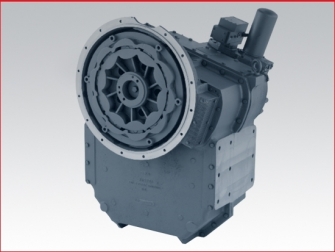

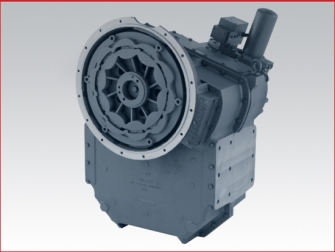

Twin Disc MG520 Marine Transmission Parts for Canada - Rebuilt MG520 Gear Section

Loading...

Loading... Twin Disc MG520 Marine Transmission Parts — Rebuilt MG520 Gear Section

Meet the heavy-duty workhorse of legacy Twin Disc marine gears. The MG520 is a deep-case, high-reduction transmission built for serious thrust at low shaft speeds—ideal for commercial fishing vessels, workboats, crew boats, ferries, tow/tug operations, dredges, and other displacement hull applications where bollard pull and reliability matter more than raw speed. This rebuilt MG520 section organizes our most requested deep-case gear ratios and gives you clear, practical guidance for choosing the right reduction for your boat, verifying compatibility, and planning an efficient core exchange. Every unit listed below is professionally remanufactured and spin-tested prior to shipment.

Quick Look at Available Ratios (Deep Case)

-

4.5:1

-

5.0:1

-

6.0:1

-

7.0:1

-

7.5:1

Rebuilt MG520, 4.5:1 Deep Case — Spin-Tested

A versatile reduction suited to medium-to-heavy displacement hulls that want strong push with a bit more propeller RPM headroom. Many operators choose 4.5:1 when they’re balancing towing power with point-to-point transit times.

Condition: Professionally remanufactured and spin-tested.

Rebuilt MG520, 5.0:1 Deep Case — Spin-Tested

A popular “do-it-all” working ratio that helps larger props bite efficiently while keeping engine RPM in its sweet spot. If you run mixed duty—harbor assist, light towing, and frequent transits—5:1 often hits the sweet balance of thrust and fuel economy.

Condition: Professionally remanufactured and spin-tested.

Rebuilt MG520, 6.0:1 Deep Case — Spin-Tested

When the job calls for more thrust at the wheel, 6:1 lets you swing larger diameter, higher-pitch propellers without overspeeding. Common on boats prioritizing bollard pull and low-speed control—think tugs that spend long hours at slow, controlled RPM.

Condition: Professionally remanufactured and spin-tested.

Rebuilt MG520, 7.0:1 Deep Case — Spin-Tested

A high-reduction favorite for heavy workboats and pusher applications. This ratio emphasizes torque multiplication and prop authority, giving skippers confident maneuvering with substantial payloads and in tight quarters or strong currents.

Condition: Professionally remanufactured and spin-tested.

Rebuilt MG520, 7.5:1 Deep Case — Spin-Tested

Maximum reduction from this lineup for maximum thrust. If you’re looking to move serious mass, hold station under adverse weather, or need the most aggressive displacement-hull push, 7.5:1 is the specialist’s choice.

Condition: Professionally remanufactured and spin-tested.

How to Choose the Right MG520 Ratio for Your Boat

Choosing among 4.5:1, 5:1, 6:1, 7:1, and 7.5:1 starts with your vessel’s job profile and propeller strategy. Below is a practical framework to zero in on the best fit.

Define Your Duty Cycle

-

Harbor assist & mixed transit: 4.5:1 or 5:1 typically deliver a balanced profile—strong low-speed control without giving up too much transit efficiency.

-

Tow/tug & push boats: 6:1 and 7:1 prioritize bollard pull and heavy-load authority.

-

Maximum thrust scenarios: 7.5:1 shines where prop authority is everything—dredge support, heavy barge handling, or persistent current/wind exposure.

Propeller Strategy & Clearance

-

Higher reduction allows larger-diameter, higher-pitch props at sensible shaft speeds.

-

Confirm tip clearance to hull and aperture. Larger wheels improve thrust—only if the boat can physically accommodate them.

Engine Sweet Spot

-

Match reduction so the engine operates in its optimal torque band at typical working speeds.

-

Too little reduction forces higher shaft RPM; too much can under-load the engine. The right ratio keeps fuel burn efficient while preserving throttle response.

Maneuvering & Control

-

Tugs, ferries, and workboats need decisive astern power and low-speed control. Higher reductions (6:1–7.5:1) provide finer throttle granularity and stronger bite in reverse.

Hull Type & Drag

-

Displacement hulls with significant wetted surface area benefit from higher reductions that turn large props slowly and efficiently.

-

Semi-displacement commercial hulls doing mixed-speed runs often live happily at 4.5:1 or 5:1.

Deep Case MG520: What That Means for You

The MG520 “deep case” architecture is designed to handle sustained heavy loads with extra housing rigidity and internal support. For operators, that translates to:

-

Robust durability under prolonged high-thrust operation.

-

Stable alignment with reduced case flex, benefiting bearing life and gear mesh stability.

-

Thermal management headroom paired with proper cooling and filtration setups.

If your vessel regularly works at high thrust for extended periods, deep case is the right foundation.

Verification & Compatibility Checklist (Before You Order)

Arriving at the perfect MG520 means verifying a few details up front. Use this checklist to reduce surprises and keep the turnaround tight.

Model & Serial Details

-

Confirm MG520 model identification from the nameplate.

-

Capture the serial number and any build data stamps available on your existing unit.

Reduction Ratio & Case Depth

-

Verify your current ratio stamped on the nameplate or in vessel records.

-

Confirm deep case configuration for replacement like-for-like fit.

Bellhousing, Input & Output

-

Identify SAE housing size and flex plate/coupling details on the engine side.

-

Note output flange pattern and size to match your shafting and coupling hardware.

Mounting & Footprint

-

Measure mounting centers, vertical stack height, and clearance.

-

Check engine bed alignment and any shims or custom brackets.

Cooling & Lube

-

Confirm cooler type (gear-oil heat exchanger), hose size, and flow direction.

-

Verify filter head style and element availability on your vessel.

Control System

-

Record shift actuation type (mechanical cable, air, or hydraulic).

-

Check linkage throw requirements and neutral safety interlocks if applicable.

What “Spin-Tested” Means (and Why It Matters)

Every rebuilt MG520 listed here is spin-tested prior to shipment. In practice, that includes:

-

Bringing the transmission up to operating speed on a test stand.

-

Verifying smooth gear engagement and shift timing.

-

Listening for abnormal noise and checking vibration signatures.

-

Confirming lube pressure and observing for leaks under test conditions.

A spin test is a functional validation that helps ensure your gear arrives ready for straightforward installation and commissioning.

Core Exchange Overview (What to Expect)

These MG520 units are offered with a refundable core deposit. Here’s how to make the process painless and quick.

Before You Remove the Old Gear

-

Photograph the nameplate, mounting feet, cooler ports, and output coupling.

-

Drain oil thoroughly and cap ports to avoid spills in transit.

Core Return Condition

-

Cores should be complete and assemblable (no missing major castings).

-

Normal wear is expected; catastrophic housing damage or missing internals may affect refund eligibility.

Logistics Tips

-

Use a stout pallet with blocking around the base; band or chain the gear securely.

-

Label with your order reference and contact info to speed receiving and inspection.

Performance Considerations by Ratio

4.5:1 — Balanced Workboat Performance

Great for operators who split time between pushing and transits. This ratio lets you leverage a slightly larger wheel without pushing shaft RPM too low at cruising speed. Expect crisp throttle and responsive handling.

5.0:1 — The Versatile Middle Ground

If you’re refitting a mixed-use commercial hull, 5:1 is often the safest choice. It supports meaningful thrust without penalizing transit legs, and it plays nicely with a broad range of engine torque curves.

6.0:1 — More Bite, More Control

Ideal for boats that need superior low-speed control, frequent station-keeping, or steady tow work. It enables a step up in prop diameter/pitch and shines in tight docking where prop authority makes or breaks the maneuver.

7.0:1 — Heavy-Duty Workhorse

When load profiles skew toward the upper end—pushing barges, towing, or heavy dredge support—7:1 provides the torque multiplication and prop leverage needed to keep the boat authoritative and predictable.

7.5:1 — Maximum Thrust Focus

For the most demanding service, 7.5:1 lets you spec truly robust props and extract maximum low-speed thrust. It’s the specialist’s tool for severe duty and adverse environmental conditions.

Propeller Matching: Practical Pointers

-

Diameter First: Within your aperture limits, favor diameter over RPM—it’s the surest path to efficient thrust.

-

Pitch with Purpose: Use pitch to fine-tune engine load at expected working RPM.

-

Blade Area: Heavy towing may benefit from higher blade area ratio propellers for grip and reduced cavitation.

-

Reverse Authority: Higher reductions enhance astern performance—key for tugs and utility craft.

-

Talk to Your Prop Shop: Provide engine curve, target RPM, vessel displacement, and the chosen MG520 ratio to model an optimal wheel.

Reliability Fundamentals for MG520 Operations

Oil & Filtration

Use the correct gear oil grade for your climate and service profile, and maintain filter changes on schedule. Clean oil is the single biggest contributor to gear longevity.

Cooling Circuit

Confirm unobstructed cooler flow and clean heat-exchange surfaces. High load at low shaft speeds is thermally demanding—give the cooler the attention it deserves.

Mounts & Alignment

Solid mounts and accurate alignment reduce vibration, protect bearings, and maintain gear mesh integrity. Monitor alignment after haul-outs or any hull changes.

Controls

Whether mechanical or hydraulic actuation, smooth, positive shifts protect clutches and extend service life. Verify linkage geometry and travel to manufacturer spec.

Planning a Refit or Ratio Change

Upgrading from, say, 4.5:1 to 6:1 (or higher) usually implies a propeller change to take advantage of the new reduction. Before committing:

-

Confirm aperture room for larger diameter.

-

Revisit shafting strength and coupling compatibility.

-

Assess vessel mission profile to ensure the new ratio aligns with how you actually work the boat.

-

Coordinate with your propeller and engine specialists to keep the engine in its efficient torque band.

Troubleshooting Cues (Operational Awareness)

-

Sluggish engagement: Inspect control travel, oil level/condition, and verify lube pressure.

-

Overheating under load: Check cooler flow, oil grade, and propeller load (fouling or over-pitched wheel).

-

Noise or vibration: Reconfirm alignment, mounts, and coupling runout; examine prop for damage or imbalance.

-

Frequent clutch slip indications: Review shift technique and operating RPM; address oil specs and contamination promptly.

Documentation You’ll Want Handy

-

Vessel engine model and rated RPM

-

Existing MG520 nameplate info (ratio, serial)

-

SAE housing and input coupling details

-

Output flange pattern and shaft size

-

Cooling hose sizes and routing notes

-

Any control system specifics (throw length, pressure if hydraulic)

Having these details ready speeds selection, build confirmation, and turnaround.

Why Choose a Rebuilt MG520 From Diesel Pro Power

When downtime is money, you want a gear that arrives ready to work. Here’s how we deliver that:

Professionally Remanufactured & Spin-Tested

Every MG520 in this section is spin-tested to validate functional performance before it leaves our facility. That test catches issues that a simple static check can’t—so your install stays on schedule.

Focused, Real-World Expertise

We live marine. Our team supports commercial operators every day—tugs, fishing fleets, ferries, crew boats, utility craft—and understands the realities of high-thrust service. That experience informs how we vet components, test, and prepare each gear.

Clear Core Exchange & Responsive Support

Our refundable core deposit program is straightforward, and we’ll help you plan the return to minimize delays. Have photos and nameplate info? Send them—we’ll confirm details fast.

Fast, Reliable Communication

From pre-order verification to after-sale support, you’ll get direct, practical answers. Need to cross-check mounting centers or cooler routing? We make it easy.

Customers Worldwide

Diesel Pro Power supports operators across industries and waterways. We’ve earned the trust of fleets and independent captains alike through consistency, clarity, and gear that performs where it counts.

Ordering & Lead-Time Planning (At a Glance)

-

Pick Your Ratio: 4.5:1, 5:1, 6:1, 7:1, or 7.5:1 deep case.

-

Gather Details: Nameplate photos, mounting centers, coupling patterns, cooler notes.

-

Confirm & Schedule: Coordinate installation windows and core return pickup to keep timelines tight.

(Note: Please disregard any price, stock, or cart elements you may see elsewhere—this rebuilt section is focused on technical selection and readiness, not e-commerce details.)

Frequently Asked Questions

Can I replace my current MG520 with a different ratio from this list?

Often yes—but expect to adjust your propeller to properly load the engine at working RPM. Higher reductions typically pair with larger-diameter or higher-pitch props. Verify aperture clearance and consult your prop shop.

What’s the advantage of deep case for the MG520?

Deep case housings are built for sustained heavy duty with added rigidity, gear support, and thermal capacity when paired with the right cooler. If your vessel pushes hard for long periods, deep case is the prudent choice.

What does spin-tested really guarantee me?

A functional run on the test stand confirms engagement quality, lube pressure, and basic running characteristics. It’s a meaningful pre-delivery validation that reduces surprises during commissioning.

Will my control system work with a rebuilt MG520?

In most refits, yes. Confirm shift actuation type and linkage throw or hydraulic requirements. If you’re updating controls, we can help you verify compatibility ahead of time.

How do I make my core exchange go smoothly?

Send nameplate photos, drain and cap ports, secure the gear to a strong pallet with blocking, and include your order reference. Cores should be complete and assemblable; catastrophic case damage can affect eligibility.

Real-World Use Cases

-

Tug and Push Boats: Higher reductions (6:1–7.5:1) deliver confident pull and reverse authority for barge handling and terminal maneuvering.

-

Commercial Fishing: 5:1 or 6:1 provides robust thrust for gear retrieval and station-keeping without sacrificing reasonable transit efficiency.

-

Ferries & Crew Boats (Displacement/Semi-Displacement): 4.5:1 or 5:1 keeps schedules tight while maintaining responsive low-speed handling in crowded harbors.

-

Dredge & Utility Craft: 7:1–7.5:1 for maximum prop leverage when conditions are adverse and loads are unrelenting.

Commissioning Notes You’ll Be Glad You Checked

-

Alignment after launch: Re-check hot alignment after the boat has settled.

-

Cooling circuit priming: Confirm flow and purge air prior to load runs.

-

Control verification: Ensure full neutral–ahead–astern travel with positive detents where applicable.

-

Baseline records: Log oil pressure, temperature, and noise/vibration observations on day one—handy for future comparisons.

Sustainability & Serviceability Considerations

Rebuilt transmissions extend the life of proven industrial hardware, reducing waste and leveraging existing castings and housings. For operators, that often means shorter lead times than sourcing new-build gear, plus the confidence of established MG520 service practices widely known by marine mechanics around the world.

Add-On Items Commonly Paired with an MG520 Refit

-

Heat Exchangers / Oil Coolers matched to flow and thermal load

-

Mounting Hardware (bolts, shims, and isolators appropriate to the frame)

-

Couplings & Guards to suit your output flange and shafting

-

Filter Elements for the chosen lube system head

-

Control Linkage Kits or updated hydraulic control components if refurbishing the helm side

Ask us to cross-check part compatibility with your specific ratio and case configuration.

Your Next Step

If you’re ready to move forward with a rebuilt Twin Disc MG520 deep-case gear in 4.5:1, 5:1, 6:1, 7:1, or 7.5:1, gather your nameplate details and vessel specs and reach out. We’ll verify the fit, confirm the ratio choice for your duty cycle, and coordinate a smooth core exchange so your boat spends less time at the dock and more time earning.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588