Twin Disc MG5111 Marine Transmission Parts for Canada - Overhaul Plate Kit Section

Loading...

Loading... Twin Disc MG-5111 Marine Transmission Parts — Overhaul Plate Kit Section

Welcome to the Twin Disc MG-5111 Overhaul Plate Kit and companion components catalog—organized in a technician-first format so you can see what the part is, what it includes, what it fixes, and how to install it right the first time. This page focuses on the MG-5111 (with concise notes where MG-5111A shares the same spec) to help you correct slip, stop weeping seals, tame vibration, and restore crisp, repeatable engagement with minimal downtime. Why buy from Diesel Pro Power? We offer MG-5111-specific curation (no guesswork), deep, ready-to-ship inventory to keep projects on schedule, clear installation guidance that maps symptoms to solutions, responsive specialist support from a team that works these gears daily, and a track record of 40,000+ satisfied customers who trust our accuracy and consistency.

Overhaul Plate Kit for Twin Disc MG-5111 / MG-5111A

What this part is

A complete clutch pack renewal engineered for the MG-5111 family. By replacing the friction and steel elements and restoring proper pack height, this kit brings back predictable take-up, clean directional shifts, and consistent torque transfer under load.

What it includes

-

Friction plates matched to MG-5111/MG-5111A control pressures and thermal loads.

-

Steel separator plates precision-ground for flatness and parallelism to prevent hot spots.

-

Stack/height guidance to help you achieve the correct clutch pack height.

-

Assembly aids (where applicable) to streamline staging, indexing, and pre-lube.

What it fixes

-

Slipping under throttle ahead or astern.

-

Delayed, harsh, or double-bump engagement from glazed frictions or warped steels.

-

Burnt-odor fluid and dark debris that signal overheated, contaminated clutch material.

-

Inconsistent maneuvering control at the dock or in tight quarters.

Fitment notes

-

Specified for MG-5111 and used on MG-5111A where the clutch configuration matches; verify against your data plate and ratio-specific build.

-

Compatible with marine lubricants commonly specified for MG-5111 service environments.

Signs you likely need this kit

-

RPM flare without proportional vessel movement when shifting into gear.

-

Shudder on pickup or a grab–release–grab sensation at low throttle.

-

Elevated gearbox temperature following repeated low-speed maneuvers.

-

Fibrous/metallic residue found in the oil strainer soon after oil changes.

Installation highlights

-

Measure as-found pack height and record plate counts before teardown.

-

Dry-stage the stack to verify order and quantity, then pre-lube all plates prior to assembly.

-

Inspect steels for warp/bluing; replace any heat-spotted components.

-

Torque carrier hardware in a star pattern to spec; verify runout.

-

Warm no-load run-in, followed by progressive load checks; recheck oil level/condition and inspect for leaks.

Related work to consider at the same time

-

Oil strainer service (clean or replace) to protect fresh clutch surfaces from residual debris.

-

Mount isolator (rubber block) inspection to prevent vibration-related glazing of new plates.

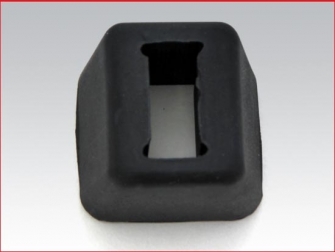

Rubber Block (Mount Isolator) for Twin Disc MG-5111 Installations

What this part is

A marine-grade vibration isolator that supports and stabilizes the MG-5111/MG-5111A and adjacent drivetrain components. Correct isolation keeps alignment true, reduces structure-borne noise, and helps seals and bearings live longer.

What it includes

-

High-durometer elastomer element designed for combined compression and shear loads.

-

Bonded/captured interfaces (design varies) for secure mounting and repeatable preload.

What it fixes

-

Persistent vibration at specific RPM bands or cruise.

-

Alignment drift that returns after a seemingly perfect shaft alignment.

-

Premature wear of couplings, seals, and bearings associated with rigid or fatigued mounts.

-

Knock or bump when shifting from neutral into gear due to excessive movement.

Fitment notes

-

Select mount load rating, footprint, and geometry appropriate for MG-5111/MG-5111A installations and the vessel’s thrust loads.

-

Replacement in matched sets is recommended to maintain even support and height.

Signs you likely need this part

-

Compression set, cracks, or delamination on existing mounts.

-

Vibration worsens under load but eases when off-throttle.

-

Repeated alignment corrections or recurring input/output seal weep.

Installation highlights

-

Replace in pairs or a full set to keep support consistent.

-

Re-align engine and gear after mount work; verify coupling face and bore readings.

-

Re-torque mount hardware after initial operating hours as elastomer settles.

MG-5111 / MG-5111A Symptom-to-Parts Quick Guide

Slipping, delayed, or shuddering engagement — Install Overhaul Plate Kit, service the oil strainer, verify control pressure and oil spec.

Chatter or vibration during shifts/cruise — Replace Rubber Blocks, confirm alignment, then reassess engagement feel.

Recurring debris in oil — Renew Overhaul Plate Kit if plates are compromised; clean/replace oil strainer and shorten initial post-repair service interval.

Heat rise after maneuvers — Check clutch clearances and oil flow; install Overhaul Plate Kit if material is glazed and verify strainer condition.

MG-5111 / MG-5111A Selection & Commissioning Checklist

Identify and document

-

Confirm MG-5111 or MG-5111A on the data plate (model and ratio).

-

Record baseline oil level/condition, control pressure, case temperature, and engagement feel.

Stage the job

-

Pre-order the Overhaul Plate Kit and Rubber Blocks if vibration or alignment drift is present.

-

Have strainer supplies ready (cleaning or replacement).

Execute

-

Install clutch pack to height and stack-order spec; verify smooth carrier rotation and correct clearances.

-

Replace mounts as required; re-align the driveline and document face/bore readings.

-

Service the oil strainer and refill with approved marine lubricant.

Commission

-

Warm idle and neutral checks, then light engagements both directions.

-

Short harbor trial with progressive load, followed by post-run inspection for leaks, temperatures, and vibration.

-

Document torque values, pressures, and alignment readings for future reference.

Why Buy Parts For Your Twin Disc MG-5111 From Diesel Pro Power

Fewer Variables, Faster Turnarounds

Pairing your Overhaul Plate Kit with fresh Rubber Blocks and timely strainer service minimizes repeat haul-outs. We emphasize parts that work together—correct pack height, stable alignment, and clean oil flow—so the gear engages crisply on sea trial.

Quality You Can Measure

We focus on plate flatness, friction consistency, seal-friendly alignment, and isolation durability—the details that separate a smooth, repeatable shift from weekends lost to troubleshooting. It’s why 40,000+ satisfied customers rely on Diesel Pro Power for marine drivetrain parts.

Bottom line: With Diesel Pro Power, MG-5111 owners cut downtime, eliminate guesswork, and finish the job right the first time.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588