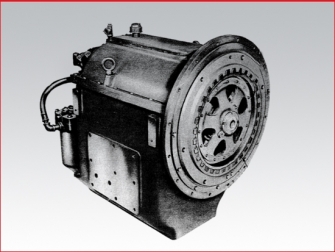

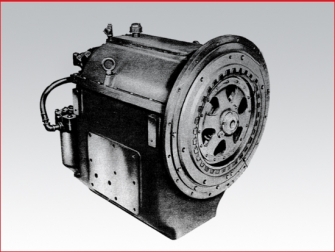

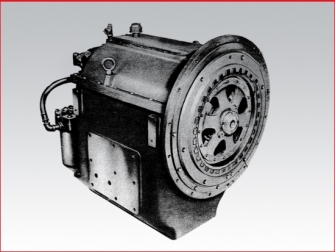

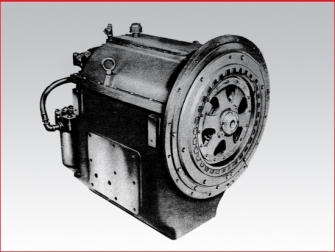

Twin Disc MG 521 Marine Transmission Parts - Rebuilt MG521 Gear Section

Loading...

Loading... Twin Disc MG521 Marine Transmission Parts — Rebuilt MG521 Gear Section

Meet the workhorse that keeps commercial crews on schedule and serious recreational captains on plane: the Twin Disc MG521. On this page you’ll find a complete, buyer-friendly overview of our rebuilt MG521 marine gears, organized by the most requested gear ratios—2.00:1, 3.00:1, 3.50:1, and 4.00:1—plus clear guidance on how to choose the right ratio for your hull, tips to streamline a core return, and a full “Specifications & Applications” section created specifically for this model. If you operate a vessel that needs predictable engagement, smooth direction changes, and dependable thrust at working RPM, the MG521 belongs on your shortlist.

All MG521 rebuilt units offered here are professionally remanufactured and spin-tested prior to shipment. That means you receive a transmission that has been function-checked on a test stand for oil pressure, clutch engagement, and neutral integrity, helping you install with confidence and return to service faster.

Rebuilt MG521: What “Spin-Tested” Means for You

A spin test is a functional check performed on a completed MG521 assembly. The unit is brought up to speed on a test stand to verify hydraulic pressure, smooth clutch engagement forward and reverse, controlled shift timing, and leak-free operation. Pressure readings are observed at critical ports, and engagement is checked under controlled load. For you, “spin-tested” translates to fewer surprises at the dock and less time troubleshooting after installation.

Key benefits of a spin-tested MG521:

-

Verified hydraulic pressures: Confirms that the pump, control valve, and clutch circuits are healthy.

-

Smooth engagement: Helps protect shafting and couplings from harsh shock loads.

-

Temperature observations: Ensures lubrication is circulating correctly.

-

Noise and vibration check: Early detection of bearing or gear concerns before the unit ships.

Rebuilt MG521—Available Gear Ratios

Below you’ll find detailed guidance for the four most-requested MG521 ratios. Each ratio section explains typical use cases and operating logic so you can align your choice with hull form, duty profile, and propeller strategy.

MG521, 2.00:1 — Rebuilt & Spin-Tested

This is the “fast cruise” choice for lighter displacement vessels and applications where engine operating RPM is relatively high for the required shaft speed. It’s popular with planing hulls that want crisp acceleration and solid mid-range efficiency without overspeeding the propeller.

Best-fit scenarios for 2.00:1:

-

Planing and semi-planing hulls that come out of the hole quickly and benefit from a slightly higher shaft speed.

-

Patrol, pilot, and fast utility boats that maintain medium to high cruise RPM and need responsive throttle changes.

-

Commercial day boats where short runs and frequent maneuvering matter as much as top speed.

Why choose 2.00:1 on an MG521:

-

Keeps propeller diameter reasonable without pushing pitch to extremes.

-

Helps engines reach their designed power band while keeping shaft speed compatible with prop slip targets.

-

Works well when there’s limited aperture for a larger wheel.

Propeller planning notes (general): A 2.00:1 ratio typically pairs with moderately pitched wheels. If your vessel is currently “lugging” (struggling to reach rated RPM), moving to a slightly deeper ratio—not shallower—often helps. If you already reach rated RPM too easily with excess slip at cruise, 2.00:1 may be the sweet spot when stepping down from even shallower gearing.

MG521, 3.00:1 — Rebuilt & Spin-Tested

Think of 3.00:1 as the MG521’s balanced work mode. It’s favored across working craft that push heavier loads, run at steady cruise, and value propeller bite over free-wheeling shaft speed. This ratio lets you swing a larger-diameter, more efficient propeller without oversizing pitch.

Best-fit scenarios for 3.00:1:

-

Heavier semi-displacement and displacement hulls that prioritize thrust and fuel economy over peak speed.

-

Trawlers, tour boats, and supply tenders that live in the mid-range and need dependable pull throughout the day.

-

Dive, survey, and research vessels where low-speed control is as important as steady cruise.

Why choose 3.00:1 on an MG521:

-

Enables larger wheel diameter for improved propulsive efficiency.

-

Reduces cavitation risk under load and during heavy weather.

-

Supports comfortable maneuvering around docks and tight channels thanks to stronger “bite” at lower RPM.

Propeller planning notes (general): With 3.00:1, wheel diameter tends to increase vs. 2.00:1 for the same engine. That improves thrust and often lowers fuel burn at work speeds. Confirm tip clearance in your aperture and allow adequate room for expected shaft deflection under load.

MG521, 3.50:1 — Rebuilt & Spin-Tested

The 3.50:1 ratio adds more leverage for heavier boats or for operators who want stubborn, low-speed authority—think pulling traps, towing gear, or pushing a barge. The deeper reduction slows the shaft further, letting you spec a still larger wheel while keeping the main engine comfortably in its torque band.

Best-fit scenarios for 3.50:1:

-

Workboats with high bollard pull needs, including small tugs, push boats, and heavy crew boats.

-

Commercial fishing where backing down under load and holding station near gear is routine.

-

Harbor craft that maneuver in tight quarters and need powerful response at minimal throttle.

Why choose 3.50:1 on an MG521:

-

Allows the propeller to do more of the work, sparing your engine from chronic lugging.

-

Improves responsiveness when alternating between forward and reverse during deck operations.

-

Provides a practical path to reduce slip without overspeeding the prop at cruise.

Propeller planning notes (general): At 3.50:1 you’ll often see the largest wheel your aperture comfortably allows. Check rudder clearance and strut geometry, and confirm you can keep recommended tip-to-hull spacing to maintain smooth flow and minimize vibration.

MG521, 4.00:1 — Rebuilt & Spin-Tested

This is the deep-reduction option for operators who need maximum push at low to moderate vessel speeds. It’s a purposeful ratio for displacement hulls tasked with towing, pushing, or hauling mass—where thrust, not sprint speed, wins the day.

Best-fit scenarios for 4.00:1:

-

Dedicated towing and pushing applications in harbors, rivers, or near-shore construction.

-

Heavy displacement cargo and supply runs where schedules demand reliable pull in all weather.

-

Research and survey crafts that must hold precise headings against current.

Why choose 4.00:1 on an MG521:

-

Lets you swing the largest practical diameter for maximum bite.

-

Keeps shaft RPM low to control cavitation and reduce wake signature at work speeds.

-

Provides commanding reverse authority—valuable for station-keeping and emergency stops.

Propeller planning notes (general): Deep reductions reward disciplined prop selection. Discuss blade area ratio, skew, and rake with your propeller shop to balance bollard pull, astern bite, and smoothness. A properly chosen wheel here can feel “grabbier” at idle, which many operators prize for docking.

Choosing the Right MG521 Ratio for Your Vessel

Picking a ratio is about matching your engine’s power curve to your hull’s resistance and the propeller’s workload. Use the guidelines below to triangulate a productive choice.

Start with Your Duty Profile

-

Fast response, higher cruise: You’ll lean toward 2.00:1.

-

Balanced thrust and economy: Shortlist 3.00:1.

-

Heavy loads, low-speed control: Consider 3.50:1.

-

Maximum pull at modest speed: Look closely at 4.00:1.

Evaluate Current Performance Symptoms

-

Can’t reach rated RPM (lugging): Consider a deeper reduction (e.g., from 2.00:1 to 3.00:1).

-

Reaches rated RPM too easily with high slip: A deeper ratio and larger wheel often stabilize cruise.

-

Harsh dockside shifts: Properly functioning MG521 clutches help; ratio also influences bite. A deeper ratio increases low-RPM authority.

Propeller and Aperture Considerations

-

Aperture size: Deeper ratios often require larger diameter wheels; confirm physical space.

-

Tip clearance: Maintain adequate clearance to minimize vibration and noise.

-

Blade area and skew: Higher blade area and optimized skew can tame cavitation at deeper ratios.

Marine Transmission Specifications & Applications — Twin Disc MG521

The following information is written for the MG521 specifically and focuses on the decisions mechanics, captains, and fleet managers make when selecting, repairing, or replacing this model.

Core Functional Role of the MG521

The MG521 is a marine reversing reduction gear designed to translate engine power into smooth, controllable thrust while protecting the driveline from shock and slippage. It’s widely adopted in commercial and serious recreational settings because it blends manageable size with robust clutching and a ratio range that covers light, medium, and heavy duty profiles.

Common Vessel Types Using the MG521

-

Crew and pilot boats: Crisp throttle response with predictable engagement for tight schedules.

-

Work skiffs and utility craft: Reliable low-speed authority and maneuverability near docks and structure.

-

Trawlers and tour boats: Efficient cruise with quiet, smooth clutch operation.

-

Harbor craft, push boats, small tugs: Deep-ratio options provide strong bollard pull and decisive reverse.

Mounting & Integration Considerations (General)

-

Engine housing interface: Verify SAE housing and coupling compatibility during planning.

-

Shaft line geometry: Ensure the gear’s output height and angle align with strut and stuffing box geometry for clean flow.

-

Controls: The MG521 is engineered for smooth shift sequencing; pair with well-maintained control linkages or quality electronic controls for best feel.

(If you’re replacing an in-service MG521, match your existing ratio where performance has been satisfactory. If you’re correcting a symptom—lugging, cavitation, or poor astern control—use the ratio guidance above to pivot.)

Applications by Ratio (Quick Reference)

-

2.00:1: Lighter hulls, higher cruise RPM, fast utility and patrol use.

-

3.00:1: Balanced choice for mixed commercial duty and economical cruise.

-

3.50:1: Heavy gear work, frequent astern maneuvers, pushing/pulling.

-

4.00:1: Maximum thrust at modest speeds, towing, construction support.

What’s Included with a Professionally Rebuilt, Spin-Tested MG521

Every rebuilt MG521 presented here is remanufactured by professionals and spin-tested before it leaves the facility. The specific contents of a rebuild can vary by unit condition and shop process, but you can expect the following standards to be met:

Core Rebuild Standards (Typical)

-

Disassembly and inspection: Gear train, bearings, clutches, and hydraulic circuits are assessed for wear.

-

Replacement of wear items as needed: Bearings, seals, and friction materials addressed according to condition and professional standards.

-

Hydraulic integrity restored: Pump, control valves, and engagement timing validated.

-

Spin test and final checks: Pressure verification, forward/reverse engagement, neutral check, and leak inspection.

Documentation You Can Use

-

Model and ratio labeling on the case or tag to simplify installation and future service.

-

Basic start-up guidance to protect your warranty and ensure a smooth first run (for example, oil type/level reference and initial checks).

Note: This page focuses on catalog content, not installation instructions; always follow the documentation included with your unit and your engine/gear manufacturer’s guidance.

Core Exchange Made Simple (Overview)

These MG521 rebuilt units are sold with a refundable core deposit. The core program keeps quality rebuilds in circulation, helps control lead times, and reduces your total cost of ownership.

How Core Exchange Helps You

-

Predictable turnaround: Your replacement ships so you can schedule the swap; your core return comes after.

-

Environmental stewardship: Reuse of serviceable cases and major components reduces waste.

-

Fleet consistency: Staying with MG521 in a core exchange keeps mounts, controls, and driveline geometry familiar to your crews.

(You’ll receive the core return details with your order. Follow the instructions for packaging and timing so your refund can be processed promptly.)

Troubleshooting Performance Symptoms (MG521 Context)

When your hull, prop, and gear are right-sized, the MG521 delivers reassuring, repeatable behavior. If you’re solving a performance riddle, use this MG521-specific checklist to narrow the cause.

Symptom: Harsh “clunk” when shifting

-

What to consider: Idle speed too high, misadjusted controls, or prop too aggressive for the ratio. The MG521’s clutching is designed for smooth engagement; harshness often points to upstream or downstream factors.

Symptom: Slow to engage

-

What to consider: Hydraulic oil level/condition, linkage issues, or internal wear in a non-rebuilt unit. A properly rebuilt, spin-tested MG521 should engage predictably.

Symptom: Chronic cavitation at cruise

-

What to consider: Wheel too small for the work, or ratio too shallow for the duty. A move from 2.00:1 to 3.00:1 (or deeper) often calms cavitation by letting you turn a larger wheel at lower shaft RPM.

Symptom: Can’t reach rated engine RPM

-

What to consider: Propeller too large or pitch too high for the chosen ratio. In many cases, a deeper MG521 ratio (e.g., 3.00:1 or 3.50:1) paired with a correctly sized wheel restores balance.

Maintenance Philosophy for Long MG521 Life

A correctly rebuilt MG521 running in clean oil with well-adjusted controls is remarkably durable. The points below are general good practice for this model.

Oil Choice and Change Interval

-

Use marine-appropriate transmission oil as specified by your gear’s documentation.

-

Maintain clean oil; contamination is the enemy of clutches and valves.

Shift Discipline

-

Avoid “racing” the throttle during shifts. Let the MG521 complete engagement before adding power.

-

Use brief pauses when shuttling between forward and reverse in tight maneuvers to keep clutch surfaces happy.

Alignment Awareness

-

Proper engine-to-gear-to-shaft alignment reduces bearing and seal wear.

-

Couplings should be inspected during installation and at routine intervals.

(Consult your service documentation for the exact procedures applicable to your configuration.)

Why Buy Your Rebuilt Twin Disc MG521 from Diesel Pro Power

Choosing where to source critical drivetrain components is as important as choosing the part itself. Diesel Pro Power serves thousands of marine customers globally, with 40,000+ satisfied customers who count on fast shipping, careful packaging, and knowledgeable support.

What Sets Diesel Pro Power Apart

-

Purpose-built marine expertise: We live and breathe marine propulsion. When you call with a MG521 question, you get clear, model-specific guidance.

-

Spin-tested rebuilt units: Every MG521 listed here is spin-tested so you start with proven engagement and pressure.

-

Consistent quality standards: Professional rebuild processes, thorough inspection routines, and attention to detail protect your investment.

-

Core exchange made straightforward: Clear instructions and responsive support make returning your core hassle-free.

-

Customer-first service: From pre-purchase ratio selection to after-sale questions, dedicated support helps you get the install done right the first time.

Support That Keeps Fleets Moving

-

Helpful documentation: Model identification tips, ratio pointers, and compatibility information reduce guesswork.

-

Fast order processing: Marine operations can’t wait—our logistics aim to minimize downtime.

-

Global reach: Whether you’re in a busy port or a remote marina, we ship where you need the gear.

MG521 Installation Planning Checklist (Buyer’s Perspective)

While this page focuses on catalog information, smart planning keeps projects on schedule. Use this buyer-oriented checklist to prep your MG521 swap:

Confirm the Essentials

-

Engine model and flywheel housing: Verify SAE interface and drive coupling style.

-

Desired ratio vs. duty: Match 2.00:1, 3.00:1, 3.50:1, or 4.00:1 to your load profile.

-

Propeller aperture: Ensure room for the wheel you intend to swing with deeper reductions.

Control & Cooling Review

-

Control system type: Mechanical or electronic—confirm proper travel and detents.

-

Oil cooling path: Verify cooler capacity and condition to protect clutch life.

Core Return Prep

-

Save your packaging: It often doubles as the safest way to ship your core.

-

Drain and plug: Follow the return instructions to keep carriers happy and docks clean.

Frequently Asked Questions — Twin Disc MG521 (Rebuilt)

Do rebuilt MG521 units come ready to install?

They are rebuilt and spin-tested prior to shipment. You’ll handle mounting, alignment, fluids, and control hookup according to your vessel’s configuration and the documentation provided with your unit.

Which ratio should I select if I tow or push frequently?

Start your evaluation at 3.50:1 or 4.00:1. These deeper reductions improve low-speed thrust and reverse authority. If you split time between light runs and heavy pulls, 3.00:1 can be a balanced compromise.

Can I reuse my existing propeller when changing ratios?

Sometimes, but often a ratio change pairs best with a propeller adjustment. Deeper reductions favor larger diameter or increased blade area to capture the ratio’s benefits.

What does “spin-tested” assure?

It confirms forward and reverse engagement, hydraulic pressures, and leak-free operation on a test stand before shipping, reducing surprises at commissioning.

How does the core deposit work?

You receive the rebuilt MG521 and return your core per the instructions supplied with your order. When the core is received and inspected, the refundable deposit is processed.

MG521 Ratio Quick-Pick Guide

-

Choose 2.00:1 if you run lighter boats and prize quick acceleration and lively cruise RPM.

-

Choose 3.00:1 if you want balanced efficiency, bigger wheel options, and calm mid-range performance.

-

Choose 3.50:1 if your work involves frequent reversing, pushing, or pulling at low speeds.

-

Choose 4.00:1 if your mission demands maximum thrust and authoritative control at modest speeds.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588