.”

MG506 units span multiple production runs. Share dataplate photos and flange measurements; we’ll confirm the correct coupling or suggest the right accessory to bridge the differences.

“I see SAE #2 on the ring drive listing—what if mine is SAE #1?”

Order to your actual housing size. If you’re not sure, measure or ask us to verify with photos. Using the wrong SAE size will cause fitment issues at the engine interface.

“Can I reuse my old rubber blocks?”

If they show cracking, hardening, or deformation, replace them. Fresh isolation protects the rebuilt gear you’re installing.

“What if my current ratio isn’t listed?”

The four ratios presented here cover the most common MG506 configurations in the field. If your dataplate shows a different ratio or an uncommon spec, contact us—oddball variants pop up on legacy builds, and we’ll help you source the right unit.

Care & Service Considerations (High-Level Planning)

While this page focuses on catalog selection rather than installation procedures, it’s smart to plan service around your swap:

Alignment & Mounts

-

Plan a post-install alignment check and inspect mounts. Tired mounts sabotage even perfectly rebuilt transmissions.

Cooling Circuit

-

Confirm cooler capacity and hose condition. Restricted flow shortens fluid life and elevates temperatures under load.

Controls & Linkages

-

Inspect cable throw and detents for smooth, positive engagement. Sticky linkages mask real problems and accelerate wear.

Companion Parts to Consider

-

Output coupling hardware (bolts, locking devices)

-

New ring drive to match the engine flywheel

-

Replacement rubber blocks/isolators

Why Buy Your Twin Disc MG506 Rebuilt Transmission & Components from Diesel Pro Power

Choosing a rebuilt marine transmission is a mission-critical decision. Here’s what sets us apart for MG506 support:

Proven Reliability

-

Every rebuilt MG506 we supply is spin tested to verify engagement, smooth operation, and consistent performance characteristics. The objective is reliability from day one—no exceptions.

Catalog Depth That Matches Real-World Needs

-

The MG506 ecosystem on this page consolidates the ratios and accessories most commonly requested by professional captains, yards, and fleet managers. That means fewer surprises at the dock and faster turnarounds.

Fitment Confidence

-

Share your dataplate and a couple of photos, and we’ll help you confirm ratio, housing, rotation, and output coupling details. Ordering with confidence saves time, freight, and rework.

In-Stock Advantage

-

“In Stock” indicators with clear product photos keep decision-making transparent. When your vessel’s schedule can’t wait, availability matters.

Clear Core Exchange Process

-

You’ll see refundable core deposit details before you buy. Keep the crate, return your core promptly, and recover your deposit quickly—no guesswork.

Marine-First Customer Support

-

Our support team works with MG-series gears every day. Whether you’re a commercial operator, a yard manager, or an owner-operator, you’ll get practical answers fast.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588